Content Menu

● Introduction to Aluminum Extruders

>> Benefits of Aluminum Extruders

● Upgrading the Replicator 2 with an Aluminum Extruder

>> Step 1: Prepare Your Printer

>> Step 2: Disassemble the Stock Extruder

>> Step 3: Install the Aluminum Extruder

>> Step 4: Calibrate Your Printer

● Real-World Examples and Case Studies

>> Case Study: Upgrading for Flexible Filaments

>> Case Study: Enhanced Durability

● Technical Considerations

● Cost-Benefit Analysis

● Community Feedback and Reviews

● Conclusion

● FAQ

>> 1. What are the main benefits of upgrading to an aluminum extruder?

>> 2. Is the aluminum extruder compatible with all 3D printers?

>> 3. Do I need to calibrate my extruder after upgrading?

>> 4. Can the aluminum extruder handle flexible filaments like TPU?

>> 5. Is it difficult to install the aluminum extruder?

● Citations:

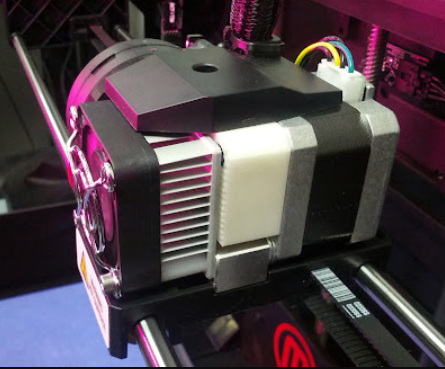

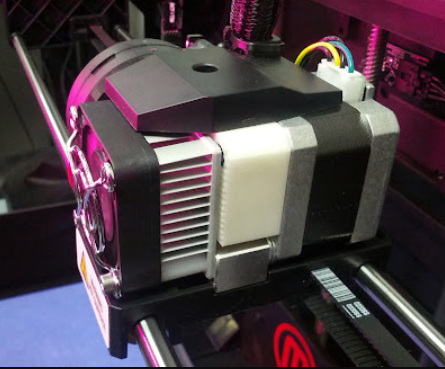

Upgrading your 3D printer with an aluminum extruder can significantly enhance its performance, durability, and print quality. The Makerbot Replicator 2, a popular model among enthusiasts, benefits greatly from such an upgrade. In this article, we will explore the reasons behind upgrading to an aluminum extruder, the benefits it offers, and provide a step-by-step guide on how to perform the upgrade.

Introduction to Aluminum Extruders

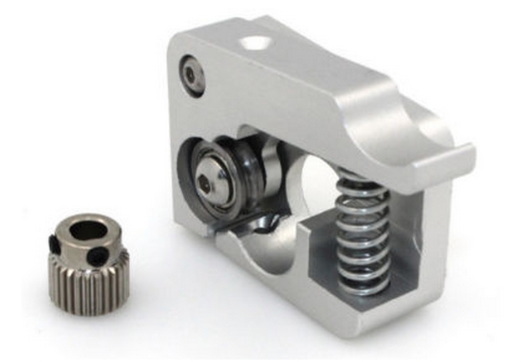

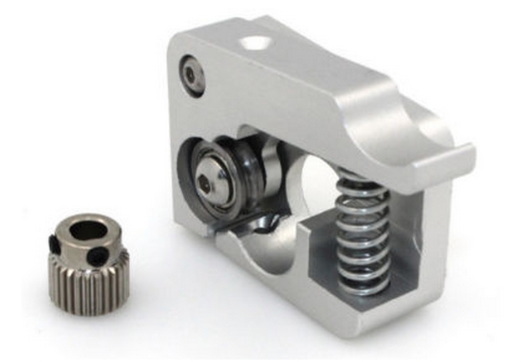

Aluminum extruders are designed to overcome the limitations of stock plastic extruders, which are prone to wear and tear, flexibility issues, and poor durability. Aluminum, being a robust material, offers enhanced durability and rigidity, ensuring consistent filament feeding and improved print quality.

Benefits of Aluminum Extruders

1. Durability: Aluminum extruders are more resistant to mechanical stress and can withstand higher temperatures, making them ideal for printing with a variety of filaments, including ABS and nylon.

2. Improved Filament Control: The aggressive grip on the filament minimizes slippage, leading to smoother feeding and more accurate prints. This is particularly beneficial for flexible filaments like TPU.

3. Higher Temperature Resistance: Aluminum can handle higher temperatures than plastic, making it suitable for printing with high-performance materials.

4. Precision Printing: Consistent filament flow and stable temperature control contribute to better layer adhesion, reduced stringing, and overall improved print quality.

5. Ease of Installation: Most aluminum extruder assemblies come as DIY kits that are easy to install, requiring minimal technical expertise.

Upgrading the Replicator 2 with an Aluminum Extruder

Upgrading the Makerbot Replicator 2 with an aluminum extruder involves several steps. Here's a comprehensive guide to help you through the process:

Step 1: Prepare Your Printer

1. Turn Off and Unplug: Ensure your printer is turned off and unplugged before starting the upgrade.

2. Remove Filament: Take out any filament from the extruder to prevent any obstructions during the upgrade.

Step 2: Disassemble the Stock Extruder

1. Detach the Bowden Tube: Remove the Bowden tube from the stock extruder.

2. Remove Screws: Use an Allen wrench to remove the screws securing the stock extruder to the printer.

Step 3: Install the Aluminum Extruder

1. Align and Secure: Align the new aluminum extruder with the mounting holes on your printer and secure it using the provided screws.

2. Connect Filament Path: Ensure the filament guide tube is properly connected to the hot end.

Step 4: Calibrate Your Printer

1. Update Firmware: Update your printer's firmware settings to accommodate any changes in extrusion parameters due to the new extruder.

2. Test Printing: Run a test print to ensure everything is functioning correctly and make any necessary adjustments.

Real-World Examples and Case Studies

Many users have reported significant improvements in print quality after upgrading to an aluminum extruder. For instance, one user noted that the metal extruder handled flexible filaments much better than the stock plastic extruder, allowing them to print more complex and functional parts.

Case Study: Upgrading for Flexible Filaments

Upgrading to an aluminum extruder is particularly beneficial when working with flexible filaments like TPU. These filaments require a consistent and firm grip to prevent slippage and ensure smooth extrusion. Aluminum extruders, especially those with dual gear systems, provide the necessary grip and durability to handle such filaments effectively.

Case Study: Enhanced Durability

Another user reported that after upgrading to an aluminum extruder, they experienced fewer instances of extruder failure due to wear and tear. This not only saved them money on replacement parts but also reduced downtime, allowing for more consistent printing.

Technical Considerations

When upgrading to an aluminum extruder, it's essential to consider the technical aspects of the upgrade:

1. Compatibility: Ensure the aluminum extruder is compatible with your printer model. Some extruders are designed specifically for certain printers, so compatibility is crucial.

2. Dual Gear System: Extruders with dual gears provide better grip on the filament, minimizing slippage and improving print quality.

3. Adjustable Tension: An adjustable tension mechanism allows you to fine-tune the pressure on the filament for optimal feeding.

4. Direct Drive Conversion: Some kits offer the option to convert to a direct drive system, which can further improve print quality with flexible filaments.

Cost-Benefit Analysis

While upgrading to an aluminum extruder requires an initial investment, it offers long-term benefits. The increased durability and improved print quality can save you money on filament and replacement parts in the long run. Additionally, the ability to print with a wider range of filaments opens up more creative possibilities and applications.

Community Feedback and Reviews

Feedback from the 3D printing community is overwhelmingly positive regarding aluminum extruder upgrades. Users report improved print quality, reduced maintenance, and increased versatility in filament choice. However, some users note that the installation process can be challenging for beginners, requiring some technical knowledge.

Conclusion

Upgrading your Makerbot Replicator 2 with an aluminum extruder is a worthwhile investment for anyone looking to enhance print quality and reliability. The increased durability, consistent filament feeding, and compatibility with a wider range of filaments make it a valuable upgrade for both beginners and experienced users.

FAQ

1. What are the main benefits of upgrading to an aluminum extruder?

Upgrading to an aluminum extruder offers enhanced durability, improved filament control, higher temperature resistance, and better print quality. It also allows for easier handling of flexible filaments like TPU.

2. Is the aluminum extruder compatible with all 3D printers?

Not all aluminum extruders are compatible with every 3D printer model. Ensure the extruder is specifically designed for your printer, such as the Replicator 2.

3. Do I need to calibrate my extruder after upgrading?

Yes, calibration is necessary after installing a new extruder to ensure accurate filament extrusion. This involves updating the E-steps value in your printer's firmware.

4. Can the aluminum extruder handle flexible filaments like TPU?

Yes, aluminum extruders, especially those with dual gear systems, can handle flexible filaments much better than stock plastic extruders. Upgrading to a metal extruder allows for experimentation with a broader range of filament types.

5. Is it difficult to install the aluminum extruder?

Most aluminum extruder assemblies are designed as DIY kits and are relatively easy to install, requiring minimal technical expertise.

Citations:

[1] https://www.yjing-extrusion.com/is-the-upgraded-aluminum-extruder-v2-worth-the-investment-for-better-print-quality.html

[2] https://www.youtube.com/watch?v=w8kXiKLdu5E

[3] https://3dprintingindustry.com/news/the-replicator-2-an-honest-overview-of-the-machine-and-the-experience-11445/

[4] https://www.instructables.com/Makerbot-Replicator-2-Aluminum-Z-Axis-Stage-Upgrad/

[5] https://www.reddit.com/r/makerbot/comments/14uifg6/acquired_a_replicator_2x_what_upgrades_should_i/

[6] https://reprap.org/forum/read.php?1%2C874326

[7] https://www.reddit.com/r/makerbot/comments/16q9uis/looking_for_makerbot_replicator_2x_new_or/

[8] https://groups.google.com/g/makerbot-users/c/vcMe4Sv0cNY

[9] https://versus.com/en/makerbot-replicator-2-vs-makerbot-replicator-z18

[10] https://groups.google.com/g/3d-printing-tips--tricks/c/g6hD_PRTwd4

[11] https://www.instructables.com/MM2X-Makerbot-Nozzle-Installation-Instructions/

[12] https://groups.google.com/g/makerbot/c/m2X36BIqEWE

[13] https://www.thingiverse.com/thing:42250

[14] https://www.yjing-extrusion.com/how-to-upgrade-your-3d-printer-with-an-aluminum-alloy-extruder.html

[15] https://www.bassybeats.co.nz/projects/3d-printing/makerbot-replicator-2-restoration/

[16] https://www.hubs.com/talk/t/best-printing-practices-on-makerbot-replicator-2-and-2x/581/37

[17] https://transistor-man.com/waking_up_a_replicator2.html

[18] https://www.thingiverse.com/groups/replicator2/forums/general/topic:578