Content Menu

● Understanding 4040 Aluminum Extrusions

>> What is 4040 Aluminum Extrusion?

>> Applications of 4040 Aluminum Extrusions

● Finding 4040 Aluminum Extrusion Suppliers Near You

>> 1. Online Search

>> 2. Local Hardware Stores

>> 3. Industry Trade Shows

>> 4. Online Marketplaces

>> 5. Manufacturer Directories

● Benefits of Using 4040 Aluminum Extrusions

>> 1. Versatility

>> 2. Strength and Durability

>> 3. Corrosion Resistance

>> 4. Easy Assembly

>> 5. Cost-Effectiveness

● Tips for Choosing the Right Supplier

● Conclusion

● Frequently Asked Questions

>> 1. What are the dimensions of a 4040 aluminum extrusion?

>> 2. What industries commonly use 4040 aluminum extrusions?

>> 3. Can I customize 4040 aluminum extrusions?

>> 4. Are 4040 aluminum extrusions easy to assemble?

>> 5. What are the benefits of using aluminum extrusions over other materials?

Understanding 4040 Aluminum Extrusions

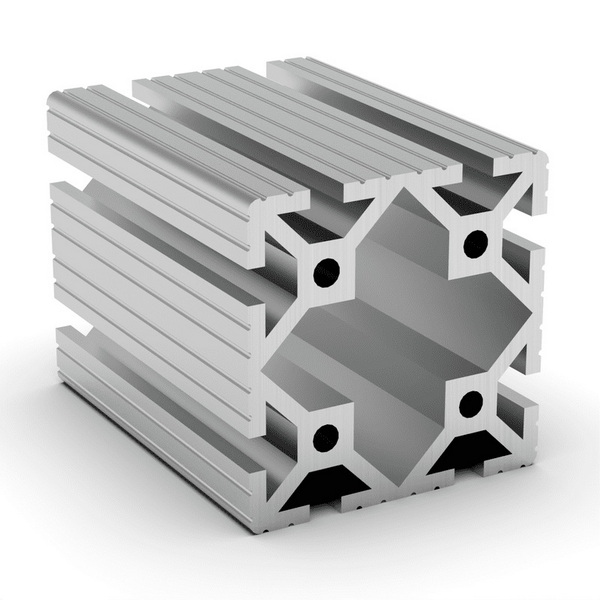

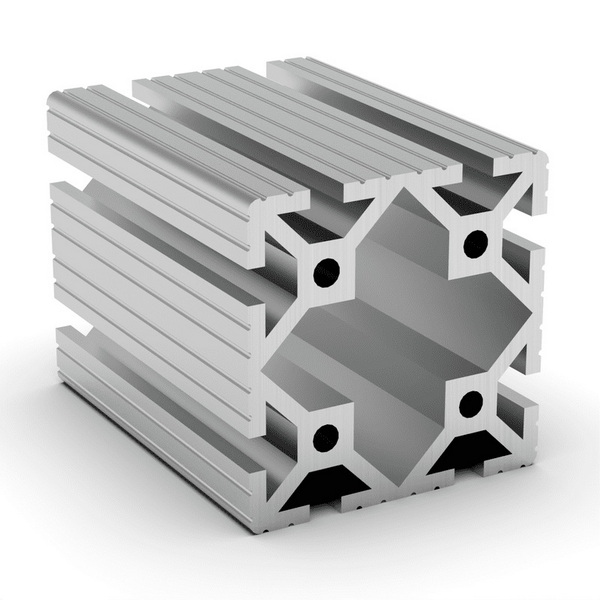

What is 4040 Aluminum Extrusion?

The term "4040" refers to the dimensions of the aluminum extrusion profile, which measures 40mm by 40mm. This square profile is designed with T-slots on all four sides, allowing for easy assembly and integration with other components. The T-slot design enables users to attach various accessories, such as brackets, panels, and connectors, making it a popular choice for building frames, workstations, and enclosures.

Applications of 4040 Aluminum Extrusions

4040 aluminum extrusions are used in a wide range of applications, including:

- Industrial Automation: These profiles are commonly used to create frames for machinery, conveyor systems, and robotic arms. Their strength and adaptability make them ideal for supporting complex automation setups.

- Workstations: Many businesses utilize 4040 aluminum extrusions to build custom workstations that can be easily modified or expanded. This flexibility allows companies to adapt their workspaces to changing needs.

- Display Stands: Retailers often use these profiles to create attractive display stands for products. The clean lines and professional appearance of aluminum extrusions enhance the visual appeal of merchandise.

- Enclosures: The strength and versatility of 4040 aluminum extrusions make them ideal for building protective enclosures for sensitive equipment. These enclosures can be designed to meet specific requirements, such as ventilation or access points.

- DIY Projects: Hobbyists and DIY enthusiasts frequently use 4040 aluminum extrusions for various projects, from building custom furniture to creating unique art installations. The ease of assembly and customization options make them a favorite among makers.

Finding 4040 Aluminum Extrusion Suppliers Near You

1. Online Search

One of the easiest ways to find suppliers of 4040 aluminum extrusions is to conduct an online search. Use search engines to look for local suppliers, distributors, or manufacturers. You can use keywords such as "4040 aluminum extrusion suppliers near me" or "aluminum extrusion distributors in [your location]." This will help you identify businesses that specialize in aluminum extrusions.

2. Local Hardware Stores

Many local hardware stores and home improvement centers carry aluminum extrusions, including 4040 profiles. Visit these stores to see their selection and speak with staff who can provide guidance on the best products for your needs. Additionally, they may be able to order specific profiles if they are not in stock.

3. Industry Trade Shows

Attending industry trade shows and exhibitions can be an excellent way to connect with suppliers of aluminum extrusions. These events often feature manufacturers and distributors showcasing their products. You can network with industry professionals, learn about new products, and find potential suppliers for your projects.

4. Online Marketplaces

Websites like Amazon, eBay, and specialized industrial supply platforms often have listings for aluminum extrusions. You can browse through various options, compare prices, and read customer reviews to find reputable suppliers. Make sure to check the seller's ratings and return policies before making a purchase.

5. Manufacturer Directories

Utilizing manufacturer directories can help you find suppliers of 4040 aluminum extrusions. Websites like ThomasNet and Maker's Row allow you to search for manufacturers based on specific criteria, including location and product type. These directories often provide contact information and company profiles, making it easier to reach out to potential suppliers.

Benefits of Using 4040 Aluminum Extrusions

1. Versatility

One of the primary advantages of 4040 aluminum extrusions is their versatility. The T-slot design allows for easy customization and modification, enabling users to create a wide range of structures and assemblies. Whether you need a simple frame or a complex assembly, 4040 aluminum extrusions can accommodate your requirements.

2. Strength and Durability

Aluminum is known for its strength-to-weight ratio, making it an ideal material for structural applications. 4040 aluminum extrusions are robust enough to support heavy loads while remaining lightweight, which is essential for many industrial and commercial applications. This strength ensures that your projects will withstand the test of time.

3. Corrosion Resistance

Aluminum naturally forms a protective oxide layer that helps prevent corrosion. This makes 4040 aluminum extrusions suitable for use in various environments, including those exposed to moisture or chemicals. The durability of aluminum ensures that your structures will last longer and require less maintenance.

4. Easy Assembly

The T-slot design of 4040 aluminum extrusions simplifies the assembly process. Users can quickly connect profiles using standard fasteners and brackets, reducing the time and effort required to build structures. This ease of assembly is particularly beneficial for projects that require frequent modifications or expansions.

5. Cost-Effectiveness

While the initial cost of aluminum extrusions may be higher than some other materials, their long-term benefits often outweigh the upfront investment. The durability, low maintenance requirements, and versatility of 4040 aluminum extrusions make them a cost-effective choice for many applications. Over time, the savings in maintenance and replacement costs can be significant.

Tips for Choosing the Right Supplier

When searching for a supplier of 4040 aluminum extrusions, consider the following tips to ensure you make the best choice:

- Reputation: Look for suppliers with a solid reputation in the industry. Check online reviews and testimonials to gauge customer satisfaction.

- Product Range: Ensure the supplier offers a wide range of aluminum extrusion profiles, including 4040, to meet your specific needs.

- Customization Options: If you require custom lengths or finishes, choose a supplier that provides these services.

- Customer Support: A good supplier should offer excellent customer support, including assistance with product selection and technical questions.

- Delivery Times: Consider the supplier's delivery times, especially if you have tight project deadlines. Reliable suppliers should provide clear information about shipping and lead times.

Conclusion

Finding suppliers of 4040 aluminum extrusions near you is a straightforward process that can be accomplished through online searches, local hardware stores, industry trade shows, online marketplaces, and manufacturer directories. The versatility, strength, corrosion resistance, ease of assembly, and cost-effectiveness of 4040 aluminum extrusions make them an excellent choice for a wide range of applications. By following the tips outlined in this article, you can ensure that you find a reputable supplier that meets your needs.

Frequently Asked Questions

1. What are the dimensions of a 4040 aluminum extrusion?

A 4040 aluminum extrusion measures 40mm by 40mm in cross-section.

2. What industries commonly use 4040 aluminum extrusions?

Industries such as manufacturing, construction, robotics, and retail frequently use 4040 aluminum extrusions.

3. Can I customize 4040 aluminum extrusions?

Yes, many suppliers offer customization options, including cutting to length and surface treatments.

4. Are 4040 aluminum extrusions easy to assemble?

Yes, the T-slot design allows for quick and easy assembly using standard fasteners.

5. What are the benefits of using aluminum extrusions over other materials?

Aluminum extrusions offer a high strength-to-weight ratio, corrosion resistance, and versatility, making them suitable for various applications.