Content Menu

● Introduction to Extrusion Blow Molding

>> Components of a Blow Molding Machine

● Advantages of China Automatic Extrusion Blow Molding Machines

>> Cost-Effectiveness

>> Versatility

>> High Production Efficiency

>> Wide Range of Raw Materials

>> Environmental Benefits

● Applications of China Automatic Extrusion Blow Molding Machines

>> Bottles and Containers

>> Automotive Parts

>> Medical Devices

>> Household Products

● Choosing the Right Machine for Your Business

>> Image: Machine Selection Criteria

● Installation and Maintenance

● Conclusion

● Frequently Asked Questions

>> 1. What are the main types of blow molding machines?

>> 2. How do I choose the right blow molding machine?

>> 3. What materials can be used in blow molding machines?

>> 4. What are the benefits of using a China automatic extrusion blow molding machine?

>> 5. How do I maintain a blow molding machine?

● Citations:

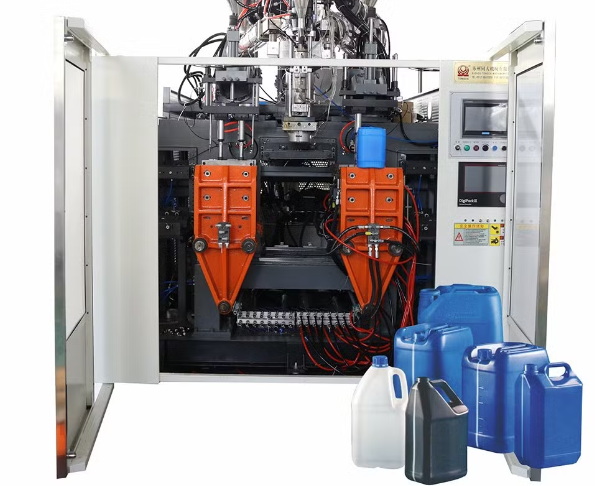

In the rapidly evolving world of plastic manufacturing, China automatic extrusion blow molding machines have emerged as a crucial tool for businesses seeking to produce high-quality, hollow plastic products efficiently. These machines are designed to cater to a wide range of applications, from bottles and containers to automotive parts and medical devices. This article delves into the advantages, applications, and considerations for choosing a China automatic extrusion blow molding machine for your business.

Introduction to Extrusion Blow Molding

Extrusion blow molding (EBM) is a process used to manufacture hollow plastic products. It involves extruding a tube of molten plastic (parison) into a mold, which is then inflated with compressed air to conform to the shape of the mold. Once cooled, the product is ejected from the mold, ready for use. This process is widely used due to its cost-effectiveness, versatility, and ability to produce large quantities of products with uniform quality.

Components of a Blow Molding Machine

A typical China automatic extrusion blow molding machine consists of several key components:

- Extruder: This is responsible for melting and shaping the plastic resin into a parison. It includes a screw, barrel, and heating elements.

Extruder Component

- Mold: The mold gives the final shape to the product. It is designed to withstand the pressure and temperature conditions during the molding process.

- Hydraulic and Pneumatic Systems: These systems control the movement of the mold and the inflation of the parison.

- Control System: This ensures precise control over temperature, pressure, and timing to maintain product quality.

Advantages of China Automatic Extrusion Blow Molding Machines

Cost-Effectiveness

China automatic extrusion blow molding machines offer lower tooling costs compared to other molding techniques. The machinery itself is also relatively inexpensive, making it accessible to small and medium-sized enterprises.

Versatility

These machines can produce a wide range of products, from simple bottles to complex automotive parts. The ability to change molds easily allows for flexibility in product design and volume.

High Production Efficiency

With automation, these machines can produce large quantities of products quickly and consistently, reducing manual labor and increasing productivity.

Wide Range of Raw Materials

They can use various plastic materials like HDPE, PP, and PVC, offering a wide range of raw material options.

Environmental Benefits

The process minimizes material waste, as excess plastic can often be recycled or repurposed.

Applications of China Automatic Extrusion Blow Molding Machines

Bottles and Containers

These machines are widely used in the production of bottles for beverages, cosmetics, and pharmaceuticals.

Automotive Parts

They produce fuel tanks, air ducts, and other components for vehicles.

Medical Devices

Used for manufacturing medical equipment and supplies, such as bedpans and medical containers.

Household Products

Produce plastic buckets, tubs, and other household items.

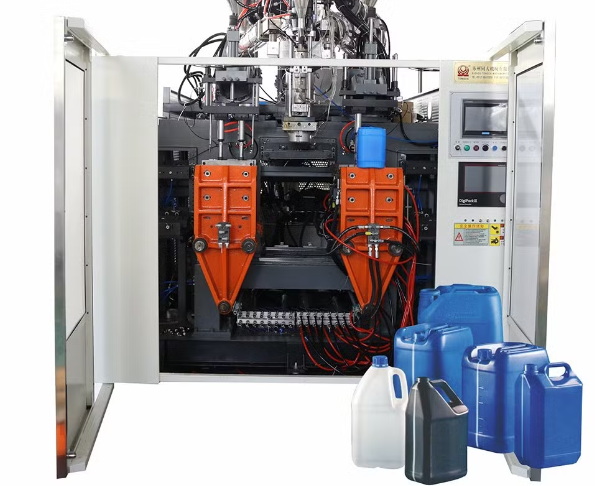

Choosing the Right Machine for Your Business

When selecting a China automatic extrusion blow molding machine, consider the following factors:

- Material Compatibility: Ensure the machine can handle the type of plastic you plan to use.

- Product Design: Choose a machine that can accommodate the size and complexity of your products.

- Production Volume: Match the machine's capacity to your output needs.

- Budget: Consider the initial investment, maintenance costs, and energy consumption.

Image: Machine Selection Criteria

Installation and Maintenance

Proper installation and regular maintenance are crucial for optimal performance. Most manufacturers provide technical support and engineer services for installation. Regular checks on hydraulic systems, molds, and control systems ensure smooth operation and extend the machine's lifespan.

Conclusion

China automatic extrusion blow molding machines are a valuable asset for businesses looking to produce high-quality plastic products efficiently. With their cost-effectiveness, versatility, and high production efficiency, these machines are ideal for a wide range of applications. By understanding the advantages and considerations for choosing the right machine, businesses can make informed decisions that enhance their production capabilities.

Frequently Asked Questions

1. What are the main types of blow molding machines?

- Extrusion Blow Molding (EBM): Ideal for medium to large containers.

- Injection Blow Molding (IBM): Used for small, precision products.

- Stretch Blow Molding (SBM): Commonly used for PET bottles.

2. How do I choose the right blow molding machine?

Consider material compatibility, product design, production volume, and budget.

3. What materials can be used in blow molding machines?

Common materials include HDPE, PP, PVC, and PET.

4. What are the benefits of using a China automatic extrusion blow molding machine?

Benefits include cost-effectiveness, high production efficiency, versatility, and environmental benefits.

5. How do I maintain a blow molding machine?

Regularly check hydraulic systems, molds, and control systems. Ensure proper lubrication and cleaning.

Citations:

[1] https://www.tzdegree.com/blow-molding-machine/

[2] https://www.tzdegree.com/extrusion-molding-machine/jerrycan-blow-molding-machine/full-automatic-double-station-extrusion-blow.html

[3] https://www.jwellextrusions.com/products/blow-molding-machine/

[4] https://tongdachinamachine.en.made-in-china.com/product/yOAtsUdZwFrg/China-Automatic-Extrusion-Blow-Molding-Machine.html

[5] https://www.tongdamachine.net/video/

[6] https://www.moldingmachinetepai.com/productstags/extrusion-blow-molding-machine.html

[7] https://sabplamach.com/advantages-of-sab-ebm-machines.html

[8] https://www.moldingmachinetepai.com/resources/what-are-the-2-types-of-extrusion-blow-moulding-machines.html

[9] https://www.leshanmachines.com/blogs/china-hdpe-blow-molding-machine

[10] https://www.apollo-china.com/industry-news/analysis-of-the-advantages-and-disadvantages-of-extrusion-blow-molding-machines/

[11] https://www.youlizn.com/news/blow-molding-machine-frequently-asked-questions.html

[12] https://www.tongdamachine.net/china-blow-molding-machine/

[13] https://www.sunmolds.com/machine/blow-molding-machine/

[14] https://changshengda.en.made-in-china.com/product/qeMndhbjpykW/China-CE-Approved-Automatic-Extrusion-Blow-Molding-Machine-With-Max-Volume-160l-EB100J1-A1-.html

[15] https://powerjet.goldsupplier.com/product.html?groupid=508455

[16] https://plasticbottlemake.com/China-automatic-one-step-pp-ppsu-pet-plastic-milk-baby-bottle-blowing-moulding-feeder-bottle-make-injection-stretch-blow-molding-machine-pd40097111.html

[17] https://www.chinaplastictech.com

[18] https://www.extrusionblow-moldingmachine.com

[19] http://jspakmachine.com/automatic-extrusion-blow-molding-machine/

[20] https://www.upg-plastic.com/extrusion-blow-molding-machine/

[21] http://www.chinalingma.com/products/Extrusion-Blow-Moulding-Machine/QCM-85-Extrusion-Blow-Moulding-Machine/Full-Automatic-Extrusion-Blow-Moulding-Machine(Double-Station)(QCM-85-20L).htm

[22] https://www.alibaba.com/product-detail/China-Automatic-HDPE-PE-Plastic-Bottle_62232972648.html

[23] https://www.meper-blowmolding.com/uploads/202208/Top-10-Blow-Molding-Machine-Manufacturers-in-China_1660967051_WNo_1000d563.jpg?sa=X&ved=2ahUKEwj4y6GEoYaMAxWonpUCHShSCrIQ_B16BAgCEAI

[24] https://www.cnziqiang.com

[25] https://www.tonva-group.com/extrusion-blow-molding-machine-with-ce/

[26] https://www.made-in-china.com/products-search/hot-china-products/Blow_Molding_Machine.html

[27] https://777pack-filling.en.made-in-china.com/product/DmaRgdboCeYZ/China-15000bph-Automatic-Extrusion-Blow-Molding-Machine-for-Pet-Plastic-Bottles.html

[28] https://www.youtube.com/watch?v=DHK1zKNs1cM

[29] https://www.biopuremax.com.br/?r=926235563081

[30] https://www.cnziqiang.com/service/video/