Content Menu

● Understanding Aluminum Extrusion

>> What is Aluminum Extrusion?

● Key Aluminum Extruders in Rhode Island

>> 1. Erickson Metals Corporation

>> 2. Senesco Marine, LLC

>> 3. Ferguson Perforating Company

>> 4. MF Engineering Company, Inc.

>> 5. Crawford Composites, LLC

● The Aluminum Extrusion Process

● Advantages of Aluminum Extrusions

● Applications of Aluminum Extrusions Across Industries

● Choosing the Right Aluminum Extruder

● Innovations in Aluminum Extrusion

● Challenges Facing the Industry

● Conclusion

● FAQs

>> 1. What types of products can be made through aluminum extrusion?

>> 2. How does the aluminum extrusion process affect material properties?

>> 3. What industries commonly use aluminum extrusions?

>> 4. Can I get custom shapes manufactured through an aluminum extruder?

>> 5. What are some common finishing processes for aluminum extrusions?

● Citations:

Aluminum extrusion is a vital manufacturing process used across various industries, including construction, transportation, and consumer goods. In Rhode Island, a state known for its rich industrial history, several companies specialize in aluminum extrusions. This article will explore the best aluminum extruders in Rhode Island, providing insights into their services, capabilities, and the overall aluminum extrusion process.

Understanding Aluminum Extrusion

What is Aluminum Extrusion?

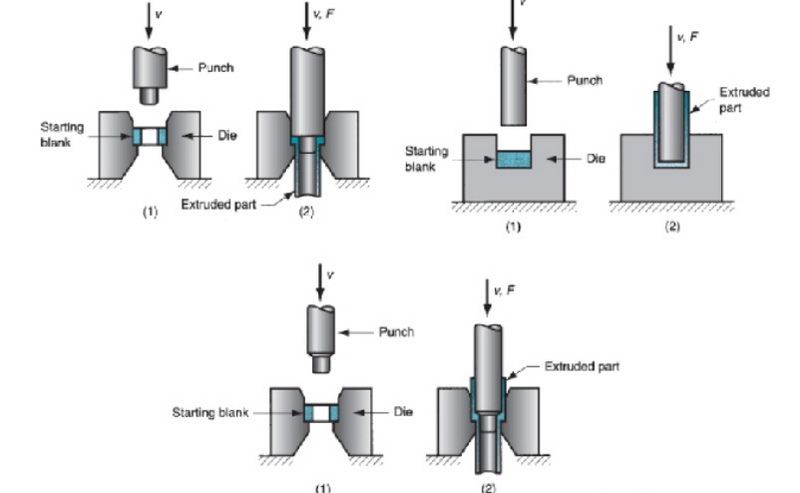

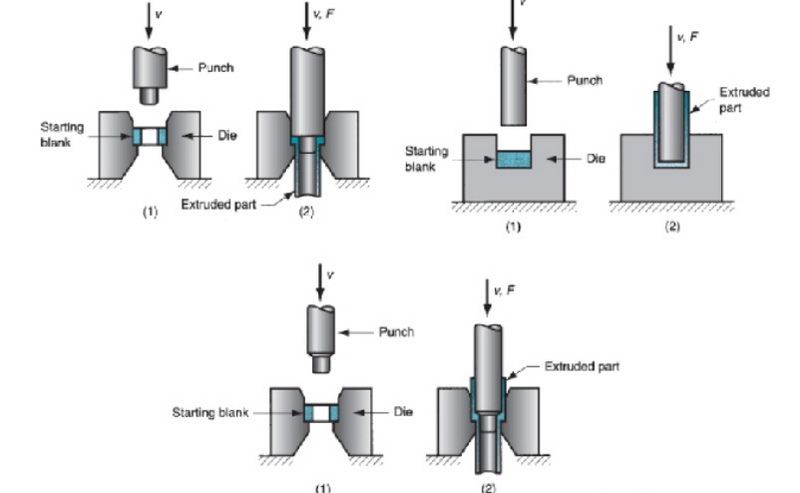

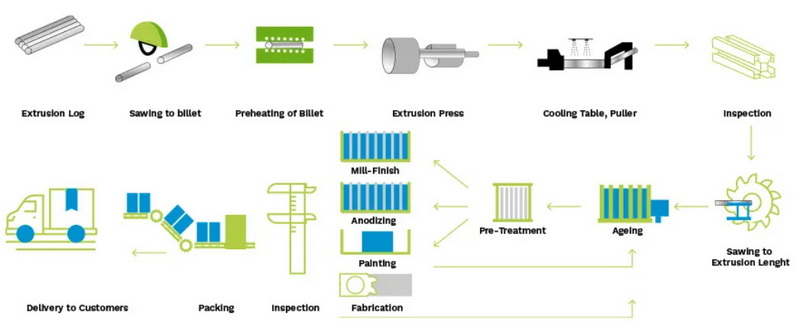

Aluminum extrusion is a manufacturing process where aluminum alloy is forced through a die to create objects with a fixed cross-sectional profile. This process allows for the production of complex shapes that are lightweight yet strong, making them ideal for various applications. The extrusion process involves several steps:

1. Billet Preparation: An aluminum billet is heated to make it malleable.

2. Extrusion: The heated billet is pushed through a die using a hydraulic press.

3. Cooling: The extruded material is cooled to set its shape.

4. Cutting and Finishing: The extruded profiles are cut to length and may undergo additional finishing processes.

Key Aluminum Extruders in Rhode Island

Rhode Island hosts several reputable aluminum extruders that cater to different industrial needs. Here are some of the top companies:

1. Erickson Metals Corporation

Located in Cheshire, CT, Erickson Metals Corporation has established itself as a leader in the aluminum extrusion industry. They offer a wide range of products, including custom extrusions tailored to specific client requirements. Their commitment to quality and customer service makes them a preferred choice for many businesses in Rhode Island.

2. Senesco Marine, LLC

Based in North Kingstown, Senesco Marine specializes in contract manufacturing with a focus on aluminum and steel fabrication. Their expertise in marine applications makes them an excellent choice for companies looking for durable and high-quality aluminum components.

3. Ferguson Perforating Company

Founded in 1927 and located in Providence, Ferguson Perforating Company provides custom aluminum solutions along with perforating services. Their long-standing presence in the industry speaks volumes about their reliability and quality.

4. MF Engineering Company, Inc.

This Bristol-based company offers both contract manufacturing and product design services, focusing heavily on aluminum manufacturing. Their engineering expertise ensures that they can meet complex design specifications effectively.

5. Crawford Composites, LLC

Situated in Providence, Crawford Composites specializes in contract manufacturing with capabilities in both aluminum and composite materials. Their innovative approach allows them to serve diverse industries effectively.

The Aluminum Extrusion Process

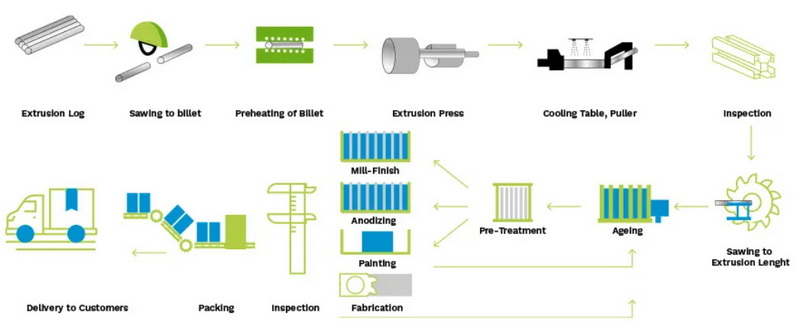

To better understand how these companies operate, it's essential to delve into the aluminum extrusion process itself:

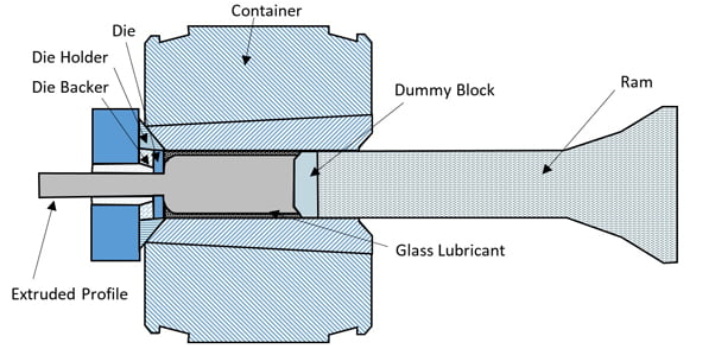

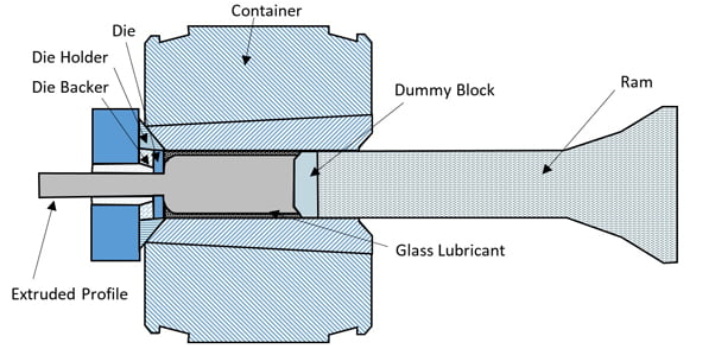

1. Preparation of the Die: The die must be preheated to ensure optimal performance during extrusion.

2. Heating the Billet: The aluminum billet is heated to between 400-500 degrees Celsius.

3. Extrusion: A hydraulic ram pushes the billet through the die, shaping it into the desired profile.

4. Cooling: After emerging from the die, the extruded material is cooled using water or air.

5. Cutting and Finishing: Finally, the profiles are cut to length and may receive additional treatments such as anodizing or painting.

Advantages of Aluminum Extrusions

Aluminum extrusions offer numerous advantages:

- Lightweight: Aluminum is significantly lighter than steel or other metals.

- Strength: Despite being lightweight, aluminum has excellent strength-to-weight ratios.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer that resists corrosion.

- Versatility: The extrusion process allows for a wide variety of shapes and sizes to be produced.

Applications of Aluminum Extrusions Across Industries

Aluminum extrusions are utilized in various sectors due to their unique properties:

- Electronics Industry: Aluminum's thermal conductivity makes it ideal for heat sinks used in CPUs and GPUs. Its lightweight nature also supports compact designs for electronic enclosures[2].

- Medical Applications: The corrosion resistance of aluminum is crucial for medical devices that require sterilization. Examples include frames for hospital beds and casings for surgical instruments[2].

- Consumer Goods: Products like bicycle frames, kitchenware handles, and furniture frames benefit from aluminum's durability and aesthetic appeal[2].

- Automotive Industry: Increasingly used for support structures and body parts due to its lightweight yet strong characteristics[7].

- Construction Sector: Aluminum extrusions are widely used for window frames, railings, and structural components due to their strength and resistance to weathering[7].

Choosing the Right Aluminum Extruder

When searching for an aluminum extruder in Rhode Island, consider the following factors:

- Experience and Reputation: Look for companies with a proven track record in aluminum extrusion.

- Capabilities: Ensure that the extruder can meet your specific needs regarding size, shape, and finishing processes.

- Customer Service: A responsive and helpful customer service team can make a significant difference in your experience.

Innovations in Aluminum Extrusion

The aluminum extrusion industry continually evolves with technological advancements that improve efficiency and quality:

- Automation Technologies: Many companies are adopting automated systems that enhance precision during the extrusion process while reducing labor costs.

- Sustainable Practices: Increasing focus on recycling scrap aluminum has made production more environmentally friendly while lowering costs.

- Advanced Alloys: Newer aluminum alloys are being developed that offer enhanced properties such as increased strength or improved corrosion resistance.

Challenges Facing the Industry

Despite its advantages, the aluminum extrusion industry faces several challenges:

- Raw Material Costs: Fluctuations in the price of raw aluminum can impact production costs significantly.

- Competition from Other Materials: While aluminum has many benefits, it competes with other materials like steel or composites that may offer lower costs or specific performance advantages.

- Regulatory Compliance: Companies must navigate various regulations related to environmental impact and workplace safety.

Conclusion

Finding the best aluminum extruders in Rhode Island involves understanding both the local industry landscape and the specific needs of your project. Companies like Erickson Metals Corporation, Senesco Marine LLC, Ferguson Perforating Company, MF Engineering Company Inc., and Crawford Composites LLC stand out for their quality products and services.

By leveraging these local resources, businesses can access high-quality aluminum extrusions tailored to their unique requirements while benefiting from the expertise of experienced manufacturers.

FAQs

1. What types of products can be made through aluminum extrusion?

Aluminum extrusion can produce various products such as structural components, frames for windows and doors, heat sinks for electronics, and custom shapes for specific applications.

2. How does the aluminum extrusion process affect material properties?

The extrusion process enhances certain material properties such as strength due to work hardening during deformation and improves surface finish options through post-extrusion treatments.

3. What industries commonly use aluminum extrusions?

Common industries include automotive, aerospace, construction, consumer goods manufacturing, and marine applications.

4. Can I get custom shapes manufactured through an aluminum extruder?

Yes! Many aluminum extruders offer custom solutions tailored to specific design requirements.

5. What are some common finishing processes for aluminum extrusions?

Common finishing processes include anodizing (for corrosion resistance), painting (for aesthetics), and machining (for precise dimensions).

Citations:

[1] https://americandouglasmetals.com/2024/05/19/understanding-the-aluminum-extrusion-process/

[2] https://proleantech.com/aluminum-extrusion-applications-across-industries/

[3] https://www.10in6.com/case-studies/aluminum-extrusion-plant-case-study/

[4] https://flowstore.com/understand-aluminium-extrusion-modern-manufacturing/

[5] https://mmgextrusions.com/capabilities/custom-aluminum-extrusions/

[6] https://aec.org/aluminum-extrusion-process

[7] https://www.linkedin.com/pulse/7-common-applications-industrial-aluminum

[8] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[9] https://www.wellste.com/custom-aluminum-extrusions/

[10] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[11] https://simmal.com/industries-that-benefit-from-aluminium-extrusion/

[12] https://www.minalex.com

[13] https://aec.org/features-benefits

[14] https://www.xometry.com/capabilities/metal-extrusion-services/custom-aluminum-extrusions/

[15] https://www.atieuno.com/2023/07/17/aluminium-extrusion-process-guide/

[16] https://www.wileymetal.com/five-common-applications-of-aluminum-extrusion/

[17] https://www.minalex.com/about-us/about/

[18] https://www.howardprecision.com/benefits-of-aluminum-extrusions/

[19] https://tri-stateal.com/products/custom-extrusions/

[20] https://deepblue.lib.umich.edu/bitstream/handle/2027.42/177714/oberhg_1.pdf?sequence=1&isAllowed=y