Content Menu

● Understanding Aluminum Extrusion

● Benefits of Aluminum Extrusion

● The Manufacturing Process of 1/4 Round Aluminum Extrusion

>> 1. Material Selection

>> 2. Billet Preparation

>> 3. Heating the Billet

>> 4. Extrusion Process

>> 5. Cooling

>> 6. Cutting to Length

>> 7. Surface Treatment

>> 8. Quality Control

>> 9. Packaging and Shipping

● Applications of 1/4 Round Aluminum Extrusions

● Innovations in Aluminum Extrusion

● Conclusion

● Frequently Asked Questions

>> 1. What is the difference between 6061 and 6063 aluminum alloys?

>> 2. Can aluminum extrusions be customized?

>> 3. What are the benefits of anodizing aluminum extrusions?

>> 4. How long does the aluminum extrusion process take?

>> 5. Is aluminum extrusion environmentally friendly?

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This process is widely used in various industries due to its versatility, strength, and lightweight properties. One specific type of aluminum extrusion is the 1/4 round aluminum extrusion, which features a rounded edge and is commonly used in applications such as architectural designs, furniture, and automotive components. In this article, we will explore the manufacturing process of 1/4 round aluminum extrusions in detail, including the materials used, the steps involved, and the benefits of this method.

Benefits of Aluminum Extrusion

Aluminum extrusion offers several advantages, including:

- Versatility: Aluminum can be extruded into a wide range of shapes and sizes, making it suitable for various applications.

- Strength-to-Weight Ratio: Aluminum is lightweight yet strong, making it ideal for structural applications.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps prevent corrosion.

- Recyclability: Aluminum is 100% recyclable, making it an environmentally friendly choice.

- Cost-Effectiveness: The extrusion process is efficient, allowing for mass production of aluminum profiles at a lower cost compared to other manufacturing methods.

The Manufacturing Process of 1/4 Round Aluminum Extrusion

The manufacturing process of 1/4 round aluminum extrusion involves several key steps:

1. Material Selection

The first step in the manufacturing process is selecting the appropriate aluminum alloy. Common alloys used for extrusion include 6061 and 6063, which offer excellent mechanical properties and corrosion resistance. The choice of alloy depends on the specific requirements of the application. For instance, 6061 is often chosen for its strength and is suitable for structural applications, while 6063 is preferred for architectural applications due to its aesthetic finish.

2. Billet Preparation

Once the alloy is selected, it is formed into a billet, which is a solid piece of aluminum that will be heated and extruded. The billets are typically cut to a specific length and diameter, depending on the desired final product. The preparation of the billet is crucial, as any imperfections can affect the quality of the final extrusion.

3. Heating the Billet

The next step is to heat the aluminum billet to a temperature between 800°F and 1000°F (427°C to 538°C). This heating process is crucial, as it makes the aluminum malleable and easier to extrude. The heating is typically done in a furnace, where the billets are placed for a specific duration to ensure uniform heating. Proper heating is essential to avoid defects such as cracking or incomplete extrusion.

4. Extrusion Process

Once the billet is heated, it is placed in an extrusion press. The press uses a ram to push the heated billet through the die. The die is specifically designed to create the 1/4 round profile. As the aluminum is forced through the die, it takes on the shape of the opening, resulting in a continuous length of 1/4 round aluminum extrusion. The extrusion process can be done using two methods: direct extrusion and indirect extrusion. In direct extrusion, the billet is pushed through the die, while in indirect extrusion, the die is moved towards the billet.

5. Cooling

After the extrusion process, the newly formed aluminum profile is cooled. This is typically done using air or water cooling methods. Cooling is essential to solidify the aluminum and maintain its shape. The cooling process also helps to relieve any internal stresses that may have developed during extrusion. Proper cooling is vital to ensure that the final product retains its dimensional accuracy and structural integrity.

6. Cutting to Length

Once cooled, the extruded aluminum profile is cut to the desired length. This is done using saws or cutting machines that ensure precise cuts. The lengths can vary based on customer specifications or application requirements. Accurate cutting is important to ensure that the extrusions fit properly in their intended applications.

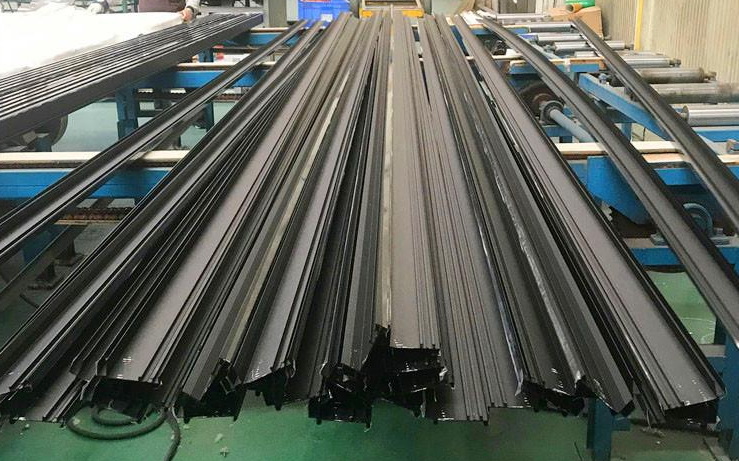

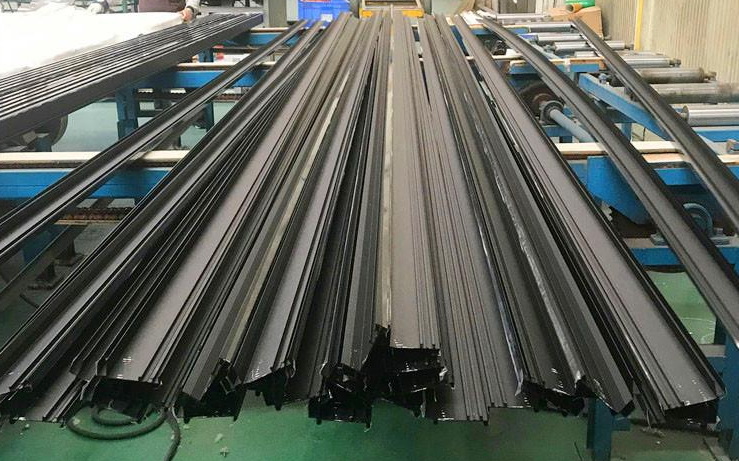

7. Surface Treatment

After cutting, the aluminum extrusions may undergo surface treatment processes such as anodizing, painting, or powder coating. These treatments enhance the appearance of the aluminum and provide additional protection against corrosion and wear. Anodizing, for example, increases the thickness of the natural oxide layer on the surface of the aluminum, improving its durability and resistance to corrosion.

8. Quality Control

Quality control is a critical step in the manufacturing process. Each batch of extrusions is inspected for dimensional accuracy, surface finish, and overall quality. This ensures that the final product meets the required specifications and standards. Quality control measures may include visual inspections, dimensional checks, and mechanical testing to assess the strength and durability of the extrusions.

9. Packaging and Shipping

Once the extrusions pass quality control, they are packaged for shipping. Proper packaging is essential to protect the aluminum profiles during transportation. The extrusions are typically bundled and secured to prevent damage. Packaging may also include labeling and documentation to ensure that the products are easily identifiable and traceable.

Applications of 1/4 Round Aluminum Extrusions

1/4 round aluminum extrusions are used in various applications, including:

- Architectural Elements: Used in window frames, door frames, and decorative trim. The rounded edges provide a sleek and modern appearance, making them popular in contemporary architecture.

- Furniture: Commonly found in tables, chairs, and shelving units. The lightweight nature of aluminum allows for easy mobility and assembly of furniture pieces.

- Automotive Parts: Used in vehicle frames and components due to their lightweight and strength. Aluminum extrusions help improve fuel efficiency by reducing the overall weight of vehicles.

- Industrial Applications: Employed in machinery and equipment for structural support. The durability of aluminum extrusions makes them suitable for heavy-duty applications.

Innovations in Aluminum Extrusion

The aluminum extrusion industry has seen significant innovations in recent years. Advances in technology have led to improved extrusion processes, resulting in higher quality products and greater efficiency. Some notable innovations include:

- 3D Printing and Extrusion: The integration of 3D printing technology with aluminum extrusion allows for the creation of complex shapes and designs that were previously difficult to achieve. This combination opens up new possibilities for custom applications and rapid prototyping.

- Smart Manufacturing: The use of automation and data analytics in the extrusion process enhances production efficiency and quality control. Smart manufacturing techniques enable real-time monitoring of the extrusion process, allowing for quick adjustments to maintain optimal conditions.

- Sustainable Practices: The aluminum industry is increasingly focusing on sustainability. Many manufacturers are adopting eco-friendly practices, such as using recycled aluminum and reducing energy consumption during the extrusion process. These efforts contribute to a more sustainable manufacturing environment.

Conclusion

The manufacturing of 1/4 round aluminum extrusions is a complex process that involves several steps, from material selection to quality control. The versatility and strength of aluminum make it an ideal choice for various applications, and the extrusion process allows for the creation of intricate shapes and profiles. As industries continue to seek lightweight and durable materials, aluminum extrusion will remain a vital manufacturing method. With ongoing innovations and a focus on sustainability, the future of aluminum extrusion looks promising.

Frequently Asked Questions

1. What is the difference between 6061 and 6063 aluminum alloys?

6061 aluminum is known for its strength and is often used in structural applications, while 6063 is more commonly used for architectural applications due to its excellent finish and workability.

2. Can aluminum extrusions be customized?

Yes, aluminum extrusions can be customized in terms of shape, size, and surface finish to meet specific project requirements. Manufacturers can work with clients to develop unique profiles that suit their needs.

3. What are the benefits of anodizing aluminum extrusions?

Anodizing enhances corrosion resistance, improves surface hardness, and allows for a variety of color finishes. This process not only protects the aluminum but also enhances its aesthetic appeal.

4. How long does the aluminum extrusion process take?

The time required for the extrusion process can vary based on the complexity of the profile and the production volume, but it typically takes a few hours from heating to cutting. Larger production runs may take longer due to setup and processing times.

5. Is aluminum extrusion environmentally friendly?

Yes, aluminum is 100% recyclable, and the extrusion process generates minimal waste, making it an environmentally friendly manufacturing option. The use of recycled aluminum also reduces the energy required for production, further enhancing its sustainability.