Content Menu

● Understanding Aluminum Extrusion

● Thermal Break Technology

● Energy Ratings and U-Values

● Weather Sealing and Insulation

● Glazing Options

● Sustainability Factors

● Durability and Maintenance

● Cost-Effectiveness

● Aesthetic Appeal

● Conclusion

● FAQ

>> 1. What are aluminum extrusion doors?

>> 2. How do thermal breaks improve energy efficiency?

>> 3. What is a U-value?

>> 4. Are aluminum extrusion doors environmentally friendly?

>> 5. How do I maintain my aluminum extrusion doors?

● Citations:

Aluminum extrusion doors have gained significant attention in the construction and home improvement industries due to their energy efficiency, durability, and aesthetic appeal. As homeowners and builders increasingly prioritize sustainability and energy conservation, understanding the features that contribute to the energy efficiency of aluminum extrusion doors becomes essential. This article delves into the various aspects that make these doors a smart choice for energy-conscious consumers.

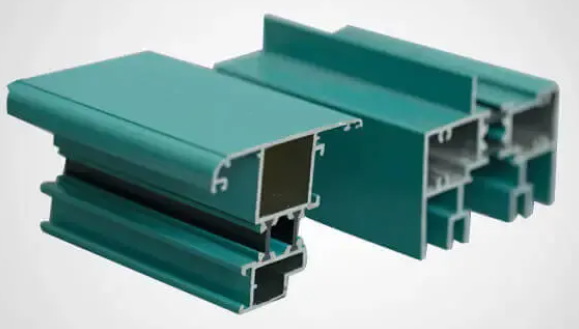

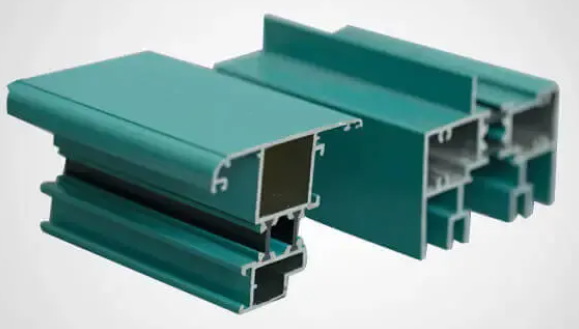

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that involves shaping aluminum by forcing it through a die. This technique allows for the creation of complex shapes and profiles that are lightweight yet strong. The resulting extruded aluminum can be used in various applications, including windows, doors, and architectural elements.

Thermal Break Technology

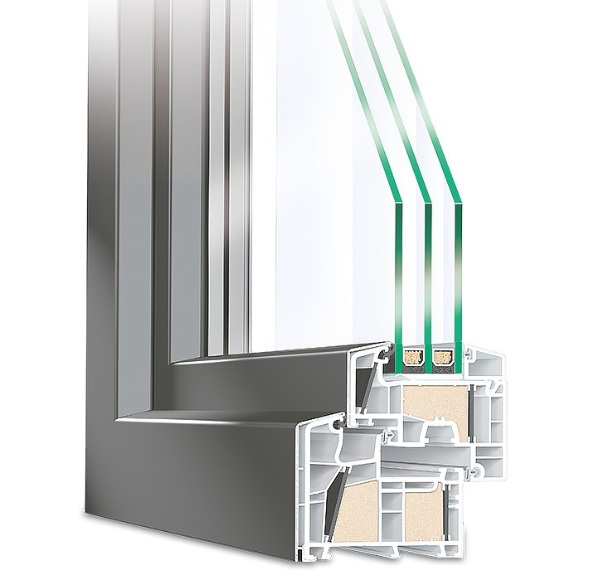

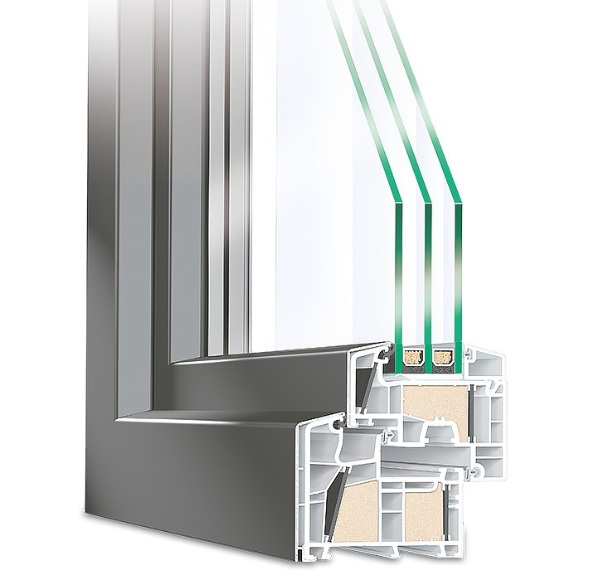

One of the key features that enhance the energy efficiency of aluminum extrusion doors is thermal break technology. Traditional aluminum is a good conductor of heat, which can lead to significant heat loss or gain through door frames.

- What is Thermal Break?

A thermal break is an insulating barrier made from materials like polyamide or polyurethane that separates the interior and exterior surfaces of the aluminum frame. This barrier minimizes thermal transfer, helping to maintain stable indoor temperatures.

- Benefits of Thermal Breaks

- Reduced Heat Loss: By minimizing heat transfer, thermal breaks significantly reduce heating costs in winter and cooling costs in summer.

- Improved Comfort: Homes equipped with thermally broken aluminum doors experience fewer drafts and cold spots, enhancing overall comfort.

Energy Ratings and U-Values

When assessing the energy efficiency of aluminum extrusion doors, two important metrics come into play: energy ratings and U-values.

- U-Value:

The U-value measures how effective a building material is as an insulator. It represents the rate of heat transfer through a material; lower U-values indicate better insulation properties. High-quality aluminum extrusion doors typically feature U-values that meet or exceed industry standards, making them comparable to other materials like uPVC.

- Energy Ratings:

Energy ratings provide an overall assessment of a door's performance based on factors such as thermal transmittance, solar heat gain, and air leakage. Choosing doors with high energy ratings ensures optimal energy efficiency.

Weather Sealing and Insulation

Effective weather sealing is crucial for preventing air leaks around doors.

- Sealing Materials:

High-quality aluminum extrusion doors utilize advanced sealing materials such as rubber or foam gaskets around the frame. These seals compress when the door is closed, filling gaps that could allow air to pass through.

- Benefits of Proper Sealing:

- Minimized Air Leakage: Proper seals prevent drafts, moisture infiltration, and noise pollution.

- Enhanced Energy Savings: By reducing reliance on heating and cooling systems, effective weather sealing contributes to significant energy savings.

Glazing Options

The type of glazing used in aluminum extrusion doors also plays a vital role in their energy efficiency.

- Double or Triple Glazing:

Many modern aluminum doors come with double or triple glazing options. These multi-layered glass panes create additional insulation layers that significantly reduce heat loss compared to single-pane glass.

- Low-E Coatings:

Low-emissivity (Low-E) coatings can be applied to glass surfaces to reflect infrared light while allowing visible light to pass through. This technology helps keep homes cooler in summer and warmer in winter.

Sustainability Factors

Aluminum itself is an environmentally friendly material due to its recyclability.

- Recyclability:

Aluminum can be recycled indefinitely without losing its properties. This characteristic makes it a sustainable choice for eco-conscious homeowners.

- Energy Efficiency in Production:

The production of recycled aluminum requires only about 5% of the energy needed to create new aluminum from raw materials, further reducing its environmental impact.

Durability and Maintenance

Aluminum extrusion doors are known for their strength and durability.

- Corrosion Resistance:

Unlike wood or steel, aluminum does not rot or corrode easily. This longevity translates into less frequent replacements and repairs over time.

- Low Maintenance Requirements:

Aluminum doors require minimal maintenance compared to other materials. A simple cleaning routine keeps them looking new without extensive upkeep efforts.

Cost-Effectiveness

While the initial investment in high-quality aluminum extrusion doors may be higher than traditional options, they offer long-term savings through reduced energy bills and lower maintenance costs.

- Return on Investment (ROI):

Homeowners can expect significant savings on heating and cooling costs over time, offsetting the upfront costs associated with purchasing these energy-efficient doors.

Aesthetic Appeal

In addition to their functional benefits, aluminum extrusion doors offer modern design flexibility.

- Sleek Design:

Their slim profiles allow for larger glass panels, which flood interiors with natural light while providing unobstructed views.

- Customization Options:

Homeowners can choose from various finishes, colors, and styles to match their architectural preferences while maintaining energy efficiency.

Conclusion

Aluminum extrusion doors stand out as a leading choice for homeowners seeking energy-efficient solutions without compromising on style or durability. With advancements in thermal break technology, effective sealing methods, superior glazing options, and sustainable manufacturing practices, these doors provide an excellent return on investment while contributing positively to environmental conservation efforts.

Investing in aluminum extrusion doors not only enhances your home's aesthetic appeal but also ensures a comfortable living environment year-round while significantly reducing energy consumption.

FAQ

1. What are aluminum extrusion doors?

Aluminum extrusion doors are made from profiles created through an extrusion process that shapes aluminum into specific forms suitable for door frames. They are lightweight yet strong and offer excellent thermal performance.

2. How do thermal breaks improve energy efficiency?

Thermal breaks create an insulating barrier within the door frame that reduces heat transfer between the interior and exterior surfaces, minimizing heat loss in winter and heat gain in summer.

3. What is a U-value?

The U-value measures how effective a building material is as an insulator; lower U-values indicate better insulation properties. High-quality aluminum extrusion doors typically have low U-values for improved energy efficiency.

4. Are aluminum extrusion doors environmentally friendly?

Yes! Aluminum is highly recyclable; using recycled aluminum significantly reduces environmental impact compared to producing new aluminum from raw materials.

5. How do I maintain my aluminum extrusion doors?

Maintaining aluminum extrusion doors involves regular cleaning with mild soap and water to remove dirt and grime. They require minimal upkeep compared to wood or steel options due to their corrosion resistance.

Citations:

[1] http://scaluminum.com/2015/01/increase-energy-efficiency-extruded-aluminum-doors-windows/

[2] https://www.cnaluguard.com/blogs/blogs/the-importance-and-advantages-of-energy-efficient-aluminum-alloy-doors-and-windows

[3] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[4] https://www.profall.com/en/aluminum-door-extrusion

[5] https://www.youtube.com/watch?v=hYQIQ0YOPJg

[6] https://silkawindows.com/doors/energy-efficient-doors/

[7] https://www.majesticdesigns.co.uk/news/can-aluminium-doors-improve-energy-efficiency/

[8] https://technical.europe.misumi-ec.com/en/support/solutions/articles/76000046645-aluminum-extrusions-general-questions

[9] https://kenanmetal.com/the-role-of-aluminum-profiles-in-energy-efficiency

[10] https://www.wb-aluminum.com/blog/faqs--common-questions-about-slim-profile-aluminium-sliding-doors

[11] https://www.lovethatdoor.com/are-aluminum-doors-the-key-to-energy-efficient-homes-and-a-greener-future/