Content Menu

● Overview of Useon Nanjing Extrusion Machinery Co.

● Key Product Categories Manufactured Using Useon Extrusion Machinery

>> 1. Polymer Compounding Products

>> 2. Foam Extrusion Products

>> 3. Film, Sheet, and Board Extrusion Products

>> 4. Recycling and Sustainable Products

>> 5. Specialty and Engineering Plastic Products

● Technological Advantages of Useon Nanjing Extrusion Machinery Co.

● Industries Served by Useon Extrusion Machinery

● Conclusion

● FAQ

>> 1. What types of extruders does Useon Nanjing Extrusion Machinery Co. manufacture?

>> 2. Can Useon equipment handle recycled polymers?

>> 3. What industries benefit most from Useon's extrusion machinery?

>> 4. How does Useon ensure energy efficiency in its extrusion machines?

>> 5. Does Useon provide customization for specific production needs?

● Citations:

Useon Nanjing Extrusion Machinery Co., Ltd., established in 2006, is a leading manufacturer specializing in advanced polymer extrusion equipment and technologies. With a strong focus on innovation, energy efficiency, and environmental sustainability, Useon has developed a diverse range of extrusion machinery that caters to various industries and product types. This article explores the types of products best produced using Useon Nanjing Extrusion Machinery Co., highlighting their technology, applications, and industry impact.

Overview of Useon Nanjing Extrusion Machinery Co.

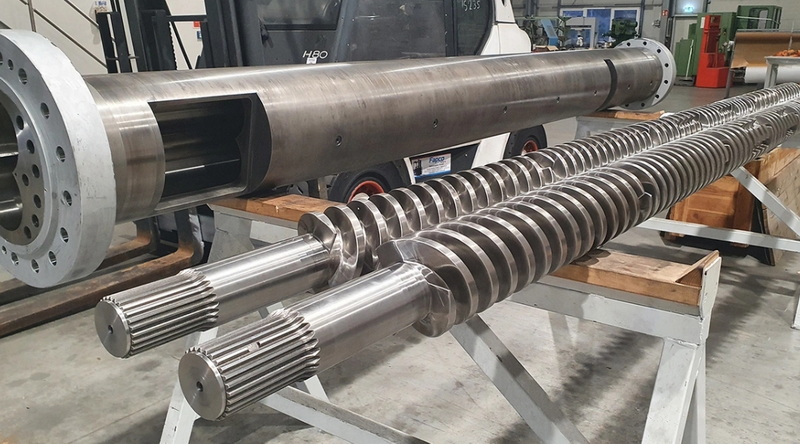

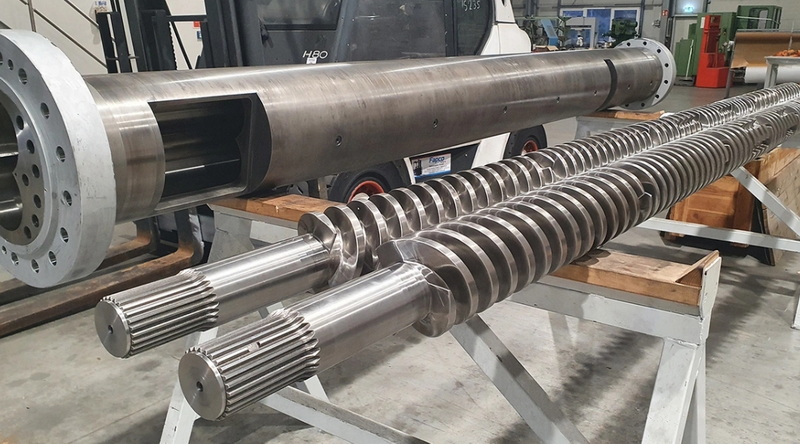

Useon Nanjing Extrusion Machinery Co. is renowned for its expertise in twin-screw and single-screw extruders, compounding lines, and foam extrusion technologies. Their equipment supports high-capacity production with throughput capabilities reaching up to 60 tons per hour, making them suitable for large-scale industrial applications. The company also emphasizes sustainable production through polymer recycling and energy-saving innovations, positioning itself as a strategic partner in the polymer processing industry[1][3][6].

Key Product Categories Manufactured Using Useon Extrusion Machinery

Useon's extrusion machinery is versatile and designed to produce a wide array of polymer-based products. Their equipment is particularly suited for:

1. Polymer Compounding Products

Useon specializes in compounding lines that process various polymers to create customized masterbatches and blends. These include:

- Color and filler masterbatches: Used for coloring and enhancing polymer properties.

- Engineering plastics reinforced with glass fibers: For high-strength applications.

- Blends and alloys: Combining different polymers for tailored performance.

- PVC/XLPE cable compounds: For electrical and telecommunication cables.

- Reactive and degassing processes: To improve polymer quality.

- Wood Plastic Composites (WPC): Combining wood fibers and plastics for durable, eco-friendly materials.

- Bioplastics and recycled PET: Supporting sustainability initiatives[5][6][7].

Useon's twin-screw extruders excel in mixing and compounding, ensuring uniform dispersion of additives and fillers, which is critical for product consistency and performance.

2. Foam Extrusion Products

Useon is a leader in polymer foam extrusion, particularly in:

- CO2 and Freon-based XPS (Extruded Polystyrene) foam boards: Widely used in construction for insulation due to their thermal resistance and lightweight properties.

- PET foam boards: Used in applications such as wind power, rail traffic, aviation, and interior decoration.

- PLA foam beads and sheets: Biodegradable foam products for environmentally friendly packaging and insulation.

- Polymer foam sheets like XPE/IXPE: Used in automotive, sports equipment, and packaging industries[1][3][5].

Their foam extrusion lines incorporate advanced screw designs, cooling barrel structures, and intelligent control systems to optimize foam quality and production efficiency.

3. Film, Sheet, and Board Extrusion Products

Useon manufactures extrusion lines for producing various films, sheets, and boards, including:

- PC (Polycarbonate) sheets for LED lighting: Offering high transparency and impact resistance.

- EVA (Ethylene Vinyl Acetate) films for solar cells: Used as encapsulating layers in photovoltaic modules.

- PET sheets for thermoforming: For packaging and industrial applications.

- PVB (Polyvinyl Butyral) sheets for automotive glass: Providing safety and sound insulation.

- BOPP (Biaxially Oriented Polypropylene) films: Common in packaging due to their strength and clarity[7].

These extrusion lines benefit from Useon's precise screw and barrel technology, enabling high-speed production with energy savings and reduced waste.

4. Recycling and Sustainable Products

Useon is at the forefront of polymer recycling technology, offering:

- PET recycling lines: Converting waste PET into high-quality pellets for reuse.

- Foam and film recycling systems: Supporting circular economy goals.

- Bioplastic extrusion lines: Processing biodegradable polymers for sustainable product development[1][3][6].

Their recycling equipment integrates efficient pelletizing and compounding systems, enhancing material recovery and reducing environmental impact.

5. Specialty and Engineering Plastic Products

Useon's extrusion machinery also caters to specialty applications such as:

- High torque twin-screw extruders: For engineering plastics compounding and reactive extrusion.

- Triple-screw extruders: For super high dispersion and distribution in complex polymer blends.

- EVA solar cell encapsulating films: With line speeds up to 10 m/min for high throughput.

- BOPET extrusion lines: Eliminating pre-drying steps to save energy by up to 35%[3][6].

These specialized products require precise control over extrusion parameters, which Useon's intelligent systems and innovative screw designs provide.

Technological Advantages of Useon Nanjing Extrusion Machinery Co.

Useon's machinery stands out due to several technological innovations:

- High-capacity extruders: Including jumbo extruders with throughput up to 60 T/hr and large extruders like the SAT 250 with 15,000 kg/hr capacity.

- Energy-saving designs: Such as pre-dry-free PET extrusion technology and efficient cooling systems.

- Intelligent control systems: Enabling real-time monitoring and remote debugging.

- Advanced screw profiles: Optimized for mixing, compounding, and foam extrusion.

- Environmental compliance: CE-certified equipment and UNIDO HCFC replacement plans[1][2][3].

These features ensure that Useon's equipment delivers high productivity, product quality, and sustainability.

Industries Served by Useon Extrusion Machinery

Useon's extrusion machinery supports a broad range of industries, including:

- Construction: Through XPS foam boards and insulation materials.

- Automotive: Via PVB sheets and engineering plastic compounds.

- Packaging: Using PET sheets, BOPP films, and biodegradable foam products.

- Renewable energy: EVA films for solar cells.

- Consumer goods: WPC and bioplastics for eco-friendly products.

- Recycling and environmental management: Polymer waste processing and pelletizing[1][3][6].

Their global customer base spans North America, Europe, Asia, and other regions, reflecting their international reputation.

Conclusion

Useon Nanjing Extrusion Machinery Co. offers a comprehensive portfolio of extrusion equipment that excels in producing a diverse range of polymer products. From high-capacity compounding lines and advanced foam extrusion to sustainable recycling technologies and specialty plastic products, Useon's machinery is designed for efficiency, quality, and environmental responsibility. Their innovations in extrusion technology make them a preferred partner for industries seeking reliable, high-performance polymer processing solutions.

FAQ

1. What types of extruders does Useon Nanjing Extrusion Machinery Co. manufacture?

Useon manufactures both twin-screw and single-screw extruders, including co-rotating and counter-rotating parallel twin screws. They also produce specialized extruders for compounding, foam extrusion, and recycling applications[1][5][7].

2. Can Useon equipment handle recycled polymers?

Yes, Useon offers innovative PET recycling technology and foam/film recycling systems that efficiently process polymer waste into high-quality recycled pellets, supporting sustainable manufacturing[1][3][6].

3. What industries benefit most from Useon's extrusion machinery?

Industries such as construction, automotive, packaging, renewable energy, consumer goods, and polymer recycling benefit from Useon's extrusion solutions due to their versatility and advanced technology[1][3].

4. How does Useon ensure energy efficiency in its extrusion machines?

Useon integrates energy-saving features like pre-dry-free PET extrusion technology, optimized screw profiles, efficient cooling barrel structures, and intelligent control systems that reduce energy consumption and improve process efficiency[1][3].

5. Does Useon provide customization for specific production needs?

Yes, Useon offers customized extrusion solutions tailored to client requirements, including high torque gearboxes, triple-screw extruders, and specialized compounding lines for diverse polymer processing needs[6][7].

Citations:

[1] https://www.useon.com

[2] https://www.useon.com/no-limits-at-useon/

[3] https://www.useon.com/about-us/

[4] https://leadmachinery.net/top-extrusion-machining-compare/

[5] https://www.allproducts.com/manufacture100/extruder/

[6] https://mynapple.en.made-in-china.com

[7] https://www.made-in-china.com/showroom/compoundingline/

[8] https://www.linkedin.com/company/useon/

[9] https://discovery.patsnap.com/company/useon-nanjing-extrusion-machinery/patent/

[10] https://ritmindustry.com/manufacturer/useon-nanjing-extrusion-machinery-co/

[11] https://www.chinaplasonline.com/eMarketplace/productinfo/eng?compid=1046281&SeqId=11876

[12] https://fa.machinery-hitech.com/blog/asia-s-top-10-parallel-twin-screw-extruder-brand-list-271764.html

[13] https://www.machinehitech.com/blog/asia-s-top-10-conical-twin-screw-extruder-brand-list-220892.html

[14] https://www.k-online.de/vis-content/event-k2022/exh-k2022.2680444/K-2022-Useon-Nanjing-Extrusion-Machinery-Co.-Ltd.-Paper-k2022.2680444-E6TyvSDtQ3ukBHnIR1bkFg.pdf

[15] https://www.k-online.de/vis-content/event-k2022/exh-k2022.2680444/K-2022-Useon-Nanjing-Extrusion-Machinery-Co.-Ltd.-Paper-k2022.2680444-jjKAR80PR66VTjVQNLdC9w.pdf

[16] https://www.chinaplasonline.com/eMarketplace/ProductInfo/eng?compid=1046281&seqid=11875

[17] https://www.chinaplasonline.com/eMarketplace/companyprofile/eng/USEON_TECHNOLOGY_LIMITED?compid=1046281

[18] https://tr.qunying-screw.com/blog/detail-112615.html

[19] https://www.globalsources.com/nanjing-useon/homepage_6008825858080.htm

[20] https://www.alibaba.com/product-detail/XLPE-Cable-Extrusion-Machine-USEON-Extruder_1600188913406.html