Content Menu

● What is an Extruder?

● The Rise of Aluminum in 3D Printer Extruders

● Benefits of Using Aluminum Extruders

>> Lightweight Strength

>> Durability and Longevity

>> Enhanced Filament Feeding

>> Heat Dissipation

>> Cost-Effectiveness

>> Versatility and Customization

● Examples of Aluminum Extruders in Popular 3D Printers

● Maintenance Tips for Aluminum Extruders

● The Future of Aluminum Extruders in 3D Printing

● Potential Challenges and Considerations

● Conclusion

● FAQ

>> 1. What types of filaments can I use with a Creality aluminum extruder?

>> 2. How do I know if my current extruder needs an upgrade?

>> 3. Can I install a Creality aluminum extruder on any 3D printer?

>> 4. Is it difficult to install a Creality aluminum extruder?

>> 5. How often should I maintain my aluminum extruder?

● Citations:

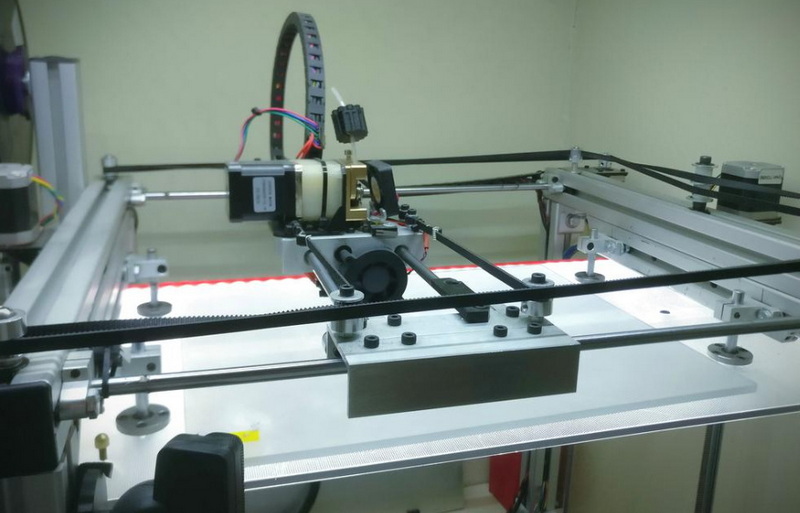

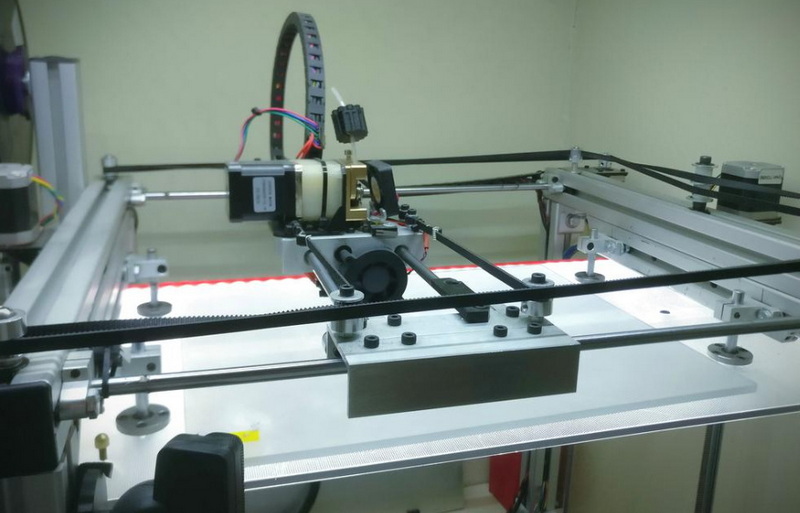

3D printing has revolutionized manufacturing, offering unprecedented flexibility and efficiency. Within this dynamic field, the choice of materials and components significantly impacts the quality, precision, and reliability of printed objects. Among these components, the "extruder" stands out as a critical element responsible for feeding filament, the raw material, into the printer's hot end where it's melted and deposited layer by layer to create the final product.

"Aluminum extruders" have emerged as a popular and advantageous choice in 3D printing due to their unique properties and benefits. This article explores in depth why opting for an aluminum extruder can be a game-changer for your 3D printing endeavors, covering aspects from enhanced printer performance to cost reduction and overall improvement in print quality.

What is an Extruder?

The extruder is essentially the engine of a 3D printer's material deposition system. Its primary function is to precisely control the feeding of filament into the hot end, ensuring a consistent and reliable flow of material for accurate printing.

There are generally two main types of extruders:

- Direct Drive Extruders: These mount the extruder motor and feeding mechanism directly on top of the hot end. This configuration minimizes the distance the filament has to travel, offering better control, especially with flexible filaments.

- Bowden Extruders: In this setup, the extruder motor is located remotely, typically on the printer frame, and the filament is fed to the hot end through a PTFE (Teflon) tube. Bowden extruders reduce the weight on the moving print head, allowing for faster printing speeds but may require more retraction tuning.

The Rise of Aluminum in 3D Printer Extruders

Traditionally, extruders were made from various materials, including plastics and other metals. However, aluminum has gained prominence due to its unique combination of properties perfectly suited for 3D printing applications[1].

Benefits of Using Aluminum Extruders

Lightweight Strength

Aluminum is renowned for its exceptional strength-to-weight ratio[1]. This characteristic is particularly advantageous in 3D printing for several reasons:

- Reduced Printer Weight: A lighter extruder reduces the overall weight of the moving parts of the 3D printer, enabling faster movements and higher print speeds. This is especially important for Bowden extruder setups, where minimizing weight on the print head is crucial[1].

- Improved Stability: Despite being lightweight, aluminum provides sufficient strength to maintain the stability of the extruder assembly. This stability minimizes vibrations during printing, which is essential for achieving high-quality prints with accurate dimensional tolerances[1].

Durability and Longevity

Aluminum extruders exhibit excellent durability and resistance to wear and tear. This is especially crucial considering the continuous operation and mechanical stress that extruders endure during printing.

- Wear Resistance: Aluminum's inherent hardness allows it to withstand prolonged use without significant degradation. This is particularly beneficial for the gears and moving parts within the extruder mechanism, which are subject to constant friction and pressure[5].

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer when exposed to air, making it highly resistant to corrosion. This property ensures that the extruder maintains its structural integrity and performance even in environments with varying humidity levels[1].

Enhanced Filament Feeding

An "aluminum 3D printer extruder" significantly improves the precision and reliability of filament feeding, which directly impacts the quality of the printed object.

- Consistent Extrusion: Aluminum extruders often incorporate advanced gear designs, such as dual-drive mechanisms, which provide a more secure grip on the filament[5]. This reduces slippage and ensures a consistent and uniform flow of material, leading to better layer adhesion and overall print quality.

- Compatibility with Various Filaments: Aluminum extruders are compatible with a wide range of 3D printing filaments, including PLA, ABS, PETG, TPU, and nylon[5]. This versatility allows users to experiment with different materials and applications without having to switch extruders.

Heat Dissipation

Although the hot end is responsible for melting the filament, the extruder itself can generate heat due to friction and motor operation. Aluminum's excellent thermal conductivity helps dissipate this heat, preventing heat creep and potential clogging issues.

- Heat Sink Capability: Aluminum extruders can act as a heat sink, drawing heat away from critical components and maintaining a stable operating temperature[8]. This is particularly important when printing with filaments that are sensitive to temperature fluctuations, such as PLA.

Cost-Effectiveness

Compared to other materials like stainless steel or titanium, aluminum extruders offer a cost-effective solution without compromising on performance and durability[1].

- Efficient Manufacturing: Aluminum extrusion is an efficient and well-established manufacturing process, making it possible to produce aluminum extruders in large quantities at a lower cost[1].

- Long Lifespan: Due to their durability, aluminum extruders have a longer lifespan than plastic counterparts, reducing the need for frequent replacements and minimizing overall costs.

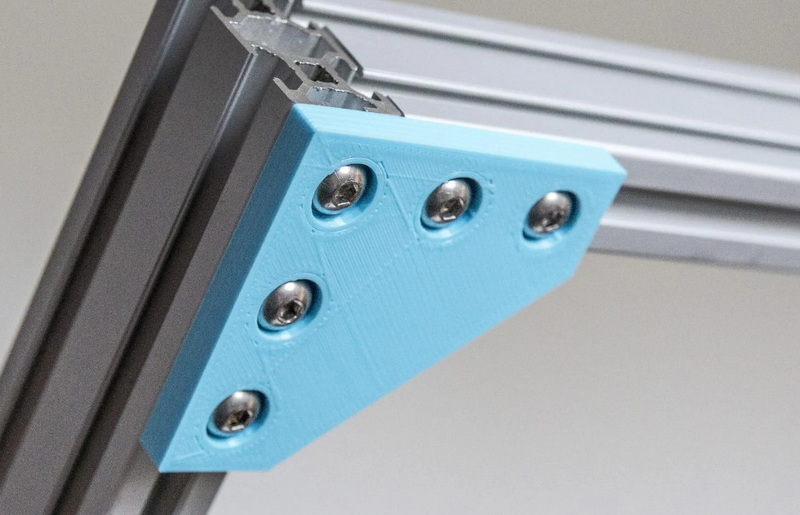

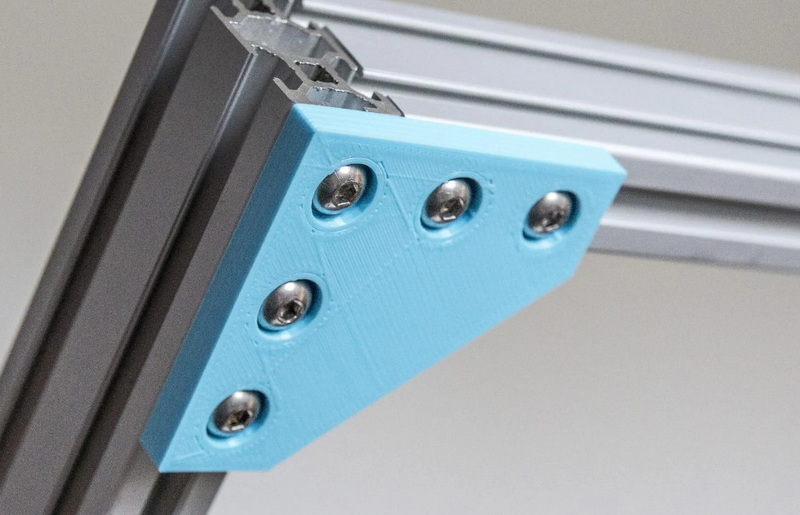

Versatility and Customization

Aluminum extruders are versatile and can be easily machined, modified, or customized to suit specific 3D printing requirements[1].

- Custom Designs: Aluminum extrusions can be designed to accommodate various mounting configurations, gear ratios, and filament guide systems, allowing for tailored solutions for different 3D printer models.

- Easy Integration: Aluminum extruders can be seamlessly integrated with other printer components, such as hot ends, fans, and sensors, ensuring optimal performance and functionality.

Examples of Aluminum Extruders in Popular 3D Printers

Many leading 3D printer manufacturers utilize aluminum extruders in their designs to enhance performance and reliability[1]. Here are a few notable examples:

- Creality Ender Series: The Creality Ender 3 and Ender 5 series are known for their robust aluminum extruders, which provide reliable filament feeding and consistent print quality[1]. The aluminum extruder upgrade for the Ender 3 V2 is a popular modification among 3D printing enthusiasts[4].

- Prusa i3 Series: The Prusa i3 MK3S+ features a well-designed aluminum extruder that contributes to its reputation for precision and dependability[1].

- Dyzextruder Pro: This high-performance extruder is designed for advanced 3D printing applications, featuring an all-metal design for durability and heat resistance[8].

- Red Metal Extruder Kit: This kit offers enhanced extrusion consistency and compatibility with a wide range of filaments[8].

Maintenance Tips for Aluminum Extruders

To ensure optimal performance and longevity of your aluminum extruder, regular maintenance is essential. Here are some helpful tips:

- Cleaning: Periodically clean the extruder gears and filament path to remove any debris or filament residue that may accumulate over time[1]. Use a brush or compressed air to dislodge any particles.

- Inspection: Regularly inspect the extruder for any signs of wear, such as worn gears, loose screws, or damaged components[1]. Replace any worn parts promptly to prevent further damage.

- Lubrication: Apply a small amount of lubricant to the moving parts of the extruder, such as the gears and bearings, to reduce friction and ensure smooth operation[3]. Use a lubricant that is compatible with aluminum and the specific components.

- Tension Adjustment: Check and adjust the tension of the extruder spring or idler arm to ensure proper filament grip[3]. Too much tension can cause filament deformation, while too little tension can lead to slippage.

The Future of Aluminum Extruders in 3D Printing

As 3D printing technology continues to evolve, the role of aluminum extruders is expected to expand, driven by ongoing innovations in materials and manufacturing processes[1].

- Advanced Aluminum Alloys: Research is underway to develop new aluminum alloys with enhanced properties, such as increased strength, improved thermal conductivity, and greater corrosion resistance. These advanced alloys will further enhance the performance and capabilities of aluminum extruders.

- Additive Manufacturing Integration: The integration of aluminum extrusion with additive manufacturing techniques is expected to grow, enabling the creation of more complex and customized extruder designs[1]. This will allow manufacturers to optimize extruders for specific printing applications and materials.

- Smart Extruders: Future aluminum extruders may incorporate sensors and feedback control systems to monitor filament flow, detect clogs, and automatically adjust printing parameters[1]. These smart extruders will improve print quality, reduce waste, and enhance the overall user experience.

Potential Challenges and Considerations

Despite the numerous advantages of using aluminum extruders, there are a few potential challenges and considerations to keep in mind:

- Thermal Expansion: Aluminum has a relatively high coefficient of thermal expansion, which means it expands and contracts more than other materials when subjected to temperature changes. This can affect the precision of the extruder if not properly accounted for in the design.

- Cost: While aluminum extruders are generally cost-effective, high-quality extruders with advanced features can be more expensive than basic plastic models.

- Compatibility: Not all aluminum extruders are compatible with every 3D printer model. It's important to ensure that the extruder you choose is compatible with your printer and its specific requirements.

Conclusion

In conclusion, opting for an "aluminum 3D printer extruder" offers a multitude of benefits that can significantly enhance your 3D printing experience. From its lightweight strength and durability to its enhanced filament feeding and cost-effectiveness, aluminum extruders provide a reliable and versatile solution for a wide range of printing applications. As technology continues to advance, the potential for aluminum in 3D printing will only expand, paving the way for innovative solutions and improved print quality. By understanding the advantages and potential challenges of using aluminum extruders, you can make an informed decision and unlock the full potential of your 3D printer.

FAQ

1. What types of filaments can I use with a Creality aluminum extruder?

Creality aluminum extruders are compatible with a wide range of filaments, including PLA, ABS, PETG, TPU, and nylon[5]. This versatility makes them suitable for various printing applications.

2. How do I know if my current extruder needs an upgrade?

Signs that your current extruder may need an upgrade include inconsistent filament feeding, slippage, wear and tear, and difficulty printing with flexible filaments[5]. Upgrading to an aluminum extruder can address these issues and improve print quality.

3. Can I install a Creality aluminum extruder on any 3D printer?

While Creality aluminum extruders are primarily designed for Creality models like the Ender 3 and CR-10 series, they can often be adapted for use on other 3D printers with some modifications[5]. However, it's essential to check compatibility and follow the manufacturer's instructions for installation.

4. Is it difficult to install a Creality aluminum extruder?

The installation process for a Creality aluminum extruder is generally straightforward and can be completed with basic tools and mechanical skills[5]. Many resources, including video tutorials, are available online to guide you through the process.

5. How often should I maintain my aluminum extruder?

The frequency of maintenance depends on the amount of use and the printing environment. However, it's generally recommended to clean and inspect your aluminum extruder at least once a month or after every 100 hours of printing[1].

Citations:

[1] https://www.yjing-extrusion.com/what-are-the-benefits-of-using-aluminum-extrusion-in-3d-printing.html

[2] https://www.solidprint3d.co.uk/prototyping-aluminium-extrusion-profiles-with-3d-printing/

[3] https://garrettgoss.com/blog/2019/05/extruded-aluminum-3d-printer.html

[4] https://www.youtube.com/watch?v=UtemZqFJ5rY

[5] https://www.yjing-extrusion.com/what-is-a-creality-aluminum-extruder-and-why-should-you-use-it.html

[6] https://top3dshop.com/blog/homemade-frame-pros-and-cons

[7] https://aluminumextrusions.net/prototyping-aluminum-extrusions/

[8] https://blog.goldsupplier.com/metal-extruder/

[9] https://www.reddit.com/r/3Dprinting/comments/lbtobl/what_is_the_benefit_of_a_metal_extruder_for_an/

[10] https://www.yjing-extrusion.com/is-the-ender-3-pro-aluminum-extruder-worth-the-upgrade.html

[11] https://www.cnckitchen.com/blog/which-is-the-strongest-3d-printing-extruder

[12] https://www.yjing-extrusion.com/why-should-you-choose-an-mk8-extruder-aluminum-over-stock-extruders.html

[13] https://garrettgoss.com/blog/2019/05/extruded-aluminum-3d-printer.html

[14] https://www.3deo.co/featured/metal-3d-printing-processes-metal-extrusion-3d-printing/

[15] https://www.azom.com/article.aspx?ArticleID=21232

[16] https://all3dp.com/1/3d-printing-aluminum/

[17] https://forum.v1e.com/t/community-thoughts-on-3d-printed-extrusion-brackets-vs-aluminum/36919

[18] https://jlcmc.com/blog/optimizing-aluminum-extrusion-frames-for-enhanced-3d-printing-accuracy

[19] https://www.reddit.com/r/ender3/comments/eqeddp/the_all_aluminum_extruder_upgrade_is_only_ten/

[20] https://www.reddit.com/r/ender3/comments/roa1rg/i_can_strongly_recommend_this_printable_extruder/

[21] https://www.robotshop.com/collections/aluminum-extrusions-3d-printers

[22] https://www.indiamart.com/proddetail/extruder-kit-left-side-mk8-aluminum-3d-printer-block-2854189265948.html

[23] https://www.reddit.com/r/3Dprinting/comments/16vzxk8/why_does_almost_every_diy_printer_use_aluminium/

[24] https://www.walmart.com/ip/3D-Printer-Accessories-Aluminum-Extruder-Kit-Full-Metal-Feeding-Extruder-for-CR-10MK8/5769821743

[25] https://www.aliexpress.com/w/wholesale-aluminum-extrusion-3d-printer.html

[26] https://support.th3dstudio.com/helpcenter/upgraded-aluminum-extruder-installation-video-v2/

[27] https://cults3d.com/en/tags/aluminum%20extrusion

[28] https://www.youtube.com/watch?v=hbq5H7R1NLg

[29] https://www.alibaba.com/showroom/aluminum-extrusion-3d-printer.html

[30] https://www.youtube.com/watch?v=m6dRh0oVzhc

[31] https://www.youtube.com/watch?v=UtemZqFJ5rY

[32] https://addinor.eu/articles/frequently-asked-questions-metal-3d-printing/

[33] https://www.reddit.com/r/3Dprinting/comments/16o9h0w/what_are_common_aluminum_alloy_extrusions_for_3d/

[34] https://www.creality.com/pages/faq

[35] https://www.voxelmatters.com/everything-you-need-to-know-about-aluminum-3d-printing/

[36] https://community.ultimaker.com/topic/10081-aluminum-extrusion-2020-um2-printer/

[37] https://www.3dnatives.com/en/a-complete-guide-to-aluminum-3d-printing-131220234/

[38] https://makenica.com/everything-to-know-about-3d-printing-extruders/

[39] https://forum.makerforums.info/t/i-seriously-question-the-reasoning-behind-typical-extruder-designs/44931

[40] https://reprap.org/forum/read.php

[41] https://www.youtube.com/watch?v=ikVFselJO4Y

[42] https://hackaday.com/2018/05/08/how-to-build-anything-out-of-aluminum-extrusion-and-3d-printed-brackets/

[43] https://www.youtube.com/watch?v=3L3nPJZo04E

[44] https://www.youtube.com/watch?v=tDrq8q4rCn4

[45] https://www.youtube.com/watch?v=OgI-rJljayY

[46] https://www.yjing-extrusion.com/what-is-a-creality-aluminum-extruder-and-why-should-you-use-it.html

[47] https://www.wevolver.com/article/3d-print-aluminum

[48] https://www.yjing-extrusion.com/can-you-use-an-aluminum-extruder-on-ender-3.html

[49] https://3dformtech.fi/en/blog/3d-printing-metal-answers-to-the-most-common-questions/

[50] https://www.designnews.com/metals/your-aluminum-extrusion-questions-answered