Content Menu

● 1. Introduction to Aluminum Extrusion

● 2. Overview of the Aluminum Extrusion Process

● 3. Key Components of an Aluminum Extrusion Press

>> 3.1 Hydraulic Ram

>> 3.2 Container

>> 3.3 Die

>> 3.4 Dummy Block

>> 3.5 Back and Front Platens

>> 3.6 Tie Rods

>> 3.7 Runout Table

● 4. Detailed Diagram of an Aluminum Extrusion Press

● 5. Step-by-Step Process of Aluminum Extrusion

>> 5.1 Step 1: Billet Preparation

>> 5.2 Step 2: Loading into the Press

>> 5.3 Step 3: Applying Pressure

>> 5.4 Step 4: Shaping Through Die

>> 5.5 Step 5: Cooling Process

>> 5.6 Step 6: Cutting to Length

● 6. Conclusion

● 7. FAQs

>> 1. What materials can be extruded besides aluminum?

>> 2. How does temperature affect the extrusion process?

>> 3. What types of dies are used in aluminum extrusion?

>> 4. How do you ensure quality control during extrusion?

>> 5. Can recycled aluminum be used in extrusion?

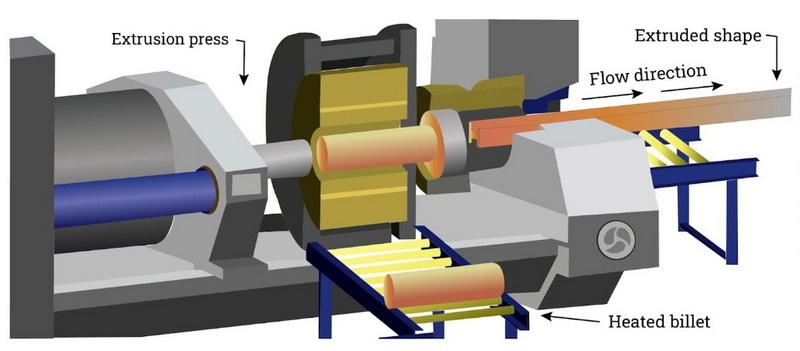

Aluminum extrusion is a vital manufacturing process that allows for the creation of complex shapes and profiles from aluminum alloys. Understanding the key components of an aluminum extrusion press and how they work together is essential for anyone involved in this industry. This article will explore the main elements of an aluminum extrusion press, providing diagrams, images, and videos to enhance comprehension.

1. Introduction to Aluminum Extrusion

Aluminum extrusion involves forcing heated aluminum through a die to create a specific cross-sectional shape. The process is widely used in various industries, including construction, automotive, and aerospace, due to aluminum's lightweight and durable properties.

2. Overview of the Aluminum Extrusion Process

The aluminum extrusion process can be broken down into several steps:

- Billet Preparation: The aluminum alloy is cast into logs known as billets.

- Heating: The billets are heated to a malleable state, typically between 700°F and 930°F (370°C to 500°C).

- Extrusion: A hydraulic ram pushes the heated billet through a die.

- Cooling: The extruded material is cooled to set its shape.

- Cutting: The extruded profiles are cut to the desired lengths.

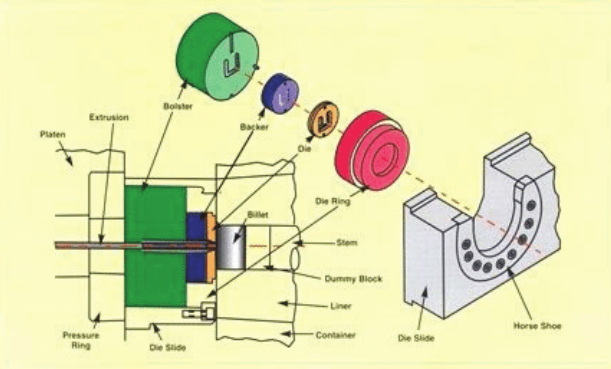

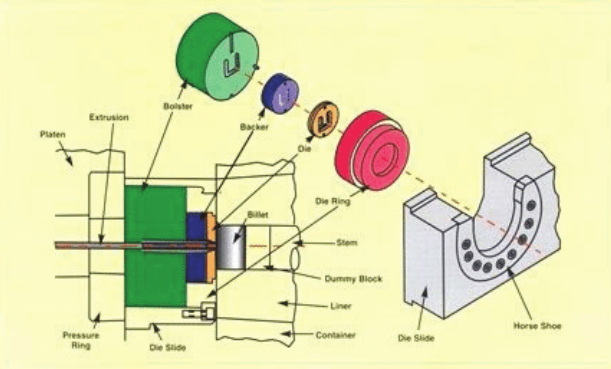

3. Key Components of an Aluminum Extrusion Press

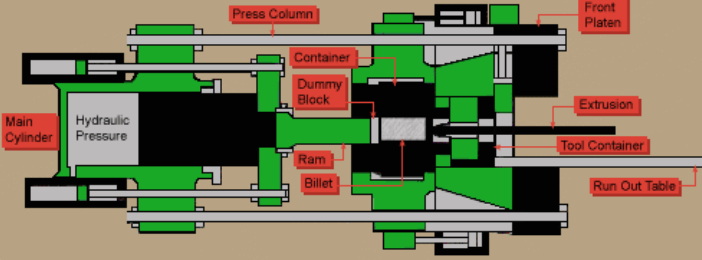

Understanding the components of an aluminum extrusion press is crucial for grasping how the process works. Below are the primary elements:

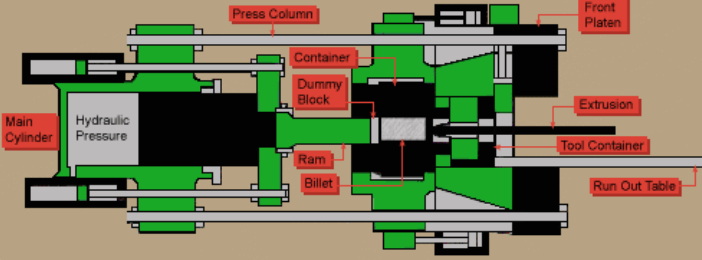

3.1 Hydraulic Ram

The hydraulic ram is a critical component responsible for applying pressure to the billet. It can exert forces ranging from 1,000 to 15,000 tons, depending on the design of the press.

3.2 Container

The container holds the preheated billet before it is pushed through the die. It is designed to maintain optimal temperatures and support the billet during extrusion.

3.3 Die

The die shapes the aluminum as it is extruded. It consists of a die body and may include mandrels for creating hollow profiles or complex shapes.

3.4 Dummy Block

The dummy block sits between the ram and the billet. It helps distribute pressure evenly across the billet and prevents back-feeding into the ram.

3.5 Back and Front Platens

These platens hold the components of the press together and provide structural integrity during operation.

3.6 Tie Rods

Tie rods connect the front and back platens, ensuring that they remain aligned under pressure.

3.7 Runout Table

After exiting the die, the extruded profile moves along a runout table where it is cooled and prepared for further processing.

4. Detailed Diagram of an Aluminum Extrusion Press

Aluminum Extrusion Press Diagram

This diagram illustrates the layout of an aluminum extrusion press, highlighting each component's position and function within the system.

5. Step-by-Step Process of Aluminum Extrusion

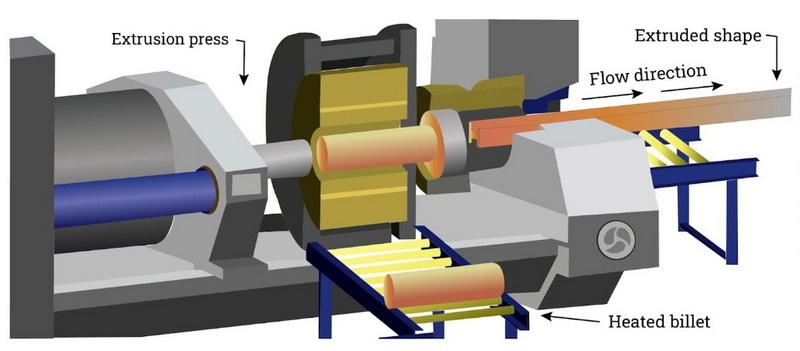

To better understand how these components work together, let's delve into each step of the aluminum extrusion process:

5.1 Step 1: Billet Preparation

Before extrusion, billets are prepared by cutting them from larger logs and heating them in a furnace until they reach malleability.

5.2 Step 2: Loading into the Press

Once heated, lubricants are applied to both the billet and ram to prevent sticking during extrusion.

5.3 Step 3: Applying Pressure

The hydraulic ram pushes against the dummy block, forcing the billet into the container and against the die.

5.4 Step 4: Shaping Through Die

As pressure builds, aluminum flows through the die opening, taking on its shape as it exits.

5.5 Step 5: Cooling Process

The extruded profiles are guided along a cooling table where they undergo quenching—rapid cooling with water or air—to solidify their shape.

5.6 Step 6: Cutting to Length

Once cooled, extrusions are cut to specified lengths using saws or shears.

6. Conclusion

Understanding the key components of an aluminum extrusion press is essential for anyone involved in manufacturing or engineering with aluminum materials. Each part plays a crucial role in ensuring that high-quality profiles are produced efficiently and effectively. From heating billets to shaping them through dies, every step in this intricate process contributes to creating versatile products used across various industries.

7. FAQs

1. What materials can be extruded besides aluminum?

Other materials that can be extruded include copper, magnesium, and some plastics.

2. How does temperature affect the extrusion process?

Temperature significantly impacts malleability; higher temperatures allow for easier shaping but can also affect material properties if too high.

3. What types of dies are used in aluminum extrusion?

Common types include solid dies for simple shapes and hollow dies for creating tubes or complex profiles.

4. How do you ensure quality control during extrusion?

Quality control involves monitoring temperature, pressure, and dimensions throughout production and conducting tests on finished products.

5. Can recycled aluminum be used in extrusion?

Yes, recycled aluminum can be used effectively in extrusion processes, often leading to cost savings and environmental benefits.

Come and contact us to shop! ! !