Content Menu

● Understanding the Aluminum Bagel Extruder

● Importance of Regular Maintenance

● Key Maintenance Practices

>> 1. Daily Cleaning

>> 2. Lubrication

>> 3. Regular Inspections

>> 4. Calibration

>> 5. Preventative Maintenance Schedule

● Advanced Maintenance Techniques

>> 1. Predictive Maintenance

>> 2. Use of Cleaning Filaments

● Troubleshooting Common Issues

● Additional Tips for Long-Term Use

● Conclusion

● FAQs

>> 1. How often should I clean my aluminum bagel extruder?

>> 2. What type of lubricant should I use?

>> 3. How can I tell if my extruder needs repairs?

>> 4. Is it necessary to calibrate my extruder regularly?

>> 5. What should I do if my extruder becomes clogged?

Maintaining an aluminum bagel extruder is crucial for ensuring its longevity and efficiency in producing high-quality bagels. This article will explore various maintenance practices, tips, and techniques that can help you keep your extruder in optimal condition. Regular maintenance not only extends the life of the equipment but also ensures consistent product quality and minimizes downtime.

Understanding the Aluminum Bagel Extruder

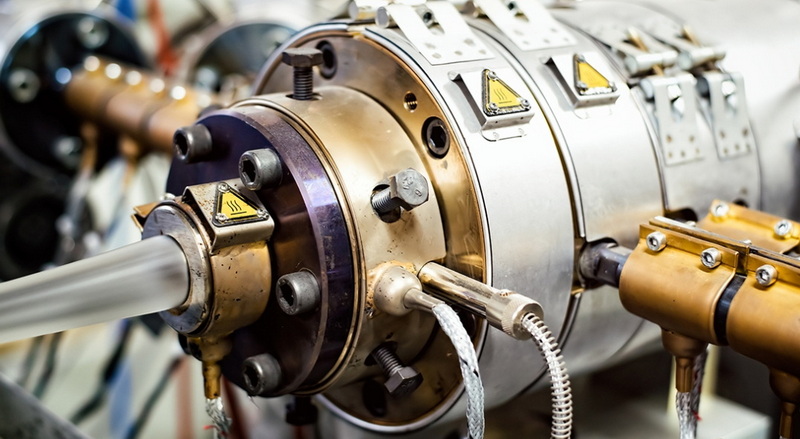

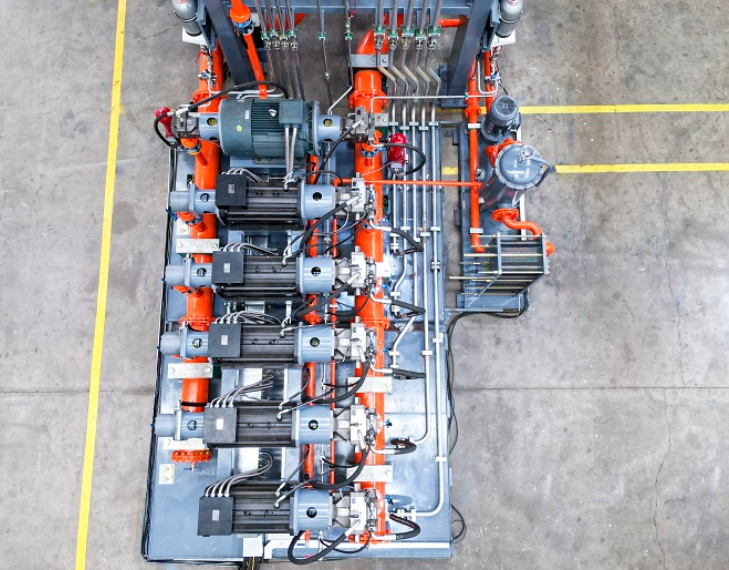

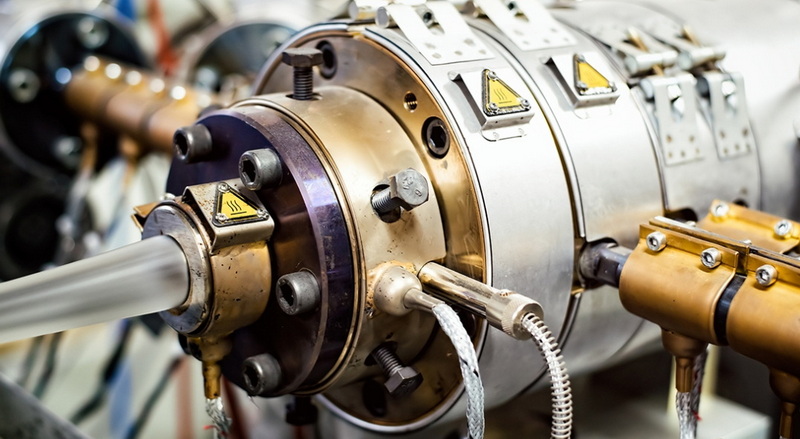

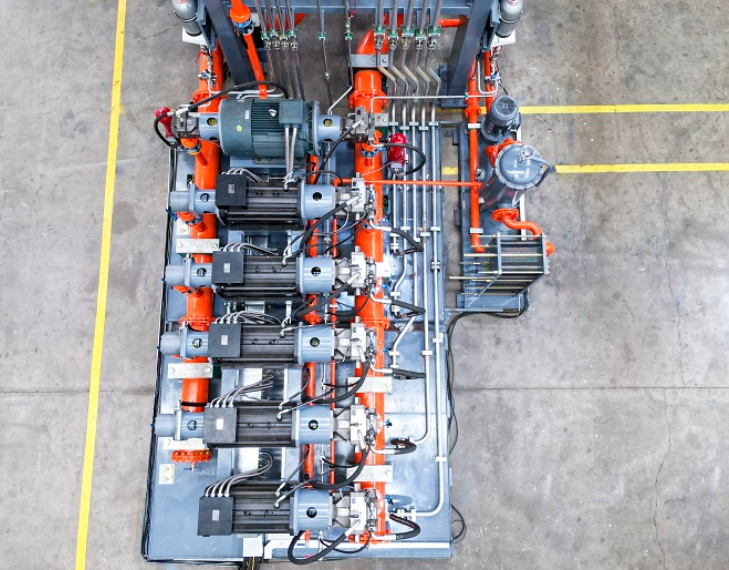

An aluminum bagel extruder is a specialized machine designed to shape dough into bagels. The extruder typically consists of a feed system, a shaping mechanism, and an output section where the formed bagels are released. The feed system typically involves a hopper where the dough is loaded, and a screw or piston mechanism that pushes the dough towards the shaping die. The shaping mechanism includes a die or nozzle that forms the dough into the desired bagel shape. Finally, the output section often includes a conveyor belt or a cutting mechanism that separates individual bagels.

Due to its continuous operation in a demanding environment, proper maintenance is essential to avoid breakdowns and ensure consistent product quality. The aluminum construction provides durability and resistance to corrosion, but it still requires regular care to prevent wear and tear.

Importance of Regular Maintenance

Regular maintenance of your aluminum bagel extruder can lead to several benefits:

- Increased Lifespan: Consistent care can significantly extend the lifespan of your equipment. By addressing issues early and preventing them from escalating, you can avoid costly repairs and replacements.

- Improved Efficiency: A well-maintained extruder operates more efficiently, reducing energy consumption and production costs. Regular cleaning and lubrication ensure that the machine operates smoothly, reducing friction and energy waste.

- Consistent Quality: Regular checks ensure that the quality of the bagels produced remains high. Proper calibration and maintenance of the shaping mechanism ensure that the bagels are consistently formed to the desired shape and size.

- Reduced Downtime: Proactive maintenance helps prevent unexpected breakdowns that could halt production. By identifying and addressing potential issues before they cause a breakdown, you can minimize downtime and keep your production schedule on track.

Key Maintenance Practices

1. Daily Cleaning

Cleaning the extruder daily is vital to remove dough residues and prevent build-up that can lead to clogs. Dough residues can harden over time, making them difficult to remove and potentially causing damage to the machine.

- Procedure: After each production run, disassemble the extruder components as per the manufacturer's guidelines. Use warm water and a mild detergent to clean all surfaces. Pay special attention to areas where dough may accumulate. Be sure to rinse all components thoroughly to remove any traces of detergent, which could affect the taste or quality of the bagels.

- Tools Needed: Soft brushes, cloths, and non-abrasive sponges. Avoid using abrasive cleaners or scouring pads, as they can scratch the aluminum surface and damage the machine.

2. Lubrication

Proper lubrication is essential for reducing friction between moving parts. Friction can cause wear and tear on the machine, leading to breakdowns and reduced efficiency.

- Schedule: Lubricate moving parts daily or as recommended by the manufacturer. Check the manufacturer's guidelines for specific lubrication schedules and recommendations.

- Lubricants: Use food-grade lubricants to avoid contamination of the dough. Food-grade lubricants are specifically designed for use in food processing equipment and are safe for contact with food products.

3. Regular Inspections

Conduct regular inspections to identify any signs of wear or damage. Early detection of potential problems can prevent them from escalating into more serious issues.

- Components to Check:

- Gaskets and seals for leaks. Leaks can cause loss of pressure and affect the consistency of the bagels.

- Motors and belts for wear. Worn belts can slip, causing the machine to operate inefficiently.

- Heating elements for proper functioning (if applicable). Malfunctioning heating elements can affect the texture and quality of the bagels.

- Check the shaping die for any signs of wear or damage. A damaged die can result in misshapen bagels.

- Inspect the feed system for any signs of blockages or wear. A blocked or worn feed system can result in inconsistent dough flow.

- Frequency: Perform detailed inspections weekly or monthly based on usage intensity. More frequent inspections may be necessary if the extruder is used heavily or if you notice any signs of problems.

4. Calibration

Ensure that the extruder is calibrated correctly for consistent product quality. Calibration ensures that the machine is operating within the specified parameters and producing bagels of the correct size and shape.

- How to Calibrate: Follow the manufacturer's instructions for calibrating the machine settings based on the type of dough being used. Calibration may involve adjusting the pressure, speed, or other settings of the machine.

5. Preventative Maintenance Schedule

Develop a preventative maintenance schedule that includes:

- Cleaning routines

- Lubrication tasks

- Inspection timelines

- Replacement schedules for worn-out parts

A well-defined preventative maintenance schedule can help you stay on top of maintenance tasks and prevent unexpected breakdowns.

Advanced Maintenance Techniques

1. Predictive Maintenance

Implement predictive maintenance strategies using sensors that monitor machine performance metrics such as temperature and vibration. This approach allows you to anticipate failures before they occur, minimizing downtime. Predictive maintenance can involve using sensors to monitor the temperature of the motor, the vibration of the moving parts, or the pressure of the dough flow.

2. Use of Cleaning Filaments

Consider using specialized cleaning filaments that can be run through the extruder periodically to remove any residual material without disassembling components. Cleaning filaments can be particularly useful for cleaning hard-to-reach areas of the extruder.

Troubleshooting Common Issues

Despite regular maintenance, issues may still arise. Here are some common problems and their solutions:

- Clogs: If you notice a decrease in output or irregular shapes, check for clogs in the nozzle or feed system. Clean thoroughly using appropriate tools. Clogs can be caused by dough residues, foreign objects, or a buildup of starch.

- Inconsistent Shapes: This may indicate misalignment or calibration issues. Recalibrate according to the manufacturer's specifications. Inconsistent shapes can also be caused by a worn or damaged shaping die.

- Motor Overheating: This could be due to excessive friction or a faulty motor. Check lubrication and motor function. A motor that is constantly overheating may need to be replaced.

- Unusual Noises: Investigate the source of the noise. It could indicate a loose component or a worn bearing. Ignoring unusual noises can lead to more serious problems down the road.

Additional Tips for Long-Term Use

- Use High-Quality Dough: Using dough with consistent texture and composition can reduce the strain on the extruder and prevent clogs.

- Train Your Staff: Proper training on machine operation and maintenance is crucial. Make sure your staff knows how to clean, lubricate, and inspect the extruder correctly.

- Keep a Maintenance Log: Maintain a detailed log of all maintenance activities. This will help you track the performance of the extruder and identify potential problems early.

- Consult the Manufacturer: If you encounter any issues that you cannot resolve, consult the manufacturer or a qualified technician.

Conclusion

Maintaining an aluminum bagel extruder requires diligence and attention to detail. By following regular cleaning protocols, lubrication schedules, inspections, and implementing advanced maintenance techniques like predictive maintenance, you can ensure your extruder operates efficiently for years to come. A well-maintained machine not only produces better quality bagels but also enhances productivity and reduces operational costs. Implementing these practices will result in a durable, reliable, and efficient bagel extrusion process.

FAQs

1. How often should I clean my aluminum bagel extruder?

Cleaning should be performed after every production cycle to prevent build-up and maintain hygiene standards. This includes disassembling the key components and cleaning them thoroughly with warm water and a food-safe detergent.

2. What type of lubricant should I use?

Always use food-grade lubricants specifically designed for machinery used in food production to avoid contamination. Check the manufacturer's recommendations for the specific type of lubricant best suited for your extruder.

3. How can I tell if my extruder needs repairs?

Signs include unusual noises, decreased output quality, or visible wear on components during inspections. If you notice any of these signs, consult a qualified technician to diagnose and repair the problem.

4. Is it necessary to calibrate my extruder regularly?

Yes, regular calibration ensures consistent product quality and helps maintain operational efficiency. Calibration should be performed according to the manufacturer's instructions and may involve adjusting the pressure, speed, or other settings of the machine.

5. What should I do if my extruder becomes clogged?

Disassemble the affected parts according to the manufacturer's guidelines and clean thoroughly using warm water and appropriate tools. Avoid using excessive force or abrasive cleaners, as this could damage the machine.