Content Menu

● Understanding PC Optical Grade Sheets

>> Key Properties of PC Optical Grade Sheets

● The Extrusion Process

● Advantages of Using PC Optical Grade Sheet Extrusion Production Lines

● Technological Innovations in Extrusion Lines

● Applications of PC Optical Grade Sheets

● Market Demand for Optical Grade Sheets

● Environmental Considerations

● Future Trends in PC Optical Grade Sheet Production

● Conclusion

● FAQ

>> 1. What materials can be processed using a PC optical grade sheet extrusion line?

>> 2. How does the extrusion process affect the properties of the final product?

>> 3. Can these production lines be used for small-scale manufacturing?

>> 4. What maintenance is required for a PC optical grade sheet extrusion line?

>> 5. Are there any environmental considerations when using these production lines?

● Citations:

Polycarbonate (PC) optical grade sheets have become essential in various industries due to their remarkable properties, including high impact resistance, excellent optical clarity, and versatility in applications. The production of these sheets involves sophisticated extrusion processes that ensure quality and efficiency. This article explores the reasons for choosing PC optical grade sheet extrusion production lines for manufacturing, detailing the technology, benefits, applications, and more.

Understanding PC Optical Grade Sheets

PC optical grade sheets are transparent thermoplastic materials known for their outstanding light transmission and mechanical strength. These sheets are produced through a specialized extrusion process that involves melting polycarbonate resin and forming it into sheets of varying thicknesses.

Key Properties of PC Optical Grade Sheets

- High Transparency: PC sheets can transmit over 90% of light, making them ideal for applications requiring clarity.

- Impact Resistance: They are virtually unbreakable, providing safety in environments where durability is crucial.

- UV Stability: Many PC sheets come with UV protection, preventing degradation from sunlight exposure.

- Thermal Stability: They can withstand a wide range of temperatures without losing their structural integrity.

The Extrusion Process

The extrusion process for producing PC optical grade sheets involves several stages:

1. Raw Material Preparation: Polycarbonate pellets are prepared and dried to remove moisture.

2. Extrusion: The dried pellets are fed into an extruder where they are heated and melted. A specially designed screw ensures uniform melting and mixing of the material.

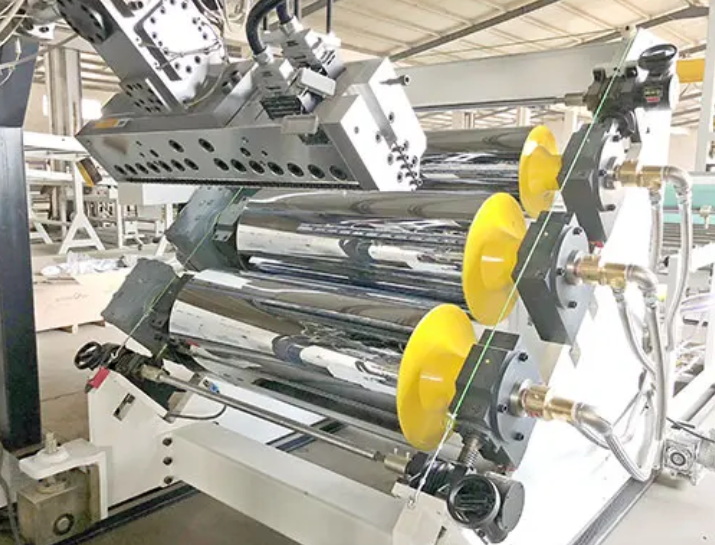

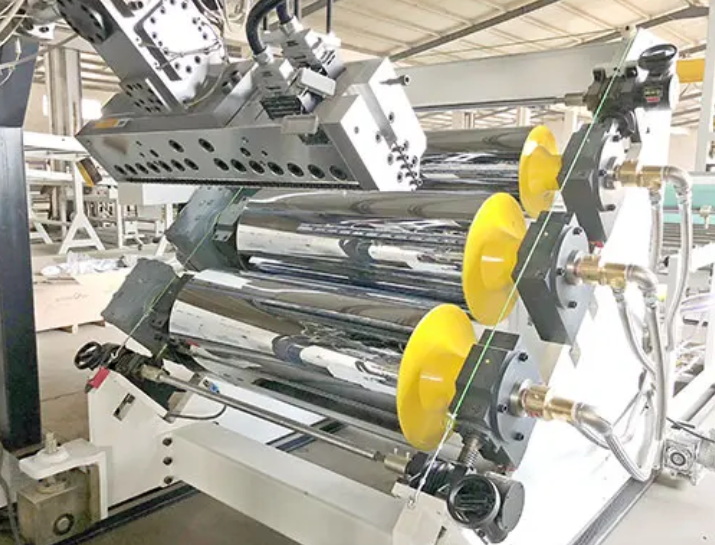

3. Sheet Formation: The molten polycarbonate is pushed through a die to form a continuous sheet.

4. Cooling: As the sheet exits the die, it is cooled using either air or water to solidify it quickly.

5. Trimming and Finishing: After cooling, the sheets are trimmed to the desired dimensions and may undergo additional processing like surface treatments or coating.

Advantages of Using PC Optical Grade Sheet Extrusion Production Lines

Investing in a dedicated extrusion line for producing PC optical grade sheets offers numerous advantages:

- Precision Engineering: Modern extrusion lines are equipped with advanced technology that allows for precise control over the thickness and quality of the sheets produced. This precision minimizes defects and ensures uniformity across batches.

- High Efficiency: These production lines are designed for high throughput, enabling manufacturers to produce large quantities of sheets quickly without compromising quality.

- Versatility: With the ability to produce different grades of optical sheets, manufacturers can cater to diverse market needs ranging from automotive components to electronic displays.

- Cost-Effectiveness: By optimizing production processes and reducing waste, manufacturers can achieve significant cost savings over time.

Technological Innovations in Extrusion Lines

Modern PC optical grade sheet extrusion lines incorporate several technological advancements that enhance production capabilities:

- High-Precision Calendering Systems: These systems ensure that the thickness and surface finish of the sheets meet stringent quality standards.

- Real-Time Monitoring Systems: Equipped with sensors that monitor temperature, pressure, and thickness during production to maintain consistent quality.

- Automation Features: Many lines include automated winding and cutting systems that improve efficiency and reduce labor costs.

Applications of PC Optical Grade Sheets

PC optical grade sheets find applications across various sectors due to their unique properties:

- Automotive Industry: Used in headlight lenses and interior components where clarity and impact resistance are critical.

- Electronics: Essential for display screens in devices such as smartphones, tablets, and televisions due to their excellent light transmission.

- Construction: Utilized in skylights, roofing panels, and safety barriers because of their durability and UV resistance.

- Medical Devices: Employed in equipment requiring clear visibility and sterilization capabilities.

Market Demand for Optical Grade Sheets

The demand for PC optical grade sheets is on the rise due to several factors:

- Increased Safety Regulations: Industries such as automotive and construction are subject to stringent safety regulations that require high-performance materials like polycarbonate sheets.

- Technological Advancements: Innovations in manufacturing processes have led to improved performance characteristics of PC optical grade sheets, making them more attractive for various applications.

- Sustainability Concerns: As industries move towards more sustainable practices, polycarbonate's recyclability makes it a preferred choice over traditional materials like glass or acrylic.

Environmental Considerations

While producing PC optical grade sheets offers many benefits, it's essential to consider environmental impacts:

- Energy Consumption: The extrusion process can be energy-intensive; thus, manufacturers should look into energy-efficient machinery to minimize carbon footprints.

- Waste Management: Implementing recycling programs for scrap material generated during production can significantly reduce waste. Many modern extrusion lines also incorporate reclaim systems that recycle trimmed edges back into the process[1][4].

Future Trends in PC Optical Grade Sheet Production

The future of PC optical grade sheet production is promising with ongoing innovations:

- Smart Materials Development: Research into smart materials that can change properties based on environmental conditions is underway. This could lead to new applications in energy efficiency or adaptive lighting solutions.

- Enhanced Co-extrusion Techniques: Advances in co-extrusion techniques allow manufacturers to create multi-layered sheets with varying properties tailored for specific applications[7][10].

- Integration of AI Technologies: The incorporation of artificial intelligence into manufacturing processes could enhance quality control by predicting failures before they occur based on real-time data analysis[8][12].

Conclusion

Investing in a PC optical grade sheet extrusion production line is a strategic decision for manufacturers looking to enhance product quality while maximizing efficiency. The combination of advanced technology, high precision, and versatility makes these production lines indispensable in today's competitive market. As industries continue to demand high-quality materials with exceptional properties, PC optical grade sheet extrusion lines will play a pivotal role in meeting these needs effectively.

FAQ

1. What materials can be processed using a PC optical grade sheet extrusion line?

PC optical grade sheet extrusion lines primarily process polycarbonate but can also handle other materials like PMMA (Polymethyl Methacrylate) depending on the design of the machine.

2. How does the extrusion process affect the properties of the final product?

The extrusion process influences properties such as thickness uniformity, surface finish, transparency, and overall mechanical strength by controlling temperature, pressure, and cooling rates during production.

3. Can these production lines be used for small-scale manufacturing?

Yes, many modern extrusion lines are designed to accommodate both large-scale industrial production as well as smaller batches, allowing flexibility based on market demand.

4. What maintenance is required for a PC optical grade sheet extrusion line?

Regular maintenance includes cleaning the extruder screw and die, checking calibration settings for precision equipment, monitoring cooling systems for efficiency, and ensuring that all mechanical parts are lubricated properly.

5. Are there any environmental considerations when using these production lines?

Manufacturers should consider energy consumption during operation as well as waste management practices related to scrap material generated during the extrusion process. Implementing recycling programs can help mitigate environmental impacts.

Citations:

[1] https://www.jwellmachine.com/pc-pmma-optical-sheet-extrusion-line/

[2] http://www.omipa-extrusion.com/extrusion-lines/clear-sheet-foil/

[3] https://zetarmold.com/pc-injection-molding-guide/

[4] https://www.jwellextrusions.com/video/pc-pmma-optical-grade-sheet-production-line.html

[5] https://www.fusionoptix.com/oem/manufacturing-2/film-sheet-extrusion/

[6] https://www.valcogroup-valves.com/faq-2/manufacturing-process-of-polycarbonate/

[7] https://www.bgplast.it/the-advantages-of-a-bg-plast-pc-optical-quality-sheet-extrusion-line/

[8] https://www.sheetcoextrusion.com/pmma-optical-film-extrusion-line-supplier-pc-pmma-optical-filmssheets-extrusion-line-leader-3-product/

[9] https://omnexus.specialchem.com/selection-guide/polycarbonate-pc-plastic

[10] https://jwellextrusion.en.made-in-china.com/product/xmXYQbhCYOWE/China-PC-Polycarbonate-PMMA-Polymethyl-Methacrylate-Optical-Sheet-Extruder-Extrusion-Production-Machine-Line.html

[11] https://www.m-ep.co.jp/assets/document/product/pdf/en/physicality.pdf

[12] https://jieyatwinscrew.com/blog/pc-profile-extrusion-line/

[13] https://plaskolite.com/docs/default-source/fab/fab015_tuf_en.pdf

[14] https://www.jwellextrusions.com/products/pc-sheet-extrusion-line/

[15] http://www.pc-film.com/productionxline.html

[16] https://www.jwellplas.com/Advantages-of-PC-optical-grade-sheet-extrusion-line.html

[17] https://en.fcfc-plastics.com/optical-grade.htm

[18] https://www.emcoplastics.com/pc-optical-grade/