Content Menu

● Introduction

● Understanding Aluminum Extrusion

● Key Benefits of Aluminum Extrusion

>> Lightweight and Strength Advantages

>> Design Flexibility and Customization Options

>> Cost-Effectiveness in Production

● Applications of Aluminum Extrusion

>> Construction

>> Automotive

>> Aerospace

>> Electronics

>> Transportation

● Choosing Custom Aluminum Extrusions

>> Material Selection

>> Design Considerations

>> Manufacturer Experience

● The Role of Aluminum Extrusion Suppliers

>> Quality Assurance

>> Lead Times and Flexibility

>> Customer Support

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of aluminum extrusion products?

>> 2. How does the aluminum extrusion process work?

>> 3. Which industries primarily use aluminum extrusion products?

>> 4. What factors should I consider when choosing custom aluminum extrusions?

>> 5. How can I find a reliable aluminum extrusion supplier?

Introduction

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This versatile technique has gained immense popularity across various industries due to its numerous advantages, including lightweight, strength, and design flexibility. As industries continue to evolve, the demand for aluminum extrusion products has surged, making it essential to understand which sectors benefit the most from these applications. This article explores the key industries that leverage aluminum extrusion, highlighting the benefits and applications of aluminum extrusion products.

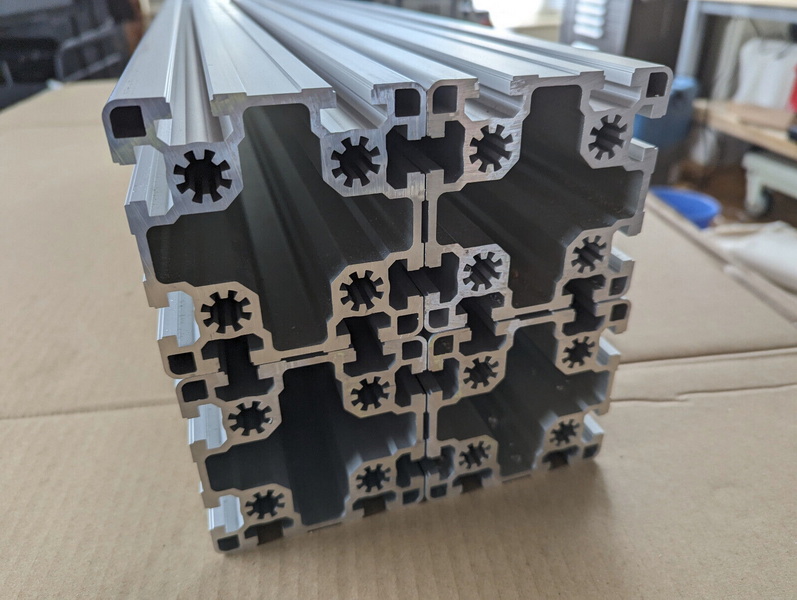

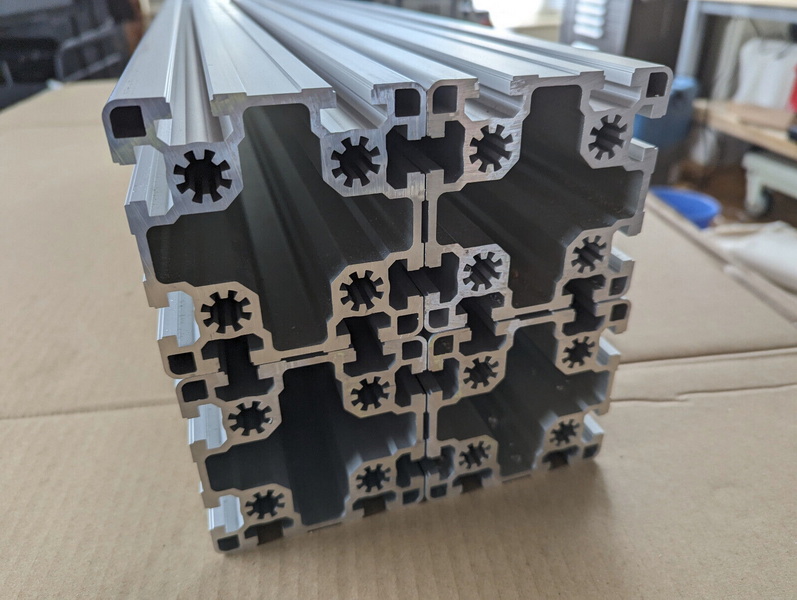

Understanding Aluminum Extrusion

Aluminum extrusion involves forcing aluminum alloy through a die to create a specific shape. The process begins with heating the aluminum to a malleable state, allowing it to be pushed through the die. Once extruded, the aluminum is cooled and cut to the desired length. This method allows for the production of complex shapes and profiles that are difficult to achieve with other manufacturing techniques.

Aluminum extrusion products come in various forms, including bars, tubes, and custom profiles. These products are widely used in construction, automotive, aerospace, electronics, and many other sectors. The ability to create lightweight yet strong components makes aluminum extrusion an attractive option for manufacturers looking to enhance their products' performance.

Key Benefits of Aluminum Extrusion

The benefits of aluminum extrusion products are numerous, making them a preferred choice for many industries. Here are some of the key advantages:

Lightweight and Strength Advantages

Aluminum is known for its lightweight properties, which significantly reduce the overall weight of products. This is particularly beneficial in industries such as automotive and aerospace, where weight reduction can lead to improved fuel efficiency and performance. Despite being lightweight, aluminum extrusion products maintain high strength, making them suitable for structural applications.

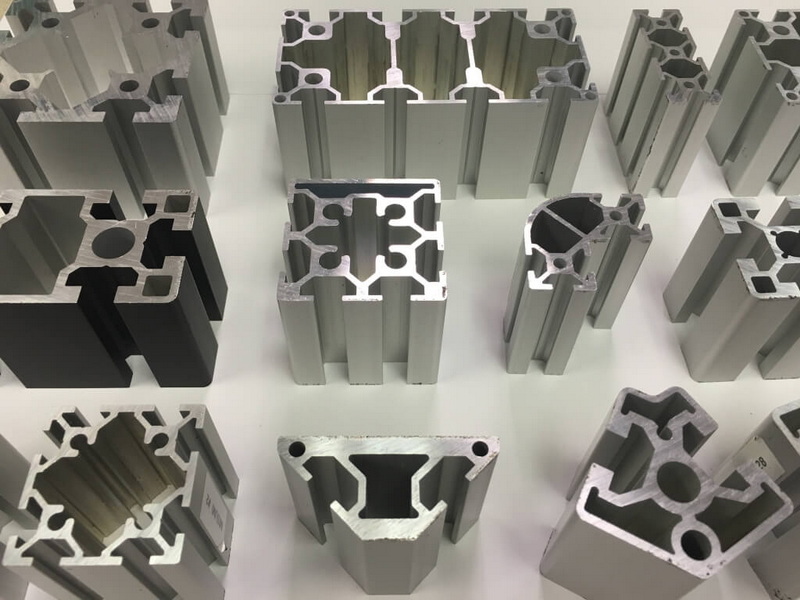

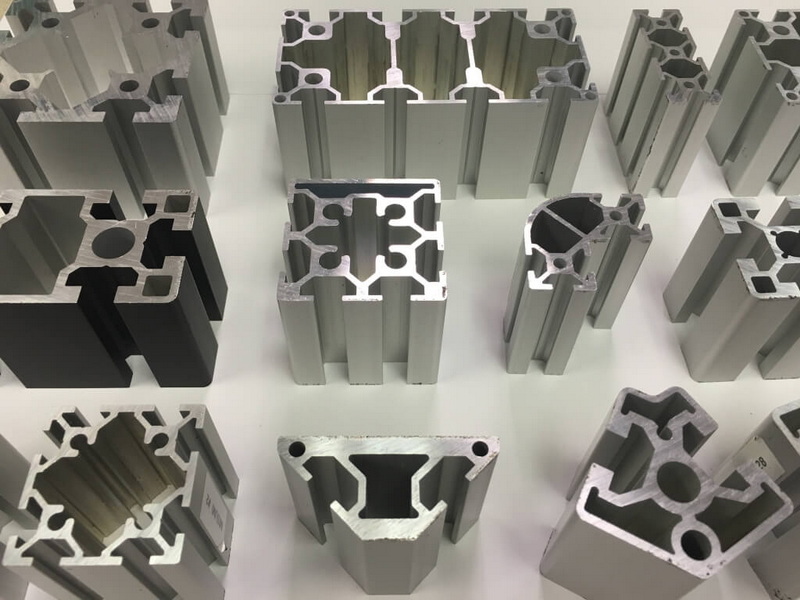

Design Flexibility and Customization Options

One of the most significant advantages of aluminum extrusion is the design flexibility it offers. Manufacturers can create custom profiles tailored to specific applications, allowing for innovative designs that meet unique requirements. This flexibility enables industries to develop products that stand out in the market, enhancing their competitiveness.

Cost-Effectiveness in Production

Aluminum extrusion is a cost-effective manufacturing process, especially for large production runs. The ability to produce complex shapes in a single operation reduces the need for additional machining or assembly, lowering overall production costs. Additionally, aluminum's recyclability contributes to its cost-effectiveness, as recycled aluminum requires less energy to process than primary aluminum.

Applications of Aluminum Extrusion

Aluminum extrusion products find applications in various industries, each benefiting from the unique properties of aluminum. Here are some key sectors that leverage aluminum extrusion:

Construction

The construction industry is one of the largest consumers of aluminum extrusion products. From window frames and curtain walls to structural components and roofing systems, aluminum's lightweight and corrosion-resistant properties make it an ideal choice for construction applications. Aluminum extrusion products enhance the aesthetic appeal of buildings while providing durability and energy efficiency.

Automotive

In the automotive sector, aluminum extrusion products are used in various components, including chassis, bumpers, and heat exchangers. The lightweight nature of aluminum helps reduce vehicle weight, leading to improved fuel efficiency and lower emissions. Additionally, aluminum's ability to withstand high temperatures makes it suitable for engine components and other critical parts.

Aerospace

The aerospace industry demands materials that are both lightweight and strong, making aluminum extrusion products a perfect fit. Components such as aircraft frames, wing structures, and landing gear often utilize aluminum extrusions to achieve the necessary strength-to-weight ratio. The use of aluminum in aerospace applications contributes to enhanced performance and fuel efficiency.

Electronics

Aluminum extrusion products are widely used in the electronics industry for heat sinks, enclosures, and structural components. The excellent thermal conductivity of aluminum helps dissipate heat from electronic devices, ensuring optimal performance and longevity. Additionally, aluminum's lightweight properties make it an attractive option for portable electronic devices.

Transportation

In the transportation sector, aluminum extrusion products are utilized in various applications, including railings, bus frames, and trailers. The lightweight nature of aluminum helps improve fuel efficiency in transportation vehicles, while its strength ensures safety and durability. The versatility of aluminum extrusions allows for innovative designs that enhance the functionality of transportation equipment.

Choosing Custom Aluminum Extrusions

When selecting custom aluminum extrusions, several factors should be considered to ensure the best results for your project. Here are some key considerations:

Material Selection

Choosing the right aluminum alloy is crucial for achieving the desired properties in your extrusion products. Different alloys offer varying levels of strength, corrosion resistance, and machinability. Understanding the specific requirements of your application will help you select the most suitable material.

Design Considerations

The design of the extrusion profile plays a significant role in its performance. Collaborating with experienced engineers and designers can help optimize the profile for strength, weight, and functionality. Considerations such as wall thickness, shape complexity, and surface finish should be taken into account during the design phase.

Manufacturer Experience

Working with a reputable aluminum extrusion manufacturer is essential for ensuring high-quality products. Look for manufacturers with a proven track record in producing custom extrusions and a commitment to quality control. Experienced manufacturers can provide valuable insights and recommendations throughout the design and production process.

The Role of Aluminum Extrusion Suppliers

Selecting the right aluminum extrusion supplier is critical to the success of your project. Here are some factors to consider when choosing a supplier:

Quality Assurance

Ensure that the supplier adheres to strict quality control measures to guarantee the consistency and reliability of their products. Look for suppliers with certifications and industry standards that demonstrate their commitment to quality.

Lead Times and Flexibility

Consider the supplier's lead times and ability to accommodate changes in your project requirements. A reliable supplier should be able to provide timely deliveries and adapt to your needs as they evolve.

Customer Support

Strong customer support is essential for addressing any questions or concerns that may arise during the production process. Choose a supplier that offers responsive communication and assistance throughout your project.

Conclusion

Aluminum extrusion products play a vital role in various industries, offering numerous benefits such as lightweight, strength, and design flexibility. From construction and automotive to aerospace and electronics, the applications of aluminum extrusion are vast and diverse. As industries continue to seek innovative solutions, the demand for aluminum extrusion products is expected to grow, making it essential for manufacturers to understand the advantages and applications of this versatile material.

By choosing the right custom aluminum extrusions and working with reputable suppliers, businesses can enhance their products' performance and competitiveness in the market. The future of aluminum extrusion looks promising, with ongoing advancements in technology and design paving the way for even more innovative applications.

Frequently Asked Questions

1. What are the main advantages of aluminum extrusion products?

Aluminum extrusion products offer several advantages, including lightweight properties, high strength, design flexibility, and cost-effectiveness in production. These benefits make aluminum extrusions suitable for various applications across multiple industries.

2. How does the aluminum extrusion process work?

The aluminum extrusion process involves heating aluminum alloy to a malleable state and then forcing it through a die to create a specific shape. Once extruded, the aluminum is cooled and cut to the desired length, allowing for the production of complex profiles.

3. Which industries primarily use aluminum extrusion products?

Aluminum extrusion products are widely used in industries such as construction, automotive, aerospace, electronics, and transportation. Each sector benefits from the unique properties of aluminum, including its lightweight and strength.

4. What factors should I consider when choosing custom aluminum extrusions?

When selecting custom aluminum extrusions, consider factors such as material selection, design considerations, and the experience of the manufacturer. Collaborating with knowledgeable engineers can help optimize the profile for your specific application.

5. How can I find a reliable aluminum extrusion supplier?

To find a reliable aluminum extrusion supplier, look for companies with a proven track record, strict quality assurance measures, and strong customer support. Researching supplier reviews and industry certifications can also help ensure you choose a reputable partner.