Content Menu

● The Importance of Aluminum Extrusion in Modern Manufacturing

● Cutting-Edge Technology and Innovation

>> State-of-the-Art Extrusion Presses

>> Advanced Control Systems

● Comprehensive Product Range

● Quality and Precision

>> Robust Design and Construction

>> Precision Engineering

● Energy Efficiency and Sustainability

● Customer-Centric Approach

>> Customization and Flexibility

>> Comprehensive Support Services

● Industry Expertise and Experience

● Global Presence and Local Support

● Continuous Innovation and R&D

● Case Studies and Success Stories

● Industry Recognition and Certifications

● Conclusion

● Frequently Asked Questions

>> 1. What factors should I consider when choosing an aluminum extrusion press manufacturer?

>> 2. How do leading aluminum extrusion press manufacturers ensure the quality of their products?

>> 3. What innovations are leading aluminum extrusion press manufacturers introducing?

>> 4. How important is after-sales support from aluminum extrusion press manufacturers?

>> 5. Can leading aluminum extrusion press manufacturers customize their products for specific needs?

● Citations:

In the competitive world of aluminum extrusion, manufacturers are constantly striving to differentiate themselves and stand out from the crowd. But what truly sets apart a leading aluminum extrusion press manufacturer? This article will explore the key factors that contribute to excellence in this industry, from cutting-edge technology to customer-centric approaches.

The Importance of Aluminum Extrusion in Modern Manufacturing

Aluminum extrusion is a crucial process in various industries, from construction to automotive and aerospace. The ability to create complex profiles with high precision has made aluminum extrusion an indispensable manufacturing technique. As such, the role of aluminum extrusion press manufacturers cannot be overstated.

Cutting-Edge Technology and Innovation

State-of-the-Art Extrusion Presses

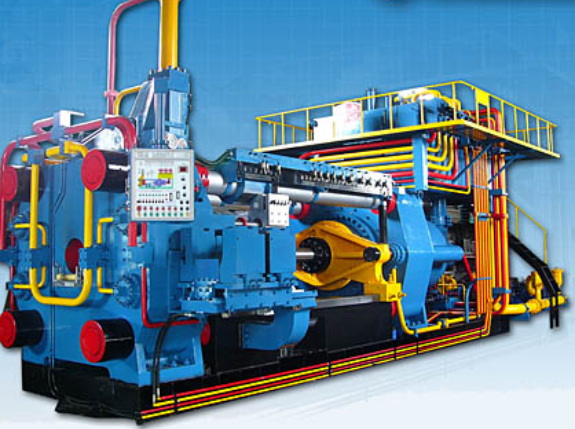

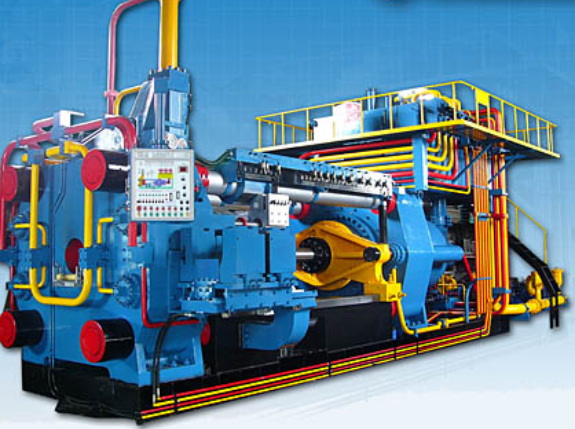

Leading aluminum extrusion press manufacturers invest heavily in research and development to create state-of-the-art extrusion presses. These machines are designed to offer:

1. Higher extrusion speeds

2. Improved precision and consistency

3. Enhanced energy efficiency

4. Greater versatility in handling different alloys and profiles

For instance, companies like SMS group GmbH have developed innovative solutions such as the HybrEx® extrusion presses, which consume up to 55% less energy while increasing productivity by up to 20%[3].

Advanced Control Systems

Top-tier aluminum extrusion press manufacturers incorporate advanced control systems into their machines. These systems offer:

- Real-time monitoring of extrusion parameters

- Automated adjustments for optimal performance

- Data logging and analysis capabilities

- Integration with other production systems

Comprehensive Product Range

A leading aluminum extrusion press manufacturer typically offers a wide range of products to cater to diverse customer needs. This may include:

1. Front-loading and back-loading presses

2. Direct and indirect extrusion presses

3. Specialized presses for tube extrusion

4. Auxiliary equipment such as billet heaters, handling systems, and cooling systems

For example, companies like YUEN-SUN MACHINERY CO., LTD. provide a comprehensive range of aluminum extrusion equipment, including extrusion presses, sawing machines, billet furnaces, and automatic handling systems[10].

Quality and Precision

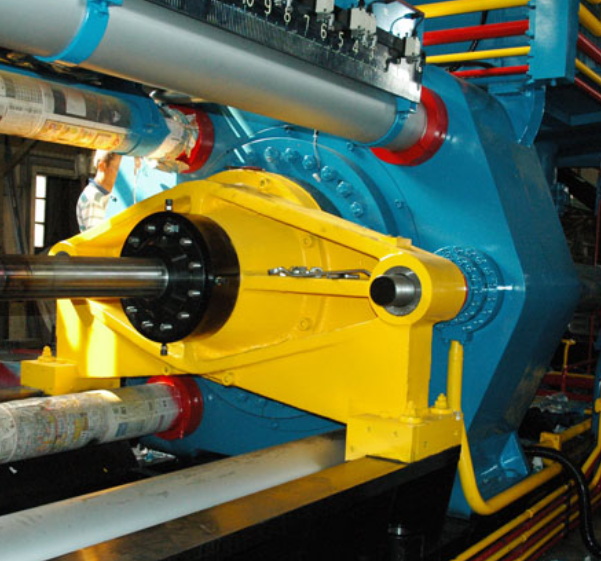

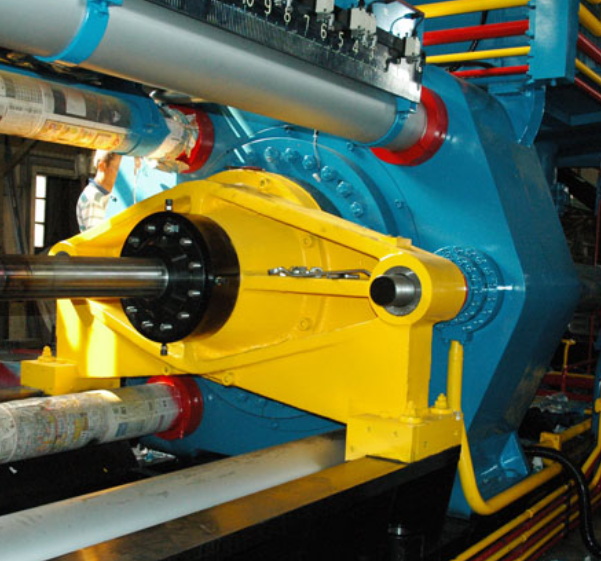

Robust Design and Construction

Leading aluminum extrusion press manufacturers prioritize quality in every aspect of their machines. This includes:

- Using high-grade materials for critical components

- Implementing stringent quality control measures

- Conducting thorough testing and validation before delivery

For instance, SMS group's extrusion presses feature FEM-optimized, pre-stressed press frames in the classic Schloemann lamellar tie rod/pressure box design, ensuring high rigidity and excellent profile quality[3].

Precision Engineering

Precision is paramount in aluminum extrusion. Top manufacturers employ advanced engineering techniques to ensure their presses deliver consistent, high-quality extrusions. This involves:

- Tight tolerances in machine construction

- Precise control of extrusion parameters

- Advanced die design and manufacturing capabilities

Energy Efficiency and Sustainability

In today's environmentally conscious world, leading aluminum extrusion press manufacturers are focusing on energy efficiency and sustainability. This includes:

1. Developing energy-efficient press designs

2. Implementing heat recovery systems

3. Optimizing hydraulic and electrical systems

4. Using eco-friendly materials and manufacturing processes

For example, some manufacturers have introduced hybrid drive systems that combine electric servomotors with hydraulic drives, resulting in significant energy savings[3].

Customer-Centric Approach

Customization and Flexibility

Leading aluminum extrusion press manufacturers understand that one size doesn't fit all. They offer:

- Customizable press designs to meet specific customer requirements

- Flexibility in press configurations and auxiliary equipment

- Scalable solutions for different production volumes

Comprehensive Support Services

Top manufacturers go beyond just selling equipment. They provide comprehensive support services, including:

1. Installation and commissioning

2. Operator training

3. Preventive maintenance programs

4. Rapid response technical support

5. Spare parts availability

Industry Expertise and Experience

Leading aluminum extrusion press manufacturers have accumulated vast industry knowledge and experience over the years. This expertise is reflected in:

- Deep understanding of extrusion processes and metallurgy

- Ability to provide valuable insights and recommendations to customers

- Continuous improvement of press designs based on real-world feedback

For instance, companies like International Extrusions, Inc., PARCO, INC., and Minalex Corporation have established themselves as industry leaders through years of experience and expertise[1].

Global Presence and Local Support

Top aluminum extrusion press manufacturers often have a global presence, allowing them to:

- Serve customers in different regions effectively

- Provide localized support and service

- Adapt to regional market requirements and regulations

Continuous Innovation and R&D

Leading manufacturers invest heavily in research and development to stay ahead of the curve. This includes:

1. Developing new extrusion technologies

2. Improving existing press designs

3. Exploring new materials and alloys

4. Collaborating with research institutions and industry partners

Case Studies and Success Stories

To illustrate their capabilities, top aluminum extrusion press manufacturers often showcase case studies and success stories. These may include:

- Challenging projects successfully completed

- Innovative solutions developed for specific customer needs

- Measurable improvements in productivity and quality achieved by customers

Industry Recognition and Certifications

Leading manufacturers often receive industry recognition and hold important certifications, such as:

- ISO 9001 for quality management

- ISO 14001 for environmental management

- Industry-specific awards and accolades

For example, many top manufacturers listed on Made-in-China.com hold various ISO certifications, demonstrating their commitment to quality and environmental standards[4].

Conclusion

In conclusion, what makes a leading aluminum extrusion press manufacturer stand out is a combination of factors: cutting-edge technology, comprehensive product range, unwavering commitment to quality and precision, focus on energy efficiency and sustainability, customer-centric approach, industry expertise, global presence, continuous innovation, and proven track record of success. By excelling in these areas, top manufacturers like International Extrusions, Inc., PARCO, INC., and Minalex Corporation have established themselves as leaders in the aluminum extrusion industry.

As the demand for aluminum extrusions continues to grow across various sectors, the role of these leading manufacturers becomes increasingly crucial. They not only provide the machinery that forms the backbone of the aluminum extrusion industry but also drive innovation and set new standards for quality and efficiency. For businesses looking to invest in aluminum extrusion equipment, choosing a leading manufacturer can make all the difference in achieving optimal production outcomes and long-term success.

Frequently Asked Questions

1. What factors should I consider when choosing an aluminum extrusion press manufacturer?

When selecting an aluminum extrusion press manufacturer, consider factors such as the manufacturer's experience, product range, technological capabilities, customer support, energy efficiency of their presses, and their ability to provide customized solutions. It's also important to evaluate their global presence, industry reputation, and certifications.

2. How do leading aluminum extrusion press manufacturers ensure the quality of their products?

Leading manufacturers ensure quality through robust design and construction, using high-grade materials, implementing stringent quality control measures, and conducting thorough testing before delivery. They also often hold ISO certifications and employ advanced engineering techniques to maintain tight tolerances and precise control over extrusion parameters.

3. What innovations are leading aluminum extrusion press manufacturers introducing?

Top manufacturers are introducing innovations such as hybrid drive systems for energy efficiency, advanced control systems for real-time monitoring and automated adjustments, and new press designs for improved productivity. They're also exploring new materials and alloys, and developing more sustainable manufacturing processes.

4. How important is after-sales support from aluminum extrusion press manufacturers?

After-sales support is crucial. Leading manufacturers offer comprehensive support services including installation, commissioning, operator training, preventive maintenance programs, rapid response technical support, and reliable spare parts availability. This ensures optimal performance and longevity of the equipment.

5. Can leading aluminum extrusion press manufacturers customize their products for specific needs?

Yes, top manufacturers understand that different customers have unique requirements. They offer customizable press designs, flexible configurations, and scalable solutions to meet specific customer needs. This customization capability is often a key differentiator for leading manufacturers in the industry.

Citations:

[1] https://us.metoree.com/categories/100086/

[2] https://www.aluminum-extrusion-machine.com

[3] https://www.sms-group.com/plants/light-metal-extrusion-presses

[4] https://www.made-in-china.com/products-search/hot-china-products/Aluminum_Extrusion_Press.html

[5] https://www.fszhelu.com/extrusion-press-machine-product/

[6] https://www.youtube.com/watch?v=iiGlq7408ME

[7] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[8] https://aec.org/faqs

[9] https://profileprecisionextrusions.com/choosing-an-aluminum-extrusion-manufacturer-partner/

[10] https://www.yuensun.com.tw