Content Menu

● Introduction

● Understanding Aluminum Extrusion

>> The Basics of Aluminum Extrusion Sizes

● The Impact of Aluminum Extrusion Sizes on Design Flexibility

>> Design Options and Customization

>> Structural Integrity and Performance

>> Aesthetic Considerations

>> Cost Efficiency and Material Utilization

>> Manufacturing and Assembly Considerations

● Key Applications of Aluminum Extrusion Sizes

>> Construction and Architecture

>> Automotive Industry

>> Aerospace Applications

>> Consumer Electronics

>> Industrial Equipment

● Conclusion

● Related Questions

>> 1. What are the most common aluminum extrusion sizes used in construction?

>> 2. How do aluminum extrusion sizes affect weight and strength in automotive applications?

>> 3. Can aluminum extrusion sizes be customized for specific projects?

>> 4. What factors should be considered when selecting aluminum extrusion sizes for industrial equipment?

>> 5. How do aluminum extrusion sizes impact the assembly process?

Introduction

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This technique is widely used in various industries due to its versatility, lightweight nature, and strength. One of the critical factors that influence the effectiveness of aluminum extrusion is the size of the extrusions. Understanding how aluminum extrusion sizes impact design flexibility is essential for engineers, designers, and manufacturers alike. This article delves into the intricacies of aluminum extrusion sizes, their classifications, and how they affect design choices in various applications.

Understanding Aluminum Extrusion

Aluminum extrusion involves forcing heated aluminum through a die to create a specific shape. The process allows for the production of complex profiles that can be tailored to meet specific requirements. The versatility of aluminum extrusion makes it suitable for a wide range of applications, from structural components in buildings to intricate parts in electronics.

The Basics of Aluminum Extrusion Sizes

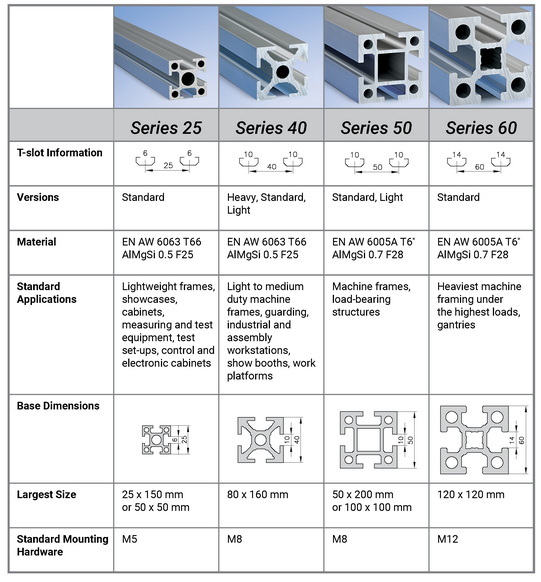

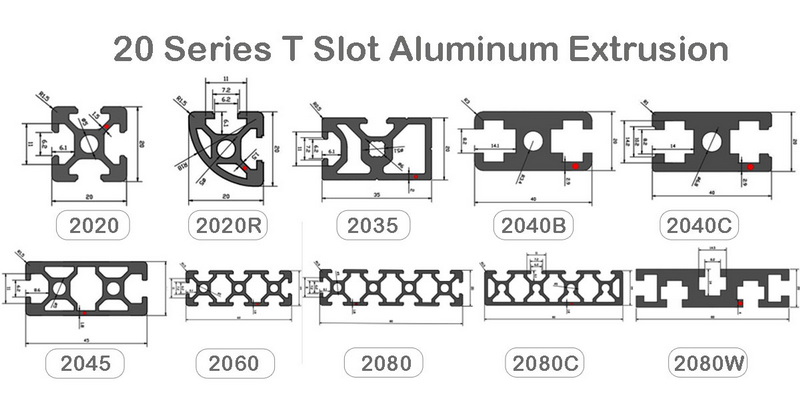

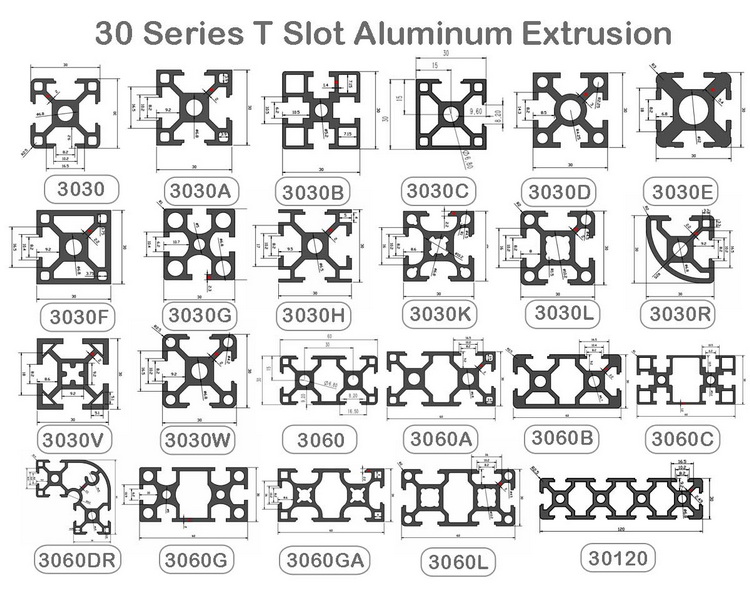

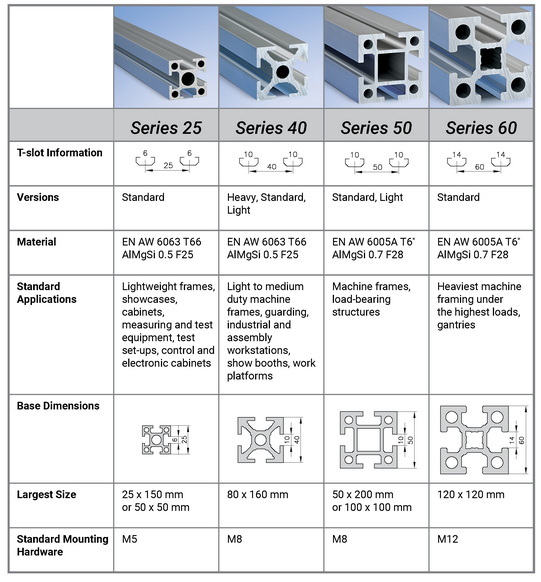

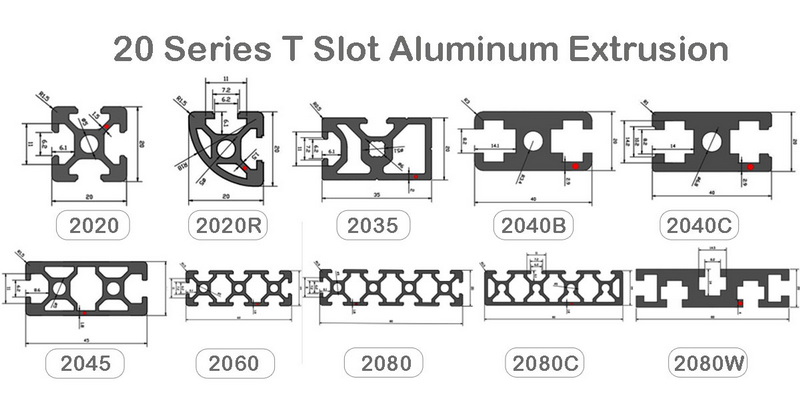

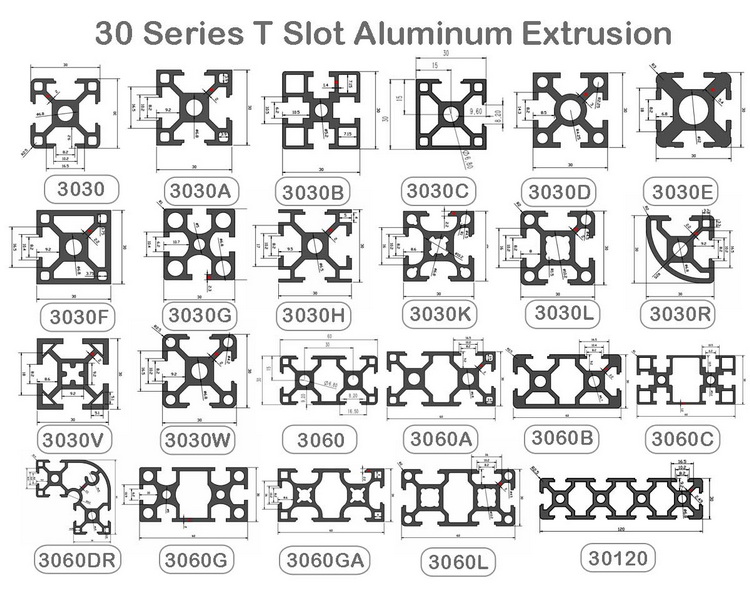

Aluminum extrusion sizes refer to the dimensions and shapes of the extruded profiles. These sizes can vary significantly based on the intended application. Common sizes include standard profiles, custom shapes, and T-slot extrusions. Each size offers unique advantages and can impact the overall design flexibility of a project.

The Impact of Aluminum Extrusion Sizes on Design Flexibility

Design Options and Customization

One of the primary advantages of aluminum extrusion is the ability to create custom profiles. Designers can specify the exact dimensions and shapes needed for their projects. This customization allows for greater design flexibility, enabling engineers to create components that fit specific requirements without compromising on performance.

For instance, when designing a frame for a solar panel, the size of the aluminum extrusion can be tailored to accommodate the panel's dimensions while ensuring structural integrity. The ability to customize sizes means that designers can optimize the weight and strength of the frame, leading to more efficient energy production.

Structural Integrity and Performance

The size of aluminum extrusions also plays a crucial role in determining the structural integrity of a design. Larger profiles can provide greater strength and stability, making them suitable for load-bearing applications. Conversely, smaller profiles may be more appropriate for lightweight structures where flexibility is essential.

In applications such as automotive manufacturing, the choice of aluminum extrusion sizes can significantly impact the vehicle's overall performance. For example, using larger extrusions in the chassis can enhance safety and durability, while smaller extrusions can reduce weight, improving fuel efficiency.

Aesthetic Considerations

In addition to functional aspects, aluminum extrusion sizes can also influence the aesthetic appeal of a design. Designers often consider how the size and shape of extrusions will affect the overall look of a product. For instance, sleek, narrow profiles may be preferred in consumer electronics, while robust, larger profiles may be more suitable for industrial applications.

The ability to choose from a variety of sizes allows designers to create visually appealing products that align with brand identity and market trends. This flexibility in design can be a significant competitive advantage in industries where aesthetics play a crucial role.

Cost Efficiency and Material Utilization

Selecting the appropriate aluminum extrusion sizes can also lead to cost savings. By optimizing the size of extrusions, manufacturers can reduce material waste and lower production costs. For example, using a larger profile than necessary can lead to excess material that does not contribute to the final product's performance.

Designers must balance the need for strength and durability with cost considerations. By carefully selecting aluminum extrusion sizes, they can achieve the desired performance while minimizing expenses. This approach is particularly important in industries with tight profit margins, such as construction and manufacturing.

Manufacturing and Assembly Considerations

The size of aluminum extrusions can impact the manufacturing and assembly processes. Larger profiles may require specialized equipment for handling and machining, while smaller profiles can be more easily integrated into existing production lines. Understanding the implications of extrusion sizes on manufacturing processes is essential for ensuring efficient production.

Moreover, the assembly of components can be influenced by the size of the extrusions. For instance, T-slot extrusions allow for easy assembly and disassembly, making them ideal for modular designs. This flexibility can streamline production and reduce lead times, ultimately benefiting the end product.

Key Applications of Aluminum Extrusion Sizes

Construction and Architecture

In the construction industry, aluminum extrusions are commonly used for window frames, curtain walls, and structural components. The size of the extrusions must be carefully considered to ensure they meet building codes and safety standards. Custom sizes can be designed to fit specific architectural requirements, enhancing both functionality and aesthetics.

Automotive Industry

The automotive industry relies heavily on aluminum extrusions for various components, including chassis, bumpers, and interior parts. The size of the extrusions directly impacts the vehicle's weight, safety, and performance. Manufacturers often use larger profiles in critical areas to enhance strength while utilizing smaller profiles in non-structural components to reduce weight.

Aerospace Applications

In aerospace, aluminum extrusions are used for structural components, fuselage frames, and wing structures. The size and weight of these extrusions are critical for ensuring the aircraft's performance and fuel efficiency. Engineers must carefully select extrusion sizes to balance strength and weight, contributing to overall aircraft design.

Consumer Electronics

Aluminum extrusions are increasingly used in consumer electronics for enclosures, heat sinks, and structural supports. The size of the extrusions can affect the product's thermal management and overall performance. Designers often opt for smaller, more intricate profiles to create sleek, modern devices that appeal to consumers.

Industrial Equipment

In industrial applications, aluminum extrusions are used for machine frames, conveyor systems, and workstations. The size of the extrusions must be tailored to the specific requirements of the equipment, ensuring stability and durability. Custom sizes can enhance the functionality of industrial equipment, making it more efficient and effective.

Conclusion

Aluminum extrusion sizes play a pivotal role in determining design flexibility across various industries. The ability to customize sizes allows designers to create components that meet specific performance, aesthetic, and cost requirements. By understanding the impact of extrusion sizes on structural integrity, manufacturing processes, and overall design, engineers can optimize their projects for success.

As industries continue to evolve, the demand for innovative aluminum extrusion solutions will only grow. By leveraging the advantages of aluminum extrusion sizes, manufacturers can stay competitive and meet the ever-changing needs of the market.

Related Questions

1. What are the most common aluminum extrusion sizes used in construction?

Common aluminum extrusion sizes in construction include standard profiles for window frames, curtain walls, and structural supports. These sizes are designed to meet building codes and safety standards while providing aesthetic appeal.

2. How do aluminum extrusion sizes affect weight and strength in automotive applications?

Larger aluminum extrusions provide greater strength and stability, making them suitable for load-bearing components in vehicles. Smaller extrusions can reduce weight, improving fuel efficiency without compromising safety.

3. Can aluminum extrusion sizes be customized for specific projects?

Yes, aluminum extrusion sizes can be customized to meet the specific requirements of a project. This flexibility allows designers to optimize performance and aesthetics based on their needs.

4. What factors should be considered when selecting aluminum extrusion sizes for industrial equipment?

When selecting aluminum extrusion sizes for industrial equipment, factors such as load-bearing capacity, stability, manufacturing processes, and cost efficiency should be considered to ensure optimal performance.

5. How do aluminum extrusion sizes impact the assembly process?

The size of aluminum extrusions can influence the assembly process by determining the equipment needed for handling and machining. Larger profiles may require specialized tools, while smaller profiles can be more easily integrated into existing production lines.