Content Menu

● Understanding Aluminum Extrusion

● Why Choose Canadian Aluminum Extruders?

● Top Aluminum Extruders in Canada

● How to Select the Right Aluminum Extruder

● Where to Buy Aluminum Extrusion in Canada

● Applications of Aluminum Extrusion

>> Automotive

>> Aerospace

>> Architecture & Construction

>> Electronics

>> Renewable Energy

>> Medical Devices

>> Urban Furniture

● Advantages of Aluminum Extrusion

● Innovations in Aluminum Extrusion Technology

>> Nano-Coating Technologies

>> AI-Powered Precision Control

>> Hybrid Extrusion Techniques

>> Smart Extrusion Lines

● Sustainability and Aluminum Extrusion

>> The Recycling Process: Step by Step

● Conclusion

● FAQs

>> 1. What is aluminum extrusion?

>> 2. What are the benefits of using local aluminum extruders?

>> 3. How can I ensure quality when selecting an aluminum extruder?

>> 4. What additional services do Canadian aluminum extruders offer?

>> 5. How much does aluminium extrusion cost in Canada?

● Citations:

Aluminum extrusion is a manufacturing process that is increasingly vital across various industries due to its versatility, strength, and lightweight properties. In Canada, numerous companies specialize in aluminum extrusion, providing a wide range of services and products tailored to meet diverse project requirements. This article will explore where to find aluminum extruders in Canada, the benefits of working with local suppliers, and key considerations for selecting the right extruder for your needs.

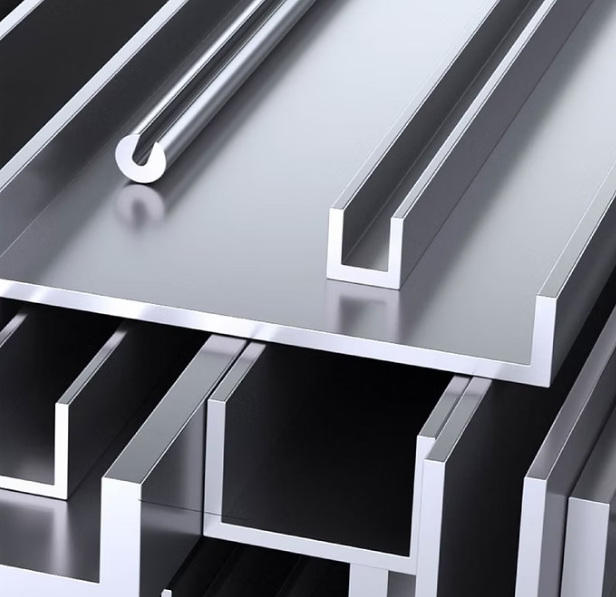

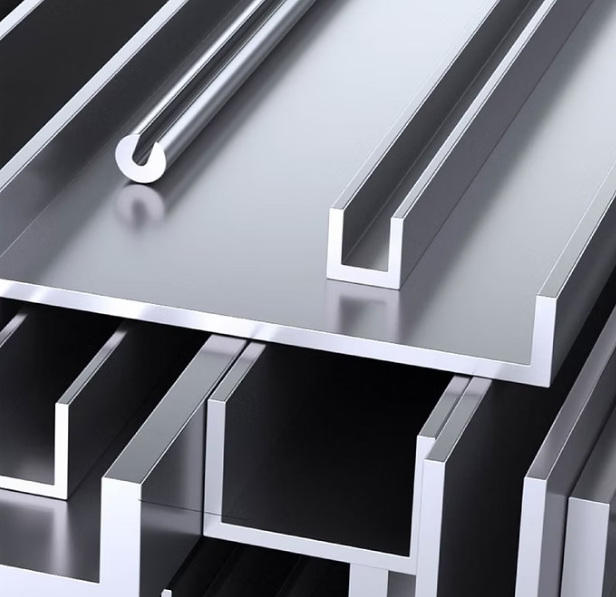

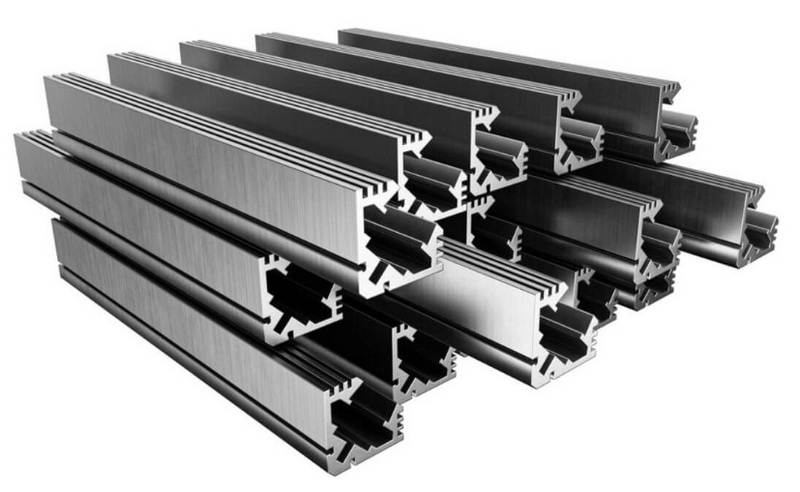

Understanding Aluminum Extrusion

Aluminum extrusion involves forcing heated aluminum through a die to create objects with specific cross-sectional profiles. This method allows for the production of complex shapes and sizes while maintaining high precision. The process begins by heating an aluminum billet to approximately 900°F (482°C), after which it is pushed through a die using a hydraulic press. The resulting extruded aluminum can be cut to desired lengths and further treated with processes such as anodizing or painting to enhance its properties and aesthetics.

The aluminum extrusion process can be broken down into several key steps:

- Heating the Billet: The aluminum billet is heated to a malleable state.

- Extrusion: The heated billet is pushed through a die by a hydraulic ram, forming the desired shape.

- Cooling: The extruded shape is cooled, often in a water bath, to set its form.

- Cutting: The extruded aluminum is cut to length based on customer specifications.

- Finishing: Additional processes such as anodizing or painting may be applied to enhance durability and appearance.

Why Choose Canadian Aluminum Extruders?

Choosing an aluminum extruder in Canada offers several advantages:

- Quality Standards: Many Canadian manufacturers adhere to stringent quality standards and certifications, such as ISO 9001:2015, ensuring high-quality products.

- Local Sourcing: Working with local suppliers can reduce shipping costs and lead times associated with overseas suppliers.

- Support for Local Economy: Sourcing materials locally supports the Canadian economy and promotes sustainability by minimizing transportation emissions.

- Comprehensive Services: Canadian aluminum extrusion companies often provide a full range of services beyond just extrusion, including design assistance, fabrication, anodizing, machining, and assembly services.

Top Aluminum Extruders in Canada

Here is a list of notable aluminum extruders across Canada:

- Dajcor Aluminum Ltd.

- Location: Southwestern Ontario

- Specialties: Extruded, fabricated/machined, anodized aluminum components for various markets including automotive and renewable energy.

- Spectra Aluminum Products

- Location: Bradford West Gwillimbury

- Specialties: Custom finished anodized aluminum products with over 30 years of experience.

- Extrudex Aluminum

- Location: Vaughan

- Specialties: A diverse range of products and surface finishes for various industries including construction and transportation.

- APEL Extrusions Ltd.

- Location: Calgary

- Specialties: High-performance manufacturing solutions for various industries with over 45 years of experience.

- Alfiniti Inc.

- Location: Saguenay

- Specialties: Custom aluminum extrusions and drawn aluminum tube and pipe.

How to Select the Right Aluminum Extruder

When searching for an aluminum extruder in Canada, consider the following factors:

1. Experience and Reputation: Look for companies with a proven track record in the industry.

2. Capabilities: Ensure the extruder can meet your specific requirements regarding design complexity, volume, and finishing options.

3. Quality Assurance: Inquire about quality control processes and certifications.

4. Customer Service: Evaluate their responsiveness and willingness to assist with your project needs.

5. Pricing: Compare quotes from different suppliers but also consider the value offered in terms of quality and service.

Where to Buy Aluminum Extrusion in Canada

Finding suppliers for aluminum extrusion can be straightforward if you know where to look. Here are some recommended sources:

- Metal Supermarkets: Known for their extensive inventory of metals including aluminum extrusions.

- Fazstore: Offers a variety of aluminum products with good customer feedback.

- Misumi: Provides custom parts including aluminum extrusions with shipping options across borders.

Applications of Aluminum Extrusion

Aluminum extrusion is utilized across various industries due to its unique properties. Here are some key applications:

Automotive

Aluminum extrusions are essential in modern vehicles, helping manufacturers reduce weight while maintaining strength and safety. Common applications include:

- Engine blocks and transmission housings

- Chassis components

- Roof rails

Aerospace

In aerospace applications where weight reduction is critical, aluminum extrusions are used for:

- Aircraft frames

- Structural components

- Cooling devices

Architecture & Construction

Aluminum's durability makes it ideal for construction applications such as:

- Window frames[4]

- Door systems[4]

- Building facades[4]

Electronics

In the electronics sector, aluminum extrusions serve as:

- Heat sinks for thermal management

- Protective enclosures for sensitive equipment

Renewable Energy

The development of sustainable products in the renewable energy sector heavily depends on aluminum extrusion[1]. Solar panel frames, wind turbine components, and electric vehicle charging stations are examples of extruded aluminum being used to provide strength, resistance to corrosion, and a lower environmental footprint[1].

- Solar Panel Frames: Lightweight yet strong frames made from extruded aluminum support solar panels while resisting corrosion from environmental exposure[1]. Approximately 85% of the components in photovoltaic (PV) systems, which convert sunlight into electricity, are made from aluminum, underscoring its significance in this industry[7].

- Wind Turbine Components: Parts such as rotor hubs, rotor shafts, base frames, and machine carriers, benefit from aluminum extruded profiles, contributing to the overall structural integrity and efficiency of wind turbines[7].

- Hydropower Infrastructure: Aluminum extrusions provide corrosion-resistant properties making them an ideal material for applications in moisture-rich environments, ensuring the longevity and reliability of the infrastructure[7].

Medical Devices

Aluminum extrusions are critical components in medical equipment manufacturing, offering unique advantages such as lightness, durability, and flexibility[2]. The use of extrusions has enabled equipment designers to create products that are tailored to specific medical requirements, resulting in better performance, greater efficiency, and improved patient outcomes[2].

- Wheelchair Frames: Require a combination of precision cuts and bends, resulting in a wheelchair that is strong, light, and easy to maneuver[2].

- Imaging Mechanisms: Equipment requires an elaborate frame to support its functionality, and with the flexibility of aluminum extrusions, manufacturers can create a robust and precise structure that can withstand high vibration and shock loads[2].

- Prosthetic Limbs and Dental Implants: The lightweight and strong nature of aluminum ensures these devices are durable and easy to handle, while its biocompatibility makes it safe for use with the human body[7].

Urban Furniture

The trend of using reusable and sustainable materials has increased the use of aluminum as the main component of most elements of urban furniture[3]. Extruded aluminum imbues superior strength, allowing for a reduction in thickness (less amount of material), very precise tolerances, smooth surfaces, and high resistance to weathering[3].

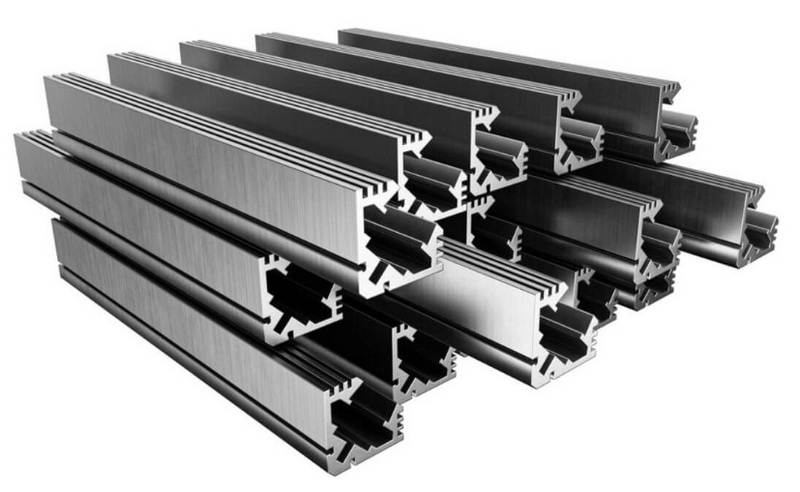

Advantages of Aluminum Extrusion

The benefits of aluminum extrusion are numerous and have a considerable impact on contemporary manufacturing techniques:

- Flexibility in Design: Allows for complex geometries that conventional manufacturing processes may find challenging.

- Lightweight yet Durable: Ideal for applications where weight is an issue without compromising strength.

- Cost Effectiveness: Reduces manufacturing costs by minimizing waste during production[10].

- Rapid Prototyping: Facilitates quick iterations in design leading to faster market releases.

Innovations in Aluminum Extrusion Technology

The field of aluminum extrusion is continuously evolving with advancements aimed at improving efficiency and sustainability. Some notable innovations include:

Nano-Coating Technologies

Recent advancements have introduced nano-coating technologies that enhance the durability of extruded profiles by providing additional protection against corrosion and abrasion.

AI-Powered Precision Control

Integrating artificial intelligence into extrusion processes allows real-time adjustments based on data analysis from machinery operations, ensuring adherence to exact specifications while boosting efficiency.

Hybrid Extrusion Techniques

New hybrid methods combine traditional techniques with innovative processes to create stronger profiles suited for demanding applications in sectors like aerospace and automotive.

Smart Extrusion Lines

The implementation of IoT technology into extrusion lines enables comprehensive monitoring that enhances productivity while reducing downtime through predictive maintenance strategies.

Sustainability and Aluminum Extrusion

Aluminum extrusion is considered environmentally responsible because of its energy efficiency[4]. Aluminum is a very lightweight metal with an excellent strength-to-weight ratio[4]. Therefore, there is very low energy consumption in the extrusion process, which reduces operating costs and greatly reduces carbon emissions[4].

- Recyclability: Aluminum can be recycled many times without losing its inherent properties[4]. The recycling process requires only a fraction of the energy required for primary production, thus saving significant amounts of energy and reducing greenhouse gas emissions[4]. Approximately 75% of all aluminum ever produced is still in use today, signifying the metal's durability and efficient recyclability[5][8].

- Closed-loop Recycling Systems: Closed-loop recycling systems within extrusion facilities reduce waste by reclaiming and reusing aluminum, supporting a circular economy[10].

- Energy Efficiency: Modern extrusion presses consume less energy and generate lower emissions, aligning with global environmental standards[10].

The Recycling Process: Step by Step

- Collection and Sorting: Aluminum extrusions are collected from various sources and meticulously sorted to segregate aluminum from other metals and impurities[5].

- Cleaning and Shredding: The aluminum extrusions are cleansed of any coatings, paints, or other surface treatments and then shredded into smaller pieces, facilitating their subsequent melting[5].

- Melting: The shredded aluminum is melted in large furnaces, and this process is relatively energy-efficient due to aluminum's lower melting point compared to other metals[5].

- Removal of Impurities: During melting, impurities and contaminants within the aluminum are eliminated, ensuring that the recycled aluminum meets the requisite quality standards for its intended applications[5].

- Casting: The purified, molten aluminum is cast into large ingots or billets that are convenient for transportation and further processing, serving as the basis for producing new aluminum extrusions[5].

- Extrusion: The recycled aluminum billets are heated and forced through dies to create new extrusions that undergo many treatments and finishes before entering the market anew[5].

Conclusion

Finding an aluminum extruder in Canada is essential for businesses looking to utilize this versatile material effectively across various sectors including automotive, aerospace, construction among others while also supporting local economies through sustainable practices that prioritize environmental responsibility alongside quality assurance measures within production processes themselves ensuring customer satisfaction remains paramount throughout every project undertaken by manufacturers involved within this industry sector overall leading towards enhanced innovation opportunities moving forward into future developments surrounding advanced technologies related directly back towards improving efficiency levels seen throughout all aspects related back towards utilizing these resources effectively within modern-day applications today!

FAQs

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process that shapes heated aluminum by forcing it through a die to create specific cross-sectional profiles used widely across multiple industries today!

2. What are the benefits of using local aluminum extruders?

Local suppliers offer reduced shipping costs alongside shorter lead times while also supporting local economies promoting sustainability initiatives aimed at reducing overall carbon footprints associated with transportation emissions generated during logistics operations themselves!

3. How can I ensure quality when selecting an aluminum extruder?

Look for companies possessing ISO certifications alongside established quality control processes ensuring adherence towards meeting exact specifications set forth within each individual project undertaken throughout production cycles themselves!

4. What additional services do Canadian aluminum extruders offer?

Many offer comprehensive design assistance coupled together alongside fabrication services including anodizing options available upon request ensuring all aspects related back towards enhancing product performance levels achieved overall!

5. How much does aluminium extrusion cost in Canada?

Costs typically range between $3-$8 per pound depending upon various factors influencing pricing structures including design complexity levels along with quantity ordered impacting final pricing outcomes realized after negotiations completed successfully!

Citations:

[1] https://taberextrusions.com/not-just-a-new-years-resolution-aluminum-extrusion-sustainability/

[2] https://www.pailian-aluminium.com/news/aluminum-extrusions-in-medical-equipment-67919527.html

[3] https://extrual.com/en/use-of-aluminium-in-urban-furniture-a-sustainable-trend/

[4] https://www.retop-industry.com/news/aluminum-profile.html

[5] https://simmal.com/can-aluminium-extrusions-be-recycled/

[6] https://mahasaialuminium.com/uncategorized/aluminum-extrusions-for-a-sustainable-future-lightweight-durable-and-recyclable/

[7] https://shop.machinemfg.com/5-uses-of-aluminium-extrusions/

[8] https://kimsen.vn/the-benefits-of-aluminum-extrusion-for-sustainable-manufacturing-ne142.html

[9] https://dajcor.com/learning-centre/content/2014/03/25/recycling-aluminum-extrusion

[10] https://nationalindustries.world/2025/01/02/the-future-of-aluminum-how-extrusion-technology-is-transforming-industries/

[11] https://www.nicerapid.com/project/the-impact-of-aluminum-extrusion-process-on-the-environment/

[12] https://www.customaluminiumwa.com.au/lightweight-strong-aluminium-extrusion-furniture-you-can-diy/

[13] https://www.aluminum.org/aluminum-key-material-renewable-energy

[14] https://profileprecisionextrusions.com/medical-devices/

[15] http://scaluminum.com/2019/04/growth-of-aluminum-extrusion-design-in-the-furniture-industry/

[16] https://www.kloecknermetals.com/blog/how-are-aluminum-extrusions-used-in-the-solar-industry/

[17] https://www.nicerapid.com/blog/benefits-of-aluminum-extrusion-to-the-medical-industry/

[18] https://www.pinterest.com/imagocaeli/aluminum-extrusion-ideas/

[19] https://gloriaaluminium.com/blog/the-role-of-aluminum-extrusion-in-renewable-energy-projects/

[20] https://www.compass-anvil.com/blog/index.php/2021/05/21/how-are-aluminum-extrusions-used-in-healthcare/

[21] https://www.shapesbyhydro.com/en/sustainable-design/with-ikea-a-new-way-of-manufacturing-furniture-with-aluminium/

[22] https://www.linkedin.com/pulse/quest-renewable-energy-aluminium-extrusion-solution-

[23] https://www.alineautomation.com/7-ways-aluminum-is-used-in-medical-devices/

[24] http://www.scienpress.com/download.asp?ID=3066143

[25] https://aluminumextrusions.net/sustainability-practices/

[26] https://www.jetir.org/papers/JETIR1611012.pdf

[27] https://european-aluminium.eu/policy_areas/circular-economy/

[28] https://aec.org/sustainability

[29] https://www.youtube.com/watch?v=BWHGGY_azy4

[30] https://aecshapemakers.libsyn.com/aluminum-extrusion-the-circular-economy-a-sustainable-future

[31] https://www.canart.com/blog/canart-aluminium-creating-a-greener-future-by-design-with-sustainable-aluminum-extrusions/

[32] https://www.ghs.sg/metal-recycling/aluminium-extrusion-recycling/

[33] https://www.alcircle.com/news/aluminium-driving-the-circular-economy-95068

[34] https://www.atieuno.com/aluminium-sustainability/

[35] https://core.ac.uk/download/pdf/82308573.pdf

[36] https://aec.org/healthcare

[37] https://www.lightmetalage.com/news/industry-news/applications-design/extrusions-at-the-heart-of-circular-furniture-design-at-milan-design-week/

[38] https://www.energetica-india.net/articles/the-next-frontier-aluminium-extrusions-potential-in-emerging-renewable-energy-markets

[39] https://www.goudsmit.co.uk/aluminium-extrusions-in-healthcare-applications/

[40] https://www.galaxymetals.com.au/innovative-approaches-to-aluminum-extrusion-scrap-recycling/