Content Menu

● Understanding Aluminum Extrusion Conveyors

● Key Advantages of Aluminum Extrusion Conveyors

>> 1. Lightweight Design

>> 2. Corrosion Resistance

>> 3. Flexibility and Modularity

>> 4. Cost-Effectiveness

>> 5. Easy Assembly and Modification

>> 6. Aesthetic Appeal

● Environmental Considerations

● Applications of Aluminum Extrusion Conveyors

● Maintenance Considerations

● Conclusion

● Frequently Asked Questions

>> 1. What are the main benefits of using aluminum extrusion conveyors?

>> 2. How do aluminum extrusion conveyors compare in terms of strength?

>> 3. Are aluminum extrusion conveyors suitable for outdoor use?

>> 4. Can I modify an existing aluminum extrusion conveyor system?

>> 5. What industries commonly use aluminum extrusion conveyors?

In the world of industrial manufacturing and logistics, conveyor systems play a crucial role in enhancing productivity and efficiency. Among the various materials used for constructing these systems, aluminum extrusion conveyors have gained significant traction over their steel counterparts. This article delves into the numerous advantages of aluminum extrusion conveyors, highlighting why they are often the preferred choice in modern manufacturing environments.

Understanding Aluminum Extrusion Conveyors

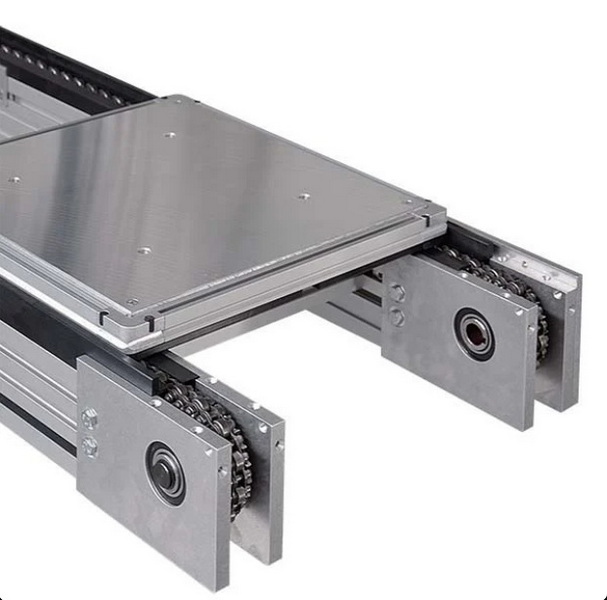

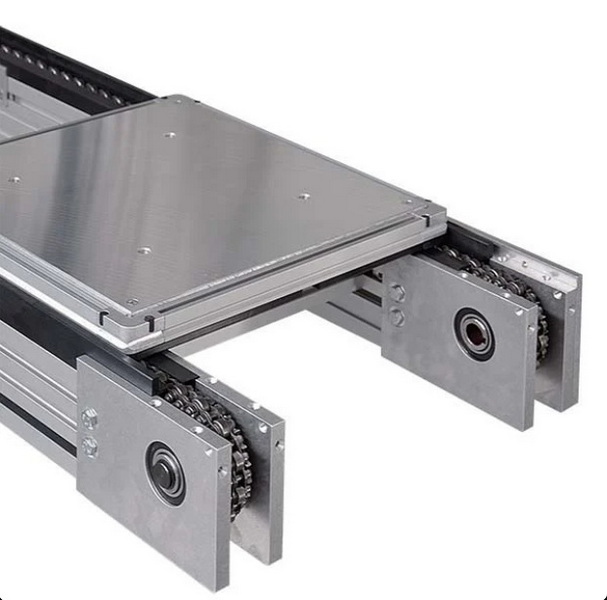

Aluminum extrusion is a manufacturing process that involves shaping aluminum by forcing it through a die to create a specific cross-sectional profile. This method allows for the creation of lightweight yet strong components that can be easily assembled into versatile structures. The resulting aluminum extrusion conveyors are not only robust but also offer a range of benefits that make them superior to traditional steel conveyors.

Key Advantages of Aluminum Extrusion Conveyors

1. Lightweight Design

One of the most significant advantages of aluminum extrusion conveyors is their lightweight nature. Aluminum is approximately one-third the weight of steel, making it easier to handle and install. This reduction in weight translates to lower operational costs as less energy is required to move and operate the conveyors.

The lightweight design also facilitates quicker installation and setup times, which is crucial in industries where time is money. Companies can reduce downtime during installation or modifications, allowing for a more agile response to changing production demands.

2. Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to air, which makes it highly resistant to corrosion. Unlike steel, which can rust and deteriorate over time, aluminum maintains its structural integrity even in harsh environments. This property is particularly beneficial in industries where exposure to moisture or chemicals is common.

For instance, in food processing and pharmaceutical applications, where hygiene is paramount, aluminum's resistance to corrosion ensures that the conveyor system does not contaminate products or require frequent replacements due to rust damage.

3. Flexibility and Modularity

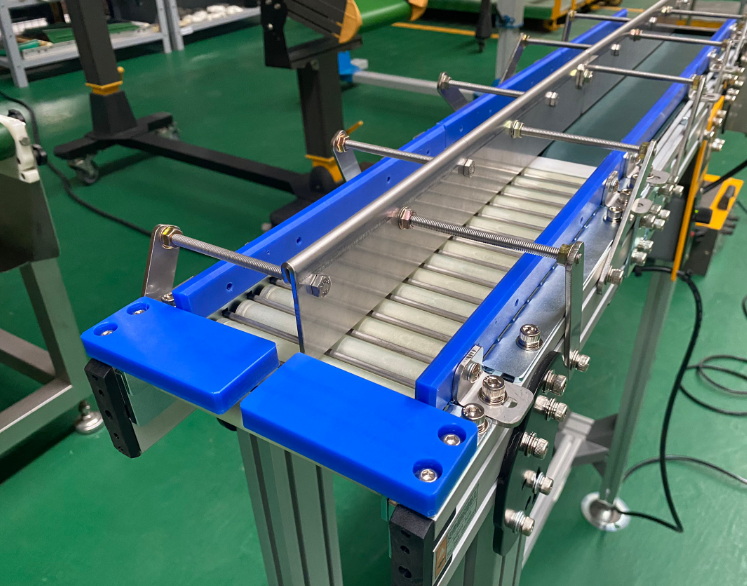

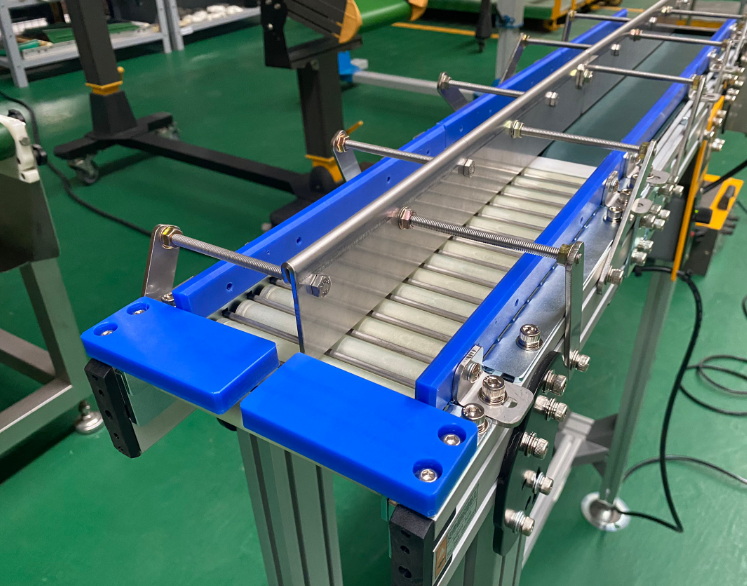

Aluminum extrusion conveyors are designed with modular components that can be easily reconfigured or expanded as needed. This flexibility allows manufacturers to adapt their conveyor systems to changing production demands without incurring significant downtime or additional costs associated with custom fabrication.

The modular design also means that if a specific section of the conveyor needs to be upgraded or replaced, it can be done with minimal disruption to the overall system. This adaptability is particularly valuable in industries where product lines frequently change or evolve.

4. Cost-Effectiveness

While the initial cost of aluminum may be higher than steel, the long-term savings associated with maintenance, energy efficiency, and durability often make aluminum extrusion conveyors more cost-effective over time. The reduced need for repairs and replacements due to corrosion or wear contributes to lower total ownership costs.

Moreover, because aluminum is lighter, it often requires less energy for operation compared to heavier steel systems. This energy efficiency can lead to significant cost savings on electricity bills over time.

5. Easy Assembly and Modification

The assembly process for aluminum extrusion conveyors is straightforward, often requiring no specialized tools or skills. The use of t-slot profiles allows for quick connections between components, enabling rapid adjustments or modifications as production needs evolve.

This ease of assembly not only reduces labor costs but also empowers teams to make changes on-the-fly without waiting for external contractors or specialists, thereby increasing operational efficiency.

6. Aesthetic Appeal

Aluminum has a sleek, modern appearance that can enhance the overall look of a manufacturing facility. Its aesthetic appeal can contribute positively to workplace morale and create a more inviting environment for employees and visitors alike.

In industries where customer interaction occurs on-site, such as food processing plants or assembly facilities open for tours, maintaining an appealing environment can reflect positively on the brand's image.

Environmental Considerations

In today's eco-conscious world, choosing sustainable materials is more important than ever. Aluminum extrusion conveyors are an environmentally friendly option for several reasons:

- Recyclability: Aluminum is 100% recyclable without loss of quality. This means that at the end of its life cycle, aluminum components can be melted down and reused indefinitely.

- Energy Efficiency: The lightweight nature of aluminum reduces energy consumption during transportation and operation compared to heavier materials like steel.

- Reduced Waste: The modular design minimizes waste during manufacturing and allows for easy upgrades instead of complete replacements.

Applications of Aluminum Extrusion Conveyors

Aluminum extrusion conveyors are utilized across various industries due to their versatility and reliability. Common applications include:

- Automotive Manufacturing: For transporting parts during assembly lines where precision and speed are crucial.

- Food Processing: Where hygiene and corrosion resistance are paramount; these conveyors can be designed with smooth surfaces that facilitate cleaning.

- Pharmaceuticals: In environments requiring strict cleanliness standards; aluminum's non-reactive nature ensures product safety.

- Electronics: For handling sensitive components without risk of damage; aluminum's lightweight properties reduce stress on delicate parts.

- Packaging: In packaging lines where flexibility and quick adjustments are necessary; aluminum conveyors can easily accommodate different packaging sizes and shapes.

Maintenance Considerations

While aluminum extrusion conveyors require less maintenance than steel systems due to their corrosion resistance, regular upkeep is still essential for longevity:

- Routine Inspections: Regular checks for wear on moving parts ensure that any issues are addressed before they lead to failures.

- Cleaning: Keeping surfaces clean prevents buildup that could affect performance; this is especially important in food processing environments.

- Lubrication: Proper lubrication of moving parts helps maintain smooth operation and prolongs the life of the conveyor system.

Conclusion

Choosing aluminum extrusion conveyors over steel offers numerous benefits that can enhance operational efficiency, reduce costs, and improve workplace safety. Their lightweight design, corrosion resistance, flexibility, cost-effectiveness, ease of assembly, aesthetic appeal, and environmental sustainability make them an ideal choice for modern manufacturing environments.

As industries continue to evolve towards more efficient and sustainable practices, aluminum extrusion conveyors stand out as a forward-thinking solution that meets both current needs and future challenges.

Frequently Asked Questions

1. What are the main benefits of using aluminum extrusion conveyors?

Aluminum extrusion conveyors offer lightweight construction, corrosion resistance, modularity for easy adjustments, cost savings over time due to lower maintenance needs, aesthetic appeal, and environmental sustainability.

2. How do aluminum extrusion conveyors compare in terms of strength?

While steel has higher tensile strength than aluminum, aluminum's strength-to-weight ratio makes it suitable for many applications where weight savings are critical without compromising structural integrity.

3. Are aluminum extrusion conveyors suitable for outdoor use?

Yes, aluminum's natural resistance to corrosion makes it an excellent choice for outdoor applications where exposure to moisture is likely.

4. Can I modify an existing aluminum extrusion conveyor system?

Absolutely! One of the key advantages of aluminum extrusion systems is their modular design, allowing for easy modifications or expansions as production needs change without significant downtime.

5. What industries commonly use aluminum extrusion conveyors?

Industries such as automotive manufacturing, food processing, pharmaceuticals, electronics, packaging, and logistics frequently utilize aluminum extrusion conveyors due to their numerous advantages in efficiency and adaptability.