Content Menu

● The Aluminum Extrusion Process

● Key Components of an Efficient Aluminum Extrusion Line

>> 1. High-Quality Aluminum Billets

>> 2. Advanced Preheating Systems

>> 3. State-of-the-Art Extrusion Presses

>> 4. Optimized Die Design

>> 5. Automated Handling Systems

>> 6. Integrated Cooling Systems

>> 7. Advanced Stretching Equipment

>> 8. Efficient Heat Treatment Facilities

● Technological Advancements Enhancing Efficiency

>> 1. Industry 4.0 Integration

>> 2. Advanced Control Systems

>> 3. Simulation and Modeling Software

● Strategies for Optimizing Aluminum Extrusion Line Efficiency

>> 1. Implement Lean Manufacturing Principles

>> 2. Continuous Improvement Programs

>> 3. Preventive Maintenance

>> 4. Employee Training and Development

>> 5. Supply Chain Optimization

● Case Study: Implementing Efficiency Improvements in an Aluminum Extrusion Line

● Environmental Benefits of Efficient Aluminum Extrusion Lines

● Future Trends in Aluminum Extrusion Line Efficiency

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What are the main factors affecting aluminum extrusion line efficiency?

>> 2. How can I measure the efficiency of my aluminum extrusion line?

>> 3. What are the benefits of upgrading an older aluminum extrusion line?

>> 4. How does automation improve aluminum extrusion line efficiency?

>> 5. What role does preventive maintenance play in maintaining aluminum extrusion line efficiency?

● Citations:

Aluminum extrusion is a crucial manufacturing process that transforms raw aluminum billets into various shapes and profiles used across numerous industries. An efficient aluminum extrusion line can significantly impact production costs, quality, and delivery times. In this article, we'll explore how an aluminum extrusion line enhances production efficiency, focusing on key components, advanced technologies, and optimization strategies.

The Aluminum Extrusion Process

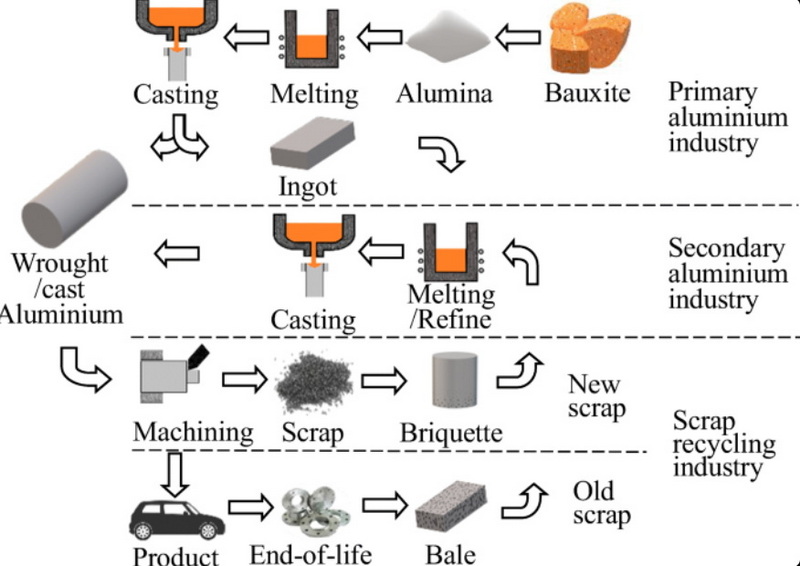

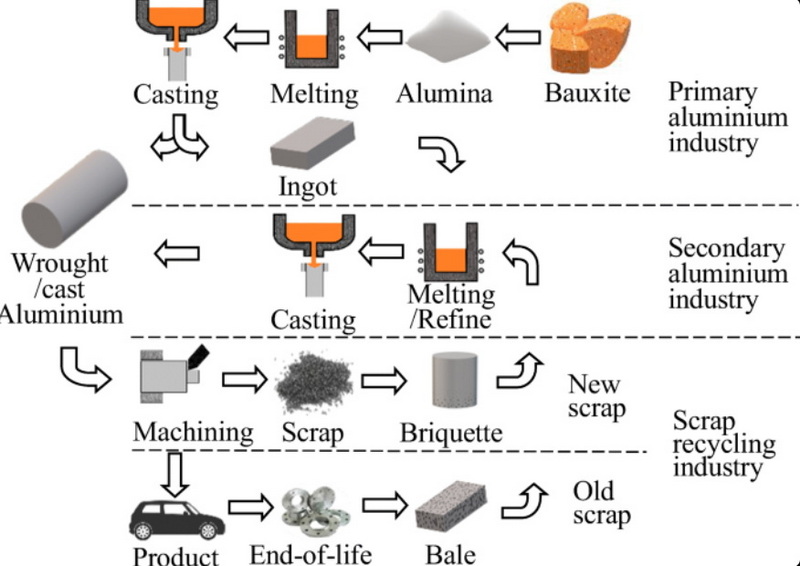

Before delving into efficiency improvements, let's briefly review the aluminum extrusion process:

1. Billet preparation

2. Preheating

3. Extrusion

4. Cooling

5. Stretching

6. Cutting

7. Heat treatment

8. Finishing

Key Components of an Efficient Aluminum Extrusion Line

1. High-Quality Aluminum Billets

The foundation of an efficient aluminum extrusion line starts with high-quality billets. These solid cylindrical blocks of aluminum alloy serve as the raw material for the extrusion process. Quality billets ensure:

- Reduced defects

- Enhanced flow properties

- Improved extrudability

2. Advanced Preheating Systems

Efficient preheating is crucial for optimal malleability without reaching a molten state. Modern aluminum extrusion lines employ advanced heating systems that offer:

- Uniform heating

- Precise temperature control

- Energy efficiency

3. State-of-the-Art Extrusion Presses

The heart of any aluminum extrusion line is the extrusion press. Advanced presses incorporate:

- High-pressure hydraulic systems

- Computerized control systems

- Automated die changing mechanisms

These features contribute to increased production speed and precision.

4. Optimized Die Design

Efficient dies are crucial for smooth extrusion and high-quality output. Modern aluminum extrusion lines utilize:

- Computer-aided design (CAD) for die optimization

- Advanced materials for increased die longevity

- Multi-hole dies for increased productivity

5. Automated Handling Systems

Automation plays a significant role in improving efficiency throughout the aluminum extrusion line. This includes:

- Robotic billet loading

- Automated profile handling and stacking

- Computerized sawing systems

6. Integrated Cooling Systems

Proper cooling is essential for maintaining product quality and dimensional stability. Efficient aluminum extrusion lines incorporate:

- Water quenching systems

- Air cooling tunnels

- Temperature-controlled cooling beds

7. Advanced Stretching Equipment

Stretching ensures straightness and proper mechanical properties. Modern stretchers offer:

- Precise tension control

- Automated length measurement

- Quick changeover capabilities

8. Efficient Heat Treatment Facilities

Heat treatment is crucial for achieving desired mechanical properties. Advanced aluminum extrusion lines feature:

- Computer-controlled aging ovens

- Energy-efficient heating systems

- Automated material handling for heat treatment

Technological Advancements Enhancing Efficiency

1. Industry 4.0 Integration

The integration of Industry 4.0 technologies has revolutionized aluminum extrusion lines. Key features include:

- Internet of Things (IoT) sensors for real-time monitoring

- Big data analytics for process optimization

- Artificial Intelligence (AI) for predictive maintenance

2. Advanced Control Systems

Modern control systems offer:

- Real-time process monitoring and adjustment

- Integrated quality control

- Comprehensive data logging and reporting

3. Simulation and Modeling Software

Computer simulation and modeling tools help optimize:

- Die design

- Extrusion parameters

- Material flow

This leads to reduced trial and error, faster setup times, and improved product quality.

Strategies for Optimizing Aluminum Extrusion Line Efficiency

1. Implement Lean Manufacturing Principles

Applying lean principles to the aluminum extrusion line can significantly improve efficiency by:

- Reducing waste

- Optimizing workflow

- Enhancing value-added activities

2. Continuous Improvement Programs

Establishing a culture of continuous improvement encourages:

- Employee engagement in efficiency initiatives

- Regular review and optimization of processes

- Implementation of best practices

3. Preventive Maintenance

A robust preventive maintenance program ensures:

- Reduced downtime

- Increased equipment lifespan

- Consistent product quality

4. Employee Training and Development

Investing in workforce training is crucial for maximizing the efficiency of an aluminum extrusion line. Well-trained operators can:

- Optimize machine settings

- Troubleshoot issues quickly

- Contribute to process improvements

5. Supply Chain Optimization

Efficient management of the supply chain contributes to overall line efficiency by:

- Ensuring timely delivery of raw materials

- Optimizing inventory levels

- Streamlining logistics

Case Study: Implementing Efficiency Improvements in an Aluminum Extrusion Line

To illustrate the impact of efficiency improvements, let's consider a case study of a medium-sized aluminum extrusion company that implemented several upgrades to their extrusion line:

1. Upgraded to a new 3500-ton extrusion press with advanced control systems

2. Implemented an automated billet loading system

3. Installed a new cooling system with precise temperature control

4. Integrated IoT sensors for real-time monitoring

5. Implemented a lean manufacturing program

Results after one year:

- 30% increase in production output

- 15% reduction in energy consumption

- 25% decrease in scrap rate

- 20% improvement in on-time delivery

This case study demonstrates the significant impact that targeted improvements can have on the efficiency of an aluminum extrusion line.

Environmental Benefits of Efficient Aluminum Extrusion Lines

Improving the efficiency of aluminum extrusion lines not only enhances productivity but also contributes to environmental sustainability:

- Reduced energy consumption

- Decreased material waste

- Lower emissions

Many modern aluminum extrusion lines incorporate recycling systems to reprocess scrap material, further improving their environmental footprint.

Future Trends in Aluminum Extrusion Line Efficiency

As technology continues to advance, we can expect to see further improvements in aluminum extrusion line efficiency:

1. Increased use of AI and machine learning for process optimization

2. Development of new alloys for improved extrudability

3. Advanced automation and robotics throughout the extrusion process

4. Integration of additive manufacturing techniques for die production

5. Enhanced recycling and circular economy practices

Conclusion

An efficient aluminum extrusion line is crucial for maintaining competitiveness in today's manufacturing landscape. By focusing on key components such as high-quality billets, advanced equipment, and optimized processes, manufacturers can significantly improve their production efficiency. The integration of modern technologies like IoT, AI, and advanced control systems further enhances these improvements.

Implementing strategies such as lean manufacturing, continuous improvement programs, and employee training ensures that efficiency gains are sustained and built upon over time. As the industry continues to evolve, staying abreast of technological advancements and best practices will be crucial for maintaining and improving the efficiency of aluminum extrusion lines.

The benefits of an efficient aluminum extrusion line extend beyond just increased productivity. They include improved product quality, reduced costs, enhanced sustainability, and better responsiveness to market demands. As such, investing in efficiency improvements for aluminum extrusion lines is not just a operational necessity but a strategic imperative for long-term success in the aluminum extrusion industry.

Frequently Asked Questions (FAQ)

1. What are the main factors affecting aluminum extrusion line efficiency?

The main factors affecting aluminum extrusion line efficiency include:

- Quality of aluminum billets

- Extrusion press capabilities

- Die design and quality

- Preheating and cooling systems

- Automation level

- Process control and monitoring

- Operator skill and training

2. How can I measure the efficiency of my aluminum extrusion line?

You can measure the efficiency of your aluminum extrusion line by tracking:

- Output per hour

- Scrap rate

- Energy consumption per unit produced

- Setup and changeover times

- Overall Equipment Effectiveness (OEE)

- On-time delivery performance

3. What are the benefits of upgrading an older aluminum extrusion line?

Upgrading an older aluminum extrusion line can provide numerous benefits:

- Increased production capacity

- Improved product quality

- Reduced energy consumption

- Lower maintenance costs

- Enhanced process control and monitoring

- Improved safety features

4. How does automation improve aluminum extrusion line efficiency?

Automation improves aluminum extrusion line efficiency by:

- Reducing labor costs

- Minimizing human error

- Increasing production speed

- Improving consistency in quality

- Enabling 24/7 operation

- Facilitating real-time data collection and analysis

5. What role does preventive maintenance play in maintaining aluminum extrusion line efficiency?

Preventive maintenance is crucial for maintaining aluminum extrusion line efficiency:

- It reduces unexpected downtime

- Extends equipment lifespan

- Ensures consistent product quality

- Helps identify potential issues before they cause major problems

- Optimizes equipment performance

- Reduces overall maintenance costs in the long run

Citations:

[1] https://www.linkedin.com/pulse/how-improve-working-efficiency-aluminum-profile-extrusion-machine-

[2] https://www.tensilemillcnc.com/blog/the-most-efficient-aluminum-extrusion-process-with-precise-quality-control-will-guarantee-the-best-results-of-your-production

[3] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[4] https://www.dreamstime.com/photos-images/aluminum-extrusion.html

[5] https://www.youtube.com/watch?v=iiGlq7408ME

[6] https://www.nomexfelt.com/list-news/the-aluminum-extrusion-process-in-10-steps-video-clips/

[7] https://www.linkedin.com/pulse/some-ways-improving-extrusion-production-efficiency-stan-hua

[8] https://www.machine4aluminium.com/9-effective-ways-to-improve-aluminum-profile-yield/

[9] https://www.alamy.com/stock-photo/aluminum-extrusion.html

[10] https://www.youtube.com/watch?v=Bc7o_sEdX8U

[11] https://www.yjing-extrusion.com/how-does-aluminum-extrusion-billet-improve-production-efficiency.html