Content Menu

● Introduction to Aluminum Extrusion

>> Key Players in the Midwest

● Advantages of Aluminum Extrusion

● Midwest as a Hub

>> Role of the Automotive Industry

>> Impact of Technological Advancements

● Cost Considerations

>> Raw Material Volatility

● Custom Aluminum Extrusions

>> Sustainability Initiatives

● Future Trends and Technologies

>> Impact of Global Competition

● Regional Analysis

>> Market Growth and Projections

● Conclusion

● Frequently Asked Questions

>> 1. What is the Midwest Premium in Aluminum Pricing?

>> 2. How Does the Midwest Location Benefit Aluminum Extruders?

>> 3. What Are the Key Advantages of Aluminum Extrusion?

>> 4. How Can Costs Be Reduced in Custom Aluminum Extrusions?

>> 5. What Role Do Companies Like SAF Midwest Play in the Industry?

● Citations:

The Midwest region of the United States has emerged as a significant hub for aluminum extrusion due to its strategic location, robust infrastructure, and strong demand from various industries such as automotive and construction. This article will delve into the reasons behind the Midwest's prominence in aluminum extrusion, highlighting key players, processes, and benefits associated with this industry.

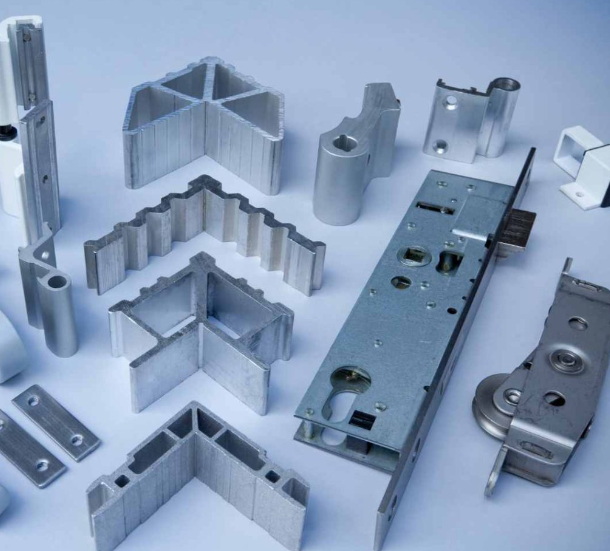

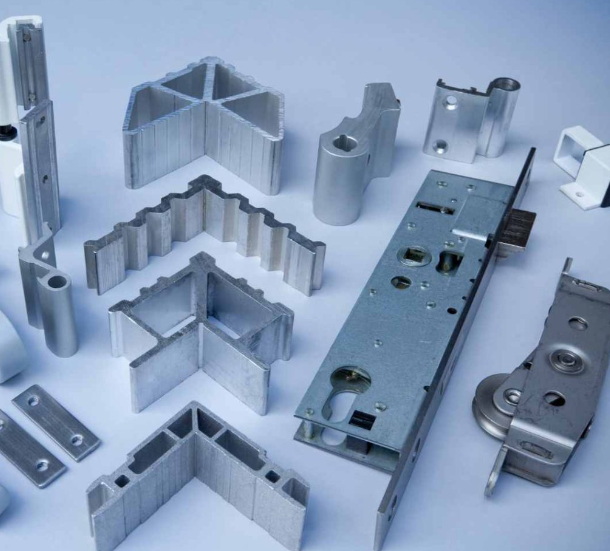

Introduction to Aluminum Extrusion

Aluminum extrusion is a manufacturing process where aluminum is forced through a die to create a desired shape. This process is widely used in producing components for various sectors, including construction, automotive, and aerospace. The Midwest's role in this industry is multifaceted, involving both production and distribution.

Key Players in the Midwest

Companies like SAF Midwest and Wakefield Extrusion are prominent players in the Midwest aluminum extrusion market. SAF Midwest, located in Indianapolis, offers a comprehensive range of aluminum extrusions and fabrication services, catering to commercial construction and architectural needs. Wakefield Extrusion, with facilities in the Northeast and Midwest, provides custom aluminum extrusions, serving thousands of customers across the U.S..

Advantages of Aluminum Extrusion

Aluminum extrusion offers several advantages, including:

1. Energy Efficiency: The process is energy-efficient, especially when compared to other metalworking processes.

2. High Precision: Extrusions can achieve high precision, although they may require additional processing for optimal surface quality.

3. Increased Strength: Products made through extrusion have increased strength due to their homogeneous structure.

4. Design Versatility: Aluminum extrusions can be customized to fit specific design requirements, making them versatile for various applications.

Midwest as a Hub

The Midwest is strategically positioned to serve as a hub for aluminum extrusion due to its:

- Central Location: The region's central location facilitates efficient distribution across the U.S., making it an ideal spot for both domestic and international trade.

- Strong Demand: Industries like automotive and construction drive demand for aluminum extrusions, contributing to the region's economic growth.

- Infrastructure: The Midwest boasts well-developed infrastructure, including transportation networks and manufacturing facilities, which support the extrusion industry.

Role of the Automotive Industry

The automotive industry plays a crucial role in driving demand for aluminum extrusions in the Midwest. The need for lightweight materials to enhance fuel efficiency and reduce emissions has led to increased use of aluminum in vehicle manufacturing. This trend is expected to continue, with advancements in aluminum extrusion technology supporting the production of complex, high-strength profiles necessary for critical automotive components.

Impact of Technological Advancements

Technological advancements in aluminum extrusion have significantly improved the efficiency and precision of the extrusion process. The integration of Industry 4.0 technologies, such as automation, data analytics, and machine learning, enhances process efficiency, optimizes production, and enables predictive maintenance. These advancements are crucial for maintaining competitiveness in the global market and addressing the challenges posed by fluctuating raw material costs and intense competition.

Cost Considerations

The cost of aluminum extrusions can be influenced by several factors, including:

- Material Costs: Fluctuations in aluminum prices, such as the Midwest Premium, affect production costs.

- Design Complexity: Simplifying designs and reducing material usage can lower costs.

- Supply Chain Efficiency: Integrating value-added services can streamline production and reduce overall costs.

Raw Material Volatility

One of the primary challenges faced by aluminum extrusion manufacturers is the volatility in raw material costs. Aluminum prices fluctuate continuously due to global economic conditions, geopolitical factors, and supply chain disruptions. These fluctuations can significantly impact production costs and profit margins, making it crucial for manufacturers to employ effective cost management strategies[2].

Custom Aluminum Extrusions

Custom aluminum extrusions offer tailored solutions for specific applications, enhancing design flexibility and material efficiency. This approach is particularly beneficial for industries requiring unique profiles or complex shapes. The use of advanced technologies, such as high-pressure extrusion and automation, allows for the production of complex profiles with minimal deformation, which is crucial for aerospace and automotive components requiring high precision and resilience[3].

Sustainability Initiatives

Sustainability initiatives are critical to the aluminum extrusion industry, with a focus on reducing waste, energy usage, and CO2 generation. Lean management practices and automation play significant roles in these efforts. For instance, automating processes like skimming and scrap charging can reduce energy usage and CO2 generation by up to 30%[4].

Future Trends and Technologies

The future of aluminum extrusion is shaped by emerging trends and technologies. Innovations such as rapid extrusion profile inspection using Computerized Topology (CAT) X-ray scanning enhance efficiency and accuracy in quality control. Additionally, the development of higher strength aluminum alloys and the integration of artificial intelligence in the extrusion process are expected to further drive industry growth[5].

Impact of Global Competition

The U.S. aluminum extrusion market faces significant challenges from global competition, particularly from China. The structure of the existing Section 232 exclusion process makes it difficult for domestic aluminum extrusion companies to compete with foreign manufacturers. Despite these challenges, the U.S. market is expected to grow, driven by increasing demand for lightweight materials and advancements in manufacturing technologies[7].

Regional Analysis

The U.S. aluminum extrusion market is geographically segmented into different regions, each with its unique characteristics and drivers. The Midwest, known for its automotive manufacturing sector, is a key region for aluminum extrusion due to the demand for lightweight materials. Other regions, such as the West Coast and Northeast, also play significant roles in the market, driven by industries like aerospace and construction[1].

Market Growth and Projections

The U.S. aluminum extrusion market is projected to grow at a CAGR of 4.02% from 2024 to 2032, reaching 4.1 million tons by 2032[6]. This growth is driven by increasing demand for extruded products in industries such as construction, automotive, and aerospace. The market also benefits from technological innovations and product enhancements, which improve efficiency and reduce costs.

Conclusion

The Midwest's status as a hub for aluminum extrusion is supported by its strategic location, robust infrastructure, and strong demand from key industries. Companies like SAF Midwest and Wakefield Extrusion play crucial roles in this sector, offering a range of services from standard to custom extrusions. Understanding the advantages and cost considerations of aluminum extrusion can help businesses optimize their supply chains and product designs.

Frequently Asked Questions

1. What is the Midwest Premium in Aluminum Pricing?

The Midwest Premium refers to the regional pricing of aluminum in the Midwest, influenced by factors such as energy costs, transportation expenses, and global market conditions.

2. How Does the Midwest Location Benefit Aluminum Extruders?

The Midwest's central location facilitates efficient distribution and supports strong demand from industries like automotive and construction, making it an ideal hub for aluminum extruders.

3. What Are the Key Advantages of Aluminum Extrusion?

Aluminum extrusion offers advantages such as energy efficiency, high precision, increased strength, and design versatility, making it a preferred manufacturing process for various applications.

4. How Can Costs Be Reduced in Custom Aluminum Extrusions?

Costs can be reduced by simplifying designs, reducing material usage, and streamlining the supply chain through value-added services.

5. What Role Do Companies Like SAF Midwest Play in the Industry?

Companies like SAF Midwest provide comprehensive aluminum extrusion and fabrication services, catering to commercial construction and architectural needs, and contributing to the Midwest's prominence in the industry.

Citations:

[1] https://markwideresearch.com/united-states-aluminum-extrusion-market/

[2] https://www.atieuno.com/2023/10/09/aluminium-extrusion-manufacturers/

[3] https://nationalindustries.world/2025/01/02/the-future-of-aluminum-how-extrusion-technology-is-transforming-industries/

[4] https://www.psiextrusions.com/blog/innovations-in-aluminum-extrusion-sustainability-and-ai/

[5] https://profileprecisionextrusions.com/the-evolution-of-aluminum-extrusions-emerging-trends-and-technologies/

[6] https://www.imarcgroup.com/united-states-aluminum-extrusion-market

[7] https://www.lightmetalage.com/news/industry-news/extrusion/aec-testifies-u-s-aluminum-extruders-disadvantaged-by-exclusion-process/

[8] https://www.grandviewresearch.com/industry-analysis/us-aluminum-extrusion-market-report

[9] https://taberextrusions.com/not-just-a-new-years-resolution-aluminum-extrusion-sustainability/

[10] https://www.richardsonmetals.com/innovations-in-aluminum-extrusion-pioneering-precision-and-quality/

[11] https://www.thebusinessresearchcompany.com/report/aluminum-extrusion-global-market-report

[12] https://www.linkedin.com/pulse/3-major-challenges-aluminum-extruders-face-commonly-warren-kang-vrnbc

[13] https://www.lightmetalage.com/news/industry-news/extrusion/superior-extrusion-secures-its-future-with-new-expansion/

[14] https://aluminum-extrusions.net/mi-metals-2/

[15] https://www.recyclingtoday.com/news/atomic-13-reshaping-the-aluminum-extrusion-industry/

[16] https://www.cognitivemarketresearch.com/aluminum-extrusion-market-report

[17] https://aluminumextruderscoalition.com/news/

[18] https://www.aluminum.org/investment

[19] https://nanshanusa.com/low-carbon-aluminum-manufacturing/

[20] https://www.hydro.com/en/global/about-hydro/hydro-worldwide/americas/united-states/midwest/