Content Menu

● The Aluminum Extrusion Process: An Overview

● Benefits of Choosing an Aluminum Extruder in the United States

>> Superior Quality Control

>> Reliable Supply Chain and Reduced Lead Times

>> Support for American Jobs and Economy

>> Environmentally Responsible Manufacturing

>> Customization and Design Support

>> Cost-Effectiveness

● Case Studies and Examples

● Conclusion

● FAQ

>> 1. What is the largest product you can extrude?

>> 2. What is the difference between anodized aluminum and mill finished aluminum?

>> 3. What is the cost of a die?

>> 4. What is the minimum order quantity?

>> 5. Can you use existing dies from other profile extrusions?

● Citations:

In today's globalized world, businesses have numerous options when it comes to sourcing materials and manufacturing components. Among these choices, selecting an aluminum extruder in the United States offers distinct advantages that can significantly impact the quality, reliability, and overall success of your projects. This article explores the compelling reasons to prioritize American aluminum extrusion, highlighting the benefits of domestic manufacturing, quality control, supply chain stability, and more.

The Aluminum Extrusion Process: An Overview

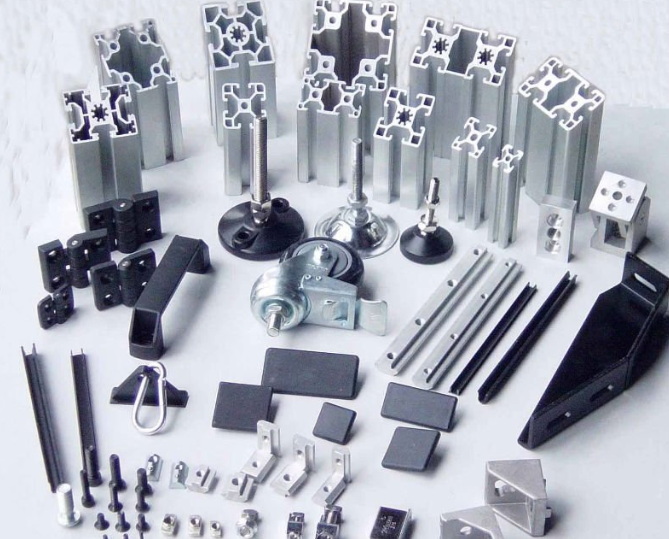

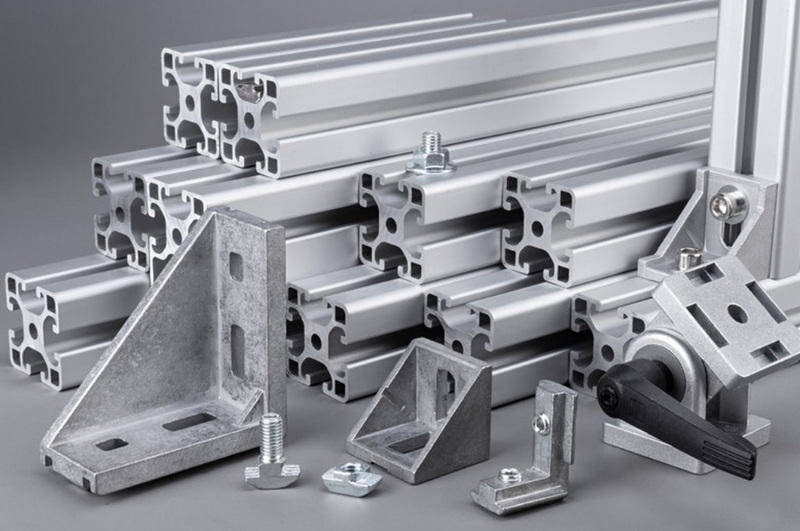

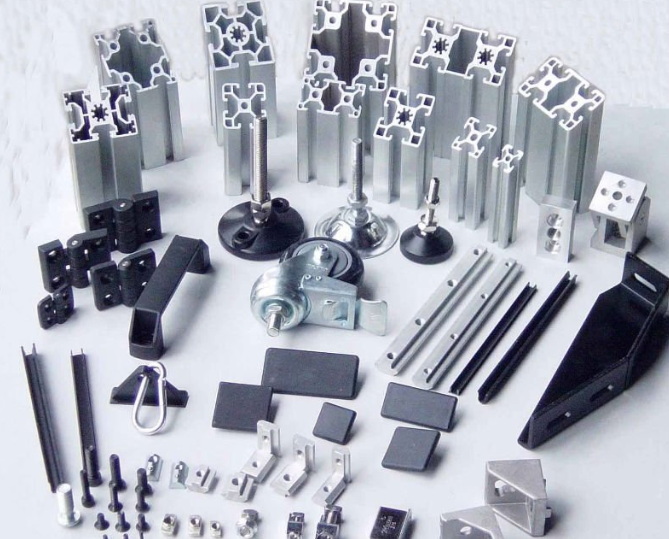

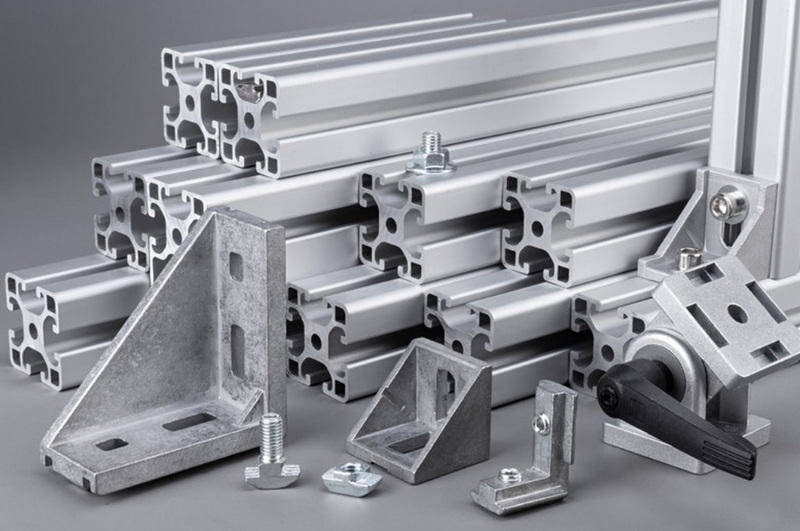

Before delving into the advantages of choosing a U.S.-based aluminum extruder, it's essential to understand the aluminum extrusion process itself. Aluminum extrusion is a manufacturing process where aluminum alloy is forced through a die of a specific cross-sectional shape[10]. This process creates various shapes and profiles, making aluminum extrusions suitable for diverse applications across industries[10].

The basic steps involved in aluminum extrusion include:

1. Die Preparation: A die with the desired profile is selected and prepared[5].

2. Billet Preparation: Aluminum billets (solid, cylindrical lengths of aluminum alloy) are heated to around 900 degrees Fahrenheit to make them pliable[5].

3. Extrusion: The heated billet is loaded into the extrusion press and forced through the die[5].

4. Cooling: The extruded aluminum profile is cooled using air or water[5].

5. Stretching: The cooled extrusion is stretched to ensure straightness and dimensional accuracy[6].

6. Cutting and Finishing: The extrusion is cut to the required length and may undergo additional finishing processes such as machining, anodizing, or powder coating[9].

Benefits of Choosing an Aluminum Extruder in the United States

Superior Quality Control

One of the most significant advantages of working with an aluminum extruder in the United States is the high standard of quality control[8]. U.S. manufacturers adhere to strict quality standards and regulations, ensuring that the final product meets or exceeds industry specifications[1].

- Stringent Oversight: Domestic extruders offer more stringent oversight throughout the extrusion process, resulting in consistently high-quality aluminum profiles[8].

- Quality Certifications: Many U.S. aluminum extrusion companies hold certifications such as ISO 9001:2015, demonstrating their commitment to quality management systems[9].

- In-House Services: Companies like Silver City Aluminum offer extrusion, fabrication, and finishing services in-house to maintain control over quality[1].

Reliable Supply Chain and Reduced Lead Times

In today's volatile global market, supply chain stability is more critical than ever. Choosing an aluminum extruder in the United States can significantly reduce supply chain risks and lead times[8].

- Stability in the Supply Chain: Domestic suppliers are less susceptible to geopolitical uncertainties, transportation disruptions, and other external factors that can impact timely delivery[8].

- Reduced Transportation Costs: Buying American can help reduce costs for deliveries by saving on inbound and outbound shipping costs[1].

- Shorter Lead Times: Domestic sourcing results in significantly shorter lead times, allowing for quicker project turnaround[1].

- Faster Response Times: Proximity to a domestic supplier facilitates faster communication and response times, which is crucial for addressing unforeseen issues or order modifications[8].

Support for American Jobs and Economy

By choosing an aluminum extruder in the United States, you directly support American jobs and contribute to the growth of the domestic economy[1].

- Job Creation: The aluminum extrusion industry supports many other businesses, including the New England marine industry, American trucking industries, consumer goods, construction, aerospace, military, and more[1].

- Economic Growth: Investing in American manufacturing stimulates economic growth and strengthens the nation's industrial base[1].

Environmentally Responsible Manufacturing

American aluminum extruders often prioritize environmentally responsible manufacturing practices[1].

- Green Material: Aluminum is a "green" material because it can be recycled over and over without losing any of its inherent qualities[1].

- Reduced Carbon Footprint: Manufacturing locally in the United States cuts down on transit and delivery costs, helping to reduce greenhouse gases associated with international shipping[1].

Customization and Design Support

Many U.S. aluminum extruders offer custom design and engineering services to meet specific project requirements[1].

- Custom Engineering: Companies like Silver City Aluminum provide professional aluminum services, including custom engineering and manufacturing[1].

- Design Assistance: Aluminum extrusion companies can help you design a new aluminum profile using computer-aided design (CAD) and computer-aided manufacturing (CAM)[9].

- Alloy Selection: Engineers and metallurgists can consult on design and manufacturing to help you select which aluminum alloys to use[2].

Cost-Effectiveness

While some companies move overseas to reduce production and labor costs, there are risks associated with that approach[1]. In many cases, using an American aluminum extruder can be more cost-effective in the long run[1].

- Reduced Overhead: Custom design can help reduce overhead and time constraints by eliminating many secondary operations, including welding and other types of fabrication[1].

- Lower Tooling Costs: Extrusion dies are relatively cheap to produce, making extruded aluminum ideal for prototype design and manufacturing[2].

- Elimination of Costly Machining: Aluminum extrusions can eliminate costly machining, reducing overall production costs[3].

Case Studies and Examples

To illustrate the benefits of choosing an aluminum extruder in the United States, here are a few examples:

- New England Marine Industry: Relies heavily on American aluminum extrusion to achieve their goals[1].

- American Automotive Manufacturers: Utilize custom aluminum extruders to support their industrial manufacturing needs[1].

- Construction Businesses: Depend on American aluminum extrusion for various structural components[1].

Conclusion

Choosing an aluminum extruder in the United States offers numerous advantages, including superior quality control, a reliable supply chain, support for American jobs, environmentally responsible manufacturing, customization options, and cost-effectiveness. While overseas options may seem appealing due to lower initial costs, the long-term benefits of partnering with a domestic extruder often outweigh the perceived savings. By selecting a U.S.-based aluminum extruder, businesses can ensure the success and sustainability of their projects while contributing to the strength of the American economy.

FAQ

1. What is the largest product you can extrude?

We have the ability to extrude aluminum products up to 48 feet long and 17 inches wide[7].

2. What is the difference between anodized aluminum and mill finished aluminum?

Mill finished aluminum refers to extrusion products that have not undergone any surface treatment. Anodized aluminum is a mill finished aluminum that goes through the anodization, which is an electrochemical process that increases corrosion resistance, durability, and decoration[9].

3. What is the cost of a die?

There is no set cost to a die. Based on the customizations including size, shape and finishing, we will give a fair price[9].

4. What is the minimum order quantity?

Typically, the minimum order quantity without set up charges is 1,000 pounds per mill finish[9].

5. Can you use existing dies from other profile extrusions?

Depending on your specific application, we offer standard dies. If we have a standard die that fits your need, we'll send you a profile print to review. If it works for your application, then we'll run it for you[9].

Citations:

[1] http://scaluminum.com/2021/10/american-aluminum-extrusion-quality-products-made-in-the-usa/

[2] https://www.pennex.com/press/the-many-benefits-of-using-aluminum-extrusions

[3] https://profileprecisionextrusions.com/benefits/

[4] https://www.industryselect.com/blog/top-aluminum-extrusion-companies-in-the-us

[5] https://www.youtube.com/watch?v=iiGlq7408ME

[6] https://aec.org/faqs

[7] https://www.extrudedaluminum.com/misson-vision

[8] https://paramountextrusions.com/blogs/the-benefits-of-domestic-aluminum-extruders

[9] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[10] https://aluminumextruderscoalition.com/key-documents/

[11] https://www.howardprecision.com/the-advantages-of-aluminum-extruded-products/

[12] https://aec.org/in-use-benefits

[13] https://aec.org

[14] https://flowstore.com/advantages-of-aluminium-extrusion-frames/

[15] https://www.howardprecision.com/benefits-of-aluminum-extrusions/

[16] https://www.impol.com/everything-you-need-to-know-about-aluminum-extrusion/

[17] http://scaluminum.com/2017/08/american-trucking-industry-benefits-from-aluminum-extrusions/

[18] https://taberextrusions.com/abundance-aluminum-and-americas-great-destiny-history-of-aluminum-for-military-use/

[19] https://www.mknorthamerica.com/blog/what-is-extruded-aluminum-and-what-are-the-benefits-1/

[20] https://starext.com/news/family-owned-vs-corporate-finding-the-best-aluminum-extrusion-manufacturer

[21] https://www.belcoind.com/the-benefits-of-designing-with-aluminum-extrusions/

[22] https://kimsen.vn/the-benefits-of-aluminum-extrusion-for-sustainable-manufacturing-ne142.html

[23] https://www.zetwerk.com/resources/knowledge-base/aluminum-extrusions/top-aluminum-extrusion-suppliers-in-the-usa/

[24] https://nanshanusa.com

[25] https://www.youtube.com/watch?v=P8BWQBP4Vhk

[26] https://www.outashi.com/blog/what-is-cost-aluminum-extrusion-machine-id18.html

[27] https://www.istockphoto.com/photos/aluminum-extrusion

[28] https://www.youtube.com/watch?v=ELgtjeJyFw8

[29] https://www.machine4aluminium.com/what-equipment-is-needed-to-set-up-an-aluminum-extrusion-factory/

[30] https://aluminum-extrusions.net/aluminum-extruders-gallery/

[31] https://www.youtube.com/watch?v=baM5hNnBcT8

[32] https://www.aluminum-extrusion.net

[33] https://www.shutterstock.com/search/aluminium-extrusion

[34] https://www.asminternational.org/video/how-are-aluminum-extrusions-made/

[35] https://technical.europe.misumi-ec.com/en/support/solutions/articles/76000046645-aluminum-extrusions-general-questions

[36] https://edmolimited.co.uk/education/frequently-asked-questions/aluminium-extrusion/

[37] https://profileprecisionextrusions.com/5-initial-questions-ask-aluminum-extruder/

[38] https://waykenrm.com/blogs/aluminum-extrusion/

[39] https://www.alufabinc.com/faqs/

[40] https://www.fonnovaluminium.com/faqs

[41] https://community.xometry.com/kb/articles/761-metal-extrusion-frequently-asked-questions

[42] https://www.apexextrusions.ca/about-apex/faq/

[43] https://www.designnews.com/metals/your-aluminum-extrusion-questions-answered

[44] https://www.linkedin.com/pulse/frequently-asked-questions-aluminium-extrusions-how-richard-hart

[45] https://www.patrickmetals.com/faqs/

[46] https://profileprecisionextrusions.com/common-questions-answered/

[47] https://rpmindinc.com/advantages-dealing-aluminum-extrusion-companies/

[48] https://nationalindustries.world/2024/09/10/from-concept-to-creation-the-power-of-custom-aluminum-extrusion/

[49] https://brunnerent.com/advantages-of-aluminum-extrusions/

[50] https://bor-usa.com/what-are-aluminum-extrusions-used-for/

[51] https://www.aluminum-extrusion-machine.com/aluminum-extrusion-machine.html

[52] https://www.uniqueextrusions.com/photo-gallery/

[53] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[54] https://www.grancoclark.com

[55] https://ensun.io/search/aluminium-extrusion/united-states

[56] https://www.youtube.com/watch?v=DqILlMsNYLw

[57] https://leadrp.net/blog/a-complete-guide-to-aluminum-extrusion/

[58] https://kundel.com/some-interesting-facts-about-using-aluminum-extrusion/