Content Menu

● Understanding Aluminum Billets

● The Extrusion Process

● Enhancing Product Quality Through Extrusion

● Technological Advancements in Extrusion

● Post-Extrusion Processes

● Applications of Aluminum Sheets

● Quality Control Measures

● Sustainability Considerations

● Future Trends in Aluminum Extrusion

● Conclusion

● FAQ

>> 1. What factors affect the quality of aluminum extrusion billets?

>> 2. How does preheating affect the extrusion process?

>> 3. What are common applications for extruded aluminum products?

>> 4. How does die design impact production efficiency?

>> 5. What advancements are being made in aluminum extrusion technology?

● Citations:

Aluminum extrusion is a vital manufacturing process that transforms aluminum billets into various shapes and profiles used across numerous industries. The transition from aluminum billet to sheet through the extrusion process not only enhances product quality but also optimizes production efficiency. This article delves into the mechanisms by which an aluminum billet to sheet extruder enhances product quality, focusing on key factors such as material properties, production techniques, and technological advancements.

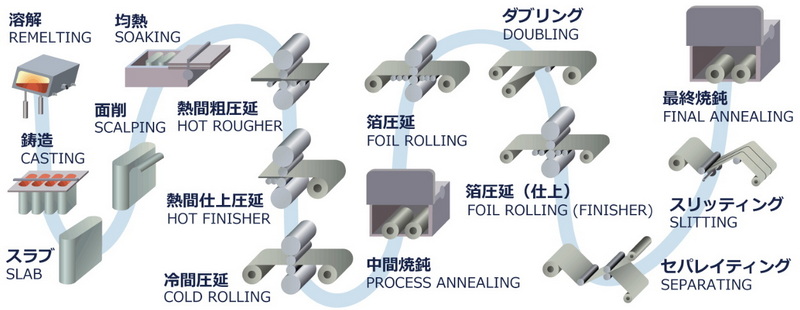

Understanding Aluminum Billets

An aluminum billet is a solid cylindrical block of aluminum alloy that serves as the raw material for the extrusion process. These billets are produced through casting methods and are characterized by their uniform composition and structural integrity, which are critical for achieving high-quality extruded products.

- Composition: The quality of aluminum billets is influenced by the purity of the aluminum used. Higher purity aluminum contains fewer additives and better mechanical properties, which directly affect the final product's strength and durability.

- Casting Process: The casting of aluminum billets involves melting aluminum and pouring it into molds. This process can include direct chill casting or other methods that ensure uniform cooling and solidification, leading to consistent material properties.

The Extrusion Process

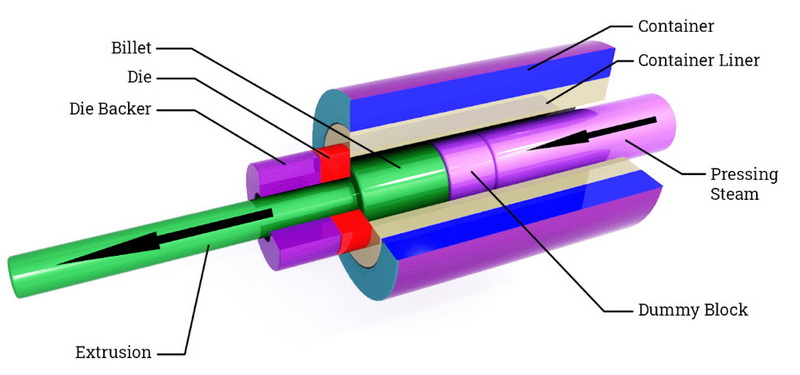

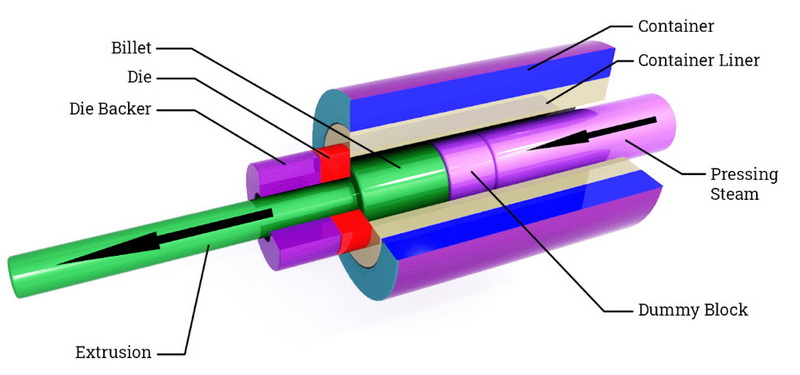

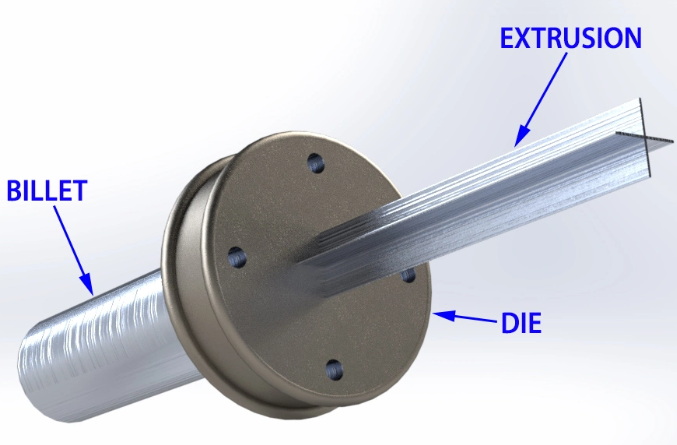

The extrusion process involves several critical steps that transform aluminum billets into sheets:

1. Preheating: Before extrusion, billets are heated in specialized furnaces to a temperature range of 400-500°C. This heating makes the aluminum malleable without reaching a molten state, allowing for easier shaping during extrusion.

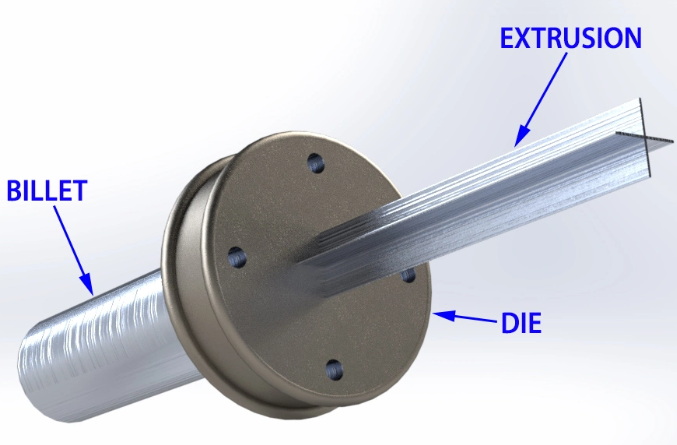

2. Extrusion: The heated billet is then placed in an extrusion press where immense pressure (up to 15,000 tons) is applied to force the aluminum through a die. This die has a specific shape that determines the cross-sectional profile of the resulting sheet.

3. Cooling: After emerging from the die, the extruded sheet is cooled either naturally or through controlled quenching processes to lock in desired mechanical properties.

Enhancing Product Quality Through Extrusion

The transition from aluminum billet to sheet via an extruder significantly enhances product quality through various mechanisms:

- Reduced Defects: High-quality billets minimize defects such as cracks or surface imperfections during extrusion. This reduction in defects leads to smoother surfaces and improved aesthetic appeal of the final product.

- Enhanced Flow Properties: Properly manufactured billets allow for smoother flow through the die, reducing energy consumption and increasing output efficiency. This results in fewer interruptions during production and higher overall quality in the extruded sheets.

- Uniformity in Thickness: The extrusion process ensures that sheets have a consistent thickness and density throughout, which is crucial for applications requiring precise tolerances.

- Mechanical Properties: The heat treatment processes applied post-extrusion enhance the strength and hardness of the sheets. Techniques such as aging improve durability, making them suitable for demanding applications in construction, automotive, and aerospace industries.

Technological Advancements in Extrusion

Modern advancements in extrusion technology play a pivotal role in enhancing product quality:

- Automated Control Systems: These systems allow for real-time monitoring and adjustment of parameters such as temperature and pressure during extrusion. This automation ensures consistent quality across production runs.

- Advanced Die Designs: Innovations in die design enable manufacturers to create more complex shapes with tighter tolerances while reducing waste material during production. This capability expands product capabilities while maintaining high-quality standards.

- Robotics Integration: The use of robotics for handling and transporting billets streamlines operations, reduces manual labor, increases safety, and minimizes human error during production processes.

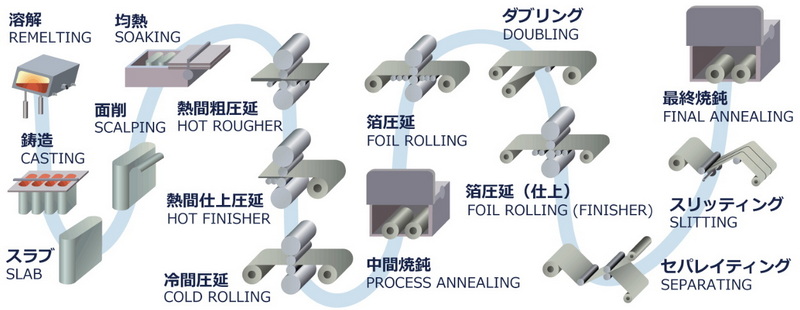

Post-Extrusion Processes

After the initial extrusion process, several post-extrusion treatments further enhance product quality:

- Quenching: Rapid cooling techniques help lock in desired mechanical properties, improving strength and hardness.

- Surface Finishing: Techniques such as anodizing not only enhance corrosion resistance but also improve aesthetic qualities, making products more appealing for consumer applications.

Applications of Aluminum Sheets

Aluminum sheets produced from billets find applications across various industries due to their enhanced properties:

- Construction: Used for roofing, siding, and window frames due to their lightweight yet strong characteristics.

- Automotive: Lightweight components made from extruded sheets contribute to fuel efficiency without compromising safety.

- Aerospace: High-strength sheets are essential for aircraft structures where weight reduction is critical.

- Consumer Goods: Products like furniture and appliances benefit from the aesthetic appeal and durability of extruded aluminum sheets.

Quality Control Measures

To ensure that aluminum sheets meet stringent industry standards, manufacturers implement rigorous quality control measures throughout the extrusion process:

- In-line Inspection Systems: Advanced technologies such as Computerized Topology (CAT) X-ray scanning are employed for rapid inspection of extruded profiles. These systems detect defects early on, allowing for immediate corrective actions before products move further down the production line.

- Mechanical Testing: Samples from each batch undergo mechanical testing to verify tensile strength, elongation, hardness, and other critical properties. These tests ensure that each sheet meets or exceeds industry specifications.

- Surface Quality Assessment: Visual inspections combined with automated systems assess surface finish quality. Any irregularities such as scratches or blemishes can be identified quickly to maintain high aesthetic standards.

Sustainability Considerations

The aluminum industry is increasingly focused on sustainability practices throughout the extrusion process:

- Recycling Initiatives: Aluminum is highly recyclable without degradation of its properties. Manufacturers often implement closed-loop systems where scrap generated during production is recycled back into new billets or sheets.

- Energy Efficiency Improvements: Modern extrusion presses are designed with energy-efficient technologies that reduce overall energy consumption during production. This not only lowers operational costs but also minimizes environmental impact.

- Carbon Footprint Reduction: Efforts are being made across the industry to reduce carbon emissions associated with aluminum production through improved processes and materials sourcing strategies that prioritize sustainability.

Future Trends in Aluminum Extrusion

As technology evolves, several trends are shaping the future of aluminum extrusion:

- Digitalization and Automation: The integration of smart technologies allows manufacturers to optimize their operations through real-time data analytics, predictive maintenance schedules, and automated adjustments during production processes.

- Hybrid Extrusion Techniques: Innovations combining traditional methods with advanced techniques enable manufacturers to create profiles with enhanced strength while maintaining lightweight characteristics essential for modern applications like automotive components.

- AI-Powered Solutions: Artificial intelligence is being leveraged to improve precision control within extrusion processes. AI algorithms analyze data from machinery to make real-time adjustments that enhance product consistency and reduce waste.

Conclusion

The transformation of aluminum billets into sheets through an extruder significantly enhances product quality by ensuring uniformity, reducing defects, and improving mechanical properties. Technological advancements in automation, die design, and post-extrusion treatments further contribute to this enhancement. As industries increasingly demand lightweight yet durable materials, the role of aluminum billet to sheet extruders will continue to grow in importance.

FAQ

1. What factors affect the quality of aluminum extrusion billets?

The quality is influenced by alloy composition, manufacturing processes (like casting), heat treatment methods used during production, and strict control over dimensional tolerances.

2. How does preheating affect the extrusion process?

Preheating improves malleability, allowing for smoother flow through dies while preventing defects such as cracking during shaping.

3. What are common applications for extruded aluminum products?

Extruded aluminum is widely used in construction (window frames), automotive parts (lightweight components), aerospace applications (aircraft structures), electrical components (heat sinks), and consumer goods (furniture).

4. How does die design impact production efficiency?

Advanced die designs can reduce material waste and improve product accuracy by enabling manufacturers to create intricate shapes with tight tolerances.

5. What advancements are being made in aluminum extrusion technology?

Innovations include automated control systems for real-time monitoring, advanced die designs for complex shapes, robotics integration for handling materials efficiently, and improved surface finishing techniques.

Citations:

[1] https://shop.machinemfg.com/aluminum-extrusion-process-a-detailed-breakdown/

[2] https://www.yjing-extrusion.com/how-does-aluminum-extrusion-billet-improve-production-efficiency.html

[3] https://profileprecisionextrusions.com/the-evolution-of-aluminum-extrusions-emerging-trends-and-technologies/

[4] https://www.mdpi.com/1996-1944/7/5/3470

[5] https://www.atieuno.com/2023/10/09/aluminium-extrusion-manufacturers/

[6] https://www.pennex.com/press/the-steps-of-aluminum-extrusion

[7] https://www.alcircle.com/news/tech-trends-driving-the-aluminium-extrusion-industry-111131

[8] https://americandouglasmetals.com/2024/05/19/understanding-the-aluminum-extrusion-process/

[9] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[10] https://www.researchgate.net/publication/257516704_Case_studies_on_virtual_extrusion_of_aluminium_alloys_in_real_size

[11] https://gloriaaluminium.com/blog/the-future-of-the-aluminum-extrusion-industry-trends-and-growth/

[12] https://hitopindustrial.com/aluminum-extrusion-process/

[13] https://www.factorytwofour.com/latest-technology-for-aluminum-extrusion/

[14] https://www.academia.edu/48162794/KL_9_Analysis_of_Material_Response_to_Processing_Conditions_A_Case_Study_of_Aluminum_Extrusion?uc-sb-sw=35558724

[15] https://www.linkedin.com/pulse/future-aluminium-alloy-extrusion-industry-developments-challenges-5ppfe

[16] https://www.chaluminium.com/aluminum-billet-manufacturing-process-and-common-types

[17] https://www.howardprecision.com/advantages-and-disadvantages-of-direct-extrusion/

[18] https://nationalindustries.world/2025/01/02/the-future-of-aluminum-how-extrusion-technology-is-transforming-industries/

[19] https://www.researchgate.net/publication/281362696_Extrusion_of_short_aluminium_billets_-_Simulation_and_semi-pilot_test

[20] https://www.fortune-alu.com/info-detail/trends-shaping-the-future-of-aluminum-extrusion