Content Menu

● Introduction

● Understanding Aluminum Extrusion Casters

>> The Importance of Aluminum Extrusion Casters

● Types of Aluminum Extrusion Casters

>> 1. Threaded Stem Casters

>> 2. Plate Mount Casters

>> 3. Leveling Casters

>> 4. T-Slot Casters

>> 5. Corner Bracket Casters

● Where to Buy High-Quality Aluminum Extrusion Casters

>> 1. MISUMI USA

>> 2. McMaster-Carr

>> 3. 80/20 Inc.

>> 4. Grainger

>> 5. Amazon

>> 6. Caster Connection

>> 7. Rockler

● Factors to Consider When Buying Aluminum Extrusion Casters

>> 1. Compatibility

>> 2. Load Capacity

>> 3. Wheel Material

>> 4. Swivel vs. Fixed

>> 5. Brakes

>> 6. Environmental Factors

>> 7. Wheel Diameter

>> 8. Bearing Type

>> 9. Aesthetics

● Installation Tips

>> Additional Installation Considerations

● Maintenance and Care

>> Preventive Maintenance Schedule

● Applications of Aluminum Extrusion Casters

>> Expanding Applications

● Innovations in Aluminum Extrusion Casters

>> Cutting-Edge Developments

● Case Studies

>> Case Study 1: Automotive Assembly Line

>> Case Study 2: Trade Show Exhibit

>> Case Study 3: Pharmaceutical Laboratory

● Future Trends

>> Emerging Technologies

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of using aluminum extrusion casters?

>> 2. How do I determine the correct size and load capacity for my aluminum extrusion casters?

>> 3. Can I use standard casters with aluminum extrusions?

>> 4. How often should I maintain my aluminum extrusion casters?

>> 5. Are there eco-friendly options for aluminum extrusion casters?

Introduction

Aluminum extrusion casters are essential components for many industrial and commercial applications, providing mobility and flexibility to structures built with aluminum extrusions. These specialized casters are designed to seamlessly integrate with aluminum profile systems, offering a perfect blend of functionality and aesthetics. In this comprehensive guide, we'll explore where to find high-quality aluminum extrusion casters, their various types, and important factors to consider when making a purchase.

Understanding Aluminum Extrusion Casters

Aluminum extrusion casters are wheeled devices specifically designed to attach to aluminum extrusion profiles. They enable easy movement of structures, machines, or equipment built using aluminum extrusions. These casters come in various styles, sizes, and load capacities to suit different applications.

The Importance of Aluminum Extrusion Casters

Aluminum extrusion casters play a crucial role in enhancing the versatility and functionality of aluminum profile systems. Their importance can be understood through several key aspects:

1. Mobility: They transform static structures into mobile ones, allowing for easy relocation of equipment or workstations.

2. Flexibility: Casters enable quick reconfiguration of workspace layouts, adapting to changing needs.

3. Efficiency: By making structures mobile, they contribute to improved workflow and space utilization.

4. Ergonomics: Mobile structures reduce the need for heavy lifting, enhancing workplace safety and comfort.

5. Cost-effectiveness: The ability to move equipment rather than disassemble and reassemble saves time and labor costs.

Types of Aluminum Extrusion Casters

1. Threaded Stem Casters

Threaded stem casters are popular for aluminum extrusion applications. They feature a threaded stem that can be directly screwed into tapped holes in the extrusion profile or into a base plate attached to the extrusion.

2. Plate Mount Casters

Plate mount casters have a flat mounting plate that can be attached to the bottom of an aluminum extrusion using T-slot nuts and bolts. These casters offer a stable base and are suitable for heavier loads.

3. Leveling Casters

Leveling casters combine the functionality of a caster with an adjustable foot. They allow for easy transitioning between mobile and stationary positions, making them ideal for equipment that needs to be both movable and stable.

4. T-Slot Casters

T-slot casters are designed to slide directly into the T-slot of an aluminum extrusion profile. They offer a clean, integrated look and are easy to install and remove without additional hardware.

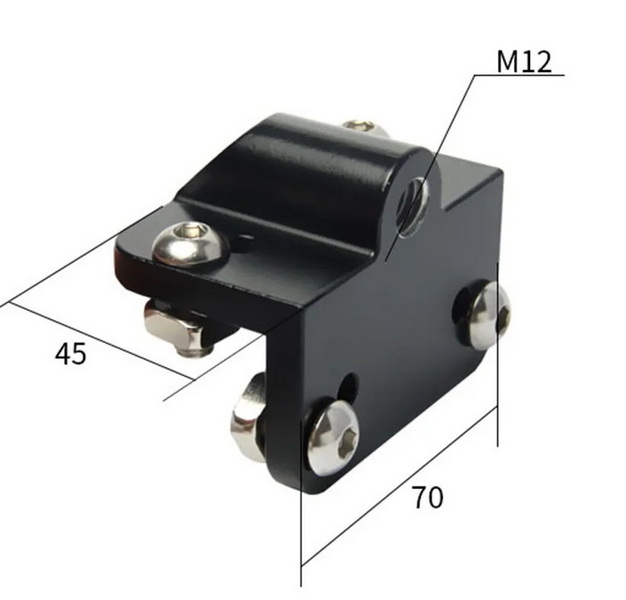

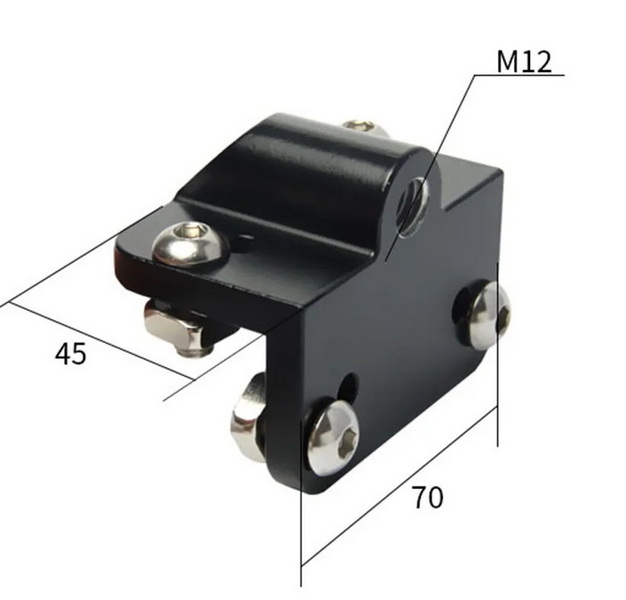

5. Corner Bracket Casters

These casters are mounted using corner brackets that attach to the aluminum extrusion frame. They're particularly useful for structures that require casters at the corners for stability and even weight distribution.

Where to Buy High-Quality Aluminum Extrusion Casters

1. MISUMI USA

MISUMI is a leading supplier of industrial components, including a wide range of aluminum extrusion casters. They offer customizable options and quick delivery times.

2. McMaster-Carr

McMaster-Carr provides an extensive selection of aluminum extrusion casters with detailed specifications and easy-to-use search filters.

3. 80/20 Inc.

80/20 Inc. specializes in aluminum extrusion systems and offers a variety of compatible casters designed specifically for their profiles.

4. Grainger

Grainger is a well-known industrial supply company that offers a wide range of casters, including those suitable for aluminum extrusions.

5. Amazon

For smaller projects or quick replacements, Amazon offers a variety of aluminum extrusion casters from different manufacturers.

6. Caster Connection

Caster Connection specializes in casters and wheels for various applications, including those compatible with aluminum extrusions. They offer expert advice and custom solutions.

7. Rockler

Rockler, primarily known for woodworking supplies, also offers a selection of casters suitable for aluminum extrusion projects, especially for DIY and small-scale applications.

Factors to Consider When Buying Aluminum Extrusion Casters

1. Compatibility

Ensure the casters are compatible with your specific aluminum extrusion profile. Check the mounting method and dimensions to guarantee a proper fit.

2. Load Capacity

Consider the total weight of your structure or equipment and choose casters with an appropriate load capacity. It's advisable to select casters with a higher load capacity than required for safety and longevity.

3. Wheel Material

Different wheel materials offer various benefits:

- Polyurethane: Quiet operation and floor protection

- Rubber: Shock absorption and smooth rolling

- Nylon: Durability and resistance to chemicals

4. Swivel vs. Fixed

Decide whether you need swivel casters for omnidirectional movement or fixed casters for straight-line motion. Many applications benefit from a combination of both.

5. Brakes

Consider casters with brakes if you need to secure your structure in place when not in motion.

6. Environmental Factors

Take into account the environment where the casters will be used. Factors like temperature, moisture, and chemical exposure can affect caster performance and longevity.

7. Wheel Diameter

The wheel diameter affects the caster's ability to roll over obstacles and impacts the overall height of your structure. Larger wheels generally offer smoother rolling and better obstacle clearance.

8. Bearing Type

The type of bearing used in the caster wheel can affect its performance and longevity:

- Plain bearings: Economical and suitable for light-duty applications

- Ball bearings: Offer smoother rolling and higher load capacities

- Roller bearings: Ideal for heavy-duty applications with high load requirements

9. Aesthetics

Consider how the casters will look when attached to your aluminum extrusion structure. Some casters are designed to blend seamlessly with the extrusion profile for a more polished appearance.

Installation Tips

1. Clean the mounting surface thoroughly before installation.

2. Use appropriate tools to avoid damaging the caster or extrusion.

3. Follow the manufacturer's torque specifications when tightening bolts.

4. Test the casters under load before full deployment.

Additional Installation Considerations

5. Ensure even distribution of casters to prevent tipping or uneven wear.

6. Consider using thread-locking compounds for threaded stem casters to prevent loosening over time.

7. When installing plate mount casters, use all provided mounting holes for maximum stability.

8. For leveling casters, adjust all casters to the same height to ensure proper weight distribution.

Maintenance and Care

Regular maintenance can extend the life of your aluminum extrusion casters:

- Clean the wheels and bearings periodically

- Lubricate moving parts as recommended by the manufacturer

- Inspect for wear and damage regularly

- Replace worn or damaged components promptly

Preventive Maintenance Schedule

Implementing a preventive maintenance schedule can significantly extend the life of your aluminum extrusion casters:

1. Daily: Visual inspection for any obvious damage or debris.

2. Weekly: Check for loose bolts or mounting hardware.

3. Monthly: Clean wheels and swivel mechanisms, removing any built-up dirt or debris.

4. Quarterly: Lubricate bearings and swivel mechanisms as per manufacturer recommendations.

5. Annually: Conduct a thorough inspection of all components, replacing any worn parts.

Applications of Aluminum Extrusion Casters

Aluminum extrusion casters find use in various industries and applications:

1. Manufacturing equipment

2. Workstations and assembly lines

3. Trade show displays

4. Medical equipment

5. Retail fixtures

6. Laboratory furniture

7. Automotive assembly

Expanding Applications

8. Aerospace Industry: Mobile tooling and equipment carts

9. Education: Movable classroom furniture and lab equipment

10. Hospitality: Modular event staging and portable bars

11. Agriculture: Mobile grow racks and harvesting equipment

12. Robotics: Adjustable test beds and development platforms

13. Film and Television: Mobile lighting rigs and camera dollies

14. Renewable Energy: Portable solar panel arrays and wind turbine maintenance platforms

Innovations in Aluminum Extrusion Casters

The field of aluminum extrusion casters continues to evolve with new innovations:

- Smart casters with integrated sensors for tracking and maintenance

- Ergonomic designs for improved maneuverability

- Advanced materials for increased durability and load capacity

- Eco-friendly options with sustainable materials and manufacturing processes

Cutting-Edge Developments

- Self-aligning casters: Automatically adjust their orientation for optimal movement

- Energy-harvesting casters: Generate small amounts of electricity from motion to power sensors or LED indicators

- Noise-reducing technologies: New wheel materials and tread designs for ultra-quiet operation

- Modular caster systems: Allow for quick swapping of wheels or entire caster units without tools

Case Studies

Case Study 1: Automotive Assembly Line

An automotive manufacturer implemented aluminum extrusion casters in their assembly line, resulting in:

- 30% increase in production flexibility

- 15% reduction in equipment setup time

- Improved worker ergonomics and safety

Case Study 2: Trade Show Exhibit

A company specializing in trade show displays switched to aluminum extrusion casters for their modular booth systems, achieving:

- 40% faster setup and teardown times

- 25% reduction in shipping costs due to lighter weight

- Increased customer satisfaction with easy-to-move displays

Case Study 3: Pharmaceutical Laboratory

A pharmaceutical research facility integrated aluminum extrusion casters into their laboratory furniture design:

- Achieved 50% improvement in lab reconfiguration speed

- Enhanced safety by enabling quick equipment relocation during emergencies

- Reduced strain-related injuries among lab technicians by 35%

Future Trends

The future of aluminum extrusion casters looks promising with several emerging trends:

1. Integration with IoT for smart factory applications

2. Development of hybrid materials for enhanced performance

3. Customization through 3D printing technologies

4. Increased focus on ergonomics and user-friendly designs

Emerging Technologies

5. AI-powered caster systems: Predictive maintenance and optimal route planning for automated guided vehicles (AGVs)

6. Biomimetic designs: Casters inspired by natural locomotion systems for improved efficiency and adaptability

7. Nanotechnology coatings: Ultra-durable and self-cleaning wheel surfaces

8. Augmented Reality (AR) integration: AR-assisted installation and maintenance procedures for complex caster systems

Conclusion

High-quality aluminum extrusion casters are essential components for many industries, offering mobility, flexibility, and efficiency to structures and equipment built with aluminum extrusions. By considering factors such as compatibility, load capacity, and specific application requirements, you can find the perfect casters for your needs from reputable suppliers like MISUMI, McMaster-Carr, 80/20 Inc., Grainger, or even Amazon for smaller projects.

Remember to prioritize quality and compatibility when making your purchase, as the right casters can significantly enhance the functionality and longevity of your aluminum extrusion-based structures. Regular maintenance and proper installation will ensure optimal performance and extend the life of your casters.

As the industry continues to innovate, we can expect to see even more advanced and specialized aluminum extrusion casters in the future, further improving the versatility and efficiency of aluminum extrusion systems across various applications. The integration of smart technologies, sustainable materials, and ergonomic designs will continue to drive the evolution of aluminum extrusion casters, making them an increasingly valuable component in modern industrial and commercial environments.

Frequently Asked Questions

1. What are the main advantages of using aluminum extrusion casters?

Aluminum extrusion casters offer several advantages:

- Seamless integration with aluminum profile systems

- Lightweight yet durable construction

- Corrosion resistance

- Versatility in design and application

- Easy installation and replacement

- Ability to create mobile structures quickly

2. How do I determine the correct size and load capacity for my aluminum extrusion casters?

To determine the correct size and load capacity:

- Calculate the total weight of your structure or equipment

- Divide the total weight by the number of casters you plan to use

- Add a safety factor of 20-25% to account for uneven load distribution

- Choose casters with a load capacity that exceeds this calculated value

- Ensure the caster's mounting method is compatible with your extrusion profile

3. Can I use standard casters with aluminum extrusions?

While it's possible to use standard casters with aluminum extrusions, it's not recommended for several reasons:

- Standard casters may not fit properly or securely attach to aluminum profiles

- They may lack the necessary mounting options for easy integration

- Aluminum extrusion-specific casters are designed to complement the aesthetics and functionality of aluminum profile systems

- Using incompatible casters may void warranties or compromise the structural integrity of your assembly

4. How often should I maintain my aluminum extrusion casters?

The maintenance frequency depends on usage and environmental conditions, but general guidelines include:

- Visual inspection: Weekly or before each use

- Cleaning: Monthly or as needed

- Lubrication: Every 3-6 months, or as recommended by the manufacturer

- Thorough inspection and part replacement: Annually or every 2000 hours of use

5. Are there eco-friendly options for aluminum extrusion casters?

Yes, eco-friendly options for aluminum extrusion casters are becoming more prevalent:

- Casters made from recycled materials

- Wheels manufactured using sustainable processes

- Biodegradable wheel materials for certain applications

- Energy-efficient production methods

- Casters designed for easy disassembly and recycling at end-of-life