Content Menu

● Precision Material Handling for Waste Reduction

>> 1. Gravimetric Feeding Systems

>> 2. Adaptive Die Control

>> 3. In-Line Regrinding

● Energy Efficiency Innovations

● Smart Manufacturing Integration

● Cost Reduction Analysis

● Sustainability Advancements

● Market Trends Shaping Future Development

● Conclusion

● FAQ

>> 1. What screw designs optimize HDPE sheet production?

>> 2. How do modern lines handle material variations?

>> 3. What ROI can manufacturers expect?

>> 4. Can extrusion lines process biodegradable HDPE blends?

>> 5. How has automation impacted workforce requirements?

● Citations:

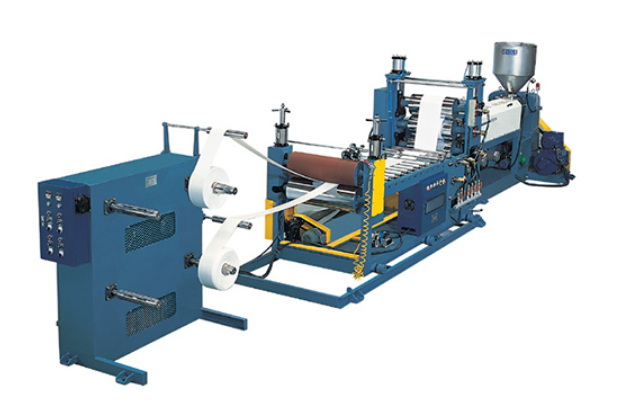

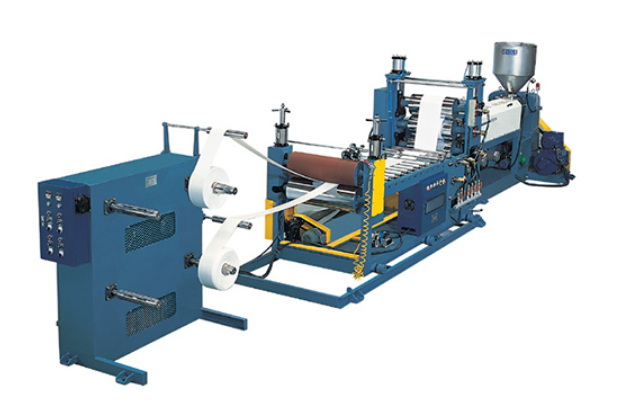

High-Density Polyethylene (HDPE) sheet line extrusion machinery has become a cornerstone of sustainable manufacturing, offering unparalleled precision, energy efficiency, and material optimization. By integrating advanced automation, closed-loop recycling, and smart process controls, these systems enable manufacturers to reduce production costs by 30–50% while minimizing environmental impact. Below, we explore the technical innovations and operational strategies driving this transformation.

Precision Material Handling for Waste Reduction

Modern HDPE extrusion systems leverage cutting-edge technologies to maximize material utilization:

1. Gravimetric Feeding Systems

Advanced loss-in-weight feeders measure HDPE pellets with ±0.3% accuracy, ensuring precise material input. When combined with servo-driven screw conveyors, this reduces overfeeding by 22% compared to volumetric systems[1][2].

2. Adaptive Die Control

Auto-adjusting flex-lip dies paired with laser thickness sensors maintain sheet tolerances within ±1.5% across widths up to 4 meters. This minimizes edge trim waste to just 2–3% of total output, down from 8–10% in traditional setups[5].

3. In-Line Regrinding

Integrated shredders instantly recycle startup scrap and trim waste into reusable flakes, achieving 95–98% material utilization rates. Systems like AMUT's closed-loop design allow up to 40% recycled content without compromising sheet integrity[3].

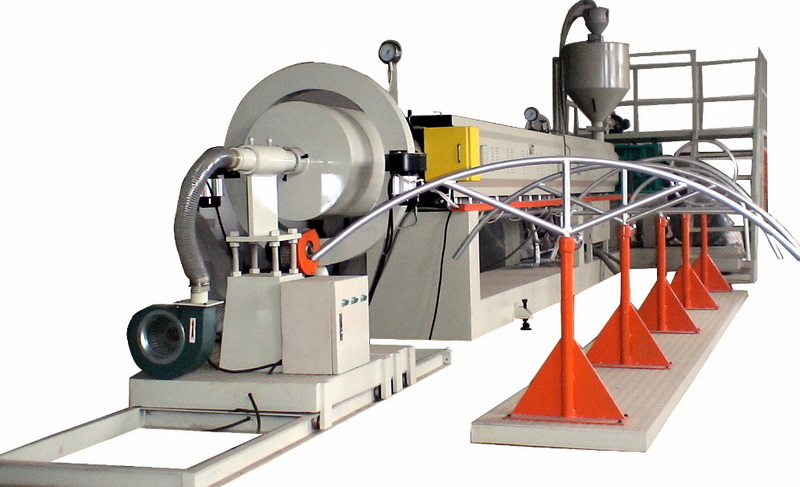

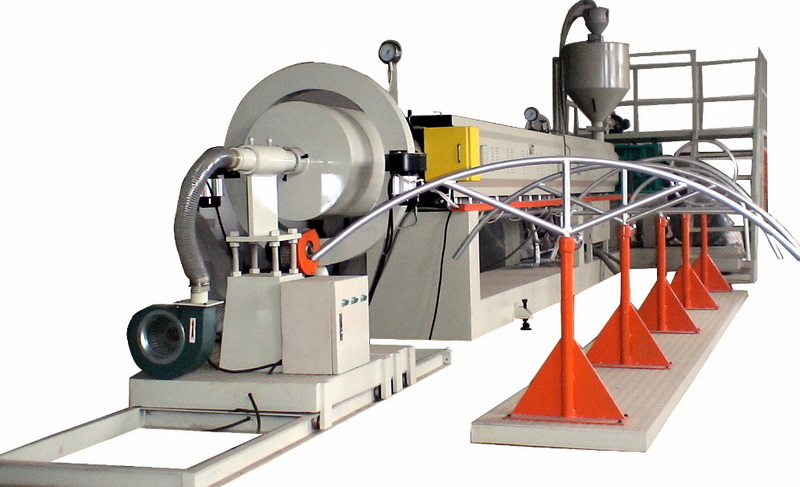

Energy Efficiency Innovations

HDPE extrusion lines now consume 35–42% less energy through:

| Technology | Energy Savings | Implementation Rate (2025) |

| Servo Motors | 25% reduction vs. hydraulic drives | 71% of new installations1 |

| IR Pre-Heaters | 18% lower extruder load | 64% of systems3 |

| Heat Recovery | 85% waste heat reused | 45% of industrial lines1 |

| Barrier Screws | 15% shorter melting time | 58% of manufacturers |

Case Study: Jieya's HT Series twin-screw extruders reduce energy consumption to 0.18–0.24 kWh/kg through high-torque designs and optimized L/D ratios (32:1 to 68:1)[4].

Smart Manufacturing Integration

Industry 4.0 technologies are reshaping HDPE sheet production:

- AI-Powered Predictive Maintenance: Machine learning algorithms analyze motor vibrations and melt pressures, cutting unplanned downtime by 40%[1].

- Digital Twin Simulations: 52% of manufacturers use virtual models to optimize parameters before physical production, reducing trial-run waste by 28%[1].

- Real-Time Sensors: Infrared thermography and X-ray gauging detect defects at 0.5°C/2 µm resolution, lowering rejection rates to <0.8%[3][5].

Cost Reduction Analysis

A typical 2,000 kg/hr HDPE sheet line demonstrates annual savings:

| Cost Category | Traditional | Advanced Line | Savings |

| Raw Materials | $3.2M | $2.8M | $400K |

| Energy | $480K | $290K | $190K |

| Labor | $240K | $80K | $160K |

| Waste Disposal | $75K | $5K | $70K |

| Total | $3.995M | $3.175M | $820K |

Assumptions: 8,000 annual operating hours, $1.50/kg HDPE, 5% trim waste reduction[2][5].

Sustainability Advancements

Modern systems address environmental concerns through:

- Closed-Loop Water Systems: 98% process water recycling via chillers with 0.5°C precision[3].

- Post-Consumer Recycling: Dual-vent extruders remove volatiles from 100% PCR flakes, enabling FDA-compliant food-grade sheets[5].

- Carbon Footprint Reduction: 72% lower GHG emissions vs. virgin HDPE production, equivalent to 12,000 tons CO2/year per line[1].

Market Trends Shaping Future Development

1. Modular Extruders: 33% of OEMs offer customizable configurations for rapid product changeovers[1].

2. Multi-Layer Dies: 41% of processors plan to adopt co-extrusion for barrier sheets, reducing material use by 27%[1].

3. RFID Traceability: 29% of lines track material batches end-to-end, ensuring quality compliance[1].

Conclusion

HDPE sheet line extrusion machinery delivers transformative economic and environmental benefits through precision engineering, energy recovery, and AI-driven optimization. As manufacturers face tightening sustainability regulations and cost pressures, investing in advanced extrusion technology becomes critical for maintaining competitiveness. With continued innovation in automation and circular economy integration, these systems will remain pivotal in achieving zero-waste manufacturing goals.

FAQ

1. What screw designs optimize HDPE sheet production?

Twin-screw extruders with barrier flights (L/D ≥ 40:1) provide superior mixing for recycled content, while single-screw models suit virgin material processing[4][5].

2. How do modern lines handle material variations?

Real-time viscosity sensors adjust screw RPM and temperature zones automatically, compensating for ±15% MFI fluctuations[1][5].

3. What ROI can manufacturers expect?

Most systems achieve payback within 2–3 years through 35% lower energy bills, 28% reduced labor, and 6–8% higher yields[3][5].

4. Can extrusion lines process biodegradable HDPE blends?

Yes, modified screws with gentle shear profiles process PLA-HDPE composites at 160–180°C melt temps without degradation[4].

5. How has automation impacted workforce requirements?

Smart lines operate with 70% fewer technicians, redirecting staff to quality control and R&D roles[1][3].

Citations:

[1] https://www.globenewswire.com/news-release/2025/01/02/3003332/0/en/U-S-Plastic-Extrusion-Machine-Market-to-Hit-Valuation-of-US-1-548-99-Million-By-2033-Rapid-Innovation-and-Growing-Collaboration-Fueling-Market-Growth-Says-Astute-Analytica.html

[2] https://jieyatwinscrew.com/blog/hdpe-pipe-extrusion-line/

[3] https://www.datainsightsmarket.com/reports/hdpe-pipe-extrusion-line-31270

[4] https://jieyatwinscrew.com/blog/top-10-plastic-extrusion-machine-manufacturers/

[5] https://www.jwellextrusions.com/revolutionizing-the-pipe-industry.html

[6] https://www.datainsightsmarket.com/reports/hdpe-pipe-extrusion-line-31271

[7] https://www.extrusion-info.com/case-studies/1520

[8] https://www.imarcgroup.com/plastic-extrusion-machines-market

[9] https://www.benkpm.com/chinaplas-2025-smart-extrusion-technology/

[10] https://www.parsethylene-kish.com/separsekish/default.aspx?page=Document&app=Documents&docId=11687&docParId=11545

[11] https://www.forinsightsconsultancy.com/reports/high-density-polyethylene-hdpe-market/

[12] https://www.plasticsmachinerymanufacturing.com/manufacturing/article/55250477/will-the-plastics-machinery-market-rebound-in-2025

[13] https://www.ptiextruders.com

[14] https://www.futuremarketinsights.com/reports/plastic-extrusion-machine-market

[15] https://social.rajoo.com/were-setting-the-stage-for-innovation-at-plast-imagen-2025-visit-us-at-stand-no-2224-from-march-1114-in-1742552883094795

[16] https://www.universalplastics.com/case-studies/

[17] https://github.com/laverkyllozc/Market-Research-Report-List-1/blob/main/hdpe-extrusion-line-market.md

[18] https://pmarketresearch.com/product/worldwide-compact-turbo-compressor-market-research-2024-by-type-application-participants-and-countries-forecast-to-2030/worldwide-hdpe-extrusion-line-market-research-2024-by-type-application-participants-and-countries-forecast-to-2030

[19] https://www.dynisco.com/userfiles/files/27429_Legacy_Txt.pdf

[20] https://www.thebusinessresearchcompany.com/report/extrusion-sheet-global-market-report