Content Menu

● Introduction to Aluminum Extruders

>> Popular Aluminum Extruder Options

>>> 1. Flexion Extruder

>>> 2. BondTech Extruders

>>> 3. All-Aluminum Extruders on eBay and Amazon

>> Installation and Modifications

● Benefits of Upgrading to an Aluminum Extruder

● Troubleshooting Common Issues

● The Role of Aluminum in 3D Printing

>> Advantages of Aluminum Extrusions in 3D Printing

● Integration of 3D Printing with Aluminum Extrusion

>> Benefits of Custom Aluminum Extrusion with 3D Printing

● Common Faults in Aluminum Extruders

>> Solutions to Common Faults

● Conclusion

● FAQ

>> 1. What are the benefits of using an aluminum extruder on the Replicator 2X?

>> 2. How do I install an aluminum extruder on the Replicator 2X?

>> 3. What modifications are needed for a Replicator 2 extruder to fit the Replicator 2X?

>> 4. Can I use any type of filament with an aluminum extruder?

>> 5. How do I troubleshoot common issues with aluminum extruders on the Replicator 2X?

● Citations:

The MakerBot Replicator 2X is a dual-extruder 3D printer known for its ability to print objects in two colors, making it a versatile tool for advanced users and makers. However, like many 3D printers, it can benefit from upgrades to enhance performance and reliability. One of the most significant upgrades is replacing the stock extruder with an aluminum extruder. In this article, we will explore the best aluminum extruder options for the Replicator 2X, discussing their features, installation, and benefits.

Introduction to Aluminum Extruders

Aluminum extruders are preferred over stock extruders for several reasons:

1. Durability: Aluminum is more durable than the materials used in stock extruders, providing better heat dissipation and resistance to wear and tear.

2. Performance: They offer improved filament feeding and extrusion, reducing the likelihood of jams and clogs.

3. Flexibility: Aluminum extruders can handle a wider range of filament types, including flexible and ultra-flexible materials.

Popular Aluminum Extruder Options

Several aluminum extruder options are available for the Replicator 2X, each with its unique features and benefits.

1. Flexion Extruder

The Flexion extruder is highly recommended for its versatility and performance. It works well with all types of filament and is particularly designed for flexible and ultra-flexible filaments. The Flexion extruder is available specifically for the Replicator 2, but with some modifications, it can be adapted for the Replicator 2X.

2. BondTech Extruders

BondTech extruders are known for their high-quality construction and performance. They are available for a variety of 3D printers, including the Replicator 2X, though they might require some modifications to fit perfectly. These extruders are praised for their ability to handle a wide range of filaments efficiently.

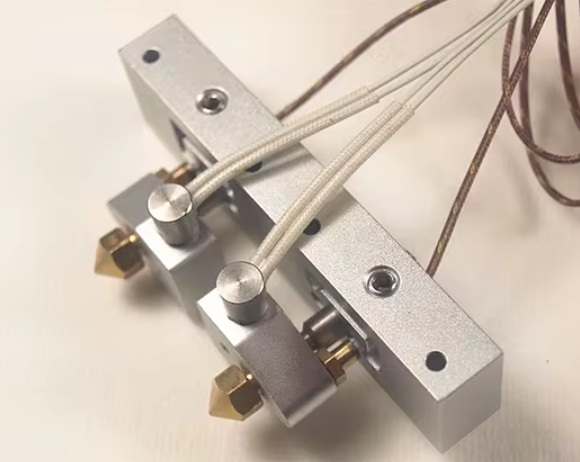

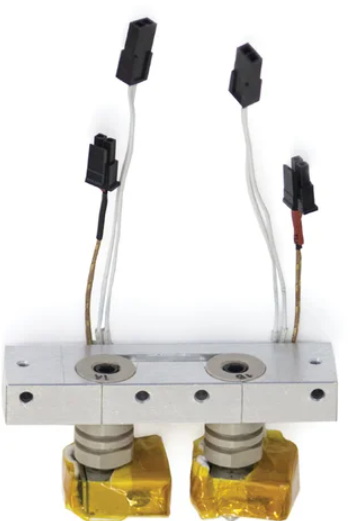

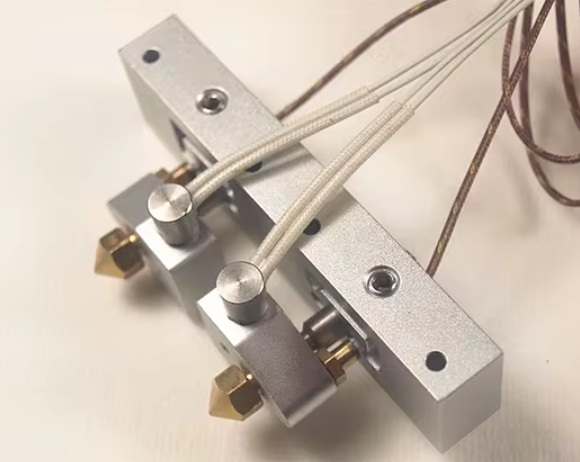

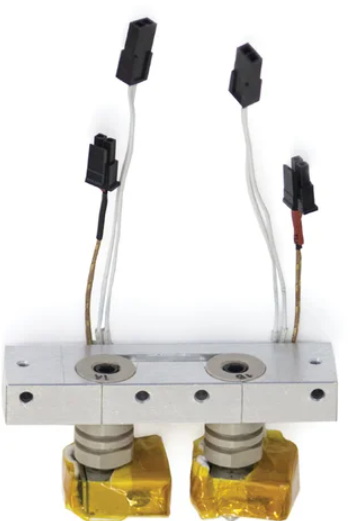

3. All-Aluminum Extruders on eBay and Amazon

There are several all-aluminum extruders available on platforms like eBay and Amazon. These are often cheaper alternatives to brand-name extruders but can still offer good performance. However, quality can vary, so it's essential to read reviews and ensure compatibility with the Replicator 2X.

Installation and Modifications

Installing an aluminum extruder on the Replicator 2X may require some modifications, especially if you're using extruders designed for the Replicator 2. The main difference is that the Replicator 2X has a wider mounting bar, so the extruder drive needs to be thicker. This can be achieved by printing a spacer to fit between the extruder drive and the stepper motor.

Benefits of Upgrading to an Aluminum Extruder

Upgrading to an aluminum extruder offers several benefits:

- Improved Print Quality: Aluminum extruders provide better heat management and filament control, leading to more consistent and higher-quality prints.

- Reduced Maintenance: They are less prone to clogging and jamming, reducing the need for frequent maintenance and troubleshooting.

- Increased Versatility: Aluminum extruders can handle a wider range of filament types, including flexible and ultra-flexible materials.

Troubleshooting Common Issues

When upgrading or using an aluminum extruder, you might encounter some common issues:

1. Extrusion Stops: Check if the extruder motor is rotating, ensure the filament is not tangled, and verify that the build plate is not too close to the extruder.

2. Clogging: Regularly clean the extruder nozzle and thermal break tube to prevent clogs.

The Role of Aluminum in 3D Printing

Aluminum plays a significant role in the 3D printing industry, not just as a material for extruders but also in the construction of 3D printer frames. Aluminum extrusions are popular for building custom 3D printer frames due to their high strength-to-weight ratio, ease of assembly, and flexibility in design. This allows makers to create custom printer setups that are both durable and lightweight.

Advantages of Aluminum Extrusions in 3D Printing

1. Strength and Lightness: Aluminum extrusions provide high structural integrity while being lightweight, making them ideal for absorbing vibrations during printing.

2. Assembly and Disassembly: They are easy to assemble and disassemble using standard fasteners like T-nuts and screws, allowing for quick modifications or upgrades.

3. Aesthetic Appeal: Aluminum profiles can be easily customized with end caps or other aesthetic elements to enhance the appearance of the printer.

Integration of 3D Printing with Aluminum Extrusion

The integration of 3D printing with aluminum extrusion has opened new avenues for innovation. Traditional aluminum extrusion processes are limited by the need for specific dies to create uniform shapes. However, 3D printing allows for the creation of complex geometries and structures that were previously impossible to produce. This has significant implications for industries like aerospace and automotive, where complex aluminum parts can offer superior performance and novel functionalities.

Benefits of Custom Aluminum Extrusion with 3D Printing

1. Unleashing Design Potential: 3D printing removes the constraints of traditional die designs, enabling the creation of complex and innovative designs.

2. Rapid Prototyping: It allows for quick testing and refinement of design concepts, speeding up the product development cycle.

3. Improved Product Performance: 3D printed aluminum parts can have improved mechanical properties, making them lighter, stronger, and more durable.

Common Faults in Aluminum Extruders

While aluminum extruders are robust, they can still encounter operational faults. Common issues include:

1. Bearing Overheating: This can be due to poor lubrication or bearing wear. Solutions include checking and adding lubricant and replacing bearings if necessary.

2. Instable Head Pressure: This might be caused by uneven motor speed or feeding volume fluctuations. Checking the motor control system and feeding system can resolve these issues.

3. Low Lubricating Oil Pressure: Adjusting the pressure regulator valve or checking the oil pump and suction pipes can fix this problem.

Solutions to Common Faults

1. Regular Maintenance: Regularly check and maintain the extruder's components to prevent faults.

2. Proper Installation: Ensure that the extruder is installed correctly, following the manufacturer's guidelines.

3. Quality Control: Use high-quality components and materials to minimize the risk of operational faults.

Conclusion

Choosing the right aluminum extruder for the MakerBot Replicator 2X can significantly enhance its performance and reliability. Options like the Flexion and BondTech extruders offer excellent durability and versatility, while cheaper alternatives on eBay and Amazon provide budget-friendly solutions. Always ensure compatibility and consider necessary modifications for a smooth upgrade process.

FAQ

1. What are the benefits of using an aluminum extruder on the Replicator 2X?

Using an aluminum extruder on the Replicator 2X offers improved durability, better heat management, and reduced clogging issues compared to stock extruders.

2. How do I install an aluminum extruder on the Replicator 2X?

Installation involves removing the stock extruder, adapting the mounting if necessary (e.g., using a spacer for Replicator 2 extruders), and connecting the new extruder to the printer's electronics.

3. What modifications are needed for a Replicator 2 extruder to fit the Replicator 2X?

The Replicator 2X requires a thicker extruder drive due to its wider mounting bar. This can be achieved by printing a spacer to fit between the extruder drive and the stepper motor.

4. Can I use any type of filament with an aluminum extruder?

Aluminum extruders can handle a wide range of filaments, including flexible and ultra-flexible materials. However, compatibility may vary depending on the specific extruder model.

5. How do I troubleshoot common issues with aluminum extruders on the Replicator 2X?

Common issues include extrusion stops and clogs. Troubleshooting involves checking the extruder motor rotation, ensuring proper filament feeding, and cleaning the nozzle and thermal break tube regularly.

Citations:

[1] https://aluminumextrusions.net/prototyping-aluminum-extrusions/

[2] https://www.linkedin.com/pulse/how-install-use-aluminum-profile-extrusion-press-machine-wonsten

[3] https://www.otalum.com/common-faults-and-solutions-in-the-work-of-aluminum-extruder.html

[4] https://www.instructables.com/3D-Printer-ExtruderHot-End-Upgrade/

[5] https://top3dshop.com/blog/homemade-frame-pros-and-cons

[6] https://www.yjing-extrusion.com/what-are-the-best-practices-for-installing-15x15-aluminum-extrusion.html

[7] https://hplmachining.com/blog/what-are-the-problems-with-aluminum-extrusion/

[8] https://www.sunrise-metal.com/what-benefits-and-applications-are-there-for-machined-aluminum-extrusion/

[9] https://www.yjing-extrusion.com/how-to-install-a-customer-aluminum-extruder-for-maximum-performance.html

[10] https://www.hugh-aluminum.com/common-problems-and-solutions-of-aluminum-extrusion/

[11] https://www.youtube.com/watch?v=ikVFselJO4Y

[12] https://www.reddit.com/r/3Dprinting/comments/lbtobl/what_is_the_benefit_of_a_metal_extruder_for_an/

[13] https://shop.machinemfg.com/10-effective-ways-of-joining-aluminum-extrusions-a-guide-for-product-designers/

[14] https://www.chaluminium.com/common-aluminum-extrusion-defects-causes-and-solutions

[15] https://www.matterhackers.com/store/c/3d-printer-extruders

[16] https://all3dp.com/1/3d-printing-aluminum/

[17] https://www.outashi.com/blog/the-best-design-practices-for-aluminum-extrusions-id38.html

[18] https://www.linkedin.com/pulse/how-solve-common-faults-aluminum-extrusion-press-wonsten

[19] https://www.3djake.com/spare-parts-upgrades/3d-printer-extruders

[20] https://www.youtube.com/watch?v=_VfmMN_hClE