Content Menu

● Understanding the Aluminum Extrusion Process

● Advantages of Aluminum Extrusion

>> 1. Design Flexibility

>> 2. Cost-Effectiveness

>> 3. Strength-to-Weight Ratio

>> 4. Surface Finish

● Comparing Aluminum Extrusion to Other Manufacturing Processes

>> Aluminum Extrusion vs. Casting

>> Aluminum Extrusion vs. Machining

>> Aluminum Extrusion vs. Rolling

>> Aluminum Extrusion vs. Forging

● Applications of Aluminum Extrusion

>> Construction Industry

>> Automotive Industry

>> Aerospace Industry

>> Consumer Goods

● The Future of Aluminum Extrusion

● Environmental Considerations

● Challenges in Aluminum Extrusion

● Conclusion

● FAQs

>> 1. What is the aluminum extrusion process PDF?

>> 2. How does the aluminum extrusion process compare to injection molding?

>> 3. What are the main advantages of the aluminum extrusion process?

>> 4. Can all aluminum alloys be used in the extrusion process?

>> 5. How does the aluminum extrusion process impact the environment?

● Citations:

Aluminum extrusion is a versatile and efficient manufacturing process that has gained widespread popularity across various industries. This article will explore how aluminum extrusion compares to other manufacturing processes, highlighting its unique advantages and applications.

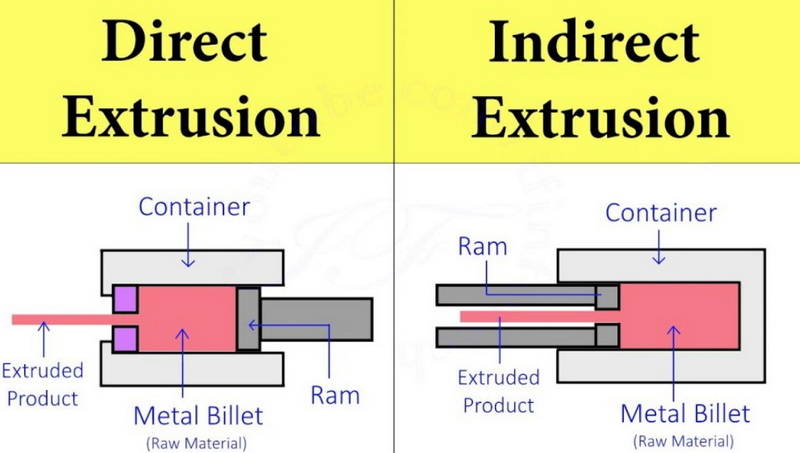

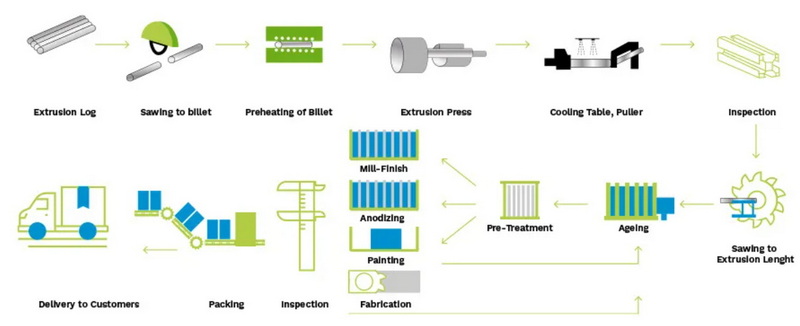

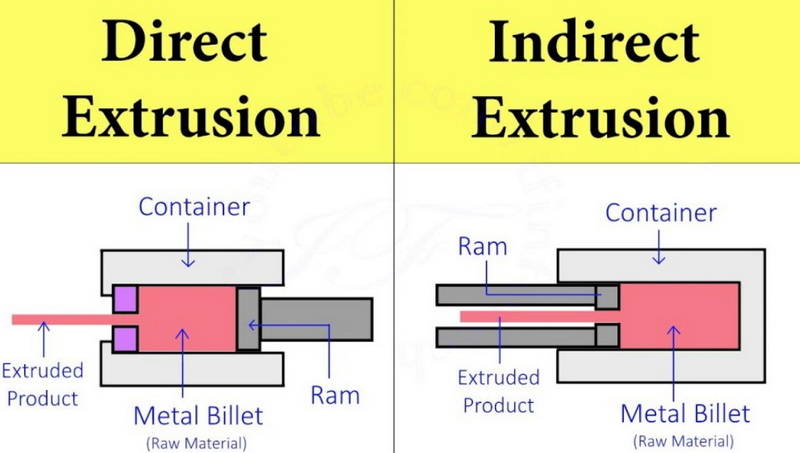

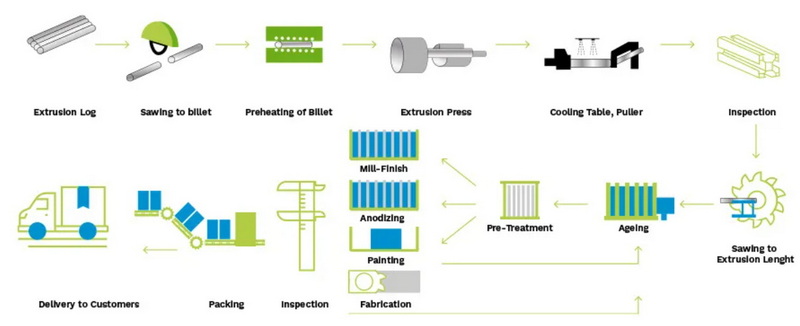

Understanding the Aluminum Extrusion Process

Before we delve into comparisons, let's first understand what aluminum extrusion entails. The process involves forcing heated aluminum billets through a die with a specific cross-sectional profile[1]. This results in a continuous profile that can be cut to desired lengths.

The aluminum extrusion process typically follows these steps:

1. Die preparation and preheating

2. Billet preheating

3. Billet transfer to the extrusion press

4. Extrusion

5. Profile cooling and quenching

6. Stretching and straightening

7. Cutting to length

8. Heat treatment (if required)

9. Finishing processes (if needed)

Advantages of Aluminum Extrusion

Aluminum extrusion offers several advantages over other manufacturing processes:

1. Design Flexibility

One of the most significant benefits of aluminum extrusion is its ability to create complex cross-sectional shapes in a single process[2]. This level of design flexibility is unmatched by many other manufacturing methods.

2. Cost-Effectiveness

For medium to high volume production, aluminum extrusion can be highly cost-effective. The process requires minimal tooling costs compared to other methods like die casting or injection molding[3].

3. Strength-to-Weight Ratio

The extrusion process enhances the mechanical properties of aluminum, resulting in a final product with an excellent strength-to-weight ratio[9].

4. Surface Finish

Extruded aluminum products typically have a smooth surface finish right out of the die, often requiring minimal post-processing[2].

Comparing Aluminum Extrusion to Other Manufacturing Processes

Let's compare aluminum extrusion to some other common manufacturing processes:

Aluminum Extrusion vs. Casting

Casting involves pouring molten metal into a mold and allowing it to solidify. While casting can produce complex shapes, it has some limitations compared to extrusion:

- Extrusion generally produces stronger parts due to its grain structure[9].

- Extrusion can create longer continuous profiles than casting.

- Casting often requires more post-processing to achieve a smooth surface finish.

Aluminum Extrusion vs. Machining

Machining involves cutting away material from a solid block to create the desired shape. Compared to machining, aluminum extrusion:

- Is more material-efficient, producing less waste.

- Can create complex internal cavities that would be difficult or impossible to machine.

- Is generally faster and more cost-effective for high-volume production.

Aluminum Extrusion vs. Rolling

Rolling is used to create flat sheets or plates of aluminum. While rolling and extrusion are both continuous processes, extrusion offers:

- The ability to create complex cross-sectional shapes.

- Better control over the internal structure of the material.

Aluminum Extrusion vs. Forging

Forging involves shaping metal through compressive forces. Compared to forging, aluminum extrusion:

- Can produce longer continuous profiles.

- Offers more design flexibility for cross-sectional shapes.

- Is generally more cost-effective for high-volume production.

Applications of Aluminum Extrusion

The versatility of aluminum extrusion makes it suitable for a wide range of applications across various industries:

Construction Industry

Aluminum extrusions are widely used in building facades, window frames, door frames, and structural components[6].

Automotive Industry

In the automotive sector, aluminum extrusions are used for body frames, bumpers, heat exchangers, and more[6].

Aerospace Industry

The aerospace industry utilizes aluminum extrusions for aircraft structures, wing spars, and fuselage components[6].

Consumer Goods

Many everyday items, from furniture to electronics housings, are made using aluminum extrusions[6].

The Future of Aluminum Extrusion

As industries continue to seek lightweight, strong, and sustainable materials, the demand for aluminum extrusions is expected to grow. Advancements in extrusion technology, such as improved die designs and process control, are likely to further enhance the capabilities of this manufacturing process.

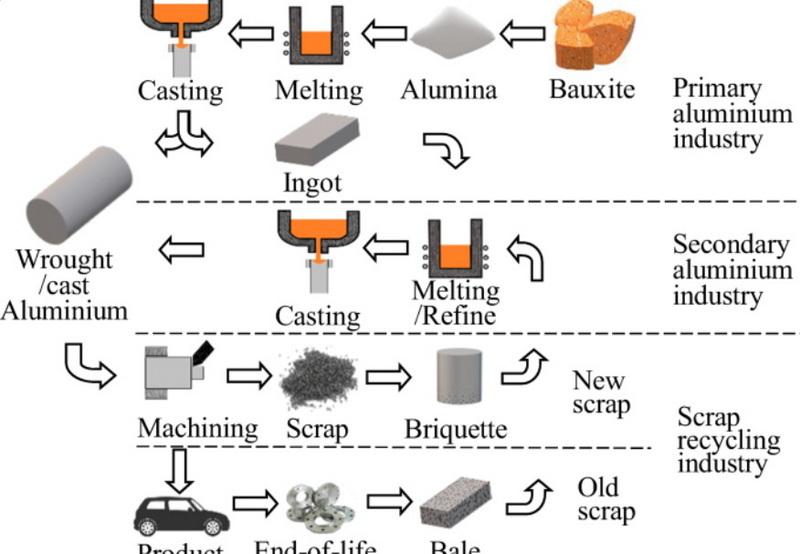

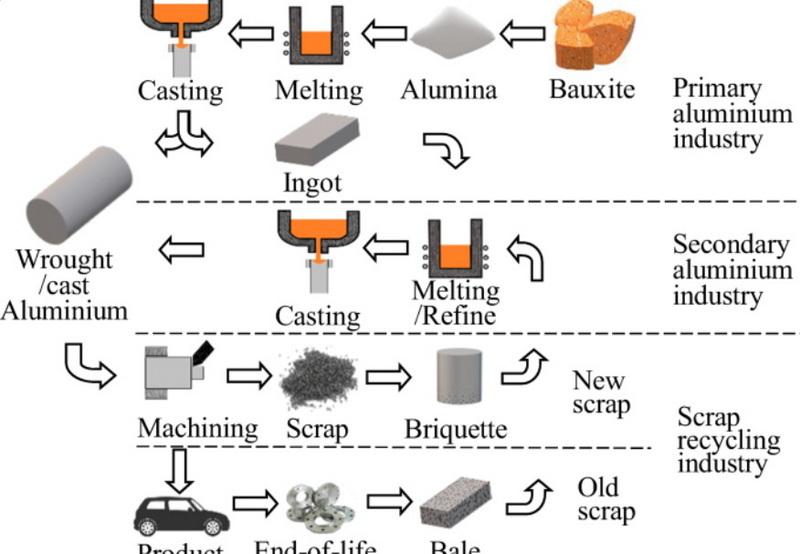

Environmental Considerations

Aluminum extrusion is generally considered an environmentally friendly process. Aluminum is 100% recyclable without loss of quality, and the extrusion process itself produces minimal waste[3]. This aligns well with the growing focus on sustainability in manufacturing.

Challenges in Aluminum Extrusion

While aluminum extrusion offers many advantages, it's not without challenges:

1. Size Limitations: The size of extrusions is limited by the capacity of the extrusion press[2].

2. Alloy Restrictions: Not all aluminum alloys are suitable for extrusion.

3. Initial Tooling Costs: While generally lower than other processes, there are still upfront costs for die creation.

Conclusion

Aluminum extrusion stands out as a versatile, cost-effective, and efficient manufacturing process. Its ability to create complex shapes with excellent material properties makes it superior to many other manufacturing methods for a wide range of applications. As industries continue to demand lightweight, strong, and sustainable materials, aluminum extrusion is likely to play an increasingly important role in modern manufacturing.

FAQs

1. What is the aluminum extrusion process PDF?

An aluminum extrusion process PDF is a document that provides detailed information about the steps involved in aluminum extrusion, including die preparation, billet heating, extrusion, cooling, and finishing. These PDFs often include diagrams, technical specifications, and best practices for the extrusion process.

2. How does the aluminum extrusion process compare to injection molding?

Aluminum extrusion and injection molding are quite different processes. Extrusion is used for creating continuous profiles of consistent cross-section, while injection molding is used for creating discrete parts. Extrusion is generally more cost-effective for larger parts and higher volumes, while injection molding is better suited for smaller, more complex parts.

3. What are the main advantages of the aluminum extrusion process?

The main advantages of aluminum extrusion include design flexibility, cost-effectiveness for medium to high volume production, excellent strength-to-weight ratio of the final product, and the ability to create complex cross-sectional shapes in a single process.

4. Can all aluminum alloys be used in the extrusion process?

Not all aluminum alloys are suitable for extrusion. The most commonly used alloys for extrusion are from the 6000 series (Al-Mg-Si alloys) due to their good extrudability and mechanical properties. Other series like 2000, 5000, and 7000 can also be extruded but may require special considerations.

5. How does the aluminum extrusion process impact the environment?

The aluminum extrusion process is generally considered environmentally friendly. Aluminum is 100% recyclable without loss of quality, and the extrusion process itself produces minimal waste. Moreover, extruded aluminum products often contribute to energy efficiency in their applications, such as in lightweight vehicles or energy-efficient building components.

Citations:

[1] https://geminigroup.net/understanding-aluminum-extrusion-dies/

[2] https://www.impol.com/everything-you-need-to-know-about-aluminum-extrusion/

[3] https://cdn.ymaws.com/members.aec.org/resource/resmgr/PDFs/BackgrounderAlExt.pdf

[4] https://www.alamy.com/stock-photo/aluminum-extrusion-manufacturing.html

[5] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[6] https://americandouglasmetals.com/2024/05/19/understanding-the-aluminum-extrusion-process/

[7] https://www.hydro.com/profiles/aluminum-extrusion-process

[8] https://www.atieuno.com/2023/07/17/aluminium-extrusion-process-guide/

[9] http://scaluminum.com/2022/02/benefits-of-aluminum-extrusion-vs-other-types-of-production/

[10] https://leadrp.net/blog/a-complete-guide-to-aluminum-extrusion/