Content Menu

● Regional Market Leaders

>> 1. Asia Pacific: The Manufacturing Powerhouse

>>> Key Drivers:

>>> Growth Metrics:

>>> Emerging Opportunities:

>> 2. North America: Innovation and Sustainability

>>> Key Drivers:

>>> Notable Players:

>>> Technological Edge:

>> 3. Europe: Precision and Regulation-Driven Growth

>>> Key Drivers:

>>> Growth Metrics:

>> 4. Emerging Markets: Latin America and the Middle East

>>> Regional Highlights:

>>> Challenges and Opportunities:

● Technological Advancements Shaping the Market

>> 1. AI and Automation

>> 2. Sustainability Initiatives

>> 3. Hybrid Manufacturing

● Market Segmentation and Future Outlook

>> Future Projections:

● Competitive Landscape

>> Innovation Spotlight:

● Conclusion

● FAQs

>> 1. What is driving growth in the global extrusion machinery market?

>> 2. Which region has the highest CAGR in extrusion machinery?

>> 3. How is Europe adapting to sustainability trends in extrusion?

>> 4. Who are the key players in the global extrusion machinery market?

>> 5. What role does AI play in extrusion machinery?

● Citations:

The global extrusion machinery market is a cornerstone of modern manufacturing, enabling the production of plastic, metal, and composite materials used across industries. With applications ranging from automotive components to construction materials, this market is projected to grow from USD 8.93 billion in 2024 to USD 16.20 billion by 2032, reflecting a 4.2–4.5% CAGR[1][4][5]. Below, we analyze the regions driving this expansion, supported by key trends, innovations, and competitive dynamics.

Regional Market Leaders

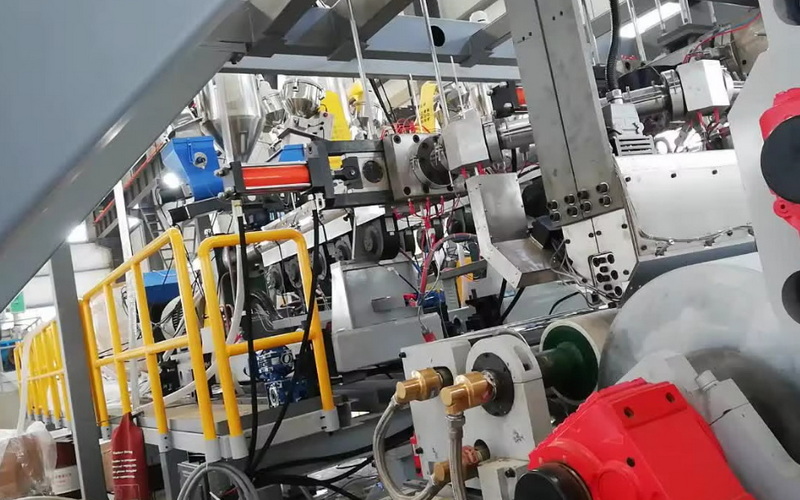

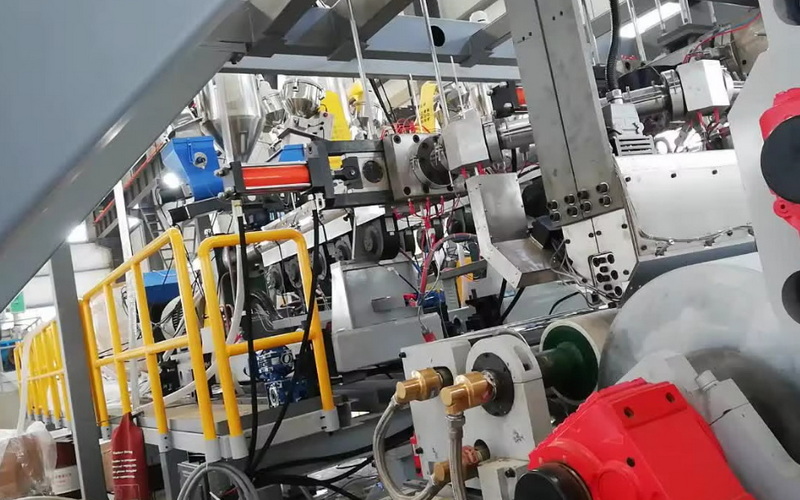

1. Asia Pacific: The Manufacturing Powerhouse

Asia Pacific dominates the global extrusion machinery market, accounting for over 40% of global revenue[1][4]. China, India, and South Korea are pivotal contributors, with China alone holding a significant portion due to its massive manufacturing and packaging sectors.

Key Drivers:

- Industrialization and Urbanization: Rapid infrastructure development in India and Southeast Asia fuels demand for extruded construction materials like pipes, profiles, and insulation[1][4].

- E-Commerce Boom: China's packaging industry relies heavily on plastic extrusion for films, containers, and bottles, driven by online retail growth[1][7].

- Government Initiatives: Policies promoting industrial expansion in India and Vietnam attract investments in extrusion technologies[4][5].

Growth Metrics:

- India's CAGR (2025–2035): 5.6%[2][7]

- South Korea's CAGR: 5.3%[2]

Emerging Opportunities:

- Recycling Infrastructure: Growing adoption of recycled plastic extruders to meet sustainability goals[5][7].

- Automotive Lightweighting: Increased use of extruded aluminum and composites in electric vehicles (EVs)[4][7].

2. North America: Innovation and Sustainability

North America, led by the U.S. and Canada, is a hub for advanced extrusion technologies. The region's market is valued at USD 377.04 million in 2024, with a 6.2% CAGR projected for the extrusion press machine segment[1][4].

Key Drivers:

- Automotive Lightweighting: Demand for fuel-efficient vehicles boosts aluminum and composite extrusion for parts like frames and trim[1][4].

- Smart Manufacturing: AI integration optimizes extrusion parameters, reducing waste and energy use[2][7].

- Recycling Focus: Companies adopt eco-friendly extrusion systems to process recycled plastics[5][7].

Notable Players:

- Corma Inc. (U.S.)

- Toshiba (Japan, with significant U.S. operations)[2]

Technological Edge:

- Additive Manufacturing Integration: Combining 3D printing with extrusion for complex geometries[2][6].

- Energy-Efficient Designs: Advanced control systems reduce power consumption by 15–20%[4][6].

3. Europe: Precision and Regulation-Driven Growth

Europe's market, valued at USD 282.78 million in 2024, thrives on stringent sustainability standards and advanced engineering. Germany is the regional leader, leveraging its automotive and construction sectors[1][2].

Key Drivers:

- Circular Economy Policies: EU regulations push manufacturers to adopt energy-efficient extrusion systems[1][5].

- Automotive Excellence: German automakers use extruded components for durability and performance[1][7].

- Technical Expertise: Companies like Bausano & Figli (Italy) and Reifenhauser Group (Germany) lead in twin-screw extruder innovation[2][5].

Growth Metrics:

- Europe's CAGR (2025–2030): 4.3%[1]

- Germany's Market Share: Largest in Europe, driven by Industry 4.0 adoption[1][2].

4. Emerging Markets: Latin America and the Middle East

Latin America and the Middle East & Africa are witnessing accelerated growth, driven by infrastructure projects and industrialization.

Regional Highlights:

- Brazil: Leads with a 6.2% CAGR (2025–2035), fueled by construction and packaging demand[2][7].

- Saudi Arabia: Boasts a 5.9% CAGR, supported by Vision 2030 diversification efforts[4][7].

- Mexico: Growth in automotive and packaging sectors drives a 5.0% CAGR[4][7].

| Region | CAGR (2025–2035) | Key Industries |

| Brazil | 6.2% | Construction, Packaging |

| Saudi Arabia | 5.9% | Infrastructure, Plastics |

| Mexico | 5.0% | Automotive, Electronics |

Challenges and Opportunities:

- Raw Material Volatility: Fluctuating polymer prices impact profitability[2][5].

- Customization Demand: Tailored solutions for niche applications (e.g., food extrusion) gain traction[3][6].

Technological Advancements Shaping the Market

Innovation is critical to maintaining competitiveness in the global extrusion machinery market. Key trends include:

1. AI and Automation

- Process Optimization: Machine learning algorithms adjust parameters in real time to minimize defects[2][7].

- Predictive Maintenance: Sensors monitor machine health, reducing downtime by 20–30%[6][7].

2. Sustainability Initiatives

- Recycled Material Compatibility: Machines like JianTai's Recycled Plastic Extruder process post-consumer waste[5][7].

- Energy-Efficient Designs: Lima Extrusion's twin-screw systems reduce power consumption by 15–20%[4][5].

3. Hybrid Manufacturing

- 3D Printing Integration: Extrusion combined with additive manufacturing enables complex geometries[2][6].

- Multi-Material Extrusion: Single machines process plastics, metals, and ceramics for diverse applications[3][6].

Market Segmentation and Future Outlook

The global extrusion machinery market is segmented by type, material, process, and end-use:

| Category | Subsegments | Growth Drivers |

| Type | Single-Screw, Twin-Screw | Twin-screw demand for precision |

| Material | Metals, Polymers, Concrete, Ceramics | Polymer dominance in packaging |

| Process | Cold, Hot, Friction Extrusion | Hot extrusion for automotive |

| End-Use | Construction, Automotive, Packaging | Construction sector growth |

Future Projections:

- Market Size by 2030: USD 11.58 billion (Grand View Research)[5].

- Key Growth Areas: Recycled plastics, EV components, and smart packaging[2][7].

Competitive Landscape

The market features a mix of global giants and regional players:

- Top Companies: Coperion, Reifenhauser Group, KraussMaffei Group[2][5].

- Strategies: R&D investments, partnerships for circular economy solutions[2][5].

Innovation Spotlight:

- Smart Extruders: IoT-enabled machines with real-time analytics[6][7].

- Modular Designs: Customizable systems for small-batch production[3][6].

Conclusion

The global extrusion machinery market is on a robust growth trajectory, with Asia Pacific, North America, and Europe leading in revenue and innovation. Emerging economies in Latin America and the Middle East are becoming vital growth frontiers, driven by industrial expansion and sustainability initiatives. As AI and recycling technologies evolve, manufacturers worldwide will prioritize efficiency and environmental responsibility to stay competitive.

FAQs

1. What is driving growth in the global extrusion machinery market?

The market is propelled by rising demand for plastic and metal products in construction, automotive, and packaging sectors, alongside advancements in AI and sustainable technologies[1][2][5].

2. Which region has the highest CAGR in extrusion machinery?

Brazil leads with a 6.2% CAGR (2025–2035), followed by Saudi Arabia (5.9%) and India (5.6%)[2][4][7].

3. How is Europe adapting to sustainability trends in extrusion?

European manufacturers focus on energy-efficient machinery and recyclable materials to comply with strict EU environmental regulations[1][5][7].

4. Who are the key players in the global extrusion machinery market?

Major companies include AMUT SPA, Toshiba, Reifenhauser Group, and Lima Extrusion[2][5][7].

5. What role does AI play in extrusion machinery?

AI enhances precision, reduces material waste, and optimizes energy consumption through real-time process monitoring[2][6][7].

Citations:

[1] https://www.grandviewresearch.com/industry-analysis/extrusion-machinery-market-report

[2] https://www.yjing-extrusion.com/what-are-the-latest-trends-in-the-extrusion-machinery-market.html

[3] https://www.thebusinessresearchcompany.com/report/extrusion-machinery-global-market-report

[4] https://www.databridgemarketresearch.com/reports/global-extrusion-machinery-market

[5] https://www.giiresearch.com/report/grvi1654338-extrusion-machinery-market-size-share-trends.html

[6] https://www.linkedin.com/pulse/continuous-extrusion-machine-market-opportunities-memnf/

[7] https://www.globenewswire.com/news-release/2025/02/05/3021359/0/en/Plastic-Extrusion-Machine-Market-to-Grow-at-4-7-CAGR-During-2025-2035-Boosting-Global-Industry-to-USD-12-343-2-Million-by-2035-Future-Market-Insights-Inc.html

[8] https://write.as/andrewwalker/extrusion-machinery-market-growth-trends-innovations-and-future-outlook