Content Menu

● Understanding Aluminum Extrusion

>> The Aluminum Extrusion Process

● Importance of Aluminum Extrusion in CVD Manufacturing

>> 1. Lightweight and Strong

>> 2. Corrosion Resistance

>> 3. Thermal Conductivity

>> 4. Customizable Shapes

>> 5. Cost-Effectiveness

● Applications of Aluminum Extrusion in CVD Manufacturing

>> Additional Applications

● Innovations in Aluminum Extrusion Technology

>> Future Trends

● Challenges Facing Aluminum Extrusion in CVD Manufacturing

● Conclusion

● FAQ

>> 1. What is aluminum extrusion?

>> 2. How does aluminum benefit CVD manufacturing?

>> 3. What are common applications of aluminum extrusions in CVD?

>> 4. What advancements are being made in aluminum extrusion technology?

>> 5. Why choose aluminum over other materials for CVD applications?

Aluminum extrusion plays a pivotal role in the manufacturing processes of various industries, particularly in Chemical Vapor Deposition (CVD) applications. This article explores the significance of aluminum extrusion in CVD manufacturing, detailing its benefits, applications, and the processes involved.

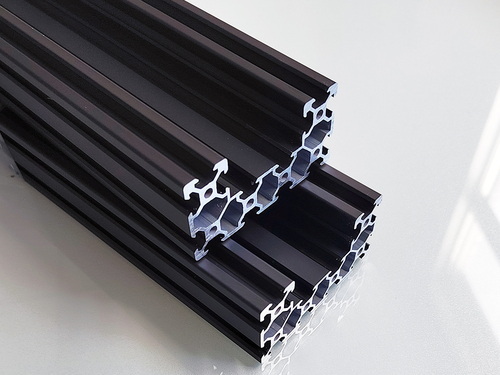

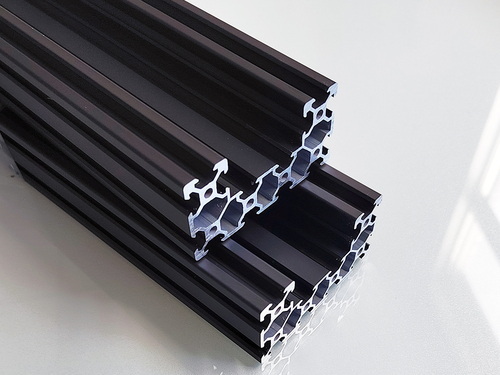

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that involves forcing heated aluminum through a shaped die to create specific profiles or shapes. This process allows for the production of complex cross-sectional shapes with high precision and minimal waste. The versatility of aluminum makes it an ideal material for various applications, including those in CVD manufacturing.

The Aluminum Extrusion Process

1. Heating: Aluminum billets are heated to a malleable state, typically between 800°F and 1000°F.

2. Extrusion: The heated aluminum is pushed through a die using a hydraulic press, creating the desired shape.

3. Cooling: The extruded aluminum is rapidly cooled to lock in its properties.

4. Aging: The material is aged to enhance strength and durability.

5. Finishing: After aging, the extrusions can undergo various finishing processes such as anodizing or machining to meet specific requirements.

Importance of Aluminum Extrusion in CVD Manufacturing

CVD is a widely used technique for producing thin films and coatings on substrates, essential in semiconductor manufacturing, solar cells, and various electronic components. Here are several reasons why aluminum extrusion is crucial in this field:

1. Lightweight and Strong

Aluminum is known for its high strength-to-weight ratio, making it an ideal choice for applications where weight reduction is critical. In CVD systems, lighter components can lead to improved efficiency and reduced energy consumption. For instance, using aluminum extrusions instead of heavier materials can decrease the overall weight of the equipment, allowing for easier handling and installation.

2. Corrosion Resistance

Aluminum naturally forms a protective oxide layer that enhances its resistance to corrosion. This property is vital in CVD processes, where exposure to chemicals can degrade other materials. The longevity of aluminum components reduces maintenance costs and downtime associated with equipment failure due to corrosion.

3. Thermal Conductivity

Aluminum has excellent thermal conductivity, which is essential in CVD systems that require precise temperature control during deposition processes. Efficient heat dissipation helps maintain optimal conditions for film growth. This characteristic allows for better temperature uniformity across the substrate, leading to improved film quality and consistency.

4. Customizable Shapes

The extrusion process allows manufacturers to create custom profiles tailored to specific CVD equipment requirements. This customization can optimize gas flow and improve deposition uniformity. By designing profiles that facilitate better gas distribution, manufacturers can enhance the efficiency of the CVD process.

5. Cost-Effectiveness

Aluminum extrusion is often more cost-effective than other manufacturing methods due to lower material waste and reduced processing times. This cost efficiency is particularly beneficial in large-scale CVD operations where material costs can significantly impact overall production expenses.

Applications of Aluminum Extrusion in CVD Manufacturing

Aluminum extrusions are utilized in various components within CVD systems:

- Chambers: Extruded aluminum can be used to construct vacuum chambers that house the CVD process.

- Supports: Structural supports made from extruded aluminum provide stability for complex equipment setups.

- Heat Exchangers: Due to its thermal properties, aluminum extrusions are often used in heat exchangers within CVD systems.

- Gas Distribution Systems: Custom extruded profiles can optimize gas flow paths within the CVD equipment.

Additional Applications

Beyond these primary uses, aluminum extrusions find applications in several other areas related to CVD manufacturing:

- Substrate Holders: Custom-designed holders made from extruded aluminum ensure that substrates remain stable during the deposition process.

- Cooling Systems: Extruded profiles are also utilized in cooling systems that help maintain appropriate temperatures during CVD operations.

- Transport Frames: Lightweight transport frames constructed from aluminum extrusions facilitate easy movement of equipment between different stages of production.

Innovations in Aluminum Extrusion Technology

Recent advancements in aluminum extrusion technology have further enhanced its application in CVD manufacturing:

- Rapid Quenching Systems: These systems allow for uniform cooling of extrusions, improving material properties and dimensional accuracy.

- AI Integration: Artificial intelligence is being used to optimize extrusion processes, enhancing efficiency and reducing defects.

- High-Strength Alloys: New aluminum alloys with improved mechanical properties are being developed specifically for demanding applications like CVD.

Future Trends

The future of aluminum extrusion technology looks promising with ongoing research focused on developing even more advanced materials and processes:

- 3D Printing Integration: Combining 3D printing with aluminum extrusion could lead to innovative designs and reduced lead times.

- Sustainability Efforts: As industries move towards greener practices, advancements in recycling methods for aluminum will contribute to more sustainable production processes.

- Smart Manufacturing Techniques: Incorporating IoT (Internet of Things) technologies into the extrusion process could lead to real-time monitoring and optimization.

Challenges Facing Aluminum Extrusion in CVD Manufacturing

Despite its many advantages, there are challenges associated with using aluminum extrusion in CVD manufacturing:

- Thermal Expansion Concerns: While aluminum has good thermal conductivity, it also expands when heated. This expansion must be carefully managed during the design phase to avoid warping or misalignment during operation.

- Surface Treatment Limitations: Although anodizing provides corrosion resistance, certain surface treatments may not be suitable for all applications within the harsh environments typical of some CVD processes.

- Cost Fluctuations: The price of raw aluminum can fluctuate based on market conditions, impacting overall production costs for manufacturers relying heavily on this material.

Conclusion

Aluminum extrusion is an essential process that significantly impacts the effectiveness and efficiency of CVD manufacturing. Its lightweight nature, corrosion resistance, thermal conductivity, and cost-effectiveness make it an ideal choice for various components within CVD systems. As technology continues to advance, the role of aluminum extrusion will likely expand further, providing innovative solutions for manufacturers across multiple industries.

FAQ

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process that shapes aluminum by forcing it through a die under high pressure, creating specific cross-sectional profiles.

2. How does aluminum benefit CVD manufacturing?

Aluminum's lightweight nature, corrosion resistance, and excellent thermal conductivity make it ideal for components used in CVD systems.

3. What are common applications of aluminum extrusions in CVD?

Common applications include vacuum chambers, structural supports, heat exchangers, gas distribution systems, substrate holders, cooling systems, and transport frames.

4. What advancements are being made in aluminum extrusion technology?

Recent advancements include rapid quenching systems for better cooling and AI integration for optimizing production processes.

5. Why choose aluminum over other materials for CVD applications?

Aluminum offers a superior strength-to-weight ratio, excellent thermal management capabilities, cost-effectiveness compared to many other materials, and customizable shapes tailored to specific needs.