Content Menu

● Introduction to Extrusion Downstream Equipment

>> Key Components of Downstream Equipment

● Applications of Extrusion Downstream Equipment

● Importance of Downstream Equipment in Production Efficiency

>> Benefits of Customizing Downstream Equipment

● Advanced Technologies in Downstream Extrusion

>> Role of Automation in Downstream Extrusion

>> Sustainability in Downstream Extrusion

● Challenges and Future Developments

● Conclusion

● Frequently Asked Questions

>> 1. What is the primary function of cooling systems in downstream extrusion?

>> 2. How do pullers contribute to the extrusion process?

>> 3. What types of cutters are commonly used in downstream extrusion?

>> 4. Why are winding systems important in downstream extrusion?

>> 5. How does customizing downstream equipment benefit production?

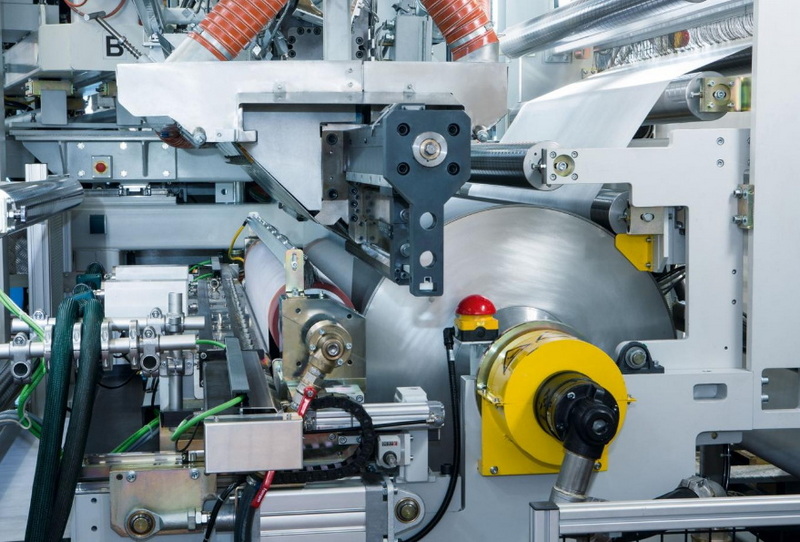

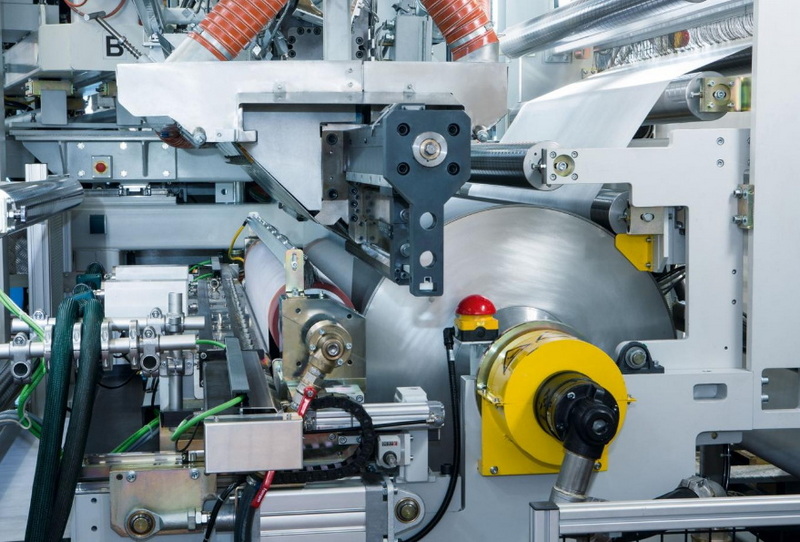

Extrusion downstream equipment plays a crucial role in the manufacturing process of various materials, including plastics, metals, and rubber. These equipment pieces are essential for transforming raw extruded materials into finished products that meet specific dimensions, shapes, and quality standards. In this article, we will delve into the key functions of extrusion downstream equipment, exploring their types, applications, and importance in ensuring efficient production processes.

Introduction to Extrusion Downstream Equipment

Extrusion downstream equipment refers to all devices and machines used after the extrusion process itself. These machines are responsible for cooling, shaping, cutting, and collecting the extruded material, ensuring it meets the required specifications for size, shape, surface quality, and performance.

Key Components of Downstream Equipment

The main components of extrusion downstream equipment include:

- Cooling Systems: These are used to solidify the extruded material rapidly after it exits the extruder. Cooling methods can include water baths, air cooling, or chilled rollers. For example, vacuum sizing tanks use negative pressure to maintain the product's shape during cooling. The choice of cooling method depends on the material's properties and the desired cooling rate.

- Pullers: These devices draw the extruded material through the production line at a controlled speed, maintaining tension and ensuring consistent dimensions. Common types include belt pullers, caterpillar pullers, and roller pullers. Each type of puller is suited for different materials and production requirements.

- Cutters: Used to separate the continuous extruded product into desired lengths. Types include rotary cutters, flying knife cutters, and saws. The choice of cutter depends on the material and desired precision. For instance, rotary cutters are often used for high-speed cutting of plastic profiles.

- Winding Systems: Crucial for collecting and storing flexible, continuous products like films, sheets, fibers, or cables into manageable rolls or spools. These systems ensure that the material is properly aligned and tensioned during winding to prevent creases or damage.

Applications of Extrusion Downstream Equipment

Extrusion downstream equipment is widely used in various industries, including:

- Plastic Extrusion: Essential for producing pipes, profiles, and sheets. Cooling tanks, pullers, cutters, and winders ensure that the shape and dimensions of extruded products are maintained during cooling. For example, in the production of PVC pipes, the cooling system ensures that the pipe maintains its circular shape and dimensions.

- Metal Extrusion: Used in the production of aluminum profiles. After extrusion, these profiles may be plastic coated, cooled, stretched, and cut before surface finishing. Downstream equipment helps maintain the precision and quality required for these applications.

- Rubber and Cable Manufacturing: Downstream equipment is crucial for handling and finishing rubber hoses and cables. For instance, rubber hoses require precise cooling and shaping to ensure flexibility and durability.

Importance of Downstream Equipment in Production Efficiency

Downstream equipment is vital for ensuring production efficiency and product quality. It helps maintain dimensional accuracy, surface quality, and reduces waste, thereby increasing overall production speed. By optimizing the cooling, pulling, cutting, and winding processes, manufacturers can achieve higher throughput rates and better product consistency.

Benefits of Customizing Downstream Equipment

Customizing downstream equipment allows manufacturers to better control the quality of end products, improving accuracy and speed during extrusions. This is particularly important for specialized products like medical tubing and automotive components, where precision and consistency are critical. Customized equipment can be tailored to handle specific materials or product geometries, enhancing the overall efficiency of the production line.

Advanced Technologies in Downstream Extrusion

Recent advancements in technology have led to more sophisticated downstream equipment, offering improved precision and automation. For example, the integration of sensors and AI can optimize cooling rates and tension control in real-time, reducing defects and improving product quality.

Role of Automation in Downstream Extrusion

Automation plays a significant role in modern downstream extrusion processes. Automated systems can monitor and adjust production parameters continuously, ensuring consistent product quality and reducing manual labor. This not only increases efficiency but also enhances safety by minimizing human intervention in potentially hazardous processes.

Sustainability in Downstream Extrusion

As environmental concerns grow, the extrusion industry is focusing on sustainable practices. Downstream equipment can be designed to minimize energy consumption and reduce waste. For instance, using efficient cooling systems can lower energy costs while maintaining product quality.

Challenges and Future Developments

Despite the advancements in downstream extrusion equipment, challenges remain. One of the main issues is balancing production speed with product quality. Future developments are likely to focus on integrating more advanced technologies, such as predictive maintenance and real-time quality monitoring, to address these challenges.

Conclusion

In conclusion, extrusion downstream equipment is indispensable in the manufacturing process, ensuring that extruded materials are properly shaped, cooled, and finished to meet specific product requirements. By understanding the key functions and applications of these equipment pieces, manufacturers can optimize their production lines for efficiency and quality.

Frequently Asked Questions

1. What is the primary function of cooling systems in downstream extrusion?

Cooling systems are used to rapidly solidify the extruded material, maintaining its shape and preventing deformation. Common methods include water baths and air cooling.

2. How do pullers contribute to the extrusion process?

Pullers draw the extruded material through the production line at a controlled speed, ensuring consistent dimensions and maintaining tension to prevent deformation.

3. What types of cutters are commonly used in downstream extrusion?

Common types include rotary cutters, flying knife cutters, and saws. The choice of cutter depends on the material and desired precision.

4. Why are winding systems important in downstream extrusion?

Winding systems collect and store flexible, continuous products like films and cables into manageable rolls or spools, facilitating storage and transportation.

5. How does customizing downstream equipment benefit production?

Customizing downstream equipment allows for better control over product quality, improving accuracy and speed during extrusions, which is particularly beneficial for specialized products.