Content Menu

● Understanding Aluminum Extrusions

>> Benefits of Using 30mm Aluminum Extrusions

● Essential Tools for Working with 30mm Aluminum Extrusions

>> 1. Cutting Tools

>> 2. Drilling Tools

>> 3. Fastening Tools

>> 4. Measuring and Marking Tools

>> 5. Finishing Tools

>> 6. Safety Equipment

● Tips for Working with 30mm Aluminum Extrusions

● Common Applications of 30mm Aluminum Extrusions

● Conclusion

● Frequently Asked Questions

>> 1. What is the best way to cut aluminum extrusions?

>> 2. Can I use a regular drill to make holes in aluminum extrusions?

>> 3. What are T-nuts, and why are they important?

>> 4. How do I ensure accurate measurements when working with aluminum?

>> 5. What safety equipment should I use when working with aluminum extrusions?

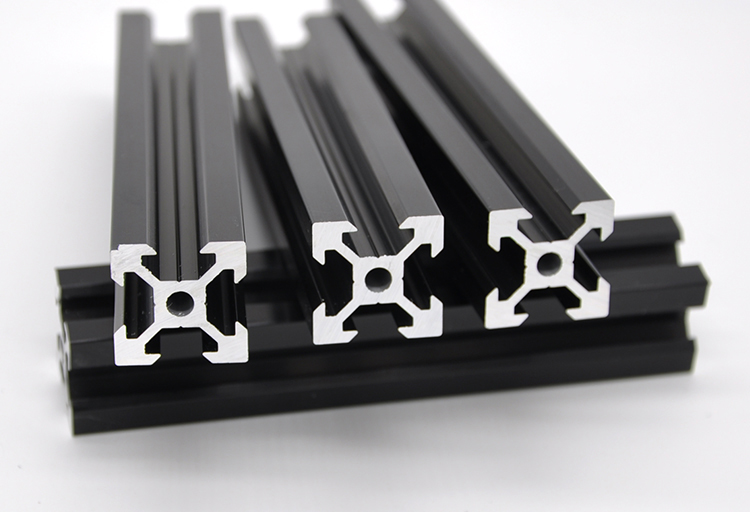

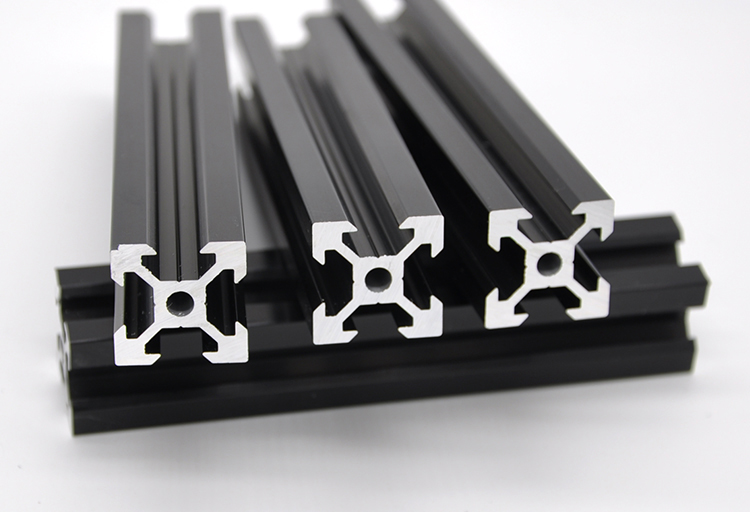

Aluminum extrusions are a popular choice in various industries due to their lightweight, strength, and versatility. Among the different sizes available, 30mm aluminum extrusions are particularly favored for their balance of size and structural integrity. Whether you are building a custom frame, a machine guard, or a display stand, having the right tools is essential for working effectively with these materials. In this article, we will explore the tools you need to work with 30mm aluminum extrusions, along with tips and techniques to ensure successful projects.

Understanding Aluminum Extrusions

Before diving into the tools required, it's important to understand what aluminum extrusions are. Aluminum extrusion is a process that shapes aluminum alloy into a desired cross-sectional profile. The process involves forcing heated aluminum through a die, resulting in long lengths of material that can be cut to size. The 30mm size refers to the width of the extrusion, which is commonly used in various applications, including structural framing, automotive parts, and furniture.

Benefits of Using 30mm Aluminum Extrusions

1. Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps resist corrosion.

3. Versatility: 30mm extrusions can be used in a wide range of applications, from DIY projects to industrial machinery.

4. Ease of Assembly: The T-slot design of many aluminum extrusions allows for easy assembly and disassembly.

Essential Tools for Working with 30mm Aluminum Extrusions

1. Cutting Tools

Cutting aluminum extrusions accurately is crucial for a successful project. Here are some of the best tools for cutting 30mm aluminum extrusions:

- Miter Saw: A miter saw equipped with a carbide-tipped blade is ideal for making precise cuts at various angles. This tool allows for clean, burr-free cuts, which are essential for proper assembly.

- Band Saw: A band saw is another excellent option for cutting aluminum. It can handle thicker extrusions and provides a smooth cut. Ensure you use a blade designed for cutting metal to achieve the best results.

- Chop Saw: A chop saw can also be used for cutting aluminum extrusions. It is particularly useful for making straight cuts quickly.

2. Drilling Tools

Drilling holes in aluminum extrusions is often necessary for assembly. Here are some tools you might need:

- Cordless Drill: A cordless drill is versatile and can be used for drilling holes and driving screws. Use high-speed steel (HSS) drill bits for best results.

- Drill Press: For more precision, a drill press can be used. It allows for consistent hole depth and alignment, which is especially important in structural applications.

3. Fastening Tools

Once your aluminum extrusions are cut and drilled, you will need tools to assemble them:

- T-Nuts and Bolts: T-nuts are specifically designed for T-slot aluminum extrusions. They slide into the slots and provide a secure anchor point for bolts.

- Wrenches and Sockets: A set of wrenches or socket sets will help tighten bolts securely. Ensure you have the right sizes for the bolts you are using.

4. Measuring and Marking Tools

Accurate measurements are critical when working with aluminum extrusions. Here are some tools to consider:

- Tape Measure: A good quality tape measure is essential for measuring lengths accurately.

- Square: A carpenter's square or framing square helps ensure that your cuts are straight and your angles are correct.

- Marking Tools: Use a fine-tip marker or scribe to mark your cut lines clearly on the aluminum.

5. Finishing Tools

After cutting and assembling your aluminum extrusions, you may want to finish the edges:

- Deburring Tool: A deburring tool helps smooth out sharp edges after cutting, making the extrusions safer to handle.

- Sanding Block or File: For finer finishing, a sanding block or metal file can be used to smooth out any rough spots.

6. Safety Equipment

Safety should always be a priority when working with tools and materials. Here are some essential safety items:

- Safety Glasses: Protect your eyes from metal shavings and debris.

- Hearing Protection: If you are using loud power tools, consider wearing ear protection.

- Gloves: Use gloves to protect your hands from sharp edges and hot materials.

Tips for Working with 30mm Aluminum Extrusions

1. Plan Your Project: Before starting, sketch out your design and plan the cuts you need to make. This will help minimize waste and ensure you have all the necessary materials.

2. Measure Twice, Cut Once: Always double-check your measurements before making cuts. This simple rule can save you time and materials.

3. Use Clamps: When cutting or drilling, use clamps to secure the aluminum extrusion in place. This will help prevent movement and ensure accurate cuts.

4. Keep Tools Sharp: Dull blades and bits can lead to poor cuts and increased risk of injury. Regularly check and replace them as needed.

5. Practice Safety: Always follow safety guidelines when using power tools. Ensure your workspace is clean and free of hazards.

Common Applications of 30mm Aluminum Extrusions

30mm aluminum extrusions are used in a variety of applications due to their strength and versatility. Here are some common uses:

- Structural Framing: Many industries use 30mm extrusions for building frames for machines, workstations, and enclosures.

- Automotive Parts: The lightweight nature of aluminum makes it ideal for automotive applications, including brackets and supports.

- Furniture: Custom furniture designs often incorporate aluminum extrusions for their modern aesthetic and durability.

- Display Stands: Retail environments frequently use aluminum extrusions to create attractive and functional display stands.

- DIY Projects: Hobbyists and DIY enthusiasts appreciate the ease of use and adaptability of aluminum extrusions for various projects.

Conclusion

Working with 30mm aluminum extrusions can be a rewarding experience, whether you are a DIY enthusiast or a professional. By equipping yourself with the right tools and following best practices, you can create strong, durable structures for a variety of applications. Remember to prioritize safety and accuracy in your projects, and you will achieve great results.

Frequently Asked Questions

1. What is the best way to cut aluminum extrusions?

The best way to cut aluminum extrusions is to use a miter saw with a carbide-tipped blade for clean, precise cuts.

2. Can I use a regular drill to make holes in aluminum extrusions?

Yes, a regular cordless drill can be used, but ensure you use high-speed steel (HSS) drill bits for best results.

3. What are T-nuts, and why are they important?

T-nuts are fasteners designed to fit into the T-slots of aluminum extrusions, providing a secure anchor point for bolts.

4. How do I ensure accurate measurements when working with aluminum?

Use a tape measure, square, and marking tools to ensure your measurements are accurate before cutting.

5. What safety equipment should I use when working with aluminum extrusions?

Always wear safety glasses, hearing protection, and gloves to protect yourself from potential hazards.