Content Menu

● Introduction to No Drying Extrusion Granulation

● Key Factors Influencing the Price

>> 1. Equipment Quality and Type

>> 2. Production Capacity

>> 3. Automation Level

>> 4. Customization Options

>> 5. Market Demand and Supply Chain Factors

● Benefits of No Drying Extrusion Granulation

● Applications Across Industries

>> 1. Pharmaceuticals

>> 2. Fertilizers

>> 3. Food Processing

● Environmental Impact

● Future Trends in No Drying Extrusion Granulation

● Conclusion

● FAQ

>> 1. What is no drying extrusion granulation?

>> 2. How does production capacity affect pricing?

>> 3. What are the advantages of automated systems?

>> 4. Can I customize my production line?

>> 5. How does market demand impact prices?

● Citations:

The price of a "no drying extrusion granulation production line" can vary significantly based on several factors. Understanding these factors is crucial for manufacturers and businesses looking to invest in this technology. This article delves into the various elements that influence the pricing of such production lines, offering insights into their operational benefits and market trends.

Introduction to No Drying Extrusion Granulation

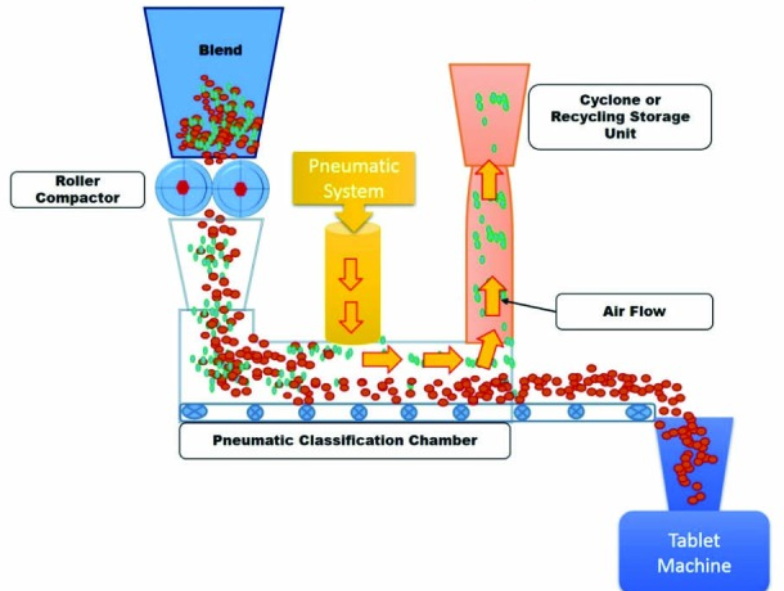

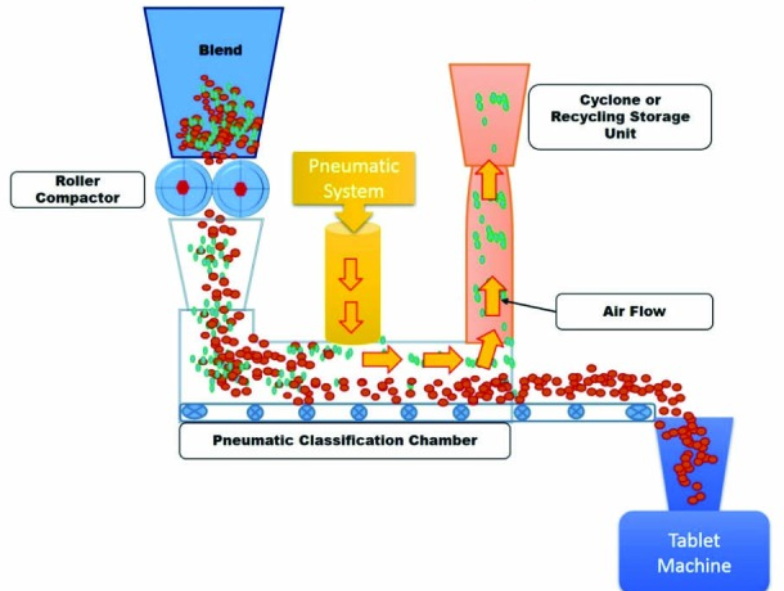

No drying extrusion granulation is a modern manufacturing process that combines extrusion and granulation without the need for a drying phase. This technology has gained popularity due to its energy efficiency, cost-effectiveness, and environmental benefits. By eliminating the drying step, manufacturers can significantly reduce operational costs and improve product quality.

Key Factors Influencing the Price

Several factors affect the price of a no drying extrusion granulation production line:

1. Equipment Quality and Type

The type and quality of equipment used in the production line play a significant role in determining its price. High-quality machinery often comes with advanced features that enhance performance, durability, and efficiency.

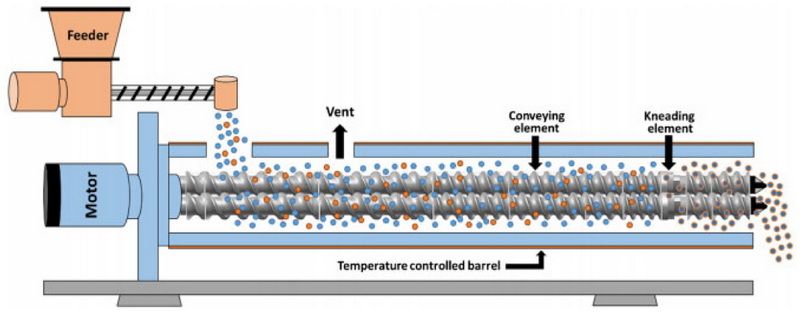

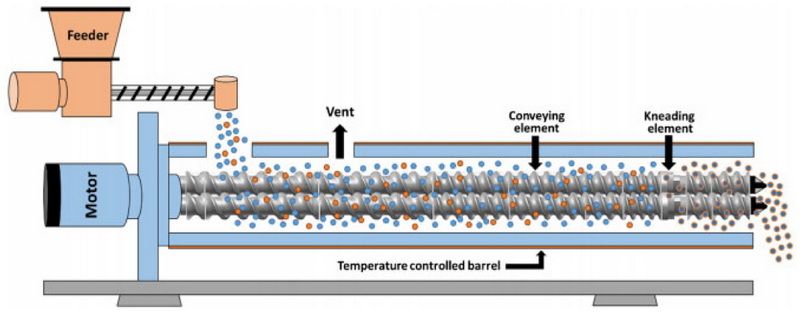

- Extruder Type: Different types of extruders (e.g., twin-screw vs. single-screw) can influence costs. Twin-screw extruders are often preferred for their ability to handle a wide range of materials and provide better mixing capabilities.

- Material Composition: Equipment made from high-grade materials (like stainless steel) tends to be more expensive but offers better longevity and resistance to wear.

2. Production Capacity

The capacity of the production line is another critical factor. Higher-capacity lines typically cost more due to the larger size and complexity of the equipment.

- Small Scale (1-5 t/h): These lines are generally less expensive, ranging from $30,000 to $45,000.

- Medium Scale (10-20 t/h): Prices can range from $60,000 to $90,000.

- Large Scale (30 t/h or more): These can exceed $360,000 depending on specifications and configurations.

3. Automation Level

The degree of automation integrated into the production line affects its price. Fully automated systems that require minimal human intervention will generally have higher upfront costs but can lead to lower long-term operational expenses.

- Manual Systems: Lower initial cost but higher labor costs over time.

- Automated Systems: Higher initial investment but reduced labor costs and increased efficiency.

4. Customization Options

Customization options for specific production needs can also impact pricing. Tailored solutions that meet unique requirements may come at a premium.

- Specific Features: Custom designs for specific materials or product types can increase costs.

- Modular Systems: Systems designed for flexibility and scalability may also incur higher prices.

5. Market Demand and Supply Chain Factors

Market dynamics, including demand for granulated products and supply chain fluctuations, can influence equipment prices.

- Increased Demand: Higher demand for fertilizers or pharmaceuticals can drive up prices.

- Supply Chain Issues: Disruptions in raw material supply can lead to increased costs for manufacturers.

Benefits of No Drying Extrusion Granulation

Investing in a no drying extrusion granulation production line offers several advantages:

- Energy Efficiency: Eliminating the drying phase reduces energy consumption significantly. Manufacturers save substantial energy costs associated with heating and cooling systems[1].

- Reduced Processing Time: The absence of drying steps accelerates production cycles, allowing for higher throughput. This is particularly beneficial in industries where time-to-market is critical[6].

- Improved Product Quality: The controlled environment during extrusion minimizes degradation of sensitive materials, resulting in higher quality granules[1].

- Lower Operational Costs: Reduced equipment requirements for drying and cooling lead to lower capital and operational expenditures[6].

Applications Across Industries

No drying extrusion granulation technology finds applications across various industries:

1. Pharmaceuticals

In pharmaceuticals, this method is utilized to produce solid dosage forms such as tablets and capsules. The absence of moisture during processing ensures that active pharmaceutical ingredients (APIs) remain stable and effective[6].

2. Fertilizers

The fertilizer industry has also benefited significantly from no-drying extrusion granulation technology. This method allows for precise control over nutrient release characteristics by adjusting the formulation during production. For example:

- Controlled-release fertilizers are designed to release nutrients slowly over time, reducing environmental impact while improving crop yield[1].

- Organic fertilizers can be produced without degrading their beneficial properties, making it suitable for sustainable agriculture practices[1].

3. Food Processing

In food processing, no-drying extrusion granulation is used to create uniform granular products such as flavorings and nutritional supplements. This method enhances solubility and dispersibility within food products[1].

Environmental Impact

One of the most compelling reasons for adopting no-drying extrusion granulation production lines is their reduced environmental footprint compared to traditional methods. By eliminating drying processes:

- There are lower emissions associated with heating systems.

- Wastewater generation is minimized since there is no need for washing or rinsing equipment post-production.

- Energy consumption is significantly reduced—up to 60% less than conventional methods—making it an environmentally friendly option[6].

Future Trends in No Drying Extrusion Granulation

As technology continues to evolve, manufacturers will need to adapt to new innovations while addressing challenges related to material variability and regulatory compliance. Key trends include:

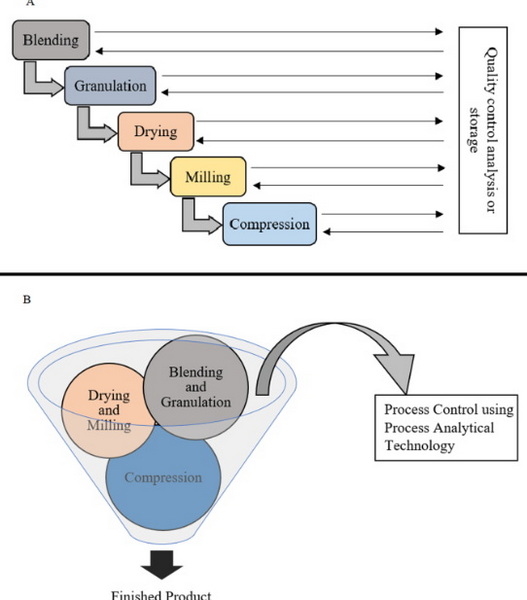

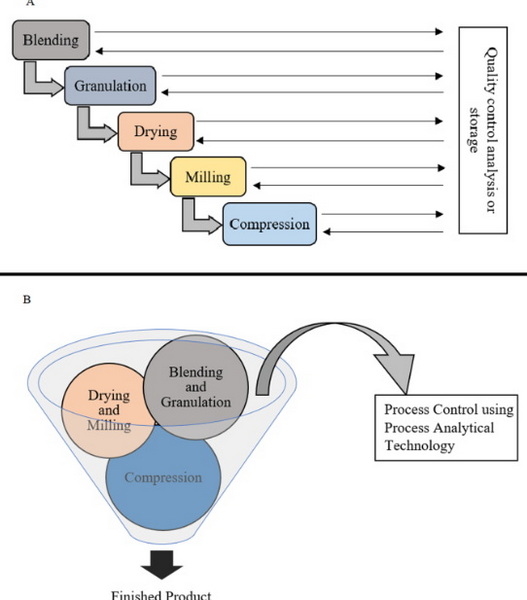

- Enhanced Process Control: The integration of Process Analytical Technology (PAT) systems will allow manufacturers to monitor processes in real-time, ensuring optimal conditions are maintained throughout production[3].

- Increased Automation: Automation will continue to play a significant role in improving efficiency and reducing labor costs across manufacturing processes[6].

- Sustainable Practices: As industries strive towards sustainability, innovations aimed at reducing waste generation during production processes will become more prevalent[3][6].

Conclusion

The price of a no drying extrusion granulation production line is influenced by various factors including equipment quality, production capacity, automation level, customization options, and market dynamics. Understanding these elements helps businesses make informed decisions when investing in this technology. As industries continue to seek sustainable manufacturing solutions, no drying extrusion granulation is likely to become increasingly popular due to its numerous advantages such as energy efficiency, cost savings, improved product quality, and reduced environmental impact.

FAQ

1. What is no drying extrusion granulation?

No drying extrusion granulation is a process that combines extrusion and granulation without requiring a drying phase, making it energy-efficient and environmentally friendly.

2. How does production capacity affect pricing?

Higher production capacities generally lead to increased equipment size and complexity, resulting in higher prices for the production line.

3. What are the advantages of automated systems?

Automated systems reduce labor costs, improve efficiency, and ensure consistent product quality compared to manual systems.

4. Can I customize my production line?

Yes, many manufacturers offer customization options to tailor the production line according to specific needs or product types.

5. How does market demand impact prices?

Increased demand for products produced through no drying extrusion granulation can drive up equipment prices due to heightened competition among manufacturers.

Citations:

[1] https://www.yjing-extrusion.com/what-are-the-latest-innovations-in-no-drying-extrusion-granulation-production-lines.html

[2] https://www.yz-mac.com/npk-compound-fertilizer-extrusion-granulation-production-line/

[3] https://www.pharmtech.com/view/exploring-advances-in-twin-screw-extrusion-for-solid-dosage-drugs

[4] https://www.yjing-extrusion.com/where-is-there-a-drying-extrusion-granulation-production-line.html

[5] https://www.pharmtech.com/view/comparing-manufacturing-process-options

[6] https://www.yjing-extrusion.com/what-are-the-advantages-of-no-drying-extrusion-granulation-production-equipment.html

[7] https://fertilizer-machinery.com/production_line/compound-fertilizer-plant/extrusion-granulator-production-line.html

[8] https://asmedigitalcollection.asme.org/astm-ebooks/book/2013/chapter-abstract/27872569/Granulation-Without-a-Drying-Step-Using-Dielectric?redirectedFrom=fulltext

[9] https://www.sciencedirect.com/science/article/pii/S0263876223008286

[10] https://www.yz-mac.com/no-drying-extrusion-compound-fertilizer-production-lines/

[11] https://www.zionmarketresearch.com/report/pharmaceutical-pellets-market

[12] https://pubs.acs.org/doi/10.1021/ie2006752

[13] https://www.matconibc.com/blog/how-to-increase-production-output-of-your-granulation-process-equipment-and-improve-your-profitability

[14] https://www.linkedin.com/pulse/advancements-dry-granulation-technology-enhancing-efficiency-steve-ku-bsgtc

[15] https://github.com/prashikb001/MarketNavigator/blob/main/Dry-Granulating-Machine-Market-Size-and-Opportunity-Analysis.md

[16] https://aiche.onlinelibrary.wiley.com/doi/full/10.1002/amp2.10136

[17] https://manufacturingchemist.com/continuous-and-efficient-dry-granulation--168506

[18] https://www.yjing-extrusion.com/news/No-Drying-Granulation.html

[19] https://www.360iresearch.com/library/intelligence/granulation-production-line

[20] https://www.energy.gov/sites/prod/files/2016/07/f33/fcto_battelle_mfg_cost_analysis_pp_chp_fc_systems.pdf

[21] https://www.linkedin.com/pulse/drying-dual-mode-extrusion-cylindrical-granulator-organic-yu-

[22] https://www.sciencedirect.com/science/article/pii/S2949866X24000674

[23] https://www.sciencedirect.com/science/article/abs/pii/S0022354916418253

[24] https://pmc.ncbi.nlm.nih.gov/articles/PMC4401168/