Content Menu

● Introduction

● Understanding 2020 Aluminum Extrusion Dimensions

>> Importance of Precise Dimensions in Manufacturing and Construction

● Common Specifications of 2020 Aluminum Extrusions

>> Overview of Standard Specifications

>> Discussion on Tolerances and Their Effects

● Applications of 2020 Aluminum Extrusions

>> Examples of Industries Using 2020 Aluminum Profiles

>> Case Studies of Specific Projects Utilizing 2020 Extrusions

● Customization and Design Considerations

>> Options for Customizing 2020 Aluminum Extrusions

>> Design Tips for Maximizing the Benefits of Aluminum Profiles

● Conclusion

● Related Questions

>> 1. What are the advantages of using 2020 aluminum extrusions in construction?

>> 2. How do I determine the load capacity of a 2020 aluminum extrusion?

>> 3. Can 2020 aluminum extrusions be used for outdoor applications?

>> 4. What tools are needed to work with 2020 aluminum extrusions?

>> 5. Are there any limitations to using 2020 aluminum extrusions?

Introduction

Aluminum extrusions have become a cornerstone in modern manufacturing and construction, offering versatility, strength, and lightweight properties. Among the various profiles available, the 2020 aluminum extrusion stands out due to its unique dimensions and applications. This article delves into the key dimensions of 2020 aluminum extrusions, exploring their specifications, applications, and design considerations. By understanding these dimensions, engineers and designers can make informed decisions that enhance the structural integrity and functionality of their projects.

Understanding 2020 Aluminum Extrusion Dimensions

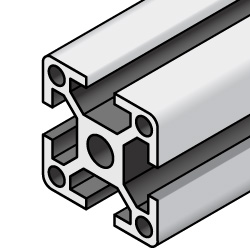

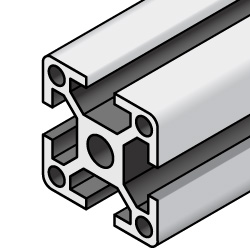

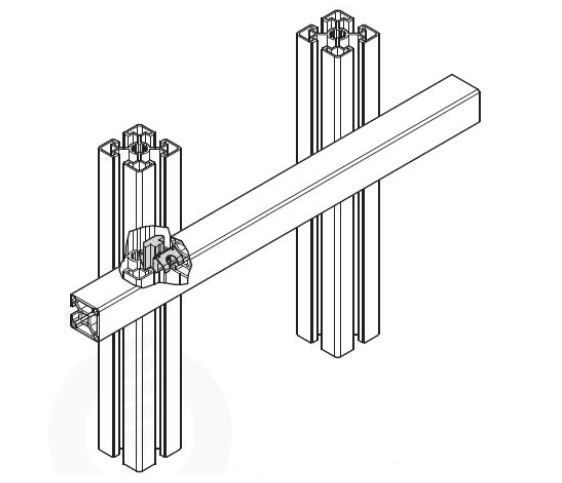

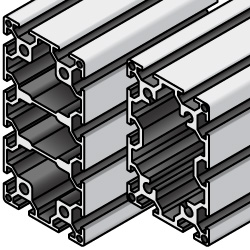

The term "2020 aluminum extrusion" refers to a specific profile that measures 20mm by 20mm in cross-section. This square shape is part of the T-slot aluminum extrusion family, which is characterized by its unique slot design that allows for easy assembly and modification. The dimensions of 2020 aluminum extrusions are crucial for various applications, as they dictate the strength, weight, and compatibility with other components.

The 2020 profile typically has a wall thickness of 1.5mm, which provides a balance between strength and weight. This thickness is sufficient for most applications while keeping the overall weight manageable. The dimensions also include the slot width, which is usually 6mm, allowing for the insertion of fasteners and connectors.

Importance of Precise Dimensions in Manufacturing and Construction

In manufacturing and construction, precision is paramount. The dimensions of 2020 aluminum extrusions must be accurate to ensure proper fit and function. Any deviation from the specified dimensions can lead to structural weaknesses, misalignments, and increased assembly time. Therefore, manufacturers adhere to strict tolerances during the extrusion process to maintain the integrity of the dimensions.

Moreover, the dimensions of 2020 aluminum extrusions influence their load-bearing capacity. The square shape allows for even distribution of forces, making it suitable for various structural applications. Understanding these dimensions helps engineers design frameworks that can withstand specific loads and stresses.

Common Specifications of 2020 Aluminum Extrusions

The specifications of 2020 aluminum extrusions encompass various factors, including weight, strength, and surface finish.

Overview of Standard Specifications

The weight of a 2020 aluminum extrusion is approximately 1.5 kg per meter. This lightweight characteristic makes it an ideal choice for applications where reducing weight is essential, such as in aerospace and automotive industries.

In terms of strength, 2020 aluminum extrusions are typically made from 6063 aluminum alloy, known for its excellent corrosion resistance and good mechanical properties. The tensile strength of this alloy can reach up to 240 MPa, making it suitable for structural applications.

Discussion on Tolerances and Their Effects

Tolerances are critical in the manufacturing process of aluminum extrusions. For 2020 profiles, the standard tolerance for length is ±0.5mm, while the width and height tolerances are typically ±0.2mm. These tolerances ensure that the extrusions fit together seamlessly during assembly.

Any variations in these tolerances can lead to issues such as gaps, misalignments, and compromised structural integrity. Therefore, it is essential for manufacturers to implement quality control measures to monitor and maintain these tolerances throughout the production process.

Applications of 2020 Aluminum Extrusions

The versatility of 2020 aluminum extrusions allows them to be used in a wide range of applications across various industries.

Examples of Industries Using 2020 Aluminum Profiles

1. Automotive Industry: In automotive manufacturing, 2020 aluminum extrusions are used for creating lightweight frames and structural components. Their strength-to-weight ratio helps improve fuel efficiency without compromising safety.

2. Aerospace Industry: The aerospace sector utilizes 2020 profiles for aircraft frames and support structures. The lightweight nature of aluminum is crucial in this industry, where every gram counts.

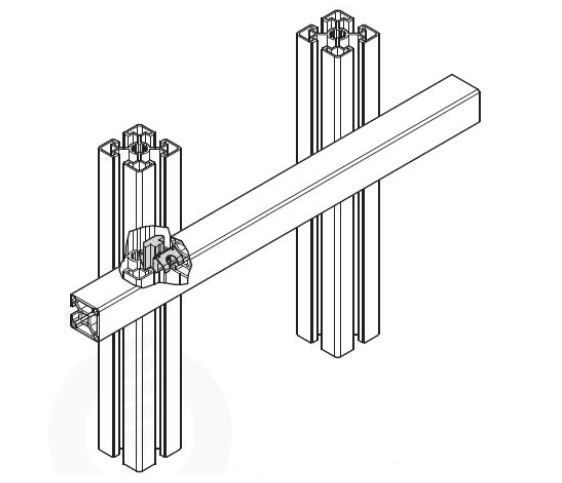

3. Construction: In construction, 2020 aluminum extrusions are employed in building frameworks, scaffolding, and modular structures. Their ease of assembly and modification makes them a popular choice for temporary and permanent installations.

4. Robotics: The robotics industry benefits from the adaptability of 2020 aluminum extrusions. They are often used to create custom frames for robotic arms and other automated systems.

5. Furniture Design: Designers use 2020 aluminum profiles to create modern furniture pieces. The sleek appearance and structural integrity of aluminum make it an attractive option for contemporary designs.

Case Studies of Specific Projects Utilizing 2020 Extrusions

One notable project that utilized 2020 aluminum extrusions is the construction of a modular exhibition booth. The lightweight and customizable nature of the extrusions allowed for easy assembly and disassembly, making it ideal for trade shows. The booth featured various configurations, showcasing the flexibility of the 2020 profile in design.

Another example is the development of a robotic assembly line. Engineers used 2020 aluminum extrusions to create a robust framework that supported various robotic components. The ability to easily modify the structure allowed for quick adjustments as the project evolved.

Customization and Design Considerations

One of the significant advantages of 2020 aluminum extrusions is the ability to customize them for specific applications.

Options for Customizing 2020 Aluminum Extrusions

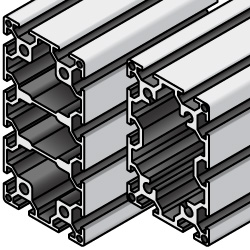

Manufacturers offer various customization options for 2020 aluminum profiles, including different lengths, finishes, and additional features such as pre-drilled holes or integrated connectors. This flexibility allows designers to tailor the extrusions to meet the unique requirements of their projects.

For instance, anodized finishes can enhance the corrosion resistance and aesthetic appeal of the extrusions. Additionally, custom lengths can be produced to minimize waste and reduce assembly time.

Design Tips for Maximizing the Benefits of Aluminum Profiles

When designing with 2020 aluminum extrusions, it is essential to consider the following tips:

- Load Distribution: Ensure that the load is evenly distributed across the profile to prevent bending or deformation.

- Connection Points: Plan connection points carefully to facilitate easy assembly and disassembly.

- Modularity: Design with modularity in mind, allowing for future modifications or expansions.

- Surface Treatment: Consider surface treatments that enhance durability and aesthetics, especially for visible applications.

Conclusion

Understanding the key dimensions of 2020 aluminum extrusions is vital for engineers, designers, and manufacturers. The 20mm x 20mm profile, along with its specifications and customization options, makes it a versatile choice for various applications. By adhering to precise dimensions and tolerances, professionals can ensure the structural integrity and functionality of their projects. As industries continue to evolve, the demand for lightweight, strong, and adaptable materials like 2020 aluminum extrusions will only increase.

Related Questions

1. What are the advantages of using 2020 aluminum extrusions in construction?

2020 aluminum extrusions offer lightweight properties, corrosion resistance, and ease of assembly, making them ideal for various construction applications.

2. How do I determine the load capacity of a 2020 aluminum extrusion?

The load capacity can be determined by considering the material properties, dimensions, and the specific application requirements. Consulting engineering guidelines can provide detailed calculations.

3. Can 2020 aluminum extrusions be used for outdoor applications?

Yes, 2020 aluminum extrusions are suitable for outdoor use due to their corrosion resistance, especially when treated with anodized finishes.

4. What tools are needed to work with 2020 aluminum extrusions?

Common tools include saws for cutting, drills for creating holes, and T-slot nuts for assembly. A basic toolkit can suffice for most projects.

5. Are there any limitations to using 2020 aluminum extrusions?

While 2020 aluminum extrusions are versatile, they may not be suitable for applications requiring extremely high load capacities or exposure to harsh chemicals without proper treatment.