Content Menu

● Introduction to Aluminum Extrusion

>> Advantages of Aluminum Extrusion

● The Role of Adjustable Spring in Aluminum Extruders

>> How Adjustable Springs Work

● Aluminum Gutter Extruders

>> Benefits of Seamless Gutters

>> How Seamless Gutters Are Made

● Emerging Trends in Aluminum Extrusion

● Applications of Aluminum Extruders

>> Advanced Guttering Systems

● Customization and Design Flexibility

>> Case Study: Sentinel Extruded Aluminium Guttering System

● Expanded Applications and Technological Advancements

>> Automotive Applications

>> Aerospace Applications

>> Electronics Applications

>> Emerging Technologies

>> Sustainability Initiatives

● Future Outlook

>> Role of AI in Predictive Maintenance

>> Impact of Circular Economy Practices

>> Potential for 3D Printing Integration

● Conclusion

● FAQs

>> 1. What are the primary advantages of using an aluminum extruder with an adjustable spring?

>> 2. How does the adjustable spring system contribute to the quality of seamless gutters?

>> 3. What types of projects benefit most from aluminum extruders with adjustable springs?

>> 4. How does the adjustable spring system impact the cost-effectiveness of aluminum extrusion?

>> 5. Are aluminum extruders with adjustable springs suitable for small-scale production?

In the realm of metal fabrication, aluminum extruders play a crucial role in producing a wide range of products, from architectural components to consumer goods. Among these, the aluminum gutter extruder is particularly notable for its ability to create seamless gutters that are both functional and aesthetically pleasing. However, when selecting an aluminum extruder for your projects, it's essential to consider the benefits of an adjustable spring system. This feature enhances the versatility and efficiency of the extrusion process, making it ideal for various applications.

Introduction to Aluminum Extrusion

Aluminum extrusion is a manufacturing process where aluminum alloy is forced through a die to create specific shapes. This method is widely used due to its ability to produce complex profiles, tubes, and custom designs for different industries. The process involves heating the aluminum to a high temperature, typically around 500°C, making it soft and pliable. It is then pushed through a die, which shapes it into the desired form.

Advantages of Aluminum Extrusion

1. Versatility: Aluminum can be molded into a variety of shapes and contours, making it suitable for complex designs.

2. Low Cost: The tooling costs are relatively low compared to other metals, and fewer components are needed, simplifying fabrication and assembly.

3. High Strength-to-Weight Ratio: Aluminum offers a higher strength-to-weight ratio than steel, making it ideal for applications where weight reduction is crucial.

4. Non-Corrosive Properties: Aluminum has a naturally occurring oxide film that protects it from corrosion, which can be further enhanced through anodizing.

5. Environmental Benefits: Aluminum is highly recyclable, reducing waste and environmental impact.

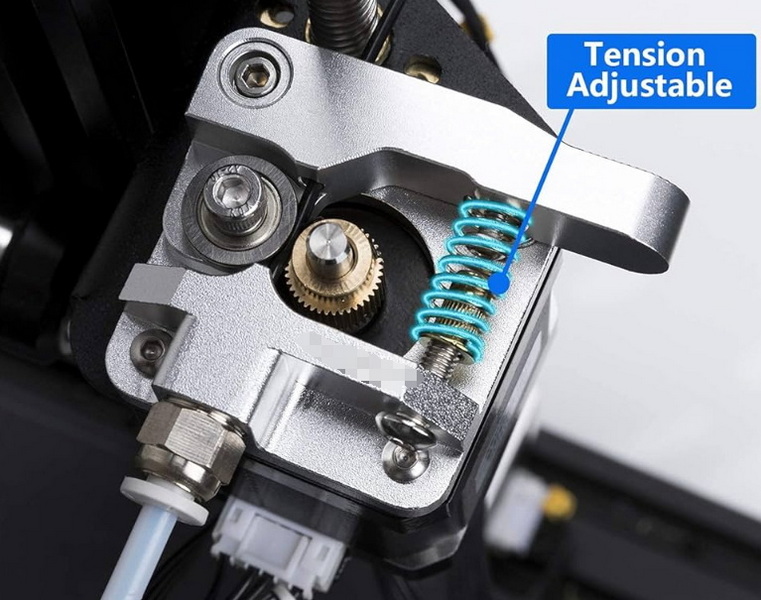

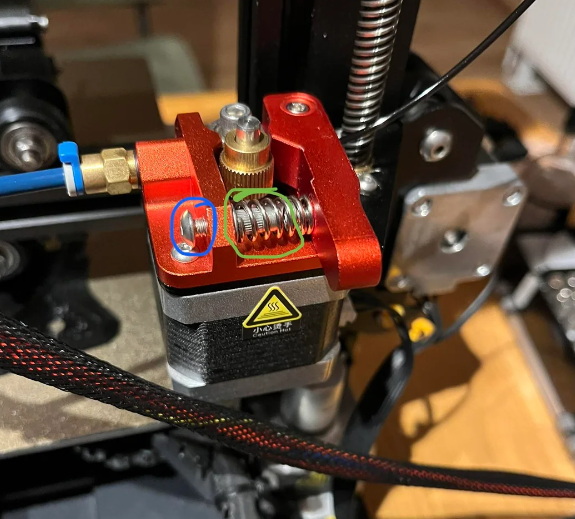

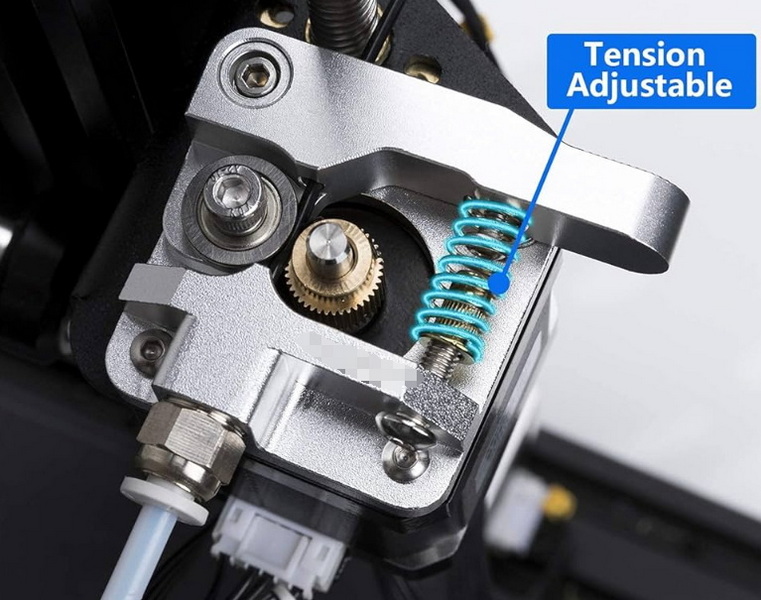

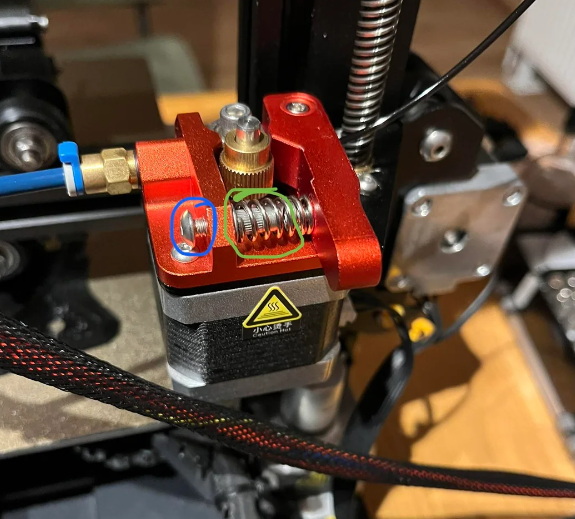

The Role of Adjustable Spring in Aluminum Extruders

An adjustable spring in an aluminum extruder allows for precise control over the tension applied to the material during the extrusion process. This feature is particularly beneficial for several reasons:

- Material Versatility: It enables the extruder to handle different types of materials with varying thicknesses and properties without significant adjustments.

- Consistent Quality: By adjusting the spring tension, you can ensure consistent product quality across different batches.

- Efficiency: The ability to fine-tune the extrusion process reduces waste and improves production speed.

How Adjustable Springs Work

The adjustable spring system typically involves a mechanism where the spring's tension can be adjusted via a screw or lever. This allows operators to customize the pressure applied to the material as it passes through the extruder. For example, softer materials might require less tension to prevent deformation, while harder materials may need more tension to ensure proper shaping.

Aluminum Gutter Extruders

In the context of aluminum gutter extruders, the adjustable spring system is particularly valuable. Seamless gutters are made by extruding aluminum through a die to create a continuous piece that fits the length of a building's roofline. This process eliminates seams, reducing the risk of leaks and improving durability.

Benefits of Seamless Gutters

1. Reduced Maintenance: With fewer seams, there are fewer places for debris to accumulate, reducing the need for frequent cleaning.

2. Durability: Seamless gutters are less prone to leaks and damage, extending their lifespan.

3. Aesthetics: The continuous design provides a sleek appearance that enhances the building's exterior.

How Seamless Gutters Are Made

The process involves feeding a coil of aluminum into an extruder machine, which shapes it into the desired gutter profile. The adjustable spring ensures that the material is properly aligned and formed without excessive stress or deformation.

Emerging Trends in Aluminum Extrusion

The aluminum extrusion industry is continuously evolving with advancements in technology and sustainability. Recent trends include:

- Reducing Carbon Emissions: Efforts are being made to minimize carbon emissions throughout the aluminum production process, enhancing sustainability.

- Rapid Extrusion Profile Inspection: Technologies like Computerized Topology (CAT) X-ray scanning are improving quality control efficiency by eliminating the need for sample preparation.

- Rapid Quench Systems: These systems enhance product quality by ensuring uniform cooling and reducing deformations.

- Higher Strength Aluminum Alloys: New alloys are being developed for applications requiring high strength and durability, such as automotive components.

Applications of Aluminum Extruders

Aluminum extruders are used in a variety of industries, including:

- Construction: For architectural components like window frames, door handles, and, of course, gutters.

- Automotive: Lightweight components such as engine parts and body frames.

- Aerospace: High-strength, lightweight components for aircraft and spacecraft.

- Electronics: Heat sinks and casings for electronic devices.

Advanced Guttering Systems

Innovations in guttering systems include self-cleaning gutters and smart guttering systems. These advanced systems reduce maintenance needs and improve functionality by incorporating features like built-in brushes or solar-powered cleaning mechanisms.

Customization and Design Flexibility

One of the key benefits of aluminum extrusion is its ability to produce complex shapes and designs. This flexibility allows for customization to meet specific project requirements, making it ideal for specialized applications.

Case Study: Sentinel Extruded Aluminium Guttering System

The Sentinel system is a prime example of how aluminum extrusion can be tailored to meet specific needs. It offers a range of profiles and sizes, with options for polyester powder coating to match various architectural styles. This system is popular for self-builds, refurbishments, and housing developments due to its durability, lightweight nature, and ease of installation.

Expanded Applications and Technological Advancements

Automotive Applications

In the automotive sector, aluminum extrusions are increasingly used for structural components due to their high strength-to-weight ratio. This trend is driven by the need for lighter vehicles to improve fuel efficiency and reduce emissions. New technologies like the HyperAl process are being developed to enhance the strength and formability of extruded profiles, making them ideal for components such as rear spring links in electric vehicles.

Aerospace Applications

In aerospace, aluminum extrusions are used for lightweight yet strong components. The precision and customization offered by adjustable spring systems are crucial for meeting the stringent requirements of this industry.

Electronics Applications

Aluminum's high thermal conductivity makes it an excellent material for heat sinks and electronic casings. The ability to produce complex shapes allows for efficient heat dissipation, which is critical in electronic devices.

Emerging Technologies

The integration of artificial intelligence (AI) in aluminum extrusion is transforming the industry by optimizing production processes, improving predictive maintenance, and enhancing die design. This technological advancement ensures that extruders can adapt to changing market demands more effectively.

Sustainability Initiatives

Efforts to reduce carbon emissions in aluminum production are gaining momentum. This includes optimizing the entire supply chain from mining to recycling, ensuring that aluminum extrusion becomes more sustainable and environmentally friendly.

Future Outlook

As the demand for sustainable and efficient manufacturing processes grows, aluminum extruders with adjustable springs are poised to play a significant role. The integration of advanced technologies and sustainable practices will continue to drive innovation in this field, offering opportunities for growth and expansion into new markets.

Role of AI in Predictive Maintenance

AI algorithms can analyze data from sensors embedded in the extrusion machinery to predict potential failures and schedule maintenance, reducing downtime and improving overall efficiency.

Impact of Circular Economy Practices

Adopting circular economy practices, such as recycling and reusing aluminum, can significantly reduce waste and environmental impact. This approach aligns with global sustainability goals and enhances the appeal of aluminum extrusion products.

Potential for 3D Printing Integration

The integration of 3D printing with aluminum extrusion could revolutionize the production of complex components by allowing for rapid prototyping and customization. This combination could open up new possibilities for design innovation and precision.

Conclusion

Choosing an aluminum extruder with an adjustable spring offers numerous benefits for projects requiring precision, versatility, and efficiency. Whether you producing seamless gutters or complex industrial components, this feature ensures consistent quality and adaptability to different materials and designs.

FAQs

1. What are the primary advantages of using an aluminum extruder with an adjustable spring?

The primary advantages include increased versatility in handling different materials, improved product consistency, and enhanced efficiency in production.

2. How does the adjustable spring system contribute to the quality of seamless gutters?

The adjustable spring ensures that the aluminum is properly aligned and formed during extrusion, reducing the risk of defects and improving the overall quality of the seamless gutters.

3. What types of projects benefit most from aluminum extruders with adjustable springs?

Projects that require complex shapes, varying material thicknesses, or high precision benefit significantly from aluminum extruders with adjustable springs.

4. How does the adjustable spring system impact the cost-effectiveness of aluminum extrusion?

By reducing waste and improving production speed, the adjustable spring system can significantly enhance the cost-effectiveness of the extrusion process.

5. Are aluminum extruders with adjustable springs suitable for small-scale production?

Yes, these extruders are suitable for small-scale production due to their flexibility and ability to handle a variety of materials and designs with minimal setup changes.