Content Menu

● Introduction to China's Dominance

>> Example of a Leading Manufacturer

● Key Features of Medical Tube Extrusion Machinery

● Advantages of China Medical Tube Plastic Extrusion Machinery Manufacturers

● Challenges and Future Developments

>> Future of Medical Tube Extrusion

● Multi-Layer Extrusion Systems

>> Benefits of Multi-Layer Systems

● Market Dynamics and Trends

>> Sustainability and Environmental Concerns

● Top Medical Tubing Manufacturers in China

>> Shanghai CAREWE Medical

● Conclusion

● FAQs

>> 1. What are the key factors contributing to China's dominance in the medical tube extrusion machinery market?

>> 2. What types of materials are commonly used in medical tube extrusion?

>> 3. How do calibration systems enhance the medical tube extrusion process?

>> 4. What role does automation play in modern medical tube extrusion machinery?

>> 5. What are some of the regulatory standards that medical tube extrusion must comply with?

● Citations:

China has emerged as a global leader in the production of medical tube extrusion machinery, with manufacturers like JWELL Extrusion Machinery Co. Ltd and Creation Glory Machinery Ltd playing significant roles. These companies excel due to their ability to produce high-quality products at competitive prices, leveraging advanced technology and a skilled workforce. This article explores the factors contributing to their success and highlights key aspects of the medical tube extrusion industry.

Introduction to China's Dominance

China's dominance in the global plastic extrusion market, including medical tube extrusion, is attributed to several factors:

1. Low Production Costs: China offers lower labor and material costs compared to many other countries, making its products more competitive globally.

2. Advanced Technology: Chinese manufacturers have adopted cutting-edge technologies to improve efficiency and precision in their products.

3. Skilled Workforce: The availability of highly skilled engineers and technicians ensures continuous innovation and quality control.

Example of a Leading Manufacturer

JWELL Machinery is one of the leading manufacturers in China, known for its high-quality extrusion lines. It has been at the forefront of the Chinese plastic extrusion market for over a decade and exports its machines to more than 120 countries worldwide.

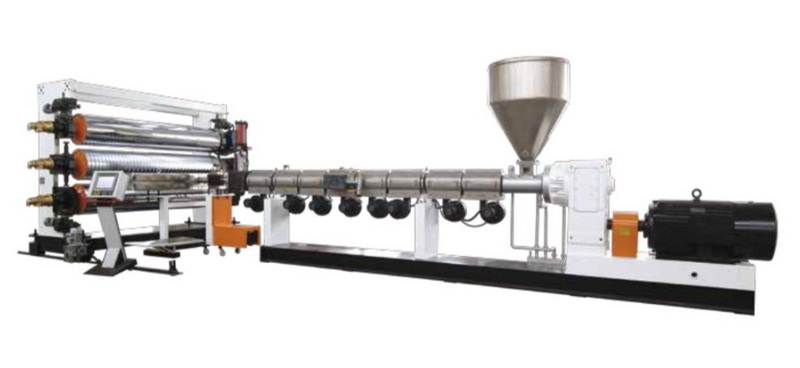

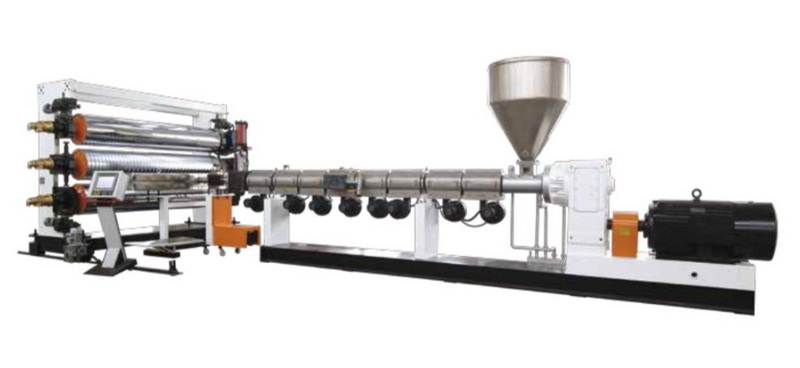

Key Features of Medical Tube Extrusion Machinery

Medical tube extrusion machinery is designed to produce tubes with precise dimensions and materials, adhering to stringent medical standards. Key features include:

- Precision Dies: These determine the shape and size of the tubes, ensuring they meet specific medical requirements.

- Calibration Systems: These systems maintain consistent dimensions throughout the extrusion process.

- Cooling Systems: Efficient cooling ensures the tubes retain their shape and dimensions post-extrusion.

Advantages of China Medical Tube Plastic Extrusion Machinery Manufacturers

China medical tube plastic extrusion machinery manufacturers offer several advantages:

1. High-Quality Products: They produce high-quality medical tubes that meet international standards.

2. Customization: Many manufacturers offer customization options to meet specific client needs.

3. Competitive Pricing: Their products are competitively priced, making them attractive globally.

Challenges and Future Developments

Despite their success, China medical tube plastic extrusion machinery manufacturers face challenges such as maintaining quality standards and adapting to new technologies. The future of the industry lies in innovation, with a focus on automation and smart manufacturing technologies.

Future of Medical Tube Extrusion

The future of medical tube extrusion is promising, with advancements in automation and smart manufacturing technologies expected to transform the production process. Real-time analytics, artificial intelligence, and IoT will play crucial roles in enhancing quality control, reducing downtime, and improving efficiency.

Multi-Layer Extrusion Systems

Multi-layer extrusion systems are valuable in manufacturing medical tubing that has more functions. These systems use multiple extruders to make tubes with different layers, each offering separate advantages:

- Outer Layer: Provides abrasion resistance and toughness.

- Middle Layer: Often contains materials like braided fibers to enhance flexibility and strength.

- Innermost Layer: Must be biocompatible to ensure safe passage of fluids or drugs.

Benefits of Multi-Layer Systems

- Increased Strength: Multi-layered tubes can handle higher internal pressures and resist environmental hazards more effectively.

- Personalization: Allows for the creation of tubes with various properties, such as different hardness levels or drug delivery systems.

Market Dynamics and Trends

The global plastic extrusion market, including medical tube extrusion, is experiencing strong growth driven by increasing demand across various regions. East Asia, led by China, dominates the market due to its robust manufacturing sector and high demand for plastic products in industries like packaging and electronics.

Sustainability and Environmental Concerns

Sustainability is becoming a critical factor in the plastic extrusion market. Manufacturers are innovating to create environmentally friendly products, such as recycled plastic extrusion machines, to cater to the global shift towards reducing waste.

Top Medical Tubing Manufacturers in China

China is home to several leading medical tubing manufacturers, including Rongfeng Medical Devices, Hebei Cangzhou Lingang Industrial Park, and Shanghai CAREWE Medical. These companies specialize in producing a wide range of medical tubes, including PTFE, FEP, and PEEK tubing, catering to various medical applications.

Shanghai CAREWE Medical

Shanghai CAREWE Medical is a prominent manufacturer of medical-grade extruded tubing, offering products such as PTFE tubing, FEP heat shrink tubing, and PEEK tubing. The company has extensive experience in manufacturing tubing for catheter assemblies and has expanded its capabilities to include secondary processing techniques like PTFE etching and tip forming.

Conclusion

In conclusion, China medical tube plastic extrusion machinery manufacturers stand out due to their ability to produce high-quality products at competitive prices, leveraging advanced technology and a skilled workforce. As the industry continues to evolve, these manufacturers will play a crucial role in meeting the demands of the global healthcare sector.

FAQs

1. What are the key factors contributing to China's dominance in the medical tube extrusion machinery market?

China's dominance is due to low production costs, advanced technology, and a skilled workforce, making its products highly competitive globally.

2. What types of materials are commonly used in medical tube extrusion?

Common materials include PVC, PE, and fluoropolymers like PTFE, which are chosen for their biocompatibility and durability.

3. How do calibration systems enhance the medical tube extrusion process?

Calibration systems ensure consistent tube dimensions by maintaining precise control over the extrusion process, reducing variability and improving efficiency.

4. What role does automation play in modern medical tube extrusion machinery?

Automation enhances precision and efficiency by using real-time monitoring systems and programmable logic controllers (PLCs) to maintain consistent product quality and reduce downtime.

5. What are some of the regulatory standards that medical tube extrusion must comply with?

Medical tubes must comply with standards such as ISO 10993, USP Class VI, and FDA 21 CFR Part 820 to ensure biological safety and material compatibility.

Citations:

[1] https://www.futuremarketinsights.com/reports/plastic-extrusion-machine-market

[2] https://jieyatwinscrew.com/blog/medical-tubing-extrusion-equipment/

[3] https://datahorizzonresearch.com/medical-plastics-extrusion-market-10425

[4] https://jieyatwinscrew.com/blog/top-10-plastic-extrusion-machine-manufacturers/

[5] https://www.prm-taiwan.com/blog/Medical-Tube-Extrusion-Line-Key-Insights-and-Case-Studies_531

[6] https://www.linkedin.com/pulse/medical-tubing-industry-production-challenges-rossano

[7] https://www.grandviewresearch.com/industry-analysis/extrusion-machinery-market-report

[8] https://www.carewemedical.com/news/top-10-medical-tubing-manufacturers-in-china-81995010.html

[9] https://www.songhu3dprint.com/article/the-prospect-of-medical-tubing.html

[10] https://www.thebusinessresearchcompany.com/report/medical-tubing-global-market-report

[11] https://www.trelleborg.com/healthcare/-/media/tss-media-repository/healthcare-and-medical/pdfs/whitepaper-advanced-extrusion-techniques-en.pdf?rev=-1

[12] https://www.datainsightsmarket.com/reports/medical-tube-extrusion-equipment-1562241

[13] https://en.medtecchina.com

[14] https://www.plasticstoday.com/medical/medical-grade-silicone-tubing-extruded-in-china-offers-oems-improved-economics-says-natvar

[15] https://www.twinscrew.net/en/article/3-major-strategies-for-twinscrew-extruder-manufacturers-making-advancements.html

[16] http://southeast.newschannelnebraska.com/story/52530992/extruder-machinery-market-size-and-trends-2025

[17] https://www.accupathmed.com/extrusion-medical/

[18] https://www.grahamengineering.com/about/ge-connect/medical-extrusion-and-common-difficulties-encountered/

[19] https://www.thebusinessresearchcompany.com/report/extrusion-machinery-global-market-report

[20] https://www.baod-extrusion.com/news/baod-extrusion-high-speed-pvc-medical-tube-production-lines-ready-for-customer-acceptance/