Content Menu

● The Aluminum Extrusion Process

● Advantages of Aluminum as an Extrusion Mold Material

>> Lightweight Yet Strong

>> Thermal Conductivity

>> Corrosion Resistance

>> Design Flexibility

>> Cost-Effectiveness

● The Extrusion Mold Design Process

● Innovations in Aluminum Extrusion Mold Technology

>> 3D Printing of Molds

>> Smart Molds

>> Advanced Coatings

● Applications of Aluminum Extrusions

>> Automotive Industry

>> Aerospace

>> Construction

>> Electronics

● Environmental Benefits of Aluminum Extrusion Molds

>> Recyclability

>> Energy Efficiency

>> Lightweight Products

● Challenges and Considerations

>> Wear and Tear

>> Initial Cost

>> Skill Requirements

● Conclusion

● Frequently Asked Questions

>> 1. What is the lifespan of an aluminum extrusion mold?

>> 2. How does the cost of aluminum extrusion molds compare to other materials?

>> 3. Can aluminum extrusion molds be used for all types of aluminum alloys?

>> 4. How do aluminum extrusion molds impact the surface finish of the final product?

>> 5. Are there any limitations to the shapes that can be created with aluminum extrusion molds?

● Citations:

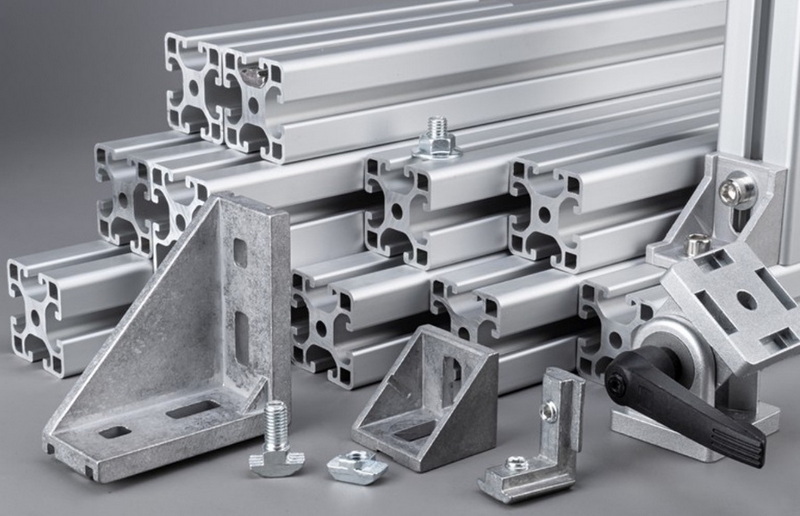

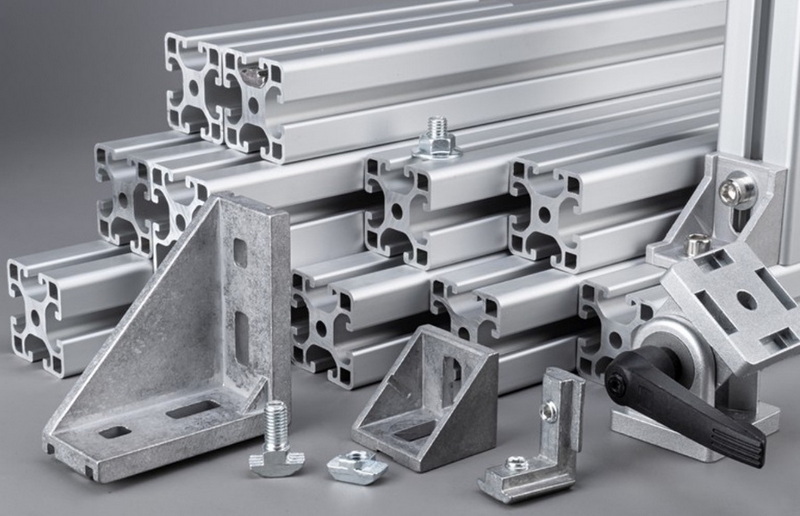

Aluminum extrusion is a versatile manufacturing process that has revolutionized various industries, from automotive and aerospace to construction and electronics. At the heart of this process lies the aluminum extrusion mold, a critical component that shapes molten aluminum into intricate profiles and shapes. In this comprehensive article, we'll explore why aluminum is the preferred material for extrusion molds and delve into the numerous advantages it offers.

The Aluminum Extrusion Process

Before we dive into the benefits of aluminum extrusion molds, let's briefly review the extrusion process itself.

The aluminum extrusion process involves the following steps:

1. Heating aluminum billets to near-melting temperatures

2. Forcing the heated aluminum through a die (the extrusion mold)

3. Shaping the aluminum into the desired profile

4. Cooling and finishing the extruded product

Advantages of Aluminum as an Extrusion Mold Material

Lightweight Yet Strong

One of the primary reasons aluminum is an excellent choice for extrusion molds is its unique combination of light weight and strength. Aluminum extrusion molds are significantly lighter than their steel counterparts, making them easier to handle and transport. This lightweight nature doesn't compromise on strength, as aluminum can be alloyed and heat-treated to achieve impressive strength-to-weight ratios.

Thermal Conductivity

Aluminum's exceptional thermal conductivity is a crucial factor in its suitability for extrusion molds. During the extrusion process, heat management is essential to maintain consistent product quality. Aluminum molds efficiently conduct heat, allowing for:

- Rapid heating and cooling of the mold

- Uniform temperature distribution across the mold surface

- Improved control over the extrusion process

Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to air, making it highly resistant to corrosion. This inherent property extends the lifespan of aluminum extrusion molds, reducing maintenance costs and downtime. The corrosion resistance of aluminum molds is particularly beneficial in environments where moisture or chemical exposure is a concern.

Design Flexibility

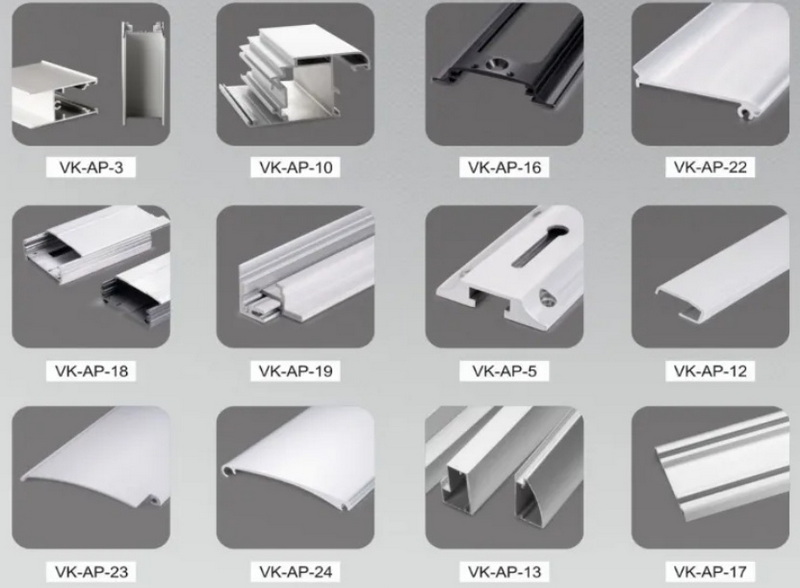

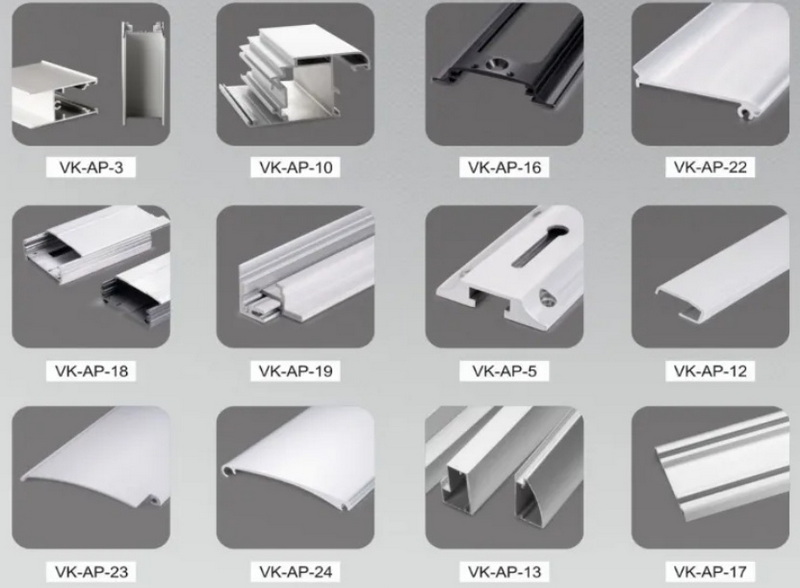

The malleability of aluminum allows for the creation of complex and intricate mold designs. This flexibility enables manufacturers to produce a wide range of aluminum profiles, from simple shapes to highly detailed cross-sections. The ability to create diverse extrusion profiles expands the potential applications of aluminum extrusions across various industries.

Cost-Effectiveness

While the initial cost of aluminum extrusion molds may be higher than some alternatives, their long-term cost-effectiveness is undeniable. Factors contributing to the economic benefits of aluminum molds include:

- Lower energy consumption during the extrusion process

- Reduced wear and tear on extrusion equipment

- Longer mold lifespan due to corrosion resistance

- Higher production efficiency

The Extrusion Mold Design Process

Creating an effective aluminum extrusion mold requires careful consideration of various factors. The design process typically involves the following steps:

1. Profile Analysis: Examining the desired extrusion profile and identifying potential challenges

2. Material Selection: Choosing the appropriate aluminum alloy for the mold based on the extrusion requirements

3. Computer-Aided Design (CAD): Using advanced software to create a 3D model of the mold

4. Simulation: Conducting virtual extrusion simulations to optimize mold design

5. Prototyping: Creating a prototype mold for testing and refinement

6. Final Production: Manufacturing the finalized aluminum extrusion mold

Innovations in Aluminum Extrusion Mold Technology

The field of aluminum extrusion mold technology is constantly evolving, with new innovations enhancing the process's efficiency and capabilities. Some recent advancements include:

3D Printing of Molds

Additive manufacturing techniques are being explored for creating aluminum extrusion molds. This technology allows for:

- Rapid prototyping of complex mold designs

- Reduced lead times for mold production

- Creation of molds with internal cooling channels for improved temperature control

Smart Molds

The integration of sensors and IoT technology into aluminum extrusion molds is revolutionizing the extrusion process. Smart molds can:

- Monitor temperature and pressure in real-time

- Adjust extrusion parameters automatically

- Predict maintenance needs and prevent unexpected downtime

Advanced Coatings

New coating technologies are being developed to enhance the performance of aluminum extrusion molds. These coatings can:

- Increase mold durability and lifespan

- Improve surface finish of extruded products

- Reduce friction during the extrusion process

Applications of Aluminum Extrusions

The versatility of aluminum extrusions, made possible by high-quality aluminum extrusion molds, has led to their widespread use across numerous industries. Some notable applications include:

Automotive Industry

Aluminum extrusions are extensively used in the automotive sector for:

- Vehicle frames and chassis components

- Heat exchangers and radiators

- Bumper reinforcements

- Interior trim and decorative elements

Aerospace

The aerospace industry relies on aluminum extrusions for:

- Aircraft fuselage components

- Wing structures

- Floor supports and seat tracks

- Cargo handling systems

Construction

In the construction sector, aluminum extrusions are used for:

- Window and door frames

- Curtain wall systems

- Solar panel mounting structures

- Structural framing for modular buildings

Electronics

The electronics industry utilizes aluminum extrusions for:

- Heat sinks for electronic components

- Enclosures for devices and equipment

- LED lighting fixtures

- Computer and server racks

Environmental Benefits of Aluminum Extrusion Molds

The use of aluminum extrusion molds aligns with growing environmental concerns and sustainability initiatives. Some key environmental benefits include:

Recyclability

Aluminum is 100% recyclable without loss of quality. This means that aluminum extrusion molds can be recycled at the end of their lifecycle, reducing waste and conserving resources.

Energy Efficiency

The thermal properties of aluminum contribute to energy savings during the extrusion process. Aluminum molds require less energy to heat and cool compared to other materials, reducing the overall energy consumption of the manufacturing process.

Lightweight Products

The lightweight nature of aluminum extrusions, made possible by precise aluminum extrusion molds, contributes to fuel efficiency in transportation applications and reduced material usage in construction projects.

Challenges and Considerations

While aluminum extrusion molds offer numerous advantages, there are some challenges to consider:

Wear and Tear

Despite their durability, aluminum extrusion molds can experience wear over time, especially in high-volume production environments. Regular maintenance and inspection are crucial to ensure consistent product quality.

Initial Cost

The upfront cost of high-quality aluminum extrusion molds can be higher compared to some alternatives. However, the long-term benefits often outweigh this initial investment.

Skill Requirements

Designing and maintaining aluminum extrusion molds requires specialized knowledge and skills. Investing in training and expertise is essential for optimal results.

Conclusion

Aluminum stands out as the best material for extrusion molds due to its unique combination of properties. Its lightweight yet strong nature, excellent thermal conductivity, corrosion resistance, and design flexibility make it an ideal choice for creating high-quality extrusion profiles. The cost-effectiveness and environmental benefits further solidify aluminum's position as the preferred material for extrusion molds.

As technology continues to advance, we can expect to see even more innovations in aluminum extrusion mold design and manufacturing. These developments will likely lead to increased efficiency, improved product quality, and expanded applications for aluminum extrusions across various industries.

By choosing aluminum extrusion molds, manufacturers can benefit from enhanced production capabilities, reduced costs, and improved sustainability. As the demand for lightweight, durable, and complex components grows, the importance of aluminum extrusion molds in modern manufacturing processes will only continue to increase.

Frequently Asked Questions

1. What is the lifespan of an aluminum extrusion mold?

The lifespan of an aluminum extrusion mold can vary depending on factors such as usage frequency, maintenance practices, and the complexity of the extrusion profile. With proper care and maintenance, a high-quality aluminum extrusion mold can last for several years or even decades. Regular inspections, cleaning, and timely repairs can significantly extend the mold's useful life.

2. How does the cost of aluminum extrusion molds compare to other materials?

While the initial cost of aluminum extrusion molds may be higher than some alternatives, they often prove more cost-effective in the long run. Factors contributing to their economic advantage include lower energy consumption during extrusion, reduced wear on equipment, and longer mold lifespan. Additionally, the superior thermal properties of aluminum can lead to faster production cycles, further improving overall cost-efficiency.

3. Can aluminum extrusion molds be used for all types of aluminum alloys?

Aluminum extrusion molds can be designed to work with a wide range of aluminum alloys. However, the specific alloy being extruded may influence the mold design and extrusion parameters. Some alloys may require special considerations in terms of temperature control or die design. It's essential to consult with extrusion experts to ensure the mold is optimized for the intended alloy.

4. How do aluminum extrusion molds impact the surface finish of the final product?

The quality of the aluminum extrusion mold directly affects the surface finish of the extruded product. Well-designed and properly maintained aluminum molds can produce extrusions with excellent surface quality. Factors such as mold surface smoothness, temperature control, and extrusion speed all play a role in determining the final surface finish. Advanced coatings and polishing techniques can further enhance the mold's ability to produce high-quality surface finishes.

5. Are there any limitations to the shapes that can be created with aluminum extrusion molds?

While aluminum extrusion molds offer great design flexibility, there are some limitations to the shapes that can be created. Extremely complex or undercut profiles may be challenging or impossible to extrude. The thickness-to-width ratio of the profile, the overall size of the extrusion, and the alloy being used can also impact the feasibility of certain shapes. However, skilled mold designers can often find creative solutions to overcome many shape limitations, making aluminum extrusion a versatile manufacturing process.

Citations:

[1] https://www.belcoind.com/the-benefits-of-designing-with-aluminum-extrusions/

[2] https://haluminium.com/Product/aluminum-extrusion-molding/

[3] https://profileprecisionextrusions.com/why-aluminum-extrusions-are-better-than-stainless-steel-6-reasons-to-choose-aluminum-over-stainless/

[4] https://rextrusion.en.made-in-china.com/product/EdzakjPGvRYu/China-Aluminum-Profile-Extrusion-Dies-Moulds-Mold-for-Extrusion-Press-Machine.html

[5] https://www.youtube.com/watch?v=iiGlq7408ME

[6] https://www.gabrian.com/what-are-aluminum-extrusions-used-for/

[7] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[8] https://www.zetwerk.com/aluminum-extrusions/

[9] https://smartdies.com.tr/en/aluminyum-ekstruzyonunda-kaliplarin-onemi/

[10] https://www.youtube.com/watch?v=vHkwq_2yY9E