Content Menu

● Introduction to Metal Extrusion

● Importance of Form Tools in Metal Extrusion

>> Precision and Accuracy

>> Durability and Longevity

● Design and Manufacturing of Form Tools

>> Material Selection

>> Tool Geometry

>> Surface Finish

● Challenges in Form Tool Design

>> Material Flow

>> Thermal Expansion

>> Tool Life

● Role of Simulation Software in Form Tool Design

● Conclusion

● Frequently Asked Questions

>> 1. What is the primary function of a form tool in metal extrusion?

>> 2. How does the material selection for form tools impact the extrusion process?

>> 3. What role does simulation software play in designing form tools for metal extrusion?

>> 4. How does the surface finish of a form tool affect the extruded product?

>> 5. What are the benefits of using advanced form tools in automatic metal extrusion?

● Citations:

Metal extrusion is a widely used manufacturing process that involves forcing metal through a die to create a desired shape. This process is crucial in producing various components for industries such as aerospace, automotive, and construction. A high-quality form tool for automatic extrusion machines plays a pivotal role in ensuring the precision, efficiency, and quality of the extruded products. In this article, we will delve into the importance of form tools in automatic metal extrusion and explore how they contribute to the overall success of the manufacturing process.

Introduction to Metal Extrusion

Metal extrusion is a versatile process that can produce a wide range of shapes and sizes, from simple profiles to complex geometries. The process involves heating a metal billet and then forcing it through a die using a hydraulic press. The die determines the cross-sectional shape of the extruded product, which can be tailored to meet specific requirements.

There are several types of metal extrusion processes, including direct, indirect, hydrostatic, and impact extrusion. Each method has its advantages and is suited for different materials and applications.

1. Direct Extrusion: This is the most common method, where the billet is pushed through a stationary die by a moving ram.

3. Hydrostatic Extrusion: This method uses fluid pressure to force the billet through the die, reducing friction and required force.

4. Impact Extrusion: Used for softer metals, this process involves rapid application of force to shape the metal.

Importance of Form Tools in Metal Extrusion

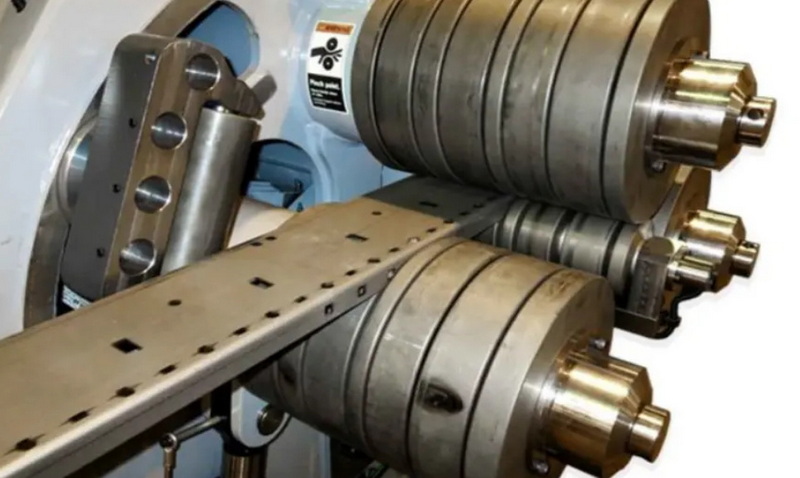

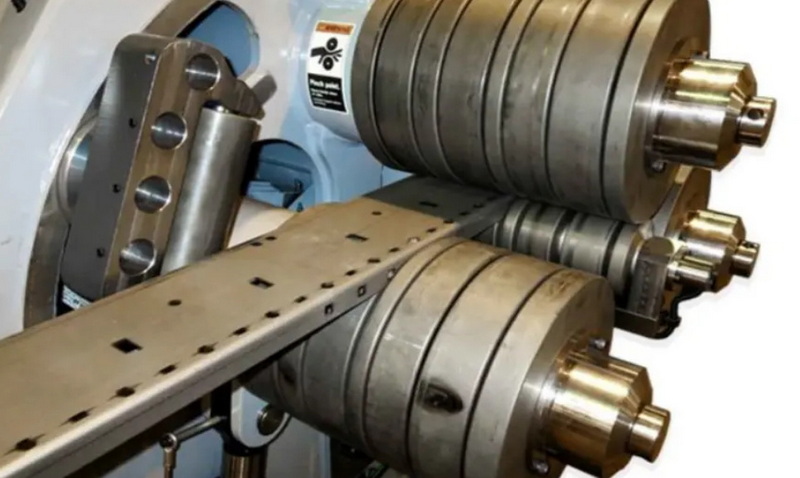

Form tools, or dies, are critical components in metal extrusion. They determine the shape and quality of the final product. A high-quality form tool ensures that the extruded metal meets precise specifications and has a smooth surface finish.

Precision and Accuracy

High-quality form tools are designed to maintain precise dimensions and tolerances. They ensure that the extruded product has a consistent cross-sectional shape, which is crucial for applications where dimensional accuracy is paramount.

Efficient form tools minimize material waste and reduce the need for post-processing operations. By producing parts with precise dimensions, they save time and resources that would otherwise be spent on machining or reworking the extrusions.

Durability and Longevity

Durable form tools can withstand the high pressures involved in metal extrusion, extending their lifespan and reducing maintenance costs. This durability is essential for maintaining consistent production quality over time.

Design and Manufacturing of Form Tools

The design and manufacturing of form tools involve careful consideration of several factors, including material selection, tool geometry, and surface finish.

Material Selection

Form tools are typically made from high-strength materials like steel alloys, which can withstand the stresses and temperatures encountered during extrusion.

Tool Geometry

The geometry of the tool must be precisely engineered to ensure smooth material flow and prevent defects. This includes features like bearing surfaces, which guide the extruded material and maintain its shape.

Surface Finish

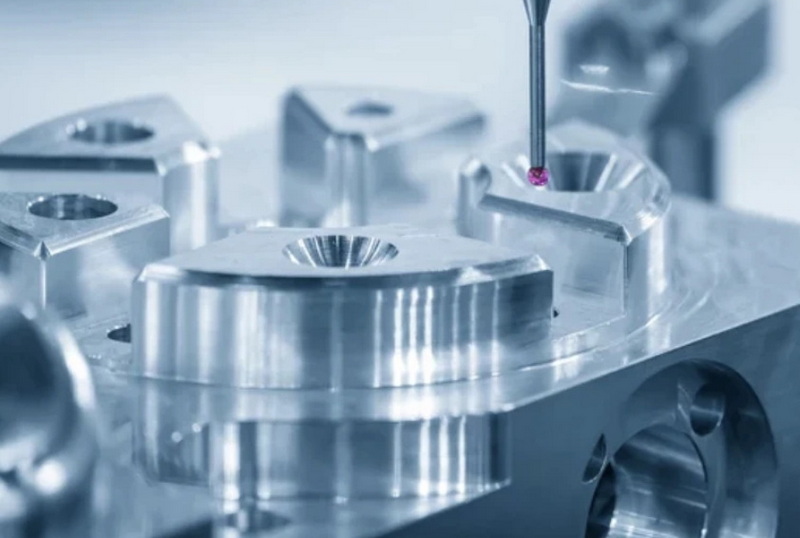

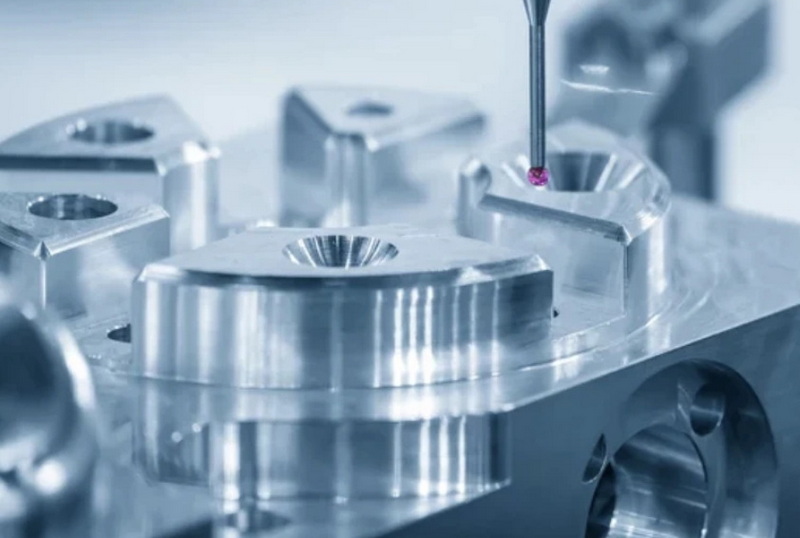

A smooth surface finish on the form tool is essential for producing extrusions with minimal surface defects. This can be achieved through various finishing techniques, such as grinding or polishing.

Challenges in Form Tool Design

Designing form tools for automatic metal extrusion presents several challenges, including ensuring material flow, managing thermal expansion, and optimizing tool life.

Material Flow

Ensuring smooth material flow through the die is critical to prevent defects like wrinkles or tears in the extruded product. This requires careful design of the die's internal geometry.

Thermal Expansion

Metal extrusion involves high temperatures, which can cause thermal expansion of the tool. This must be accounted for in the design to maintain precision and prevent tool damage.

Tool Life

Extending the life of form tools is crucial for maintaining production efficiency. This can be achieved through durable materials, proper maintenance, and optimized tool design.

Role of Simulation Software in Form Tool Design

Simulation software plays a significant role in optimizing form tool design by allowing engineers to model and analyze the extrusion process before manufacturing the tools.

1. Predictive Modeling: Simulation software can predict material flow, stress distribution, and potential defects, allowing for adjustments to be made before physical tool production.

2. Optimization: It helps in optimizing tool geometry and material selection to improve efficiency and product quality.

3. Cost Savings: By reducing the need for physical prototypes and trial runs, simulation software can significantly lower development costs.

Conclusion

In conclusion, high-quality form tools are indispensable for achieving precision, efficiency, and cost-effectiveness in automatic metal extrusion. Their design and manufacturing require careful consideration of material selection, tool geometry, and surface finish. The use of simulation software further enhances the design process by allowing predictive modeling and optimization. As the demand for complex metal components continues to grow, the importance of advanced form tools will only increase.

Frequently Asked Questions

1. What is the primary function of a form tool in metal extrusion?

- The primary function of a form tool, or die, in metal extrusion is to shape the metal billet into the desired cross-sectional profile. It determines the final shape and quality of the extruded product.

2. How does the material selection for form tools impact the extrusion process?

- The material selection for form tools is crucial as it must withstand high pressures and temperatures. Typically, high-strength materials like steel alloys are used to ensure durability and longevity.

3. What role does simulation software play in designing form tools for metal extrusion?

- Simulation software allows engineers to model and analyze the extrusion process, predicting material flow, stress distribution, and potential defects. This helps in optimizing tool design before physical production.

4. How does the surface finish of a form tool affect the extruded product?

- A smooth surface finish on the form tool is essential for producing extrusions with minimal surface defects. It ensures that the extruded product has a uniform and high-quality surface.

5. What are the benefits of using advanced form tools in automatic metal extrusion?

- Advanced form tools offer several benefits, including enhanced precision, improved efficiency, reduced material waste, and extended tool life. They are critical for maintaining consistent product quality and reducing production costs.

Citations:

[1] https://www.tensilemillcnc.com/blog/the-most-efficient-aluminum-extrusion-process-with-precise-quality-control-will-guarantee-the-best-results-of-your-production

[2] https://sinowayindustry.com/how-to-improve-your-manufacturing-process-with-sheet-metal-forming-tools/

[3] https://www.rapiddirect.com/blog/aluminum-extrusion-process/

[4] https://www.kinefac.com/extrusion-machines/

[5] https://fractory.com/metal-extrusion/

[6] https://shlejia.en.made-in-china.com/product/TnerLOoFZDkH/China-Size-I-Extrusion-Tools-Form-down-Used-in-Machine-Trupunch-Form-Punch-Tool.html

[7] https://www.youtube.com/watch?v=P8BWQBP4Vhk

[8] https://www.qform3d.com/products/qformextrusion

[9] https://shop.machinemfg.com/all-you-need-to-know-about-the-process-of-impact-extrusion/

[10] https://shop.machinemfg.com/comprehensive-guide-to-metal-extrusion/

[11] https://www.istockphoto.com/photos/metal-extrusion

[12] https://www.youtube.com/watch?v=DqILlMsNYLw

[13] https://testbook.com/objective-questions/mcq-on-extrusion--5eea6a0d39140f30f369e2ec

[14] https://www.bihler.com/technologies/automated-precision-metal-forming-solutions/

[15] https://ems-metalworking.com/metal-spinning-tools/

[16] https://www.tritech3d.co.uk/top-5-benefits-of-using-fdm-tooling-for-sheet-metal-forming/

[17] https://www.oerlikon.com/balzers/global/en/applications/tools-metal-forming/

[18] https://research.tue.nl/files/4247224/605512.pdf

[19] https://en.wikipedia.org/wiki/Extrusion

[20] https://beckwoodpress.com/triform-presses-old/stretch-forming/

[21] https://www.shutterstock.com/search/metal-extrusion

[22] https://www.youtube.com/watch?v=Y75IQksBb0M

[23] https://www.3ds.com/make/guide/process/forming

[24] https://proto3000.com/applications/3d-printing-guides-metal-forming-with-3d-printing/

[25] https://kdmfab.com/metal-extrusion/

[26] https://tri-stateal.com/resources/extrusion-guide/