Content Menu

● Introduction to Aluminum Extruders

>> Choosing the Best Aluminum Extruder

● Popular Aluminum Extruder Options for Ender 3

● Step-by-Step Installation Guide

● Maintenance and Troubleshooting

● Conclusion

● FAQ

>> 1. What are the main benefits of using an aluminum extruder over a plastic one?

>> 2. How do I ensure compatibility with my Ender 3 model?

>> 3. What tools are required for installing an aluminum extruder?

>> 4. Do I need to recalibrate my printer after installing an aluminum extruder?

>> 5. Can I use flexible filaments with an aluminum extruder?

● Citations:

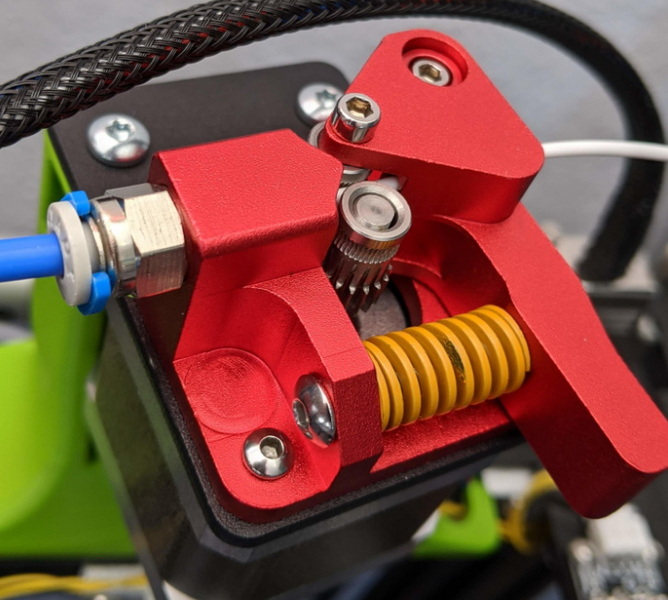

Choosing the best aluminum extruder for your Ender 3 is a crucial step in enhancing your 3D printing experience. The Ender 3, known for its affordability and versatility, can significantly benefit from upgrading its stock plastic extruder to an aluminum one. Aluminum extruders offer improved durability, consistent filament feeding, and better heat dissipation, leading to enhanced print quality and reliability. In this article, we will explore the key factors to consider when selecting an aluminum extruder for your Ender 3, along with step-by-step installation guides and maintenance tips.

Introduction to Aluminum Extruders

Aluminum extruders have become a popular upgrade for 3D printers like the Ender 3 due to their robust construction and superior performance compared to plastic extruders. Here are some key benefits of using an aluminum extruder:

- Increased Durability: Aluminum is more resistant to wear and tear than plastic, ensuring long-term reliability and reducing the risk of breakage during filament feeding[1][3].

- Improved Consistency: The rigid metal construction provides consistent filament feeding, leading to better print quality with fewer imperfections[1][3].

- Better Heat Dissipation: Aluminum efficiently conducts heat away from the motor and filament, reducing the risk of heat-related issues such as clogging[1][3].

Choosing the Best Aluminum Extruder

When selecting an aluminum extruder for your Ender 3, consider the following factors:

1. Compatibility: Ensure the extruder is specifically designed for the Ender 3 model. Some extruders may have slight variations that affect compatibility[1][3].

2. Installation Complexity: While generally straightforward, some kits may require more technical skill. Consider seeking assistance if you're not comfortable with DIY projects[1][3].

3. Cost: Aluminum extruders are more expensive than plastic ones, but they offer improved performance and longevity[1][3].

4. Maintenance: Regular cleaning and tension adjustments are necessary for optimal performance[1][3].

Popular Aluminum Extruder Options for Ender 3

Several aluminum extruder options are available for the Ender 3, each with its own set of advantages:

- Creality Aluminum Extruder: This is a no-frills, cost-effective upgrade that provides durability and ease of installation. It is compatible with the Ender 3 and CR10 series[2][4].

- Bondtech BMG Extruder: Known for its dual-gear design, this extruder provides excellent grip on the filament, making it ideal for flexible materials like TPU[4].

- E3D Hemera Extruder: Offers high-performance extrusion with a compact design, suitable for a wide range of filaments[4].

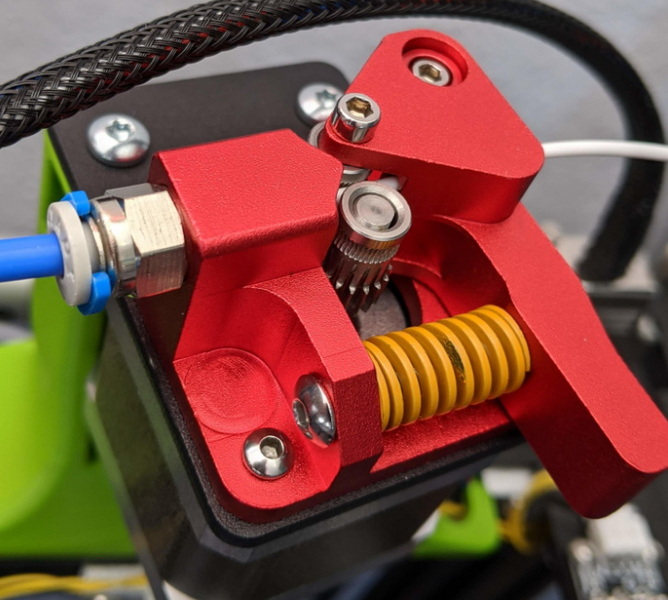

Step-by-Step Installation Guide

Upgrading to an aluminum extruder on your Ender 3 involves several steps:

1. Prepare Your Printer: Turn off and unplug your Ender 3. Allow the hot end to cool completely[1][8].

2. Gather Necessary Tools: You will need Allen wrenches, screwdrivers, and pliers[1][8].

3. Disassemble the Stock Extruder: Remove the Bowden tube and unscrew the existing extruder from the stepper motor[7][8].

4. Install the Aluminum Extruder: Align the new extruder with the stepper motor and secure it using the screws provided[7][8].

5. Reassemble and Calibrate: Reconnect the Bowden tube and recalibrate your extruder steps per millimeter (E-steps) for accurate extrusion[7][8].

Maintenance and Troubleshooting

Regular maintenance is crucial for optimal performance:

1. Regular Cleaning: Clean the extruder gear regularly to remove debris or filament residue[1][3].

2. Check Tension: Ensure proper tension on the extruder arm to prevent slippage or filament deformation[1][3].

3. Inspect for Wear: Periodically inspect for signs of wear or damage and replace worn parts promptly[1][3].

4. Lubricate Moving Parts: Apply lubricant to moving parts to keep them running smoothly[1][3].

Conclusion

Upgrading to an aluminum extruder is a worthwhile investment for Ender 3 owners looking to enhance their 3D printing experience. By considering compatibility, installation complexity, cost, and maintenance, you can choose the best aluminum extruder for your needs. Whether you opt for a Creality Aluminum Extruder or a more advanced option like the Bondtech BMG, the benefits of improved durability, consistent filament feeding, and better heat dissipation will significantly enhance your print quality and reliability.

FAQ

1. What are the main benefits of using an aluminum extruder over a plastic one?

- Aluminum extruders offer increased durability, improved consistency in filament feeding, better heat dissipation, and a longer lifespan compared to plastic extruders[1][3].

2. How do I ensure compatibility with my Ender 3 model?

- Always check that the aluminum extruder is specifically designed for your Ender 3 model. Some extruders may have variations that affect compatibility[1][3].

3. What tools are required for installing an aluminum extruder?

- You will need basic tools such as Allen wrenches, screwdrivers, and pliers. These are commonly included with most printer kits[1][8].

4. Do I need to recalibrate my printer after installing an aluminum extruder?

- Yes, recalibrating your extruder steps per millimeter (E-steps) is essential after installation for accurate filament extrusion[7][8].

5. Can I use flexible filaments with an aluminum extruder?

- Yes, aluminum extruders are better suited for handling flexible filaments due to their robust design. However, for optimal results, consider using a dual-gear or direct drive extruder[3][8].

Citations:

[1] https://www.yjing-extrusion.com/is-the-ender-3-pro-aluminum-extruder-worth-the-upgrade.html

[2] https://azurefilm.com/product/creality-aluminum-extruder-guide/

[3] https://www.yjing-extrusion.com/can-you-use-an-aluminum-extruder-on-ender-3.html

[4] https://letsprint3d.net/best-extruder-upgrades-creality-ender-3/

[5] https://letsprint3d.net/how-to-upgrade-the-extruder-ender-3/

[6] https://www.yjing-extrusion.com/why-should-you-choose-an-aluminum-extruder-for-3d-printing.html

[7] https://www.yjing-extrusion.com/can-the-ender-3-v2-aluminum-extruder-solve-jamming-issues.html

[8] https://www.yjing-extrusion.com/how-to-upgrade-to-an-ender-3-aluminum-extruder.html

[9] https://www.yjing-extrusion.com/news/Best-Aluminum-Extruder-For-Ender-3.html