Content Menu

● Understanding 2020 Aluminum Extrusions

>> What is 2020 Aluminum Extrusion?

>> Benefits of Using 2020 Aluminum Extrusions

● Finding 2020 Aluminum Extrusion Suppliers Near You

>> Online Search

>> Local Hardware Stores

>> Specialty Metal Suppliers

>> Trade Shows and Expos

>> Networking with Local Makers

● Types of Projects Using 2020 Aluminum Extrusions

>> 1. 3D Printer Frames

>> 2. Workstations

>> 3. Display Stands

>> 4. Robotics and Automation

>> 5. Furniture Design

● Tips for Working with 2020 Aluminum Extrusions

>> Cutting and Assembly

>> Finishing Touches

>> Planning Your Design

● Frequently Asked Questions

>> 1. What is the difference between 2020 and 2040 aluminum extrusions?

>> 2. Can I cut aluminum extrusions at home?

>> 3. Are aluminum extrusions recyclable?

>> 4. What tools do I need to assemble aluminum extrusions?

>> 5. Can I use 2020 aluminum extrusions for outdoor projects?

Aluminum extrusions are essential components in various industries, including construction, manufacturing, and DIY projects. Among the most popular profiles is the 2020 aluminum extrusion, which measures 20mm x 20mm and is widely used for its versatility and strength. If you're looking to find suppliers of 2020 aluminum extrusions near you, this article will guide you through the process, discuss the benefits of using aluminum extrusions, and provide insights into the types of projects you can undertake with them.

Understanding 2020 Aluminum Extrusions

What is 2020 Aluminum Extrusion?

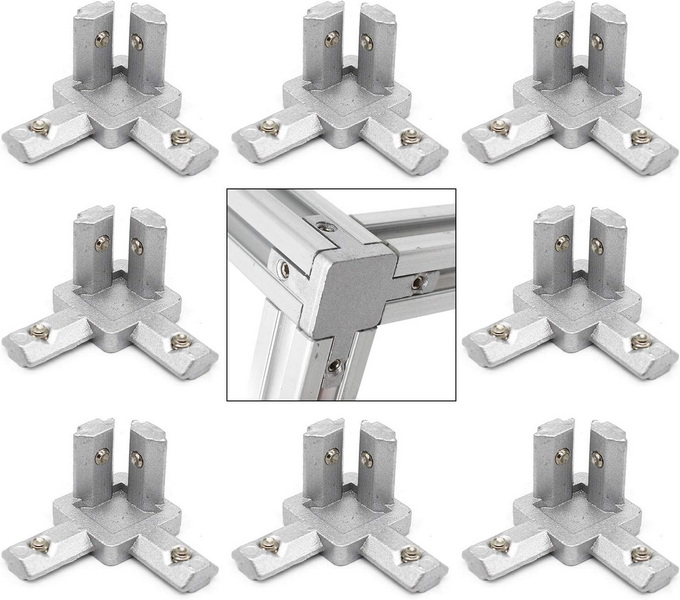

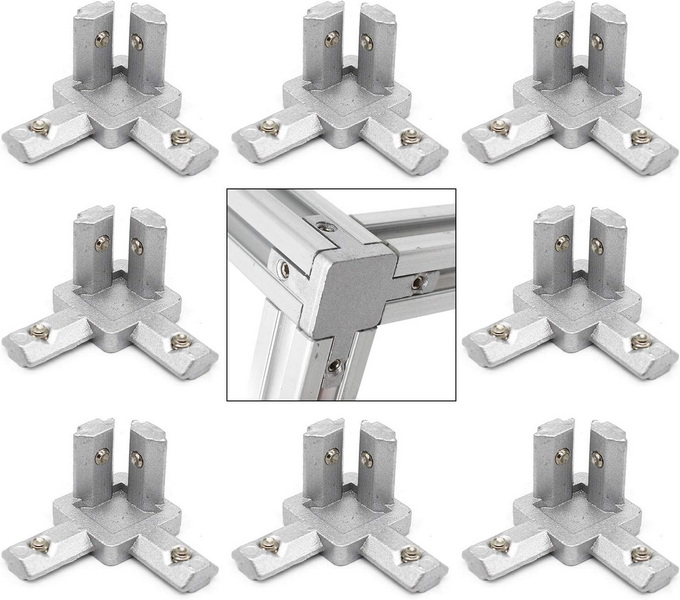

The term "2020 aluminum extrusion" refers to a specific size of aluminum profile that is commonly used in T-slot framing systems. The dimensions of 2020 mean that each side of the square profile measures 20mm. This profile is characterized by its four open T-slots, which allow for easy assembly and disassembly of structures without the need for welding or complex fasteners.

Benefits of Using 2020 Aluminum Extrusions

1. Lightweight and Strong: Aluminum is known for its excellent strength-to-weight ratio, making it ideal for applications where weight is a concern. This property allows for the construction of robust structures without adding unnecessary weight.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps prevent corrosion, making it suitable for both indoor and outdoor use. This feature is particularly beneficial for projects exposed to moisture or varying weather conditions.

3. Versatility: The 2020 profile can be used in a wide range of applications, from building frames for 3D printers to creating custom workstations and display stands. Its adaptability makes it a favorite among engineers and hobbyists alike.

4. Ease of Assembly: The T-slot design allows for quick and easy assembly, enabling users to create complex structures without specialized tools. This ease of use is a significant advantage for DIY enthusiasts and professionals who need to build and modify structures frequently.

5. Customizability: Suppliers often offer a variety of finishes and colors, allowing you to customize the appearance of your project. This flexibility enables you to match the aluminum extrusions to your design aesthetic or branding requirements.

Finding 2020 Aluminum Extrusion Suppliers Near You

Online Search

One of the easiest ways to find suppliers is to conduct an online search. Use search engines to look for "2020 aluminum extrusion suppliers near me" or "local aluminum extrusion suppliers." This will yield a list of businesses that specialize in aluminum products. Many suppliers have websites where you can view their inventory, request quotes, and even place orders online.

Local Hardware Stores

Many local hardware stores and home improvement centers carry a selection of aluminum extrusions, including the 2020 profile. Visiting these stores allows you to see the products in person and consult with staff who can provide advice on your project. Additionally, local stores may offer the advantage of immediate availability, allowing you to start your project without delay.

Specialty Metal Suppliers

In addition to general hardware stores, consider reaching out to specialty metal suppliers. These businesses focus on providing various metal products, including aluminum extrusions. They often have a more extensive selection and can offer custom cutting services to meet your specific needs. Specialty suppliers may also provide valuable insights into the best materials for your project.

Trade Shows and Expos

Attending trade shows and expos related to manufacturing, construction, or DIY projects can be an excellent way to connect with suppliers. These events often feature booths from various manufacturers and distributors, allowing you to see their products firsthand and discuss your needs directly with representatives. Networking at these events can also lead to valuable partnerships and collaborations.

Networking with Local Makers

If you're involved in a maker community or local fabrication group, networking with other members can lead you to reliable suppliers. Many makers have experience sourcing materials and can recommend suppliers based on their own experiences. Engaging with local makers can also provide inspiration for your projects and help you learn new techniques.

Types of Projects Using 2020 Aluminum Extrusions

1. 3D Printer Frames

One of the most popular uses for 2020 aluminum extrusions is in building frames for 3D printers. The rigidity and stability of the aluminum provide a solid foundation for the printer, ensuring accurate prints. The modular nature of the T-slot design allows for easy adjustments and upgrades, making it a favorite among 3D printing enthusiasts.

2. Workstations

Many DIY enthusiasts use 2020 aluminum extrusions to create custom workstations. The modular nature of the T-slot design allows for easy adjustments and expansions, making it ideal for workshops and home offices. You can design a workstation that fits your specific needs, whether for electronics, woodworking, or crafting.

3. Display Stands

Retailers and exhibitors often use aluminum extrusions to create display stands for products. The lightweight yet sturdy nature of the material makes it easy to transport and set up at events. Custom display stands can enhance product visibility and attract customers, making them a valuable investment for businesses.

4. Robotics and Automation

In the field of robotics, 2020 aluminum extrusions are frequently used to build frames for robotic arms and other automated systems. The ability to easily modify and expand the structure is crucial in this rapidly evolving field. Aluminum's lightweight properties also contribute to the efficiency and speed of robotic systems.

5. Furniture Design

Innovative furniture designers are increasingly using aluminum extrusions to create modern, minimalist furniture. The clean lines and customizable nature of the material allow for unique designs that stand out. From coffee tables to shelving units, aluminum extrusions can be used to create functional and aesthetically pleasing furniture pieces.

Tips for Working with 2020 Aluminum Extrusions

Cutting and Assembly

When working with aluminum extrusions, it's essential to use the right tools for cutting and assembly. A miter saw with a fine-toothed blade is ideal for cutting aluminum. For assembly, T-nuts and bolts are commonly used to secure the extrusions together. Ensure that you have a well-ventilated workspace and wear appropriate safety gear, such as goggles and gloves.

Finishing Touches

Consider adding finishing touches to your project, such as anodizing or powder coating, to enhance the appearance and durability of the aluminum. These processes can provide additional protection against corrosion and wear. Finishing options can also give your project a professional look, making it suitable for commercial applications.

Planning Your Design

Before starting your project, take the time to plan your design carefully. Sketch out your ideas and create a list of the materials you'll need. This will help ensure that you have everything on hand when you're ready to start building. Planning can also help you identify potential challenges and find solutions before you begin.

Frequently Asked Questions

1. What is the difference between 2020 and 2040 aluminum extrusions?

The primary difference is the size; 2020 extrusions measure 20mm x 20mm, while 2040 extrusions measure 20mm x 40mm. The 2040 profile is larger and can support heavier loads, making it suitable for different applications.

2. Can I cut aluminum extrusions at home?

Yes, you can cut aluminum extrusions at home using a miter saw with a fine-toothed blade. Ensure you take proper safety precautions while cutting, such as securing the extrusion firmly and wearing safety goggles.

3. Are aluminum extrusions recyclable?

Yes, aluminum is highly recyclable. You can recycle your aluminum extrusions at local recycling centers, contributing to environmental sustainability and reducing waste.

4. What tools do I need to assemble aluminum extrusions?

Basic tools include a miter saw for cutting, a drill for making holes, and T-nuts and bolts for assembly. Depending on your project, you may also need additional tools like a level and measuring tape.

5. Can I use 2020 aluminum extrusions for outdoor projects?

Yes, aluminum is corrosion-resistant, making it suitable for outdoor use. However, consider applying a protective finish for added durability, especially in harsh weather conditions.