Content Menu

● Introduction

● The Extrusion Press: An Overview

● The Die Holder: Key Component in Extrusion

>> Function of the Die Holder

>> Design of the Die Holder

● The Extrusion Process and the Role of the Die Holder

● Types of Die Holders

>> 1. Fixed Die Holders

>> 2. Sliding Die Holders

>> 3. Rotating Die Holders

>> 4. Adjustable Die Holders

● Importance of Proper Die Holding

● Advancements in Die Holder Technology

● Maintenance and Care of Die Holders

● Impact on Extrusion Quality

● Future Trends in Die Holder Design

● Conclusion

● Frequently Asked Questions

>> 1. How often should a die holder be replaced?

>> 2. Can a faulty die holder affect the quality of extruded profiles?

>> 3. What materials are typically used for manufacturing die holders?

>> 4. How does the die holder contribute to heat management during extrusion?

>> 5. Are there different types of die holders for solid and hollow profiles?

● Citations:

Introduction

Aluminum extrusion is a widely used manufacturing process that transforms aluminum alloys into complex shapes with consistent cross-sections. This versatile technique is essential in various industries, including construction, automotive, and aerospace. At the heart of this process lies the extrusion press, a sophisticated piece of machinery that applies immense pressure to force heated aluminum through a carefully designed die. Among the many components of an extrusion press, the part that holds the die plays a crucial role in ensuring the quality and precision of the extruded profiles.

The Extrusion Press: An Overview

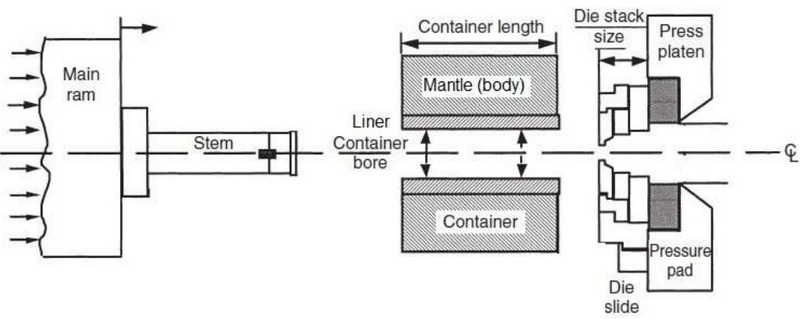

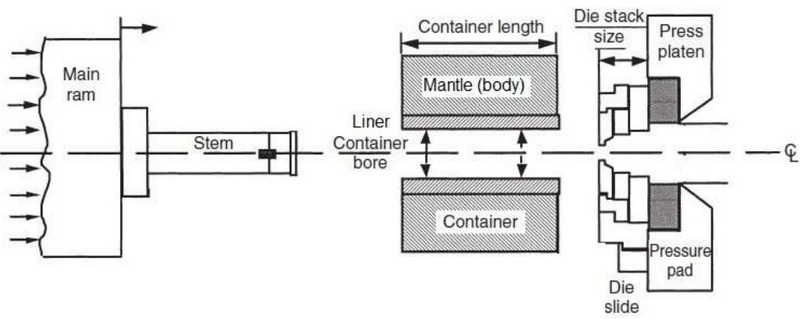

Before delving into the specific component that holds the die, it's important to understand the basic structure and function of an aluminum extrusion press.

An extrusion press typically consists of the following main components:

1. Container

2. Ram

3. Die holder

4. Die

5. Bolster

6. Dummy block

7. Billet loader

The process begins with a preheated aluminum billet being loaded into the container. The hydraulic ram then applies tremendous force, pushing the softened aluminum through the die, which shapes the metal into the desired profile.

The Die Holder: Key Component in Extrusion

The part of an aluminum extrusion press that holds the die is called the die holder or die carrier. This critical component is designed to securely position and support the die during the extrusion process[1].

Function of the Die Holder

The die holder serves several essential functions:

1. Secure Positioning: It keeps the die firmly in place, ensuring that it doesn't shift during the high-pressure extrusion process.

2. Heat Management: The die holder helps manage the heat distribution around the die, which is crucial for maintaining consistent extrusion quality.

3. Pressure Distribution: It aids in evenly distributing the immense pressure applied during extrusion across the die surface.

4. Quick Die Changes: Many modern die holders are designed for rapid die changes, improving production efficiency.

Design of the Die Holder

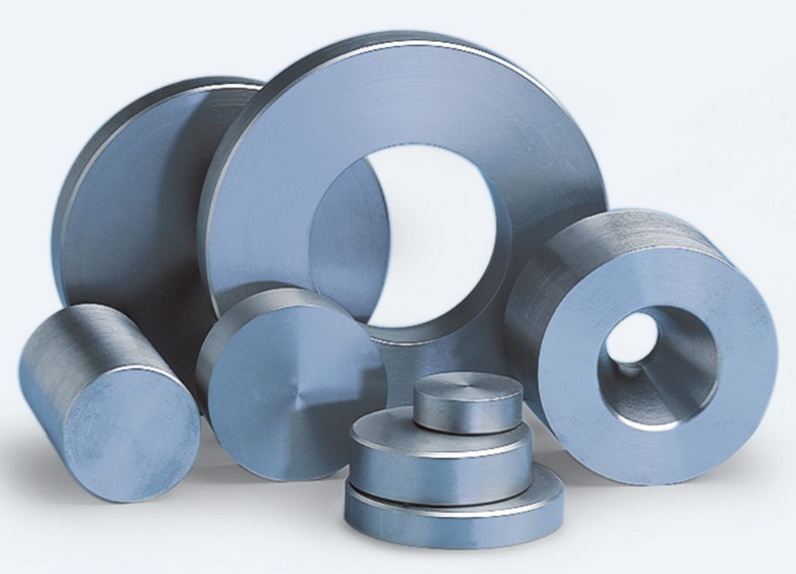

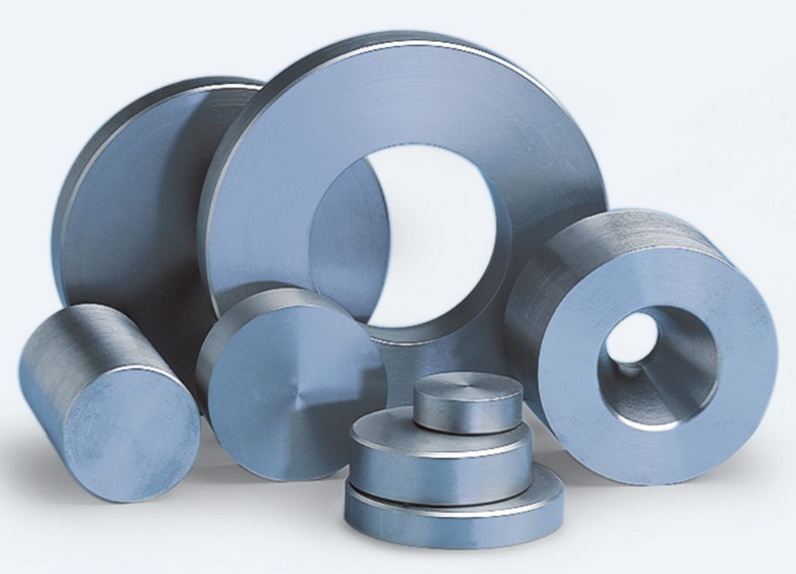

The die holder is typically a robust, cylindrical component made from high-strength steel. Its design can vary depending on the specific extrusion press model and the types of profiles being produced.

Die Holder Diagram

Key features of a die holder often include:

- A central bore to accommodate the die

- Cooling channels for temperature control

- Mechanisms for quick die installation and removal

- Reinforced structure to withstand high pressures

The Extrusion Process and the Role of the Die Holder

To better understand the importance of the die holder, let's examine the extrusion process step by step:

1. Billet Preparation: An aluminum billet is heated to the appropriate temperature, typically between 800°F to 925°F (427°C to 496°C).

2. Loading the Press: The heated billet is transferred to the container of the extrusion press.

3. Ram Activation: The hydraulic ram advances, applying pressure to the billet.

4. Extrusion Through the Die: As the ram pushes forward, the softened aluminum is forced through the die, which is securely held in place by the die holder[2].

5. Profile Formation: The aluminum emerges from the die in the shape of the die opening, creating the desired profile.

6. Cooling and Finishing: The extruded profile is cooled and may undergo additional processing steps.

Throughout this process, the die holder maintains the die's position and alignment, ensuring consistent profile production.

Types of Die Holders

There are several types of die holders used in aluminum extrusion presses, each designed for specific applications or press configurations:

1. Fixed Die Holders

Fixed die holders are permanently attached to the press and do not move during the extrusion process. They are simple and robust but may require more time for die changes.

2. Sliding Die Holders

Sliding die holders can move laterally, allowing for quicker die changes and easier access for maintenance. They are particularly useful in presses that frequently switch between different profile shapes.

3. Rotating Die Holders

Some advanced presses use rotating die holders that can switch between multiple dies without stopping the press. This design significantly reduces downtime during product changeovers.

4. Adjustable Die Holders

Adjustable die holders allow for fine-tuning of the die position, which can be crucial for achieving precise tolerances in complex profiles.

Importance of Proper Die Holding

The die holder's role in maintaining the die's position and alignment cannot be overstated. Improper die holding can lead to several issues:

1. Profile Distortion: If the die shifts during extrusion, it can result in distorted or out-of-spec profiles.

2. Premature Die Wear: Misalignment can cause uneven wear on the die, reducing its lifespan.

3. Inconsistent Extrusion Rates: Improper die holding can lead to variations in extrusion speed and quality.

4. Safety Risks: In extreme cases, a poorly secured die could pose safety hazards to operators.

Advancements in Die Holder Technology

As with many aspects of manufacturing, die holder technology continues to evolve. Recent advancements include:

- Smart Die Holders: Equipped with sensors to monitor pressure, temperature, and alignment in real-time.

- Quick-Change Systems: Advanced mechanisms that allow for die changes in minutes rather than hours.

- Composite Materials: Some manufacturers are experimenting with high-strength composite materials to reduce weight and improve heat management.

Maintenance and Care of Die Holders

Proper maintenance of die holders is crucial for ensuring consistent extrusion quality and press longevity. Key maintenance practices include:

1. Regular inspection for wear and damage

2. Cleaning and lubrication of moving parts

3. Checking and adjusting alignment

4. Periodic replacement of seals and other wear components

Impact on Extrusion Quality

The die holder's performance directly impacts the quality of the extruded profiles. A well-designed and properly maintained die holder contributes to:

- Consistent profile dimensions

- Smooth surface finishes

- Uniform mechanical properties along the length of the extrusion

- Reduced scrap rates and improved material efficiency

Future Trends in Die Holder Design

As the aluminum extrusion industry continues to advance, we can expect to see further innovations in die holder technology:

1. Integration with AI and Machine Learning: Predictive maintenance systems that can anticipate die holder issues before they occur.

2. Enhanced Thermal Management: More sophisticated cooling systems to optimize die temperature control.

3. Modular Designs: Die holders that can be quickly reconfigured for different extrusion requirements.

4. Sustainable Materials: Development of eco-friendly materials and manufacturing processes for die holders.

Conclusion

The die holder is a critical component of an aluminum extrusion press, playing a vital role in securing and positioning the die throughout the extrusion process. Its proper function is essential for producing high-quality aluminum profiles with consistent dimensions and properties. As extrusion technology continues to evolve, we can expect to see further advancements in die holder design, contributing to increased efficiency, improved quality, and greater versatility in aluminum extrusion manufacturing.

Frequently Asked Questions

1. How often should a die holder be replaced?

The lifespan of a die holder can vary greatly depending on usage, maintenance, and the specific extrusion conditions. Generally, die holders should be inspected regularly and replaced when signs of wear or damage are observed. In high-volume production environments, this might be every few years, while in less demanding applications, a well-maintained die holder could last much longer.

2. Can a faulty die holder affect the quality of extruded profiles?

Yes, a faulty die holder can significantly impact extrusion quality. Issues such as misalignment, wear, or damage to the die holder can lead to inconsistent profile dimensions, surface defects, and even structural weaknesses in the extruded product. Regular inspection and maintenance of the die holder are crucial for maintaining extrusion quality.

3. What materials are typically used for manufacturing die holders?

Die holders are usually made from high-strength tool steels that can withstand the extreme pressures and temperatures of the extrusion process. Common materials include H13 tool steel, which offers excellent wear resistance and toughness at high temperatures. Some advanced die holders may incorporate composite materials or special alloys for improved performance.

4. How does the die holder contribute to heat management during extrusion?

Die holders often incorporate cooling channels or passages that allow for the circulation of coolant. This helps manage the heat generated during the extrusion process, preventing overheating of the die and ensuring consistent extrusion temperatures. Proper heat management is crucial for maintaining product quality and extending the life of both the die and the die holder.

5. Are there different types of die holders for solid and hollow profiles?

Yes, there are specialized die holders designed for different types of extrusion profiles. Hollow profile extrusion, which requires a mandrel to form the internal cavity, often uses a more complex die holder setup. These may include additional components to support and align the mandrel. Solid profile extrusion typically uses simpler die holder designs, as they only need to support the die itself.

Citations:

[1] https://patents.google.com/patent/US2172867A/en

[2] https://bonnellaluminum.com/tech-info-resources/aluminum-extrusion-process/

[3] https://geminigroup.net/understanding-aluminum-extrusion-dies/

[4] https://www.alamy.com/stock-photo/extrusion-press.html

[5] https://www.alamy.com/stock-photo/aluminium-extrusion.html

[6] https://www.youtube.com/watch?v=iiGlq7408ME

[7] https://waykenrm.com/blogs/aluminum-extrusion/

[8] https://starext.com/frequently-asked-questions-about-aluminum-extrusions

[9] https://www.ryerson.com/metal-resources/metal-market-intelligence/5-questions-on-aluminum-extrusions

[10] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[11] https://zjaluminum-cnc.com/faqs-on-aluminum-extrusion-and-fabrication/