Content Menu

● Understanding Extruder Jamming Issues

● Why Upgrade to an Aluminum Extruder?

● Installation Process

● Troubleshooting Common Issues

● Benefits of Using High-Quality Filament

● Additional Upgrades for Improved Performance

● Understanding Different Types of Extruders

>> Bowden vs. Direct Drive Extruders

● Choosing Between Metal Extruders

● Maintaining Your Aluminum Extruder

● Conclusion

● FAQ

>> 1. What are common signs that my Ender 3 V2's extruder is failing?

>> 2. How often should I maintain my aluminum extruder?

>> 3. Can I use flexible filaments with an aluminum extruder?

>> 4. Will upgrading my extruder void my warranty?

>> 5. How do I recalibrate my E-steps after upgrading?

● Citations:

The "Ender 3 V2" is a highly regarded 3D printer, celebrated for its affordability and versatility. However, many users face jamming issues, particularly with the stock plastic extruder. Upgrading to an "Ender 3 V2 aluminum extruder" can significantly enhance performance and reliability. This article delves into the benefits of this upgrade, installation procedures, troubleshooting tips, and more.

Understanding Extruder Jamming Issues

Extruder jamming occurs when the filament fails to feed properly through the hotend, leading to print failures. Common causes include:

- Filament Quality: Poor-quality or damp filament can lead to inconsistent extrusion.

- Extruder Tension: Incorrect tension on the extruder can either crush the filament or fail to grip it adequately.

- Heat Issues: Excessive heat can soften the filament too early in the feed path, causing it to deform and jam.

- Clogged Nozzle: A blocked nozzle can prevent proper filament flow.

Why Upgrade to an Aluminum Extruder?

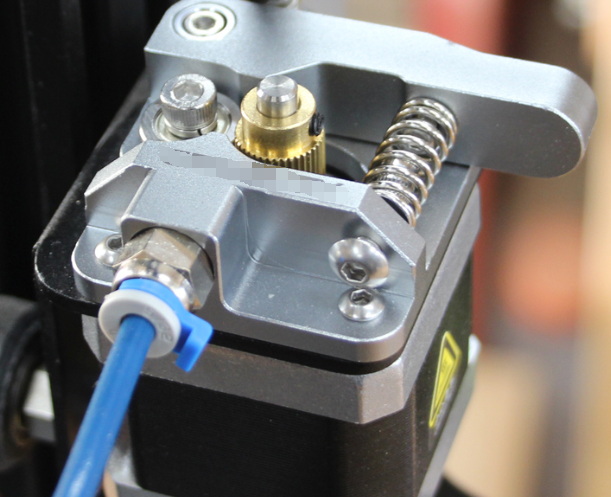

Upgrading to an aluminum extruder offers several advantages over the stock plastic version:

- Increased Durability: Aluminum is more resistant to wear and tear compared to plastic, meaning it can handle the stresses of filament feeding without breaking or deforming.

- Improved Consistency: The rigid construction of an aluminum extruder ensures consistent filament feeding, leading to better print quality.

- Better Heat Dissipation: Aluminum conducts heat more effectively, reducing the risk of heat-related issues that can lead to jamming.

- Longer Lifespan: With better durability and performance, an aluminum extruder typically lasts longer than its plastic counterpart.

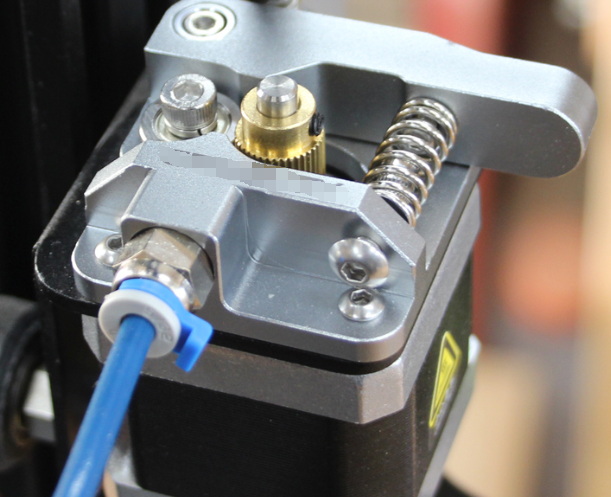

Installation Process

Installing an aluminum extruder on your Ender 3 V2 is a straightforward process. Here's a step-by-step guide:

1. Gather Your Tools: You will need an Allen wrench set, a screwdriver, and your new aluminum extruder kit.

2. Power Off the Printer: Ensure that your printer is turned off and unplugged before starting any modifications.

3. Remove Existing Filament: Heat up the hotend to remove any existing filament safely.

4. Disassemble the Stock Extruder:

- Remove the Bowden tube from the extruder.

- Unscrew the existing extruder from the stepper motor.

- Detach any springs or tension mechanisms carefully.

5. Install the Aluminum Extruder:

- Align the new aluminum extruder with the stepper motor.

- Secure it using the screws provided in your kit.

- Reattach any springs or tension mechanisms as per instructions.

6. Reconnect Bowden Tube: Ensure that the Bowden tube is securely connected to the new extruder.

7. Calibrate E-Steps: After installation, recalibrate your extruder steps per millimeter (E-steps) for accurate extrusion.

8. Test Print: Run a test print to ensure everything is functioning correctly.

Troubleshooting Common Issues

Even after upgrading to an aluminum extruder, you may still encounter issues. Here are some common problems and their solutions:

Filament Slipping:

- Check if the tension on the extruder is too low; adjust accordingly.

- Ensure that there are no blockages in the Bowden tube or nozzle.

Jamming During Printing:

- Inspect for clogs in the hotend; clean if necessary.

- Make sure you are using high-quality filament that is dry and free from defects.

Overheating Stepper Motor:

- If your stepper motor is overheating, consider adjusting voltage settings or checking for mechanical binding in the system.

Benefits of Using High-Quality Filament

Using high-quality filament can further reduce jamming issues and enhance print quality. Look for reputable brands that offer consistent diameter and material properties.

Additional Upgrades for Improved Performance

Consider these additional upgrades alongside your new aluminum extruder:

- Direct Drive Extruders: These offer better control over flexible filaments by placing the extruder directly above the hotend.

- Upgraded Hotends: A high-performance hotend can handle a wider range of materials and temperatures, reducing clogging risks.

- Better Cooling Solutions: Improved cooling can help maintain optimal temperatures in your printing environment, which is crucial for consistent extrusion.

Understanding Different Types of Extruders

When considering upgrades for your Ender 3 V2, it's essential to understand various types of extruders available:

Bowden vs. Direct Drive Extruders

| Feature | Bowden Extruders | Direct Drive Extruders |

| Filament Path | Longer path with Bowden tube | Shorter path directly on hotend |

| Filament Types | Works well with rigid filaments | Better for flexible filaments |

| Retraction Speed | Requires longer retraction | Faster retraction due to proximity |

| Installation Ease | Generally easier to install | Slightly more complex installation |

Choosing Between Metal Extruders

When selecting a metal extruder for your Ender 3 V2, consider these types:

- All-Metal Extruders: These are robust and offer excellent durability but may require more precise calibration during installation.

- Dual-Gear Extruders: These provide superior grip on filament due to their dual gear mechanism, making them ideal for flexible materials as well as standard filaments.

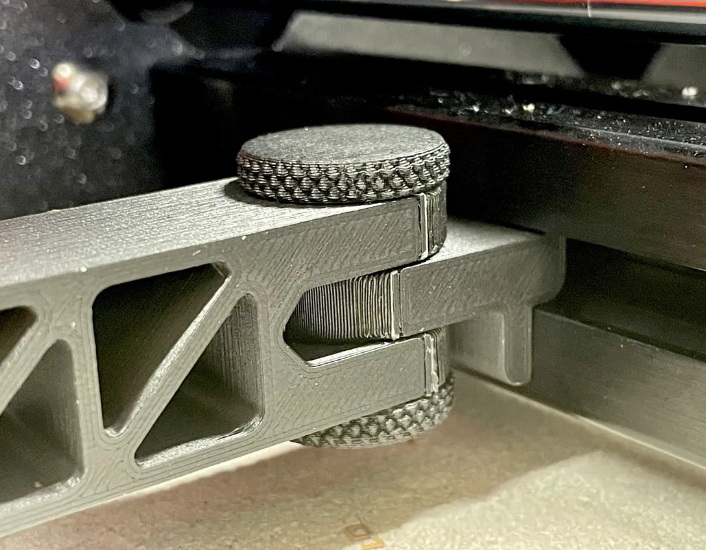

Maintaining Your Aluminum Extruder

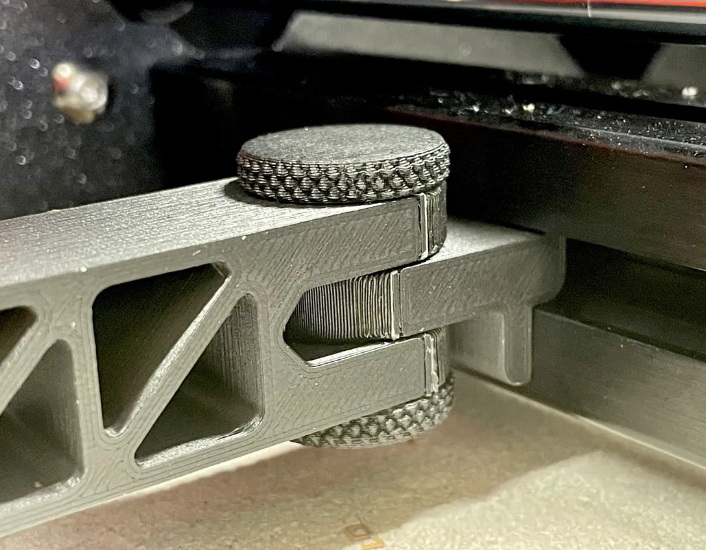

To ensure optimal performance from your new aluminum extruder:

1. Regularly clean the gear mechanism to prevent buildup of filament debris.

2. Check tension settings periodically; adjust if necessary to maintain consistent feeding without crushing filament.

3. Inspect for wear and tear on parts like springs and gears; replace them as needed to avoid performance degradation over time.

4. Keep an eye on temperature settings; ensure they are appropriate for both your printer model and filament type being used.

5. Document any changes made during maintenance or upgrades for future reference or troubleshooting needs.

Conclusion

Upgrading to an aluminum extruder on your Ender 3 V2 can effectively solve many jamming issues associated with plastic components. The increased durability, improved heat dissipation, and consistent filament feeding contribute significantly to better print quality and reliability.

By following proper installation procedures and maintaining your printer regularly, you can enjoy enhanced performance from your Ender 3 V2 for years to come.

FAQ

1. What are common signs that my Ender 3 V2's extruder is failing?

Common signs include inconsistent extrusion, clicking sounds from the stepper motor, and visible wear on plastic parts.

2. How often should I maintain my aluminum extruder?

Regular maintenance every 1-3 months is recommended, depending on usage frequency.

3. Can I use flexible filaments with an aluminum extruder?

Yes, but consider using a dual gear or direct drive system for optimal results with flexible materials.

4. Will upgrading my extruder void my warranty?

Modifying your printer may affect its warranty; check with your manufacturer for specific policies regarding upgrades.

5. How do I recalibrate my E-steps after upgrading?

You can recalibrate E-steps by using commands in your printer's firmware or through slicer software settings after installing a new extruder setup.

Citations:

[1] https://www.wevolver.com/article/ender-3-extruder-skipping

[2] https://www.crealityexperts.com/creality-extruder-upgrade-instructions

[3] https://blog.goldsupplier.com/metal-extruder/

[4] https://3dprinting.stackexchange.com/questions/15843/ender-3-v2-extruder-getting-hot

[5] https://www.bastelgarage.ch/e3d-titan-direct-extruder-upgrade-kit-for-ender-3-v2

[6] https://www.youtube.com/watch?v=hoLQGSIJIto

[7] https://letsprint3d.net/how-to-upgrade-the-extruder-ender-3/

[8] https://www.yjing-extrusion.com/can-you-use-an-aluminum-extruder-on-ender-3.html

[9] https://3dprintingspace.com/t/extruder-and-hot-end-issues/2416

[10] https://winsinn.com/ender-3-v2-upgrades/

[11] https://3dprinting.stackexchange.com/questions/11976/all-metal-hot-end-creality-ender-3-pro-jamming-issues

[12] https://www.youtube.com/watch?v=VrqZgU8G3rQ

[13] https://www.reddit.com/r/3Dprinting/comments/ml3btp/purpose_of_a_full_metal_extruder_on_am_ender_3_v2/

[14] https://www.youtube.com/watch?v=RLsALMPDb84

[15] https://www.reddit.com/r/ender3v2/comments/149wfud/metal_extruder_upgrade/

[16] https://www.reddit.com/r/ender3/comments/sc95t5/ender_3_v2_keeps_jamming_15_min_into_each_print/

[17] https://www.youtube.com/watch?v=UtemZqFJ5rY

[18] https://letsprint3d.net/best-extruder-upgrades-creality-ender-3/

[19] https://community.ultimaker.com/topic/46158-ender3-v2-all-metal-extruder-scrapes-filament-to-grit/

[20] https://www.youtube.com/watch?v=BUFC9YDIiLg