Content Menu

● Why Upgrade to an Aluminum Extruder?

>> 1. Enhanced Durability

>> 2. Improved Filament Grip

>> 3. Compatibility with Various Filaments

>> 4. Easy Installation

● Features of the TH3D Aluminum Extruder

● Installation Process

● Benefits of Using TH3D Aluminum Extruder

● Comparing Stock vs. TH3D Aluminum Extruders

● Common Issues with Stock Extruders

● User Experiences and Testimonials

● Conclusion

● FAQ

>> 1. What printers are compatible with the TH3D Aluminum Extruder?

>> 2. How much does the TH3D Aluminum Extruder cost?

>> 3. Will I need any special tools for installation?

>> 4. Can I use flexible filaments with this extruder?

>> 5. Is there customer support available if I encounter issues?

● Citations:

In the world of 3D printing, the extruder is one of the most critical components influencing print quality and reliability. Among various options available, the "TH3D Aluminum Extruder" stands out as a must-have upgrade for several reasons. This article explores the features, benefits, and installation process of the TH3D Aluminum Extruder, making it clear why this component is essential for enhancing your 3D printing experience.

Why Upgrade to an Aluminum Extruder?

The stock extruders that come with many 3D printers, particularly those from Creality like the Ender series, are often made from plastic. While they can work adequately for a time, they have several limitations:

- Durability: Plastic extruders are prone to cracking and breaking under stress or over time due to wear and tear.

- Performance: They may not provide enough grip on the filament, leading to issues like under-extrusion or filament slipping.

- Compatibility: Many plastic extruders struggle with flexible filaments or higher-temperature materials.

The "TH3D Aluminum Extruder" addresses these issues effectively. Here are some compelling reasons to consider this upgrade:

1. Enhanced Durability

Made from high-quality aluminum, the TH3D extruder is significantly more robust than its plastic counterparts. It can withstand higher pressures and is less likely to crack or break during operation. This durability translates into a longer lifespan and reduced maintenance costs.

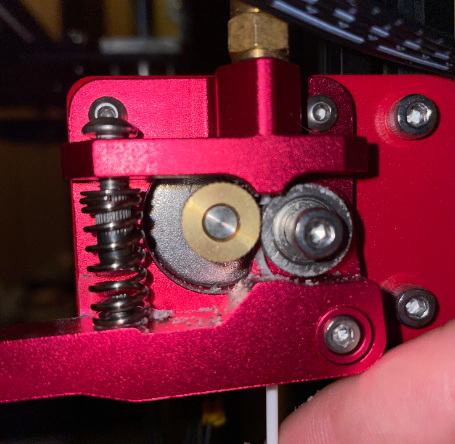

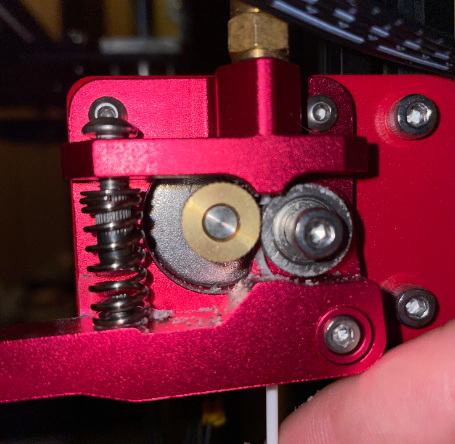

2. Improved Filament Grip

The aluminum design provides better grip on the filament, ensuring consistent extrusion. This improvement helps prevent issues like skipping or grinding of the filament, which can lead to failed prints.

3. Compatibility with Various Filaments

With its superior design and construction, the TH3D Aluminum Extruder is compatible with a wider range of filaments, including flexible materials like TPU and high-temperature plastics such as ABS and PETG. This versatility allows users to expand their printing capabilities without worrying about equipment limitations.

4. Easy Installation

Installing the TH3D Aluminum Extruder is straightforward and can typically be done in under 30 minutes. The kit comes with all necessary hardware and detailed instructions, making it accessible even for those new to 3D printing upgrades.

Features of the TH3D Aluminum Extruder

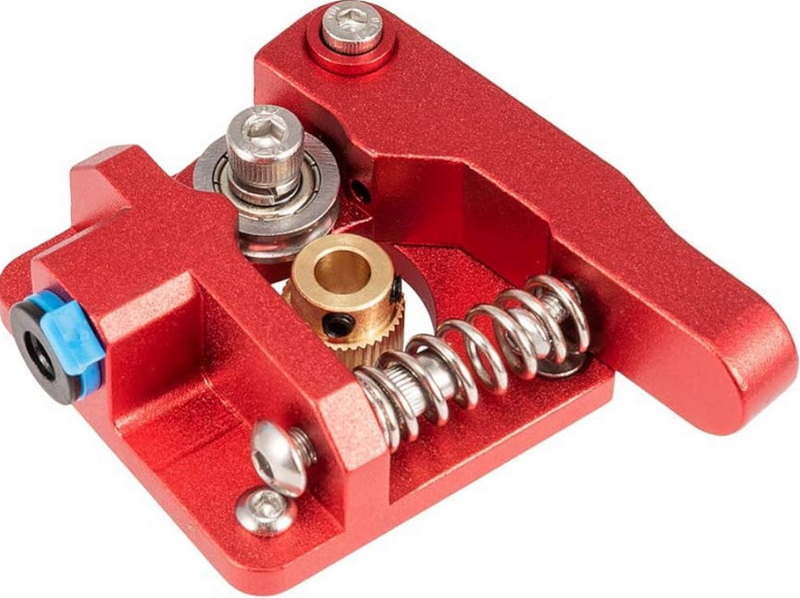

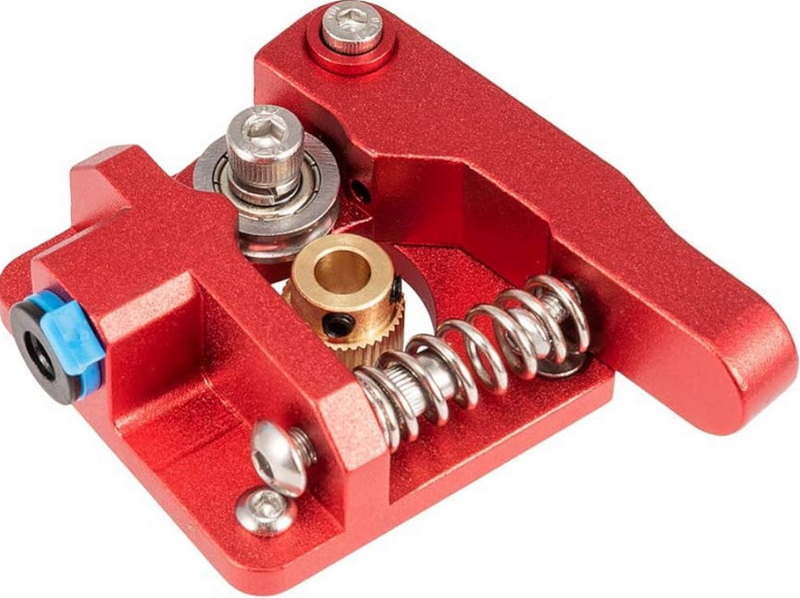

The TH3D Aluminum Extruder boasts several features that enhance its functionality:

- Steel Gear: The extruder includes a hardened steel feeder gear that resists wear and tear better than plastic gears.

- High Tension Spring: This component ensures that the filament is held tightly in place during extrusion, reducing slippage.

- PTFE Tube Compatibility: The extruder works seamlessly with PTFE tubing, which is crucial for maintaining smooth filament flow.

- Support from TH3D: Purchasing from TH3D comes with access to customer support, ensuring you have help if needed during installation or use.

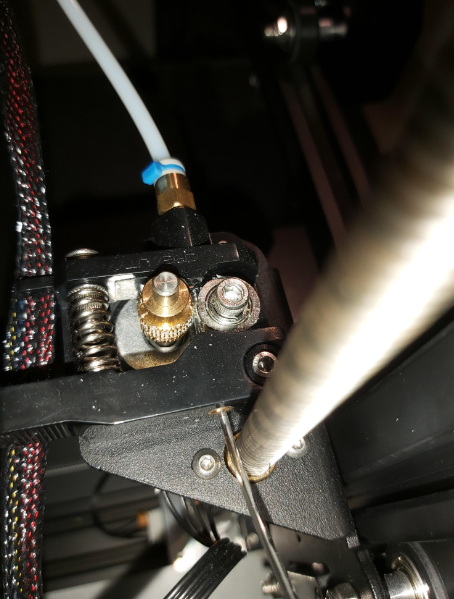

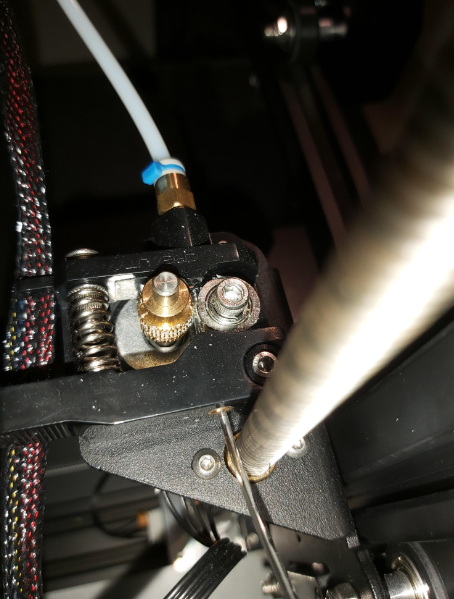

Installation Process

Upgrading to the TH3D Aluminum Extruder is a relatively simple process. Below are the steps involved:

1. Preparation: Begin by preheating your printer's nozzle to make it easier to remove any existing filament.

2. Remove Old Extruder:

- Disconnect any wires connected to the stock extruder.

- Unscrew and remove the plastic extruder from your printer.

- Carefully detach any Bowden tube fittings if applicable.

3. Install New Extruder:

- Position the new aluminum extruder onto the stepper motor.

- Secure it using the provided screws.

- Attach the Bowden tube fitting if necessary.

- Connect any wires back into place.

4. Calibration: After installation, recalibrate your e-steps to ensure accurate extrusion rates.

5. Testing: Run a test print to verify that everything functions correctly.

For a visual guide on installation, you can refer to video tutorials available online that demonstrate this process step by step.

Benefits of Using TH3D Aluminum Extruder

Switching to a TH3D Aluminum Extruder can dramatically enhance your 3D printing experience through:

- Improved print quality due to consistent extrusion.

- Reduced downtime from fewer mechanical failures.

- Greater flexibility in material choices for diverse projects.

Comparing Stock vs. TH3D Aluminum Extruders

To illustrate just how significant an upgrade this can be, let's compare some key aspects of stock plastic extruders versus the TH3D Aluminum Extruder:

| Feature | Stock Plastic Extruder | TH3D Aluminum Extruder |

| Material | Plastic | Aluminum |

| Durability | Prone to cracking | Highly durable |

| Filament Grip | Moderate | Excellent |

| Compatibility | Limited | Wide range |

| Installation Ease | Moderate | Easy |

| Price | Varies | Affordable (~$20) |

Common Issues with Stock Extruders

Many users experience common problems with stock plastic extruders that can hinder their printing experience:

- Under-extrusion: This occurs when not enough filament is pushed through the nozzle, leading to weak prints. It often results from insufficient grip on the filament or wear in the plastic gears.

- Filament Jamming: A poorly designed extruder may cause filament jams due to inconsistent feeding or misalignment within the assembly.

- Inconsistent Layering: Variations in extrusion can lead to uneven layers in prints which compromise aesthetic and structural integrity.

Switching to an aluminum extruder like TH3D's addresses these issues effectively by providing a more reliable feeding mechanism and greater durability in design.

User Experiences and Testimonials

Many users have reported significant improvements after upgrading their extruders:

- A user noted that after switching from a stock plastic extruder on their Ender 3 V2 to a TH3D aluminum version, they experienced far fewer print failures and better overall quality in their prints.

- Another user mentioned that they could finally use flexible filaments without issues—something their stock extruder struggled with consistently.

These testimonials highlight how essential an upgrade can be for those looking to enhance their 3D printing capabilities significantly.

Conclusion

In conclusion, upgrading to the TH3D Aluminum Extruder is a worthwhile investment for anyone serious about 3D printing. Its durability, performance enhancements, and compatibility with various materials make it an essential component for achieving high-quality prints consistently. Whether you're a hobbyist or a professional user, this upgrade will undoubtedly improve your overall printing experience.

FAQ

1. What printers are compatible with the TH3D Aluminum Extruder?

The TH3D Aluminum Extruder is primarily designed for Creality printers such as Ender 3 and Ender 5 models but can be adapted for use with other similar printers as well.

2. How much does the TH3D Aluminum Extruder cost?

Typically priced around $20-$30, it offers significant value compared to potential costs associated with failed prints due to inferior stock extruders.

3. Will I need any special tools for installation?

No special tools are required beyond what usually comes with your printer; standard Allen wrenches should suffice for installation.

4. Can I use flexible filaments with this extruder?

Yes! The design of the TH3D Aluminum Extruder allows for reliable feeding of flexible filaments like TPU without issues commonly associated with plastic extruders.

5. Is there customer support available if I encounter issues?

Yes, purchasing from TH3D provides access to customer support resources for troubleshooting and installation assistance as needed.

Citations:

[1] https://www.yjing-extrusion.com/what-is-a-creality-aluminum-extruder-and-why-should-you-use-it.html

[2] https://chaychaytechtime.com/top-5-best-ender-3-v2-upgrades/

[3] https://support.th3dstudio.com/helpcenter/creality-ender-3-ender-3-pro-upgrades-information-and-tips/

[4] https://forum.makewithtech.com/t/3d-printing-speed-bowden-vs-direct-extruder-ender-3-v2-vs-upgraded-ender-5/3369

[5] https://www.youtube.com/watch?v=73BBHw8Kpwk

[6] https://support.th3dstudio.com/hc-tag/extruder/

[7] https://www.youtube.com/watch?v=zajItjH57Q8

[8] https://www.youtube.com/watch?v=ikVFselJO4Y

[9] https://www.th3dstudio.com/product/nano-coated-x1-p1-extruder-gear-upgrade-kit/

[10] https://support.th3dstudio.com/helpcenter/th3d-tough-hot-end-v1-v2-faqs/

[11] https://www.extrusion.net

[12] https://aec.org/features-benefits

[13] https://www.youtube.com/watch?v=krixZklx8kc

[14] https://www.psiextrusions.com/blog/innovations-in-aluminum-extrusion-sustainability-and-ai/

[15] https://www.youtube.com/watch?v=6CiPITeQ-AM

[16] https://support.th3dstudio.com/helpcenter/upgraded-aluminum-extruder-installation-video-v2/

[17] https://www.youtube.com/watch?v=7JuBJXIumHw

[18] https://support.th3dstudio.com/helpcenter/dual-extrusion-setup-information/

[19] https://www.reddit.com/r/ender3v2/comments/nznbfr/th3d_aluminum_extruded_issues/

[20] https://aec.org

[21] https://www.youtube.com/watch?v=ufN9lrFj6s8

[22] https://support.th3dstudio.com/hc-category/extruders/

[23] https://www.youtube.com/watch?v=BUFC9YDIiLg

[24] https://www.thingiverse.com/groups/creality-cr-10/forums/general/topic:33859

[25] https://openrcforums.com/forum/viewtopic.php?t=12472

[26] https://www.thingiverse.com/groups/electronics/forums/general/topic:52742

[27] https://www.youtube.com/watch?v=-L775dsqu88

[28] https://www.youtube.com/watch?v=Ep2MrU0WCTc

[29] https://www.thingiverse.com/groups/ender3/forums/general/topic:35548

[30] https://reprapy.pl/viewtopic.php?t=6931

[31] https://www.youtube.com/watch?v=zajItjH57Q8

[32] https://3dprintingspace.com/t/bowden-tube-moving/796

[33] https://www.youtube.com/watch?v=ikVFselJO4Y

[34] https://www.otalum.com/common-faults-and-solutions-in-the-work-of-aluminum-extruder.html

[35] https://3dprinting.stackexchange.com/questions/20257/ender-3-pro-extruder-skipping-and-knocking-tried-multiple-things

[36] https://www.youtube.com/watch?v=73BBHw8Kpwk

[37] https://openrcforums.com/forum/viewtopic.php?t=12568

[38] https://github.com/MarlinFirmware/Marlin/issues/18873

[39] https://support.th3dstudio.com/helpcenter/preliminary-troubleshooting-steps/

[40] https://support.th3dstudio.com/hc-category/troubleshooting-guides/