Content Menu

● Introduction

● Understanding Aluminum Extrusion

● Key Applications of 40x40 Aluminum Extrusion

>> Structural Frameworks

>> Machine Guarding

>> CNC Framing

>> Robotics and Automation

>> 3D Printing

● Advantages of Using 40x40 Aluminum Extrusion

>> Customizability and Versatility in Design

>> Lightweight Yet Strong

>> Cost-Effectiveness

>> Corrosion Resistance

>> Aesthetic Appeal

● Conclusion

● Related Questions

>> 1. What are the main benefits of using aluminum extrusions in machine frames?

>> 2. How do 40x40 aluminum extrusions compare to steel frames?

>> 3. Can 40x40 aluminum extrusions be used in outdoor applications?

>> 4. How can I customize a 40x40 aluminum extrusion frame for my project?

>> 5. Are there any limitations to using aluminum extrusions for machine frames?

Introduction

In the world of engineering and manufacturing, the choice of materials can significantly impact the performance, durability, and cost-effectiveness of a project. One material that has gained immense popularity in recent years is aluminum, particularly in the form of 40x40 aluminum extrusions. These versatile profiles are increasingly being used for machine frames, and for good reason. This article explores the reasons behind this trend, the advantages of using 40x40 aluminum extrusions, and their various applications in modern engineering.

Understanding Aluminum Extrusion

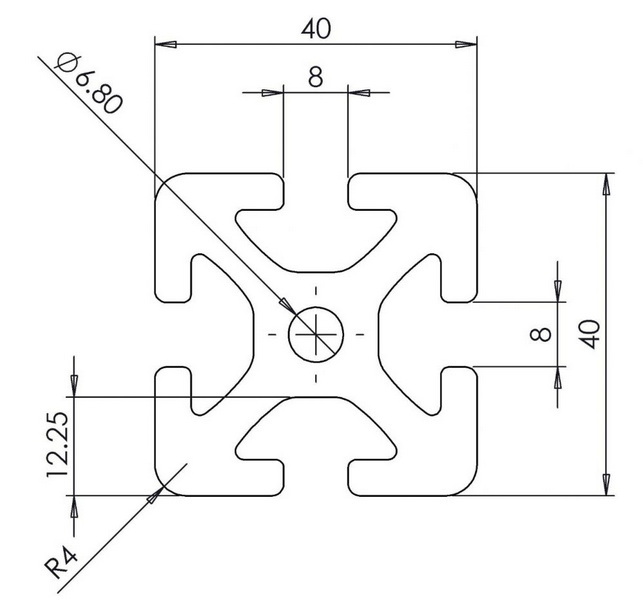

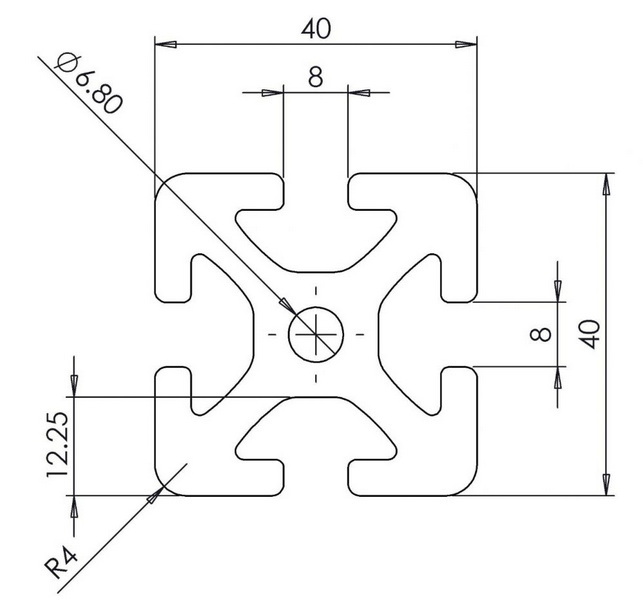

Aluminum extrusion is a manufacturing process that involves forcing aluminum alloy through a die to create a specific cross-sectional shape. This process allows for the production of complex shapes with high precision and minimal waste. The resulting aluminum extrusions are lightweight, strong, and resistant to corrosion, making them ideal for a wide range of applications.

The 40x40 aluminum extrusion profile, characterized by its square shape and T-slot design, is particularly favored for machine frames. This profile offers a robust structure while allowing for easy assembly and customization. Engineers appreciate the flexibility that 40x40 aluminum extrusions provide, enabling them to create machine frames that meet specific requirements without the need for extensive machining or fabrication.

Key Applications of 40x40 Aluminum Extrusion

Structural Frameworks

One of the primary applications of 40x40 aluminum extrusions is in the construction of structural frameworks. These profiles provide a strong and stable foundation for various machines and equipment. The lightweight nature of aluminum means that the overall weight of the machine is reduced, which can lead to lower shipping costs and easier installation.

Machine Guarding

Safety is a top priority in any industrial setting, and 40x40 aluminum extrusions are often used to create machine guarding systems. These frames can be designed to enclose machinery, protecting operators from moving parts and potential hazards. The modular nature of aluminum extrusions allows for easy adjustments and modifications, ensuring that safety measures can be tailored to specific machines and environments.

CNC Framing

Computer Numerical Control (CNC) machines require precise and stable frames to ensure accurate machining. 40x40 aluminum extrusions are ideal for CNC framing due to their rigidity and ability to absorb vibrations. Engineers can design custom frames that accommodate various CNC machines, enhancing their performance and longevity.

Robotics and Automation

The rise of automation in manufacturing has led to an increased demand for lightweight and durable materials. 40x40 aluminum extrusions are commonly used in the construction of robotic arms and automated systems. Their strength-to-weight ratio allows for the creation of agile and efficient robotic solutions that can perform complex tasks with precision.

3D Printing

As 3D printing technology continues to evolve, the need for stable and adjustable frames has become more pronounced. 40x40 aluminum extrusions are often used to build frames for 3D printers, providing a solid base that minimizes vibrations and ensures accurate printing. The ability to customize the frame dimensions and configurations makes aluminum extrusions a popular choice among 3D printing enthusiasts and professionals alike.

Advantages of Using 40x40 Aluminum Extrusion

Customizability and Versatility in Design

One of the standout features of 40x40 aluminum extrusions is their customizability. Engineers can easily modify the design of their machine frames to accommodate specific components or requirements. The T-slot design allows for the addition of brackets, panels, and other accessories without the need for complex machining. This versatility enables engineers to adapt their designs quickly, saving time and resources.

Lightweight Yet Strong

Aluminum is known for its excellent strength-to-weight ratio. The 40x40 aluminum extrusion profile is no exception. Despite being lightweight, it offers exceptional strength and rigidity, making it suitable for demanding applications. This characteristic is particularly beneficial in industries where weight reduction is crucial, such as aerospace and automotive manufacturing.

Cost-Effectiveness

Using 40x40 aluminum extrusions can lead to significant cost savings in both material and labor. The extrusion process minimizes waste, and the lightweight nature of aluminum reduces shipping costs. Additionally, the ease of assembly and customization means that engineers can complete projects more quickly, further reducing labor costs.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer that helps prevent corrosion. This property makes 40x40 aluminum extrusions ideal for use in environments where exposure to moisture or chemicals is a concern. The longevity of aluminum frames can lead to lower maintenance costs and increased reliability over time.

Aesthetic Appeal

In addition to their functional benefits, 40x40 aluminum extrusions also offer aesthetic advantages. The clean lines and modern appearance of aluminum frames can enhance the overall look of machinery and equipment. This is particularly important in industries where presentation matters, such as in consumer-facing applications.

Conclusion

The shift towards 40x40 aluminum extrusions for machine frames is driven by a combination of factors, including their lightweight nature, strength, customizability, and cost-effectiveness. As engineers continue to seek innovative solutions for their projects, aluminum extrusions are likely to remain a popular choice. The versatility of 40x40 aluminum extrusions allows for a wide range of applications, from structural frameworks to robotics, making them an essential component in modern engineering.

Related Questions

1. What are the main benefits of using aluminum extrusions in machine frames?

Aluminum extrusions offer several benefits, including lightweight construction, high strength, corrosion resistance, and ease of customization. These features make them ideal for various applications in machine frames.

2. How do 40x40 aluminum extrusions compare to steel frames?

While steel frames are strong, they are significantly heavier than aluminum extrusions. Aluminum offers a better strength-to-weight ratio, making it easier to handle and install. Additionally, aluminum is resistant to corrosion, which can lead to lower maintenance costs over time.

3. Can 40x40 aluminum extrusions be used in outdoor applications?

Yes, 40x40 aluminum extrusions are suitable for outdoor applications due to their corrosion resistance. However, it is essential to consider the specific environmental conditions and choose appropriate finishes if necessary.

4. How can I customize a 40x40 aluminum extrusion frame for my project?

Customization can be achieved by using T-slot connectors, brackets, and panels that fit the 40x40 profile. This modular design allows for easy adjustments and modifications to meet specific project requirements.

5. Are there any limitations to using aluminum extrusions for machine frames?

While aluminum extrusions are versatile, they may not be suitable for applications requiring extremely high load-bearing capacities. In such cases, engineers may need to consider alternative materials or designs to meet specific strength requirements.