Content Menu

● Introduction to Printrbot Aluminum Extruder Calibration

>> Why Calibration is Important

● Tools and Software Needed

● Step-by-Step Printrbot Aluminum Extruder Calibration

>> Step 1: Heat Up the Extruder

>> Step 2: Measure and Mark the Filament

>> Step 3: Extrude 100mm of Filament

>> Step 4: Measure the Actual Extrusion

>> Step 5: Adjust E-Steps

>> Step 6: Confirm Calibration

● Tuning the Extrusion Multiplier

● Understanding Different Extruder Types

>> Direct vs. Bowden Extruders

● Advanced Calibration Techniques

>> Calibrating Other Axes

>> Firmware Considerations

● Common Issues and Solutions

>> Clogged Nozzles

>> Incorrect Temperature Settings

● Additional Tips for Printrbot Users

● Conclusion

● FAQ

>> 1. What is the purpose of calibrating the extruder's E-steps?

>> 2. How often should I calibrate my Printrbot aluminum extruder?

>> 3. What tools do I need for extruder calibration?

>> 4. How do I adjust the extrusion multiplier in my slicer?

>> 5. Can I use the same calibration settings for different types of filament?

● Citations:

Calibrating a Printrbot aluminum extruder is a crucial step in ensuring that your 3D prints turn out accurately and with high quality. Proper calibration helps prevent issues like under-extrusion or over-extrusion, which can lead to poor print quality or even clogs in the nozzle. In this guide, we will walk through the process of calibrating a Printrbot aluminum extruder, covering both the theoretical background and practical steps involved.

Introduction to Printrbot Aluminum Extruder Calibration

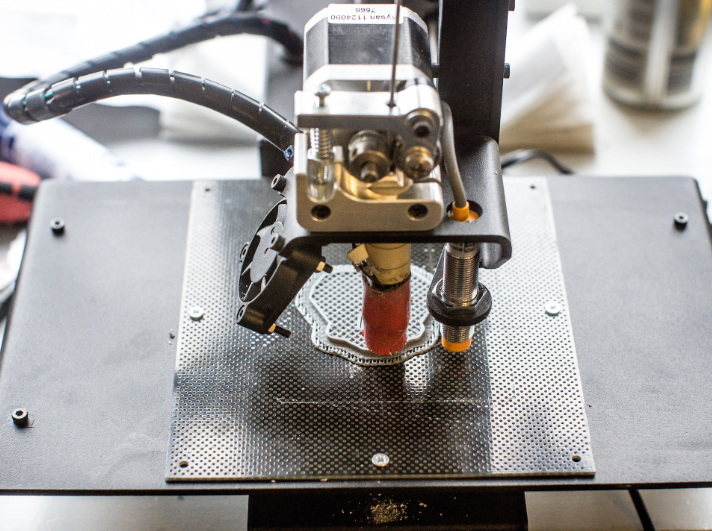

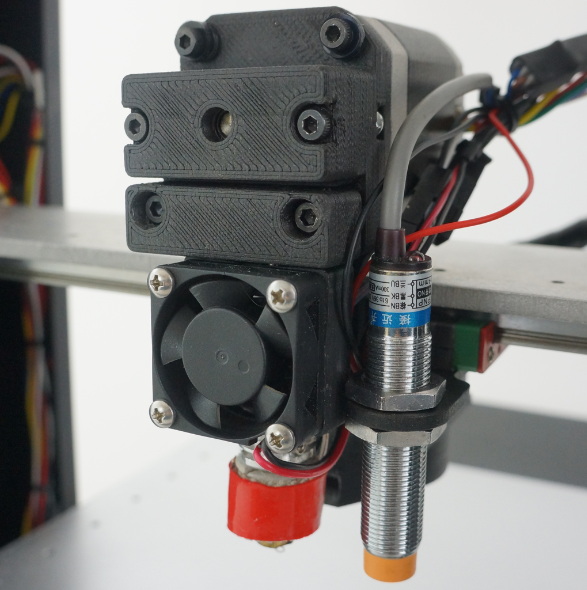

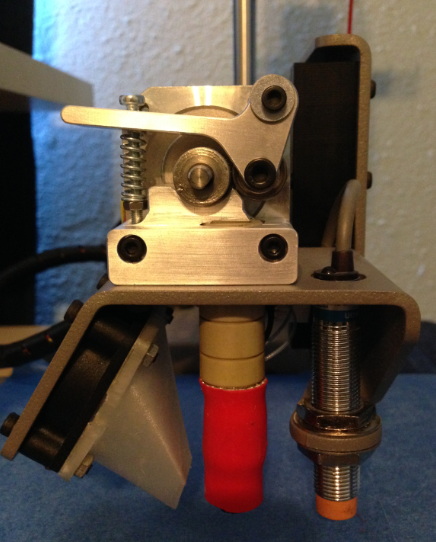

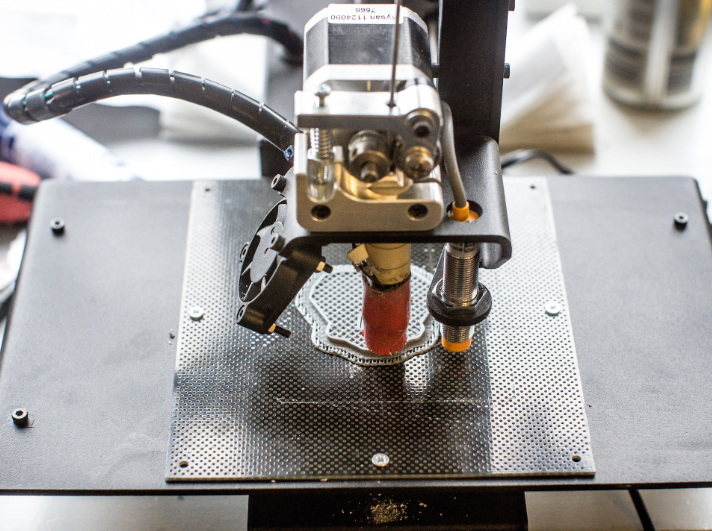

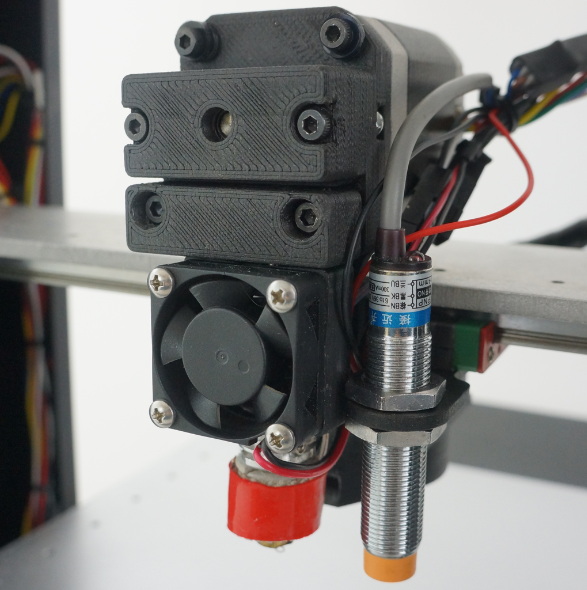

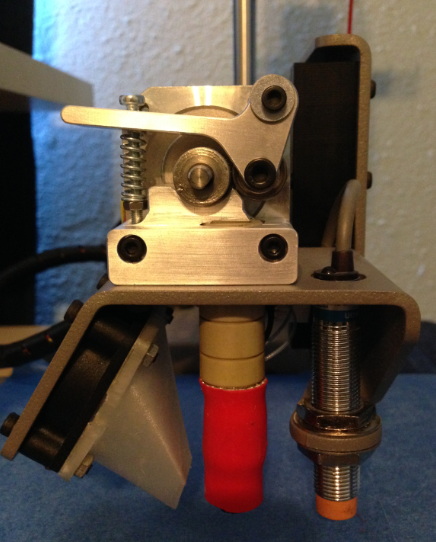

The Printrbot aluminum extruder is designed for precise filament control, making it an excellent choice for hobbyists and professionals alike. However, like all extruders, it requires calibration to ensure that the filament is fed accurately and consistently.

Why Calibration is Important

Calibration is essential for maintaining the quality of your prints. If the extruder is not calibrated correctly, it can lead to:

- Under-extrusion: Insufficient filament is extruded, resulting in weak or incomplete prints.

- Over-extrusion: Too much filament is extruded, causing blobs or excessive material buildup.

Both issues can be resolved by adjusting the extruder's steps per millimeter (SPM) value and the extrusion multiplier.

Tools and Software Needed

Before starting the calibration process, ensure you have the following tools and software:

- Digital Calipers: For measuring filament lengths accurately.

- Sharpie or Marker: For marking the filament.

- Repetier Host or Pronterface: Software for controlling and communicating with your printer.

- Printrbot Aluminum Extruder: The extruder you are calibrating.

Step-by-Step Printrbot Aluminum Extruder Calibration

Step 1: Heat Up the Extruder

Bring your extruder to the recommended temperature for the filament you are using. For PLA, this is typically around 205°C.

Step 2: Measure and Mark the Filament

Using a caliper, measure 120mm from the point where the filament enters the extruder and mark it with a Sharpie.

Step 3: Extrude 100mm of Filament

Using Repetier Host or Pronterface, command the printer to extrude 100mm of filament.

Step 4: Measure the Actual Extrusion

Measure how much filament was actually extruded by comparing the remaining marked filament.

Step 5: Adjust E-Steps

If less than 100mm was extruded, you are under-extruding. If more than 100mm was extruded, you are over-extruding. Adjust the E-steps using the formula:

New E-steps =Current E-steps/ Measured Length

Step 6: Confirm Calibration

Repeat the extrusion process to confirm that the adjustments were successful.

Tuning the Extrusion Multiplier

After calibrating the E-steps, you may need to adjust the extrusion multiplier in your slicer software to achieve optimal print quality. The extrusion multiplier affects how much filament is actually extruded compared to what is calculated by the slicer. Adjusting this value can help fine-tune your prints to prevent under or over-extrusion.

Understanding Different Extruder Types

Direct vs. Bowden Extruders

- Direct Extruders: These extruders feed filament directly into the hot end. They are more common in printers like the Printrbot and offer better control over filament flow but can be heavier and more prone to vibrations.

- Bowden Extruders: These use a tube to guide the filament from the extruder to the hot end. They are lighter and reduce vibrations but can introduce additional complexity due to the tube's length and flexibility.

Both types require similar calibration steps, but direct extruders involve extruding filament through the hot end, while Bowden extruders involve cutting the filament flush with the Bowden tube for measurement.

Advanced Calibration Techniques

Calibrating Other Axes

While extruder calibration is crucial, it's also important to calibrate the X, Y, and Z axes to ensure accurate movement and positioning. This involves adjusting the steps per millimeter (SPM) for each axis using calibration models like the "Benchy" boat, which tests various aspects of print quality.

Firmware Considerations

Different firmware like Marlin and Klipper require slightly different approaches to calibration. For example, Marlin involves calculating and adjusting E-steps directly, while Klipper focuses on the extruder's rotation distance.

Common Issues and Solutions

Clogged Nozzles

Clogs can occur due to improper calibration or filament quality issues. To unclog a nozzle, heat it up and use a needle or small tool to gently clear the blockage. Ensure the extruder's tension is correct to prevent chewing up the filament.

Incorrect Temperature Settings

Using the wrong temperature can lead to poor extrusion. Ensure you're using the recommended temperature for your filament type.

Additional Tips for Printrbot Users

For Printrbot users, it's essential to follow specific calibration guides tailored to your printer model. The Printrbot Simple Metal, for example, requires precise calibration of XY and Z steps to ensure accurate prints.

Conclusion

Calibrating a Printrbot aluminum extruder is a straightforward process that requires attention to detail and some basic tools. By following these steps, you can ensure that your prints are of high quality and that your extruder operates efficiently. Remember to regularly check and adjust your extruder settings as needed to maintain optimal performance.

FAQ

Here are some frequently asked questions about Printrbot aluminum extruder calibration:

1. What is the purpose of calibrating the extruder's E-steps?

Calibrating the E-steps ensures that the extruder accurately feeds the correct amount of filament, preventing under or over-extrusion issues.

2. How often should I calibrate my Printrbot aluminum extruder?

You should calibrate your extruder whenever you notice print quality issues or after making significant changes to your printer setup.

3. What tools do I need for extruder calibration?

You need a digital caliper, a Sharpie or marker, and software like Repetier Host or Pronterface.

4. How do I adjust the extrusion multiplier in my slicer?

Adjust the extrusion multiplier by changing the flow rate in your slicer settings until you achieve optimal print quality.

5. Can I use the same calibration settings for different types of filament?

No, different filaments may require different calibration settings due to variations in diameter and material properties.

Citations:

[1] https://www.matterhackers.com/articles/how-to-calibrate-your-extruder

[2] https://www.inov3d.net/extruder-calibration/

[3] https://additive-x.com/blog/essential-guide-3d-printer-calibration

[4] https://3dwithus.com/3d-printer-extruder-calibration-guide

[5] https://www.instructables.com/How-to-Unclog-Your-Printrbot-Plays-Extruder/

[6] https://github.com/jdwallace/3d-printing/blob/main/Printrbot%20Simple%20Metal/Calibration.md

[7] https://kingroon.com/blogs/3d-printing-guides/3d-printer-calibration

[8] https://www.instructables.com/Perfect-Prints-the-Ultimate-Guide-to-Filament-Cali/

[9] https://www.youtube.com/watch?v=JPGpEPR6Xxc

[10] https://3dprinting.stackexchange.com/questions/612/repeatedly-clogged-printrbot-simple-extruder

[11] https://blondihacks.com/printrbot-metal-plus-assembly/

[12] https://www.reddit.com/r/3Dprinting/comments/2mvygj/printrbot_simple_metal_not_printing_quite_right/

[13] https://www.youtube.com/watch?v=PChOqIBNwOs

[14] https://www.thingiverse.com/groups/printrbot-play/forums/general/topic:4389

[15] https://teachingtechyt.github.io/calibration.html

[16] https://forum.simplify3d.com/viewtopic.php?t=12707

[17] https://www.reddit.com/r/PrintrBot/comments/4cbl1d/simple_metal_setup_calibration_tips/

[18] https://www.instructables.com/How-to-calibrate-the-Extruder-on-your-3d-Printer/

[19] https://reprap.org/forum/read.php?4%2C685596

[20] https://www.dobot-robots.com/insights/news/10-common-3d-printing-troubleshooting-problems-to-expect.html