Content Menu

● The Aluminum Extrusion Process

● Local Expertise and Resources

● Advanced Technology

● Commitment to Sustainability

● Diverse Applications

● Customer-Centric Services

● Conclusion

● FAQ

>> 1. What types of products can be made using aluminum extrusion?

>> 2. How does the aluminum extrusion process work?

>> 3. What are the benefits of using aluminum over other materials?

>> 4. Are there custom options available for aluminum extrusions?

>> 5. How do companies ensure quality in aluminum extrusion?

● Citations:

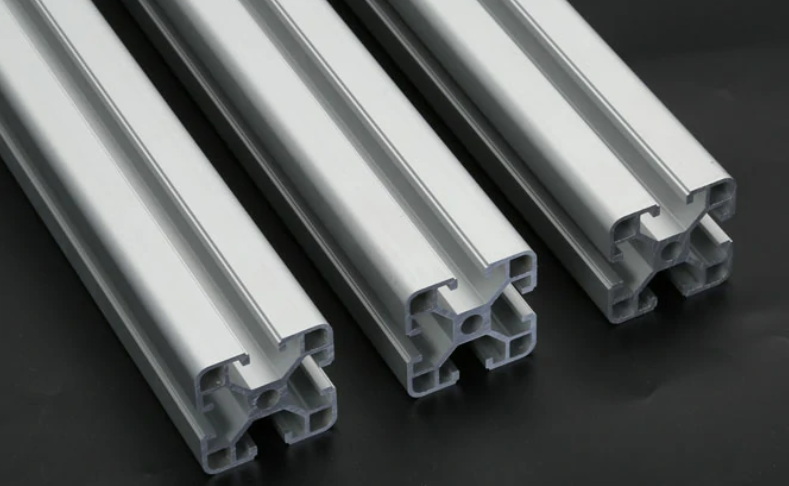

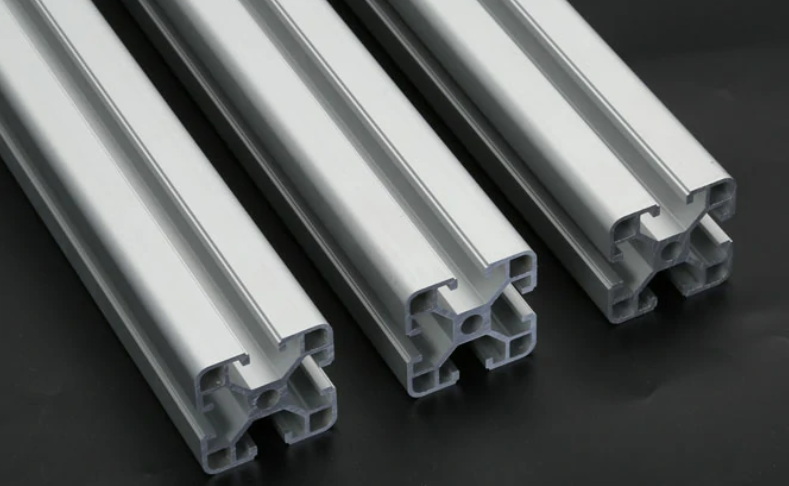

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy by forcing it through a die. This technique is widely used to create a variety of products, from simple shapes to complex designs. In Evansville, Indiana, aluminum extruder services stand out due to their unique combination of local expertise, advanced technology, and a commitment to customer satisfaction. This article explores the distinctive features of aluminum extruder services in Evansville and why they are essential for various industries.

The Aluminum Extrusion Process

Understanding the aluminum extrusion process is crucial to appreciating the services provided in Evansville. The process involves several key steps:

1. Preparation of the Die: The die, which determines the shape of the final product, is preheated to ensure optimal performance.

2. Heating the Aluminum Billet: An aluminum billet is heated to make it malleable enough for extrusion.

3. Extrusion: The heated billet is placed into an extrusion press where it is forced through the die, creating a continuous profile.

4. Cooling and Cutting: After emerging from the die, the extruded aluminum is cooled and cut into desired lengths.

This process allows for high precision and customization, making it suitable for various applications.

Local Expertise and Resources

Evansville boasts several companies specializing in aluminum extrusion, each offering unique capabilities:

- Unique Extrusions: Known for its extensive range of alloys and sizes, Unique Extrusions provides both standard and custom profiles. They are ISO 9001:2015 certified, ensuring high-quality production standards.

- Hydro Extrusion: With multiple facilities in Indiana, Hydro offers advanced manufacturing capabilities including precision cutting and finishing services. Their focus on sustainable practices and innovative solutions makes them a leader in the industry.

- Star Extruded Shapes: This company emphasizes customer satisfaction with a promise of quality extrusions delivered on time. They offer a wide range of services from fabrication to finishing.

These companies leverage local talent and resources to provide tailored solutions that meet specific client needs.

Advanced Technology

The use of advanced technology is another factor that sets Evansville's aluminum extruder services apart:

- CNC Machining: Many local extruders utilize CNC (Computer Numerical Control) machining for precise fabrication. This technology allows for complex shapes and tight tolerances that are essential in industries such as aerospace and automotive.

- Robust Quality Control: Companies maintain rigorous quality control processes to ensure that every product meets industry standards. This includes testing for strength, durability, and dimensional accuracy.

- Innovative Finishing Techniques: From anodizing to powder coating, Evansville's extrusion services offer various finishing options that enhance product performance and aesthetics.

Commitment to Sustainability

Sustainability is increasingly important in manufacturing. Aluminum is a highly recyclable material, and many Evansville extruders are committed to sustainable practices:

- Recycling Programs: Local companies often implement recycling programs that allow them to reuse scrap aluminum, reducing waste and environmental impact.

- Energy Efficiency: Many facilities invest in energy-efficient machinery and processes to minimize their carbon footprint while maintaining productivity.

Diverse Applications

The versatility of aluminum extrusion makes it suitable for a wide range of applications across different industries:

- Construction: Aluminum extrusions are commonly used in window frames, doors, and structural components due to their lightweight yet strong properties.

- Automotive: The automotive industry relies on aluminum extrusions for parts that require high strength-to-weight ratios, improving fuel efficiency without compromising safety.

- Electronics: Heat sinks made from extruded aluminum are essential for managing heat in electronic devices, enhancing performance and longevity.

Customer-Centric Services

What truly makes aluminum extruder services in Evansville unique is their customer-centric approach:

- Customization Options: Local manufacturers offer extensive customization options to meet specific client requirements, whether it's a unique shape or a specific finish.

- Responsive Support: Companies pride themselves on providing responsive customer support throughout the manufacturing process, ensuring clients are informed at every stage.

- Turnkey Solutions: Many providers offer complete turnkey solutions—from design to delivery—allowing clients to streamline their supply chain effectively.

Conclusion

Aluminum extruder services in Evansville, Indiana, are distinguished by their local expertise, advanced technology, commitment to sustainability, diverse applications, and customer-centric approach. These factors contribute to the region's reputation as a hub for high-quality aluminum extrusion manufacturing. As industries continue to evolve and demand innovative solutions, Evansville's aluminum extruders are well-positioned to meet these challenges head-on.

FAQ

1. What types of products can be made using aluminum extrusion?

Aluminum extrusion can produce various products including structural components, heat sinks for electronics, window frames, automotive parts, and custom shapes tailored to specific applications.

2. How does the aluminum extrusion process work?

The process involves heating an aluminum billet until it becomes malleable, then forcing it through a die under pressure. The resulting shape is cooled and cut into lengths as needed.

3. What are the benefits of using aluminum over other materials?

Aluminum offers several advantages including lightweight properties, corrosion resistance, excellent strength-to-weight ratio, and recyclability which makes it an environmentally friendly option.

4. Are there custom options available for aluminum extrusions?

Yes! Many manufacturers provide custom profiles and finishes tailored specifically to meet client specifications across various industries.

5. How do companies ensure quality in aluminum extrusion?

Quality assurance processes include rigorous testing for strength and dimensional accuracy during production as well as compliance with industry standards such as ISO certifications.

Citations:

[1] https://www.manta.com/mb_54_E8162_5CF/aluminum_extruded_products/evansville_in

[2] https://www.uniqueextrusions.com

[3] https://www.hydro.com/profiles/aluminum-extrusions-manufacturer-in-indiana

[4] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[5] https://starext.com

[6] https://starext.com/news/aluminums-unique-properties-and-custom-aluminum-fabrication

[7] https://aluminum-extrusions.net/category/indiana/

[8] https://www.youtube.com/watch?v=iiGlq7408ME

[9] https://www.globalspec.com/local/3408/C_US/IN/Evansville

[10] https://www.hydro.com/profiles/aluminum-extrusions-north-america

[11] https://www.extrusion.net

[12] http://www.zycon.com/Products/US-KY-Kentucky/Aluminum-Extrusions.html

[13] https://www.psiextrusions.com/capabilities/

[14] https://www.sierraaluminum.com

[15] https://extrudedplastics.com/crescent-plastics-inc/

[16] https://www.iqsdirectory.com/aluminum-extruders/indiana/

[17] https://www.uniqueextrusions.com/aluminum-extrusion/

[18] https://www.extrusion.net

[19] https://aluminum-extrusions.net/category/indiana/

[20] https://www.kaiseraluminum.com

[21] https://www.globalspec.com/local/3408/C_US/IN

[22] https://www.onealsteel.com/aluminum-extrusions/

[23] https://www.saf.com/perimeter-systems/cornice-gutter-products/designer-series-cornices/extruded-aluminum-cornices/

[24] https://www.youtube.com/watch?v=baM5hNnBcT8

[25] https://www.reddit.com/r/3Dprinting/comments/5ua1vv/tips_on_aluminum_extrusion_cutting/

[26] https://www.saf.com/astra-portfolio-categories/metal-fabrication/

[27] https://www.youtube.com/watch?v=DqILlMsNYLw

[28] https://builds.openbuilds.com/threads/cutting-aluminum-extrusion.20/

[29] https://dlbextrusions.com

[30] https://www.youtube.com/watch?v=P8BWQBP4Vhk

[31] https://www.alside.com

[32] https://www.linkedin.com/jobs/aluminum-extrusion-jobs

[33] https://www.youtube.com/watch?v=Bc7o_sEdX8U

[34] https://waykenrm.com/blogs/aluminum-extrusion/

[35] https://www.reddit.com/r/Workbenches/comments/xn5ehd/aluminum_extrusion_questions/

[36] https://spectraaluminum.com/frequently-asked-questions-about-aluminum-extrusion/

[37] https://www.reddit.com/r/metalworking/comments/8xeb8j/aluminum_extrusion_question/

[38] https://edmolimited.co.uk/education/frequently-asked-questions/aluminium-extrusion/

[39] https://boards.core77.com/t/question-about-aluminum-extrusion/15105

[40] https://aec.org/faqs

[41] https://zjaluminum-cnc.com/faqs-on-aluminum-extrusion-and-fabrication/

[42] https://www.ryerson.com/metal-resources/metal-market-intelligence/5-questions-on-aluminum-extrusions

[43] https://www.altecextrusions.com/faqs/

[44] https://www.youtube.com/watch?v=ELgtjeJyFw8

[45] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[46] https://community.xometry.com/kb/articles/761-metal-extrusion-frequently-asked-questions

[47] https://www.minalex.com/2021/10/29/10-questions-ask-aluminum-extruder/

[48] https://www.patrickmetals.com/faqs/

[49] https://starext.com/frequently-asked-questions-about-aluminum-extrusions

[50] https://www.uniqueextrusions.com/aluminum-extrusion-faq/

[51] https://www.alufabinc.com/faqs/