Content Menu

● Understanding Aluminum Extrusion

● Importance of Aluminum Extrusion Guidelines

>> 1. Design Optimization

>> 2. Material Selection

>> 3. Process Efficiency

● Key Aluminum Extrusion Guidelines

>> 1. Smooth Transitions

>> 2. Enhance Visual Surfaces

>> 3. Temperature Control

>> 4. Pressure Management

● Quality Control Measures

● Innovations in Aluminum Extrusion Technology

>> 1. Automation

>> 2. Advanced Software Solutions

>> 3. Sustainable Practices

● Conclusion

● FAQ

>> 1. What are the main benefits of using aluminum extrusion?

>> 2. How does temperature affect the aluminum extrusion process?

>> 3. What types of alloys are commonly used in aluminum extrusion?

>> 4. How can I ensure my extruded profiles meet quality standards?

>> 5. What are some common applications of aluminum extrusions?

● Citations:

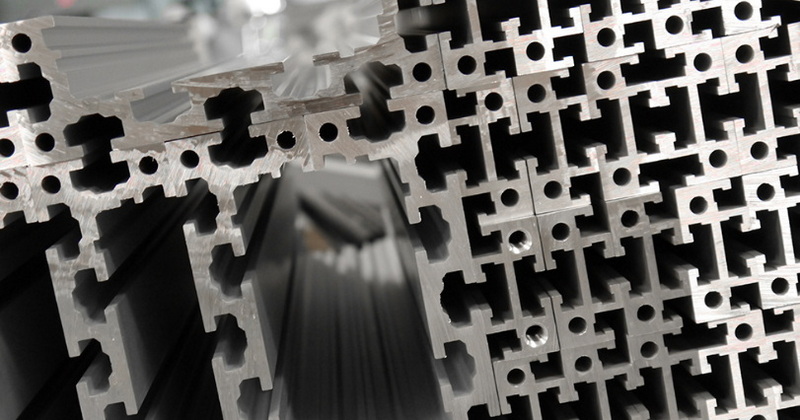

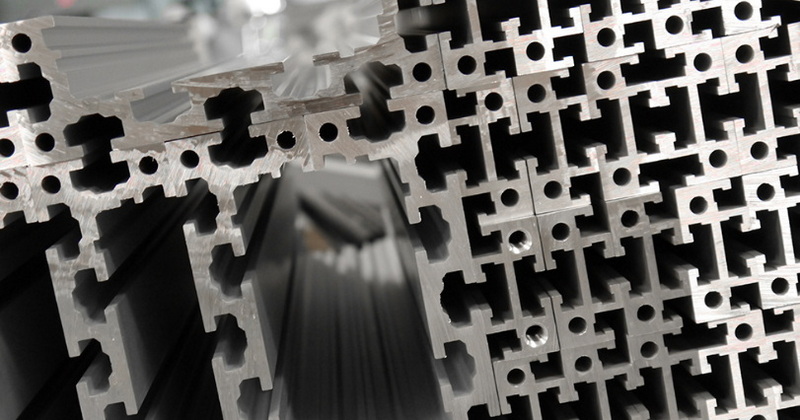

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into specific cross-sectional profiles by forcing it through a die. This versatile method is widely used in various industries, including construction, automotive, and aerospace. However, achieving high-quality results in aluminum extrusion requires adherence to specific guidelines. This article explores the importance of these guidelines and how they contribute to the overall success of aluminum extrusion projects.

Understanding Aluminum Extrusion

Aluminum extrusion involves several key steps:

1. Preparation of the Die: The die must be meticulously designed and preheated to ensure optimal metal flow.

2. Preheating the Aluminum Billet: The aluminum is heated to a temperature that allows it to be malleable but not molten.

3. Extrusion Process: A hydraulic press forces the heated aluminum through the die, forming it into the desired shape.

4. Cooling and Quenching: The extruded profile is rapidly cooled to set its shape and properties.

5. Stretching and Cutting: The profiles are straightened and cut to length for further processing or shipping.

Understanding these steps is crucial for implementing effective aluminum extrusion guidelines.

Importance of Aluminum Extrusion Guidelines

1. Design Optimization

The design of an aluminum extrusion profile significantly impacts its manufacturability and performance. Guidelines help designers create profiles that are not only functional but also cost-effective to produce. Key aspects include:

- Balanced Wall Thickness: Ensuring that wall thicknesses are uniform prevents warping and distortion during cooling.

- Avoiding Sharp Corners: Rounding corners reduces stress concentrations that can lead to cracking.

Additionally, designers should consider using finite element analysis (FEA) during the design phase to simulate how the profile will behave under various loads and conditions. This proactive approach allows for adjustments before production begins, ultimately saving time and resources.

2. Material Selection

Choosing the right aluminum alloy is essential for achieving desired mechanical properties such as strength, corrosion resistance, and weight. Guidelines provide insights into which alloys are best suited for specific applications, ensuring that the final product meets performance requirements.

- Common Alloys: Popular alloys used in extrusion include 6061, known for its good mechanical properties; 6063, favored for architectural applications due to its excellent finishing characteristics; and 7075, which offers high strength-to-weight ratios ideal for aerospace applications.

Understanding the characteristics of each alloy helps manufacturers select materials that align with their project goals.

3. Process Efficiency

Following extrusion guidelines can enhance process efficiency by minimizing waste and reducing production costs. For example:

- Weight-per-Foot Considerations: Keeping profiles lightweight (ideally under 3 pounds per foot) can improve press operation efficiency.

- Cross-Section Size Limits: Profiles should ideally fit within a circumscribing circle diameter (CCD) of 8 inches to optimize cost-effectiveness.

Efficient processes not only save time but also reduce energy consumption, contributing to more sustainable manufacturing practices.

Key Aluminum Extrusion Guidelines

To achieve high-quality results in aluminum extrusion, manufacturers should adhere to several critical guidelines:

1. Smooth Transitions

All transitions in the profile should be smooth, with generous radii at junctions between thick and thin sections. This reduces stress points and improves flow during the extrusion process.

2. Enhance Visual Surfaces

Designers should consider incorporating grooves, ribs, or decorative details into their profiles. These features not only enhance aesthetics but also improve functionality by aiding in assembly and reducing twisting during handling.

3. Temperature Control

Maintaining proper temperature throughout the extrusion process is vital. The aluminum should be heated uniformly to avoid deformation, while cooling rates must be controlled to ensure consistent mechanical properties.

Proper temperature management can also prevent defects such as surface cracking or internal voids that may compromise the integrity of the final product.

4. Pressure Management

Controlling pressure during extrusion is crucial for achieving precise shapes. Excessive pressure can lead to defects such as surface blemishes or internal voids.

Manufacturers should monitor pressure levels closely throughout the process and adjust as necessary to maintain optimal conditions.

Quality Control Measures

Implementing quality control measures throughout the aluminum extrusion process ensures that products meet industry standards and customer expectations:

- Regular Inspections: Conducting routine inspections at various stages of production helps identify potential issues early on.

- Testing Mechanical Properties: Performing tests such as tensile strength, hardness, and corrosion resistance on samples from each batch ensures consistency in quality.

- Surface Finish Assessment: Evaluating surface finishes for defects like scratches or blemishes helps maintain aesthetic standards.

By integrating quality control measures into their processes, manufacturers can enhance reliability and customer satisfaction.

Innovations in Aluminum Extrusion Technology

As technology advances, so do methods for improving aluminum extrusion processes:

1. Automation

Automation plays a significant role in enhancing efficiency within aluminum extrusion facilities. Automated systems can manage tasks such as billet loading, die changes, and quality inspections with minimal human intervention.

2. Advanced Software Solutions

Software tools enable manufacturers to simulate the extrusion process digitally before actual production begins. This capability allows for optimization of die design and adjustment of parameters based on predicted outcomes.

3. Sustainable Practices

The industry is increasingly focusing on sustainable practices by recycling scrap material generated during production and using energy-efficient machinery. These initiatives not only reduce waste but also lower operational costs.

Conclusion

In conclusion, adhering to aluminum extrusion guidelines is critical for achieving high-quality results in manufacturing processes involving this versatile material. By focusing on design optimization, material selection, process efficiency, strict adherence to established guidelines, and embracing technological innovations, manufacturers can produce extrusions that meet or exceed customer expectations while maintaining sustainability in their operations.

FAQ

1. What are the main benefits of using aluminum extrusion?

Aluminum extrusion offers numerous benefits including design flexibility, lightweight structures, corrosion resistance, and cost-effectiveness compared to other manufacturing methods like stamping or machining.

2. How does temperature affect the aluminum extrusion process?

Temperature plays a crucial role in the malleability of aluminum during extrusion. Proper heating ensures that the metal flows smoothly through the die without becoming brittle or deforming excessively.

3. What types of alloys are commonly used in aluminum extrusion?

Commonly used alloys include 6061 for structural applications due to its strength and corrosion resistance, 6063 for architectural applications due to its excellent finishing characteristics, and 7075 for aerospace applications due to its high strength-to-weight ratio.

4. How can I ensure my extruded profiles meet quality standards?

To ensure quality standards are met, follow established design guidelines, maintain strict temperature control during processing, conduct regular inspections throughout production, and implement robust quality control measures.

5. What are some common applications of aluminum extrusions?

Aluminum extrusions are widely used in various applications including window frames, door frames, heat sinks in electronics, structural components in vehicles, and architectural elements in buildings.

Citations:

[1] https://aec.org/extrusion-design-tips

[2] https://aec.org/key-design-considerations

[3] https://www.tensilemillcnc.com/blog/the-most-efficient-aluminum-extrusion-process-with-precise-quality-control-will-guarantee-the-best-results-of-your-production

[4] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[5] https://aec.org/aluminum-extrusion-process

[6] https://www.aluminum.org/understanding-aluminum-extrusion-tolerances-video-series

[7] https://leadrp.net/blog/a-complete-guide-to-aluminum-extrusion/

[8] https://tri-stateal.com/resources/extrusion-guide/

[9] https://diversified-metals.ca/blog/the-aluminum-extrusion-process-common-methods-characteristics-applications

[10] https://www.youtube.com/watch?v=Bc7o_sEdX8U

[11] https://www.alamy.com/stock-photo/aluminum-extrusion.html

[12] https://www.youtube.com/watch?v=NVhkm0Cg44w

[13] https://americandouglasmetals.com/2024/05/19/understanding-the-aluminum-extrusion-process/

[14] https://www.youtube.com/watch?v=P8BWQBP4Vhk