Content Menu

● Understanding the 3030 Aluminum Extruder

● Advantages of Aluminum Extruders

● Tools and Materials Needed

● Step-by-Step Installation Process

>> 1. Preparation

>> 2. Remove the Existing Extruder

>> 3. Assemble the New 3030 Aluminum Magnet Extruder

>> 4. Reattach Bowden Tube

>> 5. Connect the Wiring

>> 6. Calibrate the Extruder

>> 7. Fine-Tuning and Adjustments

>> 8. Final Checks

● Testing Your New Extruder

● Troubleshooting

● Maintaining Your 3030 Aluminum Extruder

● Aluminum Extrusion: More Than Just Extruders

>> Other Applications of Aluminum Extrusion

>> Advantages of Using Aluminum Extrusion

● Aluminum vs. Other Materials

● Conclusion

● FAQ

>> 1. What is a 3030 aluminum magnet extruder?

>> 2. Why should I upgrade to an aluminum extruder?

>> 3. Can I install a 3030 aluminum magnet extruder on any printer?

>> 4. How do I maintain my new aluminum extruder?

>> 5. What should I do if my filament jams?

● Citations:

Installing a 3030 aluminum 3D printer magnet extruder can significantly enhance your 3D printing experience, providing better durability and performance compared to traditional plastic extruders. This comprehensive guide will walk you through the installation process step-by-step, ensuring that you have all the necessary information to successfully upgrade your 3D printer.

Understanding the 3030 Aluminum Extruder

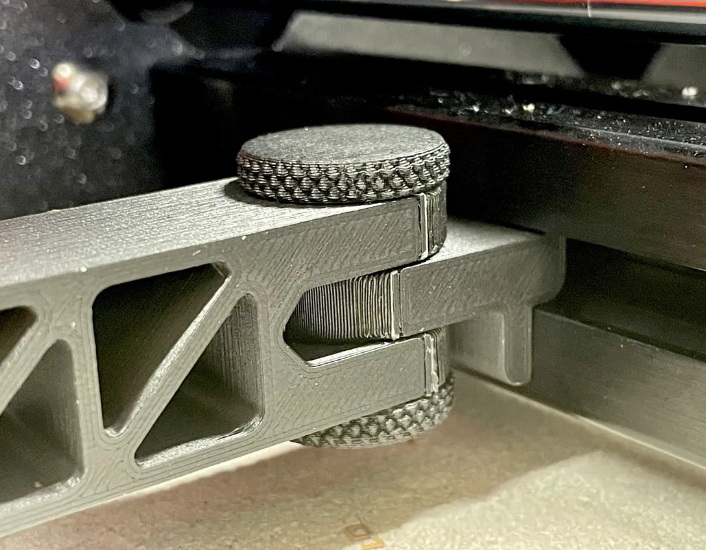

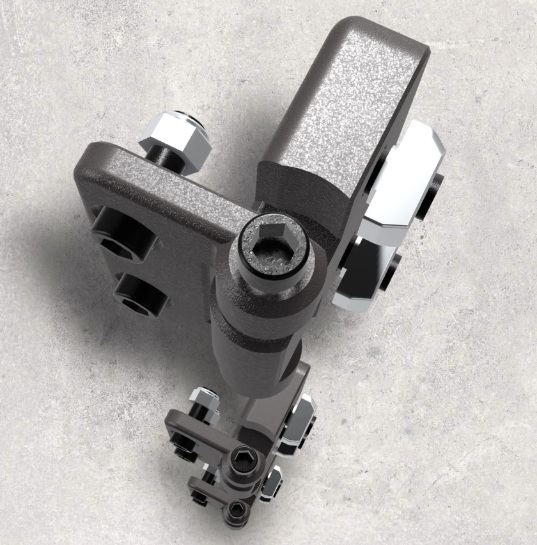

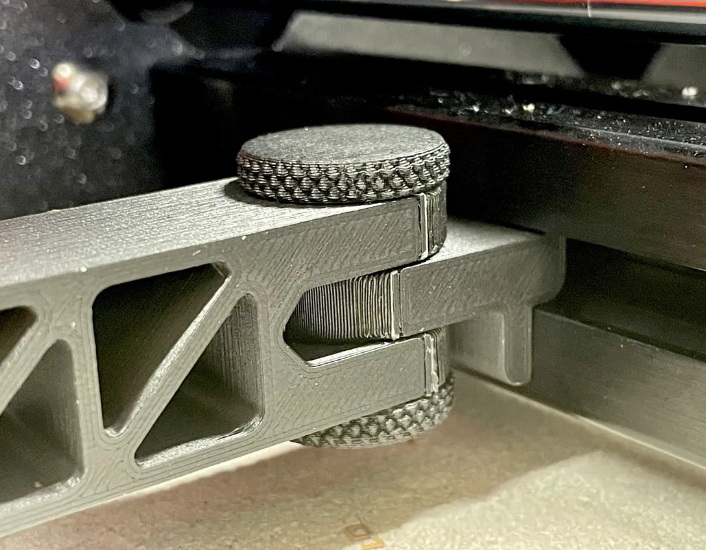

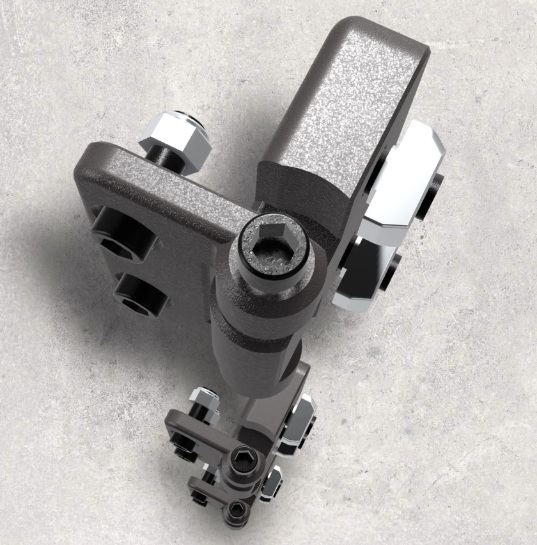

The 3030 aluminum extruder is a robust component designed for various 3D printers, particularly those using the Bowden system. The aluminum construction provides increased strength and stability, reducing the likelihood of wear and tear over time[7]. Additionally, the magnet feature allows for easy attachment and detachment of the filament feed system, making maintenance and upgrades simpler[3]. Aluminum extrusions, like the 3030, are versatile due to their strength, corrosion resistance and recyclability[7].

Advantages of Aluminum Extruders

Upgrading to an aluminum extruder offers several key advantages:

- Enhanced Durability: Aluminum extruders are significantly more resistant to wear and tear compared to their plastic counterparts[7]. This ensures a longer lifespan and reduces the need for frequent replacements.

- Improved Filament Control: The rigid structure of aluminum provides more precise control over filament feeding, resulting in more consistent and higher-quality prints.

- Better Heat Dissipation: Aluminum's excellent thermal conductivity helps dissipate heat more effectively, preventing overheating and potential jams[7].

- Increased Reliability: With fewer issues related to wear or deformation, aluminum extruders offer increased reliability, making your 3D printing process smoother and more predictable.

Tools and Materials Needed

Before starting the installation, gather the following tools and materials:

- 3030 Aluminum Magnet Extruder Kit

- Allen wrench set

- Screwdriver set

- Pliers

- Filament (to test after installation)

- Cleaning cloth

- Safety goggles

Step-by-Step Installation Process

1. Preparation

Begin by preparing your workspace:

- Ensure that your 3D printer is turned off and unplugged.

- Clear any clutter around your work area.

- Gather all tools and materials.

2. Remove the Existing Extruder

To install the new extruder, you must first remove the existing one:

a. Unload Filament: Heat the nozzle to melt any remaining filament and pull it out.

b. Disconnect Wires: Carefully unplug any wires connected to the existing extruder motor.

c. Remove Screws: Use an Allen wrench to unscrew the existing extruder from its mount. Keep these screws safe as you will need them later.

d. Detach Bowden Tube: Disconnect the Bowden tube from the old extruder by loosening the pneumatic fitting[10].

e. Remove Old Extruder: Gently lift away the old extruder assembly from its mount.

3. Assemble the New 3030 Aluminum Magnet Extruder

Now it's time to assemble your new extruder:

a. Attach Pneumatic Fitting: Securely attach the pneumatic fitting to the new aluminum extruder.

b. Install Gear and Bearing: Place the drive gear onto the motor shaft, ensuring it is tight enough to prevent slippage but not overly tight to avoid damage. Attach any bearings as per your kit instructions.

c. Connect Spring Mechanism: Insert a spring into the designated area of the extruder assembly to provide tension for filament feeding[10].

d. Secure with Screws: Use the screws from your old extruder to secure the new assembly in place.

4. Reattach Bowden Tube

Once your new extruder is securely in place:

a. Connect Bowden Tube: Insert the Bowden tube into the pneumatic fitting of your new extruder, ensuring it is seated correctly[10].

b. Use Collet Clip: If applicable, use a collet clip to secure the Bowden tube in place, preventing it from being pushed out during operation.

5. Connect the Wiring

Carefully reconnect the wiring to the new extruder motor. Ensure that the connections are secure and properly aligned to prevent any electrical issues. Refer to your printer's manual or the extruder kit instructions for the correct wiring configuration.

6. Calibrate the Extruder

After installing the new extruder, it's essential to calibrate it to ensure accurate filament extrusion. This involves adjusting the steps per millimeter (steps/mm) value in your printer's firmware. Here's how you can do it:

a. Determine the Current Steps/mm Value: Use your printer's control interface (e.g., LCD screen or software like Pronterface) to find the current steps/mm value for the extruder.

b. Measure Actual Extrusion:

- Mark a point on your filament 120mm above the extruder entrance.

- Command the printer to extrude 100mm of filament.

- Measure the actual distance from the mark to the extruder entrance.

- Calculate the actual extruded length (120mm - measured distance).

c. Calculate the New Steps/mm Value: Use the following formula:

New steps/mm = (Current steps/mm) * (100mm / Actual extruded length)

d. Update the Firmware: Use your printer's control interface or software like Pronterface to update the steps/mm value in the firmware.

e. Test and Refine: Repeat the measurement and calculation steps until the actual extruded length is very close to 100mm.

7. Fine-Tuning and Adjustments

- Adjust Tension: Adjust the tension on the extruder arm to ensure proper grip on the filament[10]. Too much tension can cause the filament to deform, while too little can lead to slipping.

- Check Alignment: Ensure that the extruder is properly aligned with the hot end to prevent any obstructions or misfeeds.

- Lubricate Moving Parts: Apply a small amount of lubricant to any moving parts, such as bearings, to ensure smooth operation.

8. Final Checks

Before powering up your printer:

a. Check Connections: Ensure all connections are secure, including electrical connections and mechanical fittings.

b. Inspect for Loose Parts: Double-check that no screws or components are left loose or unconnected.

c. Clean Up: Wipe down any surfaces that may have accumulated dust or debris during installation.

Testing Your New Extruder

After installation, it's crucial to test your new setup:

a. Power On Printer: Plug in your printer and turn it on.

b. Load Filament: Feed filament into your new extruder and check for smooth operation[10].

c. Run Test Print: Start a small test print to ensure everything functions correctly and that there are no clogs or issues with extrusion.

Troubleshooting

Even with careful installation, you might encounter some issues. Here are a few common problems and their solutions:

Filament Slipping:

- Problem: The extruder motor is turning, but the filament isn't being fed into the hot end.

- Solution: Adjust the tension on the extruder arm. Make sure the drive gear is clean and free of debris. Check that the filament diameter is correct for your printer.

Under-Extrusion:

- Problem: Not enough filament is being extruded, resulting in weak or incomplete prints[6].

- Solution: Calibrate the extruder steps/mm value. Check for clogs in the nozzle or Bowden tube. Increase the printing temperature.

Over-Extrusion:

- Problem: Too much filament is being extruded, resulting in blobs or poor print quality.

- Solution: Calibrate the extruder steps/mm value. Decrease the printing temperature. Check the filament diameter setting in your slicer software.

Extruder Motor Overheating:

- Problem: The extruder motor becomes excessively hot during printing, potentially leading to skipped steps or motor failure[11].

- Solution: Reduce the motor current in your printer's firmware. Ensure the motor is properly cooled with a heat sink or fan. Check for any obstructions that may be causing the motor to work harder than necessary.

Maintaining Your 3030 Aluminum Extruder

Proper maintenance is essential to keep your 3030 aluminum extruder performing optimally. Here are some tips:

- Regular Cleaning: Periodically clean the extruder drive gear and surrounding area to remove any accumulated filament debris. Use a brush or compressed air for this task.

- Check for Wear: Inspect the extruder components for any signs of wear or damage. Replace worn parts as needed to prevent performance issues.

- Lubricate Moving Parts: Apply a small amount of lubricant to moving parts like bearings and gears to ensure smooth operation.

- Inspect Bowden Tube: Regularly inspect the Bowden tube for wear, kinks, or clogs. Replace it if necessary to maintain consistent filament feeding[10].

- Firmware Updates: Keep your printer's firmware up to date to benefit from any performance improvements or bug fixes related to the extruder.

Aluminum Extrusion: More Than Just Extruders

The term "3030 aluminum" refers to a specific size and profile of aluminum extrusion[7]. Aluminum extrusions are widely used in various applications due to their versatility and structural properties[7]. The "3030" designation typically indicates a profile that is 30mm x 30mm, but the dimensions can slightly vary[7].

Other Applications of Aluminum Extrusion

- Frames and Structures: Aluminum extrusions are commonly used to build frames for machines, workstations, and enclosures[5]. Their modularity and ease of assembly make them ideal for creating custom structures[5].

- Linear Motion Systems: Aluminum extrusions often form the base for linear rails and guides in CNC machines and 3D printers[1][5].

- Furniture: The lightweight yet strong nature of aluminum extrusions makes them suitable for furniture construction, such as tables, shelves, and stands[7].

- Displays and Signage: Aluminum extrusions are used to create frames for displays, signs, and advertising structures due to their clean aesthetic and durability[7].

Advantages of Using Aluminum Extrusion

- Modularity: Aluminum extrusion systems are highly modular, allowing for easy customization and expansion[5].

- Strength-to-Weight Ratio: Aluminum offers a high strength-to-weight ratio, making it ideal for applications where weight is a concern[7].

- Corrosion Resistance: Aluminum naturally resists corrosion, making it suitable for use in various environments[7].

- Ease of Assembly: Aluminum extrusions can be easily assembled using simple hand tools, reducing the need for welding or complex fabrication processes[5].

- Aesthetic Appeal: Aluminum extrusions have a clean, modern look that can enhance the appearance of any project[7].

Aluminum vs. Other Materials

When choosing materials for your 3D printer or other projects, it's helpful to understand how aluminum compares to alternatives like steel and plastics.

| Feature | Aluminum | Steel | Plastics |

| Strength | High strength-to-weight ratio9 | Very strong, but heavier than aluminum9 | Lower strength, varies by type |

| Weight | Lightweight9 | Heavy9 | Lightweight |

| Corrosion Resistance | Excellent7 | Prone to rust unless treated | Generally good, depends on the plastic type |

| Thermal Conductivity | Good7 | Moderate | Low |

| Cost | Moderate | Moderate to high | Low to moderate |

| Workability | Easy to machine and assemble9 | More difficult to machine and assemble | Easy to mold, but may be less precise |

| Applications | Frames, enclosures, heat sinks, structural components5 | Heavy-duty structures, machinery9 | Enclosures, gears, cosmetic parts |

| Environmental Impact | Highly recyclable7 | Recyclable, but energy-intensive | Varies, some plastics are difficult to recycle |

Conclusion

Installing a 3030 aluminum magnet extruder can greatly improve your 3D printing capabilities by providing better material handling and durability compared to plastic alternatives[7]. By following this guide, you should be able to successfully install your new extruder with confidence[10]. Furthermore, understanding the broader applications of aluminum extrusion can open up new possibilities for your projects, leveraging its strength, modularity, and aesthetic appeal[5]. Always ensure compatibility with your specific 3D printer model before undertaking any upgrades[1][3].

FAQ

1. What is a 3030 aluminum magnet extruder?

A 3030 aluminum magnet extruder is a durable component used in 3D printers that enhances filament feeding through its robust aluminum construction and magnetic attachment features[7][3].

2. Why should I upgrade to an aluminum extruder?

Aluminum extruders offer increased strength, reduced wear over time, better heat dissipation, and improved reliability compared to plastic models[7].

3. Can I install a 3030 aluminum magnet extruder on any printer?

While many printers can accommodate an aluminum extruder, compatibility depends on specific models and their design configurations; always check manufacturer specifications before upgrading[1][3].

4. How do I maintain my new aluminum extruder?

Regularly inspect for wear on moving parts, clean any filament residue, ensure proper lubrication where necessary, and recalibrate as needed after significant changes or upgrades.

5. What should I do if my filament jams?

If you experience jamming, check for clogs in both the nozzle and Bowden tube, ensure proper temperature settings for your filament type, and verify that all components are securely connected without excessive tension[6][10].

Citations:

[1] https://www.treatstock.com/static/uploads/printers/Wombot_Exilis_Kit_Assembly_Manual_V1_3.pdf

[2] https://forum.v1e.com/t/portable-primo-24in-x-36in-pnw-3030-aluminum-extrusion-adaptor/31905

[3] https://www.printables.com/model/710528-20mm-magnet-mount-for-3030-extrusion

[4] https://kdmfab.com/aluminum-extrusion/

[5] https://www.wellste.com/t-slot-aluminum-extrusion/

[6] https://www.reddit.com/r/ender3/comments/11wvrt1/under_extrusion_issues_updated_aluminum_extruder/

[7] https://www.aliexpress.com/w/wholesale-3030-aluminium-extrusion.html

[8] https://www.youtube.com/watch?v=x30Sq6aq0wY

[9] https://www.wellste.com/aluminium-extrusion-frame/

[10] https://www.youtube.com/watch?v=UtemZqFJ5rY

[11] https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-general-discussion-announcements-and-releases/extruder-motor-getting-too-hot/paged/3/

[12] https://forum.prusa3d.com/forum/original-prusa-general-discussion-announcements-and-releases/where-are-you-putting-yours/paged/2/

[13] https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-general-discussion-announcements-and-releases/overview-of-troubleshooting-my-mk3-extrusion-issues/

[14] https://reprap.org/forum/read.php

[15] https://www.reef2reef.com/threads/diy-aluminum-extruder-stand-and-desk-setup.1087340/

[16] https://www.reef2reef.com/threads/diy-aluminum-extruder-stand-and-desk-setup.1087340/

[17] https://www.printables.com/model/147517-easy-insert-mount-for-4040-3030-aluminum-extrusion/related

[18] https://www.yeggi.com/q/3030+extrusion+drill+guide/

[19] https://kdmfab.com/tr/aluminum-extrusion/

[20] https://sg.c.misumi-ec.com/book/en_sea_2014_msm_fa_02/pdf/0715.pdf

[21] https://www.instructables.com/How-to-Design-and-Build-a-3D-Printer/

[22] https://reprap.org/forum/read.php

[23] https://www.reddit.com/r/Reprap/comments/46a5v7/where_can_i_buy_3030_aluminum_extrusions/

[24] https://www.printables.com/model/112089-magnetic-coupler-for-filament-guide-3030-extrusion

[25] https://www.dynisco.com/userfiles/files/27429_Legacy_Txt.pdf

[26] https://www.gabrian.com/joining-aluminum-extrusions/

[27] https://www.yeggi.com/q/delta+3030+extrusion/

[28] https://www.reef2reef.com/threads/guide-to-diy-with-t-slot-aluminum.903885/page-6

[29] https://www.aliexpress.com/i/32908832161.html

[30] https://kdmfab.com/aluminum-extrusion/

[31] https://www.aliexpress.com/i/32908437083.html

[32] https://mcjing.com.au/aluminium-extrusion-3030.html

[33] https://www.aliexpress.com/w/wholesale-3030-aluminium-extrusion.html

[34] https://www.alibaba.com/product-detail/Factory-Processes-aluminum-extrusion-profile-1100_1601278617429.html

[35] https://forum.v1e.com/t/portable-primo-24in-x-36in-pnw-3030-aluminum-extrusion-adaptor/31905

[36] https://www.reddit.com/r/prusa3d/comments/ifrcjt/i_designed_an_extruder_for_mk3s_that_uses_magnets/

[37] https://forum.bambulab.com/t/printhead-cover-magnets-unglued-and-cant-claim-warranty/8858

[38] https://ampere-electronics.com/product/3030-t-slot-aluminum-profile-extrusion-1m-silver-anodized/

[39] https://www.ebay.co.uk/itm/375889348544

[40] https://vitomfg.com/blog/advantages-of-wide-groove-width-in-industrial-aluminum-extrusion/

[41] https://hackaday.com/2021/05/25/getting-started-with-aluminum-extrusions/

[42] https://www.3erp.com/services/aluminum-extrusion/

[43] https://aec.org/features-benefits

[44] https://www.reef2reef.com/threads/t-slot-stand-will-3030-be-enough.968033/

[45] https://www.alibaba.com/product-detail/Aluminum-Profile-3030-Aluminum-Extrusion-Profile_1600370658183.html

[46] https://it.misumi-ec.com/files/images/products/docs/framingsupport.pdf

[47] https://www.cnczone.com/forums/plasma-edm-other-similar-machine-project-log/151355-manufacturing-engineering.html

[48] https://tangooled.com/aluminum-extrusion-vs-plastic-extrusion-a-comprehensive-guide/

[49] https://www.reddit.com/r/3Dprinting/comments/icgrtv/why_does_everyone_use_2020_and_3030_extrusion/

[50] https://www.cnczone.com/forums/diy-cnc-router-table-machines/116990-80-20-vs-misumi-extrusions.html

[51] https://www.wellste.com/t-slot-aluminum-extrusion/

[52] https://www.reddit.com/r/maker/comments/197vlyr/i_need_some_advice_do_you_think_2040_aluminum/