Content Menu

● Introduction to Medical Tubing Extrusion

>> Importance of Quality Control

● Standards and Regulations

>> Compliance with Regulations

● Key Factors in Selecting a Medical Tubing Extrusion Manufacturer

>> Role of Advanced Technology

● Industry Leaders in Medical Tubing Extrusion

>> Customization and Innovation

● Future Trends in Medical Tubing Extrusion

>> Emerging Technologies

● Conclusion

● FAQs

>> 1. What are the key materials used in medical tubing extrusion?

>> 2. How does quality control impact medical tubing extrusion?

>> 3. What are the main regulations governing medical tubing extrusion?

>> 4. Why is customization important in medical tubing extrusion?

>> 5. How does advanced technology enhance medical tubing extrusion?

● Citations:

The selection of a medical tubing extrusion manufacturer is a critical decision that impacts the quality, safety, and effectiveness of medical devices. Medical tubing plays a vital role in various healthcare applications, including catheters, intravenous lines, and surgical tools. Ensuring that these tubes meet stringent quality standards is essential to prevent adverse reactions and ensure patient safety. In this article, we will explore the importance of quality in selecting a medical tubing extrusion manufacturer and highlight key factors to consider during this process.

Introduction to Medical Tubing Extrusion

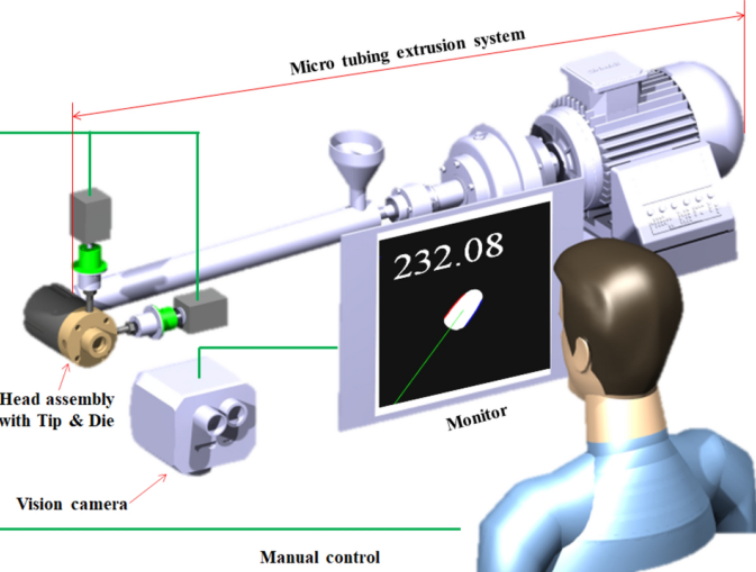

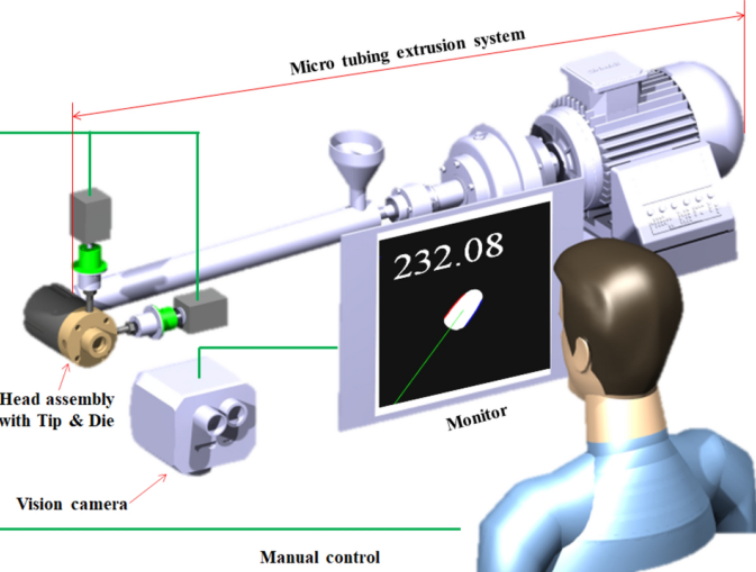

Medical tubing extrusion is a process that involves melting raw materials and shaping them into precise tubes. These tubes must adhere to strict medical standards to ensure biocompatibility, durability, and performance under different conditions. The process involves feeding raw materials into an extruder, heating them, and pushing them through a die to achieve the desired shape. The resulting tubes are then cooled and cut to the required lengths.

Importance of Quality Control

Quality control is paramount in medical tubing extrusion. It involves several stages, including raw material inspection, in-process monitoring, dimensional measurement, visual inspection, and functional testing. Each stage ensures that the tubing meets the required specifications and standards.

- Raw Material Inspection: Ensures that the materials used are free from contaminants and meet the required purity standards.

- In-Process Controls: Monitors temperature, pressure, and line speed to maintain uniform properties.

- Dimensional Measurement: Verifies the accuracy of the tubing's diameter and wall thickness.

- Visual Inspection: Checks for surface defects or discolorations.

- Leak Testing: Tests for leaks under high pressure to ensure the tubing does not compromise during use.

- Functional Testing: Conducts additional tests to verify performance under specific conditions.

Standards and Regulations

Medical tubing extrusion is subject to various national and international standards and regulations. These include:

- ISO 10993 (Biological evaluation of medical devices): Ensures biological safety.

- USP Class VI (United States Pharmacopeia Class VI): Specifies tests for material compatibility with bodily fluids.

- FDA 21 CFR Part 820 (Quality System Regulation): Mandates robust quality management systems.

- EU MDR (Medical Device Regulation): Outlines safety and performance benchmarks for devices sold in the European Economic Area.

Compliance with Regulations

Manufacturers must comply with these regulations by implementing quality management systems, conducting regular audits, and maintaining detailed documentation. Compliance ensures that products are safe for use and meet the required performance standards.

Key Factors in Selecting a Medical Tubing Extrusion Manufacturer

When selecting a medical tubing extrusion machinery manufacturer, several factors should be considered:

1. Experience and Expertise: Look for manufacturers with extensive experience in producing medical-grade tubing. Their expertise ensures that products meet stringent quality standards.

2. Quality Control Measures: Ensure the manufacturer has robust quality control processes in place to monitor and maintain product quality throughout production.

3. Material Selection: The manufacturer should offer a range of biocompatible materials suitable for different medical applications.

4. Customization Capabilities: The ability to customize tubing to specific requirements is crucial for meeting unique application needs.

5. Regulatory Compliance: Ensure the manufacturer complies with relevant regulations and standards.

6. Innovation and Technology: Manufacturers that invest in advanced technology and innovation can offer more precise and efficient production processes.

Role of Advanced Technology

Advanced technology plays a significant role in enhancing the quality and efficiency of medical tubing extrusion. Features such as real-time monitoring systems, precision dies, and automated calibration ensure consistent product quality and reduce production variability.

Industry Leaders in Medical Tubing Extrusion

Several companies are prominent in the medical tubing extrusion industry:

- Compagnie de Saint-Gobain S.A.: Known for its diverse materials and solutions.

- Teleflex Incorporated: Specializes in single-use medical devices.

- Optinova Holding AB: A leading extrusion partner for advanced medical tubing.

- Zeus Industrial Products, Inc.: Offers advanced polymer solutions.

- Duke Extrusion: Provides custom medical tubing solutions with a focus on innovation and quality.

Customization and Innovation

Customization is key in medical tubing extrusion. Manufacturers like Duke Extrusion offer tailored solutions to meet specific application requirements, ensuring that products are optimized for performance and safety.

Future Trends in Medical Tubing Extrusion

The future of medical tubing extrusion is shaped by advancements in technology and materials. Innovations such as microextrusion and multi-lumen tubing are enhancing the precision and functionality of medical devices. Automation and smart manufacturing technologies are also transforming the production process, enabling more efficient and adaptable manufacturing lines.

Emerging Technologies

Emerging technologies, including real-time analytics and IoT, are expected to further enhance quality control and production efficiency. These advancements will allow for more systematic and adaptive manufacturing processes, better aligning with evolving healthcare needs.

Conclusion

Selecting a high-quality medical tubing extrusion machinery manufacturer is crucial for ensuring the safety and effectiveness of medical devices. By focusing on quality control, regulatory compliance, customization capabilities, and technological innovation, manufacturers can produce tubing that meets the stringent standards required in healthcare applications. As technology continues to evolve, the future of medical tubing extrusion looks promising, with potential for even more precise and efficient production processes.

FAQs

1. What are the key materials used in medical tubing extrusion?

- Common Materials: Polyvinyl chloride (PVC), thermoplastic elastomers (TPE), silicone, and polyethylene are commonly used due to their biocompatibility and durability.

2. How does quality control impact medical tubing extrusion?

- Quality Control Impact: Quality control ensures that tubing meets precise specifications and standards, preventing defects that could compromise patient safety.

3. What are the main regulations governing medical tubing extrusion?

- Regulations: Key regulations include ISO 10993, USP Class VI, FDA 21 CFR Part 820, and EU MDR, which ensure biological safety and performance standards.

4. Why is customization important in medical tubing extrusion?

- Customization Importance: Customization allows tubing to be tailored to specific medical applications, ensuring optimal performance and safety in diverse healthcare settings.

5. How does advanced technology enhance medical tubing extrusion?

- Technology Advancements: Advanced technologies improve precision, efficiency, and adaptability in production, enabling real-time monitoring and predictive maintenance to enhance quality control.

Citations:

[1] https://jbmedical.com.au/how-medical-tubing-extrusion-equipment-meets-stringent-standards/

[2] https://www.mddionline.com/materials/medtech-extrusion-it-all-starts-with-the-materials

[3] https://www.bausano.com/en/press-and-news/medical-tube-extrusion

[4] https://www.supermacindia.com/tube-line-for-medical-industry.html

[5] https://www.coherentmarketinsights.com/blog/insights/top-companies-medical-tubing-industry-90

[6] https://www.dukeextrusion.com

[7] https://extrudex.de/en/products/extrusion-lines/medical-tubing

[8] https://www.youtube.com/watch?v=CDfozHaewcY

[9] https://jieyatwinscrew.com/blog/medical-tubing-extrusion-equipment/

[10] https://jieyatwinscrew.com/blog/what-is-a-medical-extruder/

[11] https://aptyx.com/solutions/extrusion/

[12] https://www.youtube.com/watch?v=ZeDQFAjKdMg

[13] https://www.twinscrew.net/en/article/Medical-Tube-Extrusion-101.html

[14] https://www.dukeextrusion.com/medical-extrusion-materials

[15] https://www.dukeempirical.com/videos

[16] https://www.mpo-mag.com/medical-tubing-extrusion-experts-offer-perspectives-on-industry/

[17] https://www.pixargus.com/products/tubes-pipes-and-cables/profilcontrol-7-surface-medictube/

[18] https://www.bausano.com/en/applications/extrusion-lines-for-medical-sector/medical-tubing

[19] https://www.supermacindia.com/blog/medical-tubing-extrusion-and-its-importance-healthcare-industry/

[20] https://www.maillefer.net/en/application/medical-tube-production/

[21] https://www.tomindmed.com/The-Role-of-Medical-Extrusion-in-Producing-High-Quality-Medical-Tubing-id40201546.html

[22] https://www.twinscrew.net/en/article/medical-tube-extrusion-line.html

[23] https://www.medicaldesignbriefs.com/component/content/article/26544-getting-the-most-from-your-extrusion-tooling

[24] https://www.medicaldesignbriefs.com/component/content/article/52164-maximizing-the-potential-of-tpu-extrusion-in-medical-tubing-applications

[25] https://www.news-medical.net/whitepaper/20171018/The-Route-to-Quality-and-Performance-of-Medical-Device-Tubing.aspx

[26] https://www.mddionline.com/cardiovascular/critical-factors-in-extruding-catheter-tubing-from-polyamide

[27] https://www.medicaltubingandextrusion.com

[28] https://www.medicaldevicedirectory.com/category/manufacturing-equipment/material-processing-equipment/extrusion-equipment

[29] https://www.marketsandmarkets.com/ResearchInsight/medical-tubing-market.asp

[30] https://www.coherentmarketinsights.com/market-insight/medical-plastic-extrusion-market-2620/companies

[31] https://www.alibaba.com/showroom/medical-tube-extrusion-machine.html

[32] https://www.grahamengineering.com/products-solutions/extrusion-systems/medical-tubing/

[33] https://medical-tubing.medicaltechoutlook.com/vendors/top-medical-tubing-companies.html

[34] http://www.medicaltubingextruders.com

[35] https://www.twinscrew.net/en/application/Medical-Tubing-Extrusion_.html

[36] https://www.cathetermachine.com/Product/1051

[37] https://multishine.en.made-in-china.com/product/ZdbAMVsYkqrP/China-PTFE-Medical-Tube-Extrusion-Machine.html

[38] https://www.shutterstock.com/search/tubing-extrusion-machines

[39] https://www.youtube.com/watch?v=1wPygT3UFKM

[40] https://www.alamy.com/stock-photo/medical-tubing.html

[41] https://www.youtube.com/watch?v=mTgzggagIeU

[42] https://www.shutterstock.com/search/extrusion-machine

[43] https://www.hmg-extrusions.at/hmg-extrusions-medical-tube-extrusion-line/

[44] https://www.youtube.com/watch?v=Q3GCHGE_9Oc

[45] https://www.made-in-china.com/products-search/hot-china-products/Medical_Tube_Extrusion_Line.html

[46] https://www.istockphoto.com/photos/medical-tubing

[47] https://www.youtube.com/watch?v=qIkT_QgTCP8

[48] https://medicalbuyer.co.in/understanding-extrusion-manufacturing-process-in-medtech-industry/

[49] https://www.pbsplastics.com/extrusion-styles/tubing-medical/

[50] https://sikora.net/en/quality-assurance-of-medical-tubes/

[51] https://www.cowellextrusion.com/top-10-plastic-extrusion-machine-manufacturers/

[52] https://www.medicaltubingandextrusion.com/suppliers/

[53] https://qmed.com/tubing-and-extrusion-code005412.html

[54] https://www.flexan.com/en/manufacturing/extrusion