Content Menu

● Introduction to Dual Extrusion

>> Dual Extruder Benefits

● Role of the Dual Extruder Mount Bar

>> Thermal Management Considerations

● Design Considerations for the Dual Extruder Mount Bar

>> Enhancing Cooling Efficiency

● Installation and Setup

● Common Issues and Solutions

>> Clogging and Heat Creep

>> Heat Soak Issues

● Advanced Cooling Solutions

>> Water Cooling System for Raise3D Pro2 Printers

● Dual Extrusion in Various Printers

● Advanced Filament Management

● Enclosed Printing Chambers

● Conclusion

● FAQs

>> 1. What are the benefits of using a dual extruder setup?

>> 2. How does the aluminum cooling block help in thermal management?

>> 3. What are common issues with dual extrusion setups?

>> 4. How can cooling efficiency be enhanced in a dual extruder setup?

>> 5. What materials are suitable for the dual extruder mount bar?

● Citations:

The dual extruder mount bar with an aluminum cooling block plays a crucial role in 3D printing, particularly in setups that utilize dual extrusion systems. This component is essential for maintaining thermal stability, ensuring efficient heat dissipation, and supporting the structural integrity of the extruder assembly. In this article, we will delve into the functions, benefits, and design considerations of the dual extruder mount bar with an aluminum cooling block.

Introduction to Dual Extrusion

Dual extrusion allows 3D printers to print objects with multiple colors or materials, enhancing the aesthetic appeal and functionality of printed models. This capability is made possible by the dual extruder setup, which includes two print heads connected by a sturdy aluminum bar.

Dual Extruder Benefits

- Complexity and Aesthetics: Dual extrusion enables the creation of more complex objects with support structures and aesthetically pleasing designs featuring multiple colors or materials.

- Material Variety: It supports printing with different materials, such as PLA and ABS, allowing for diverse applications.

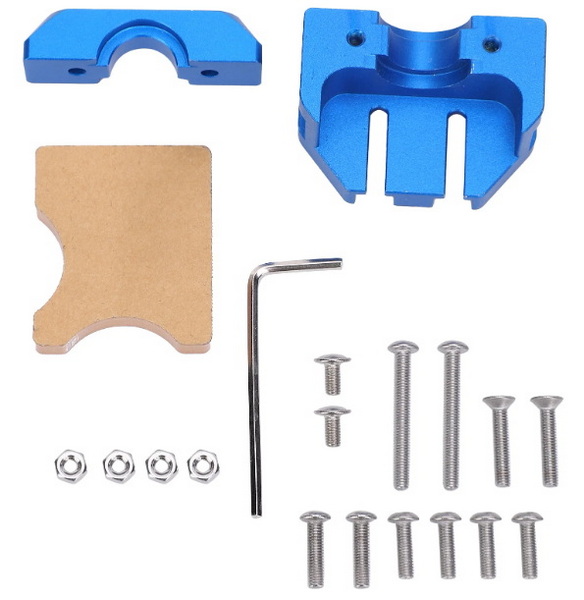

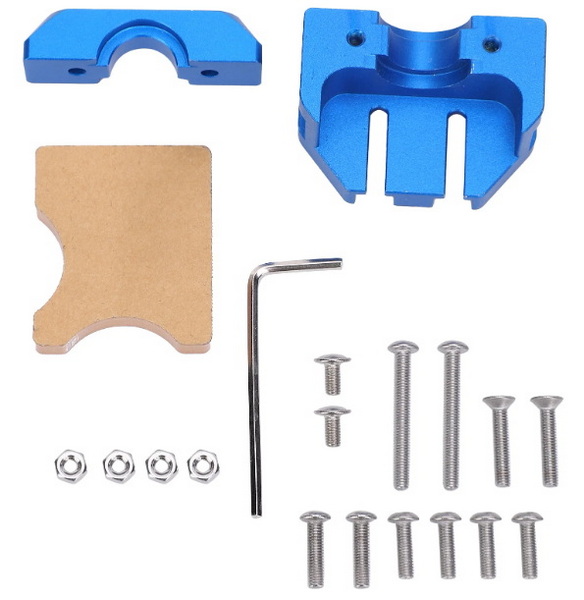

Role of the Dual Extruder Mount Bar

The dual extruder mount bar serves several key functions:

1. Structural Support: It provides a robust framework for holding the two extruders in place, ensuring precise alignment and stability during printing.

2. Thermal Management: The aluminum bar acts as a heat sink, helping to dissipate heat generated by the extruders. This is crucial for maintaining optimal operating temperatures and preventing overheating, which can lead to print failures.

Thermal Management Considerations

Effective thermal management is critical in dual extrusion setups. The aluminum cooling block helps to:

- Dissipate Heat: By efficiently removing heat from the extruders, it prevents overheating and ensures consistent print quality.

- Maintain Temperature Stability: This stability is essential for reliable extrusion and preventing issues like clogging or inconsistent filament flow.

Design Considerations for the Dual Extruder Mount Bar

When designing or selecting a dual extruder mount bar with an aluminum cooling block, several factors should be considered:

- Material Selection: Aluminum is preferred due to its high thermal conductivity and durability.

- Structural Integrity: The bar must be robust enough to support the weight and movement of the extruders without flexing or deforming.

- Cooling Efficiency: The design should maximize heat dissipation, possibly through additional cooling components like fans.

Enhancing Cooling Efficiency

To further enhance cooling efficiency, additional measures can be taken:

- Use of Thermal Compounds: Applying thermal compounds between the extruder components and the aluminum bar can improve heat transfer.

- Insulation: Insulating parts of the extruder assembly from radiative heat can help maintain optimal operating temperatures.

Installation and Setup

Installing a dual extruder mount bar involves careful alignment and secure fastening of the extruders to the bar. It is essential to ensure that all components are properly connected and that the cooling system is functioning correctly.

Common Issues and Solutions

Clogging and Heat Creep

- Clogging: Often caused by heat creep or improper retraction settings. Solutions include adjusting print settings, ensuring proper cooling, and using all-metal heat breaks.

- Heat Creep: Minimize by improving thermal insulation and ensuring efficient cooling of the extruder assembly.

Heat Soak Issues

In some cases, heat soak can be a significant problem, especially if the extruder design does not effectively manage heat transfer. Solutions include:

- Insulating Stepper Motors: Decrease heat load on the support bar by insulating stepper motors from it.

- Using Thermal Compounds: Increase conductivity between heat sinks and the support bar by using heat transfer compounds.

- Filament Guide Insulation: Insulate the filament guide assembly from radiative heat to prevent premature melting of the filament.

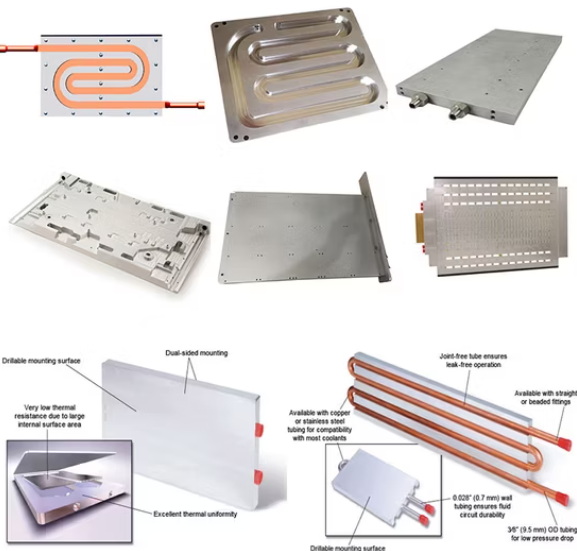

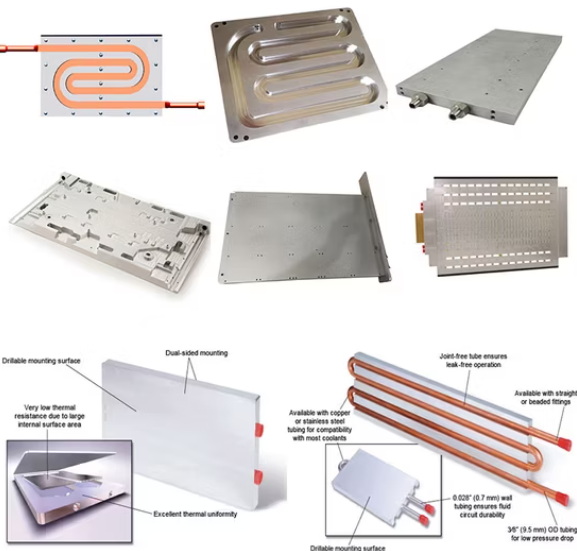

Advanced Cooling Solutions

For high-performance printing or environments requiring enhanced thermal control, advanced cooling solutions like water cooling systems can be implemented. These systems involve circulating water through channels in the heat sinks to efficiently cool the extruders, reducing issues like heat creep and clogging.

Water Cooling System for Raise3D Pro2 Printers

A notable example is the water cooling system designed for the Raise3D Pro2 printers. This system replaces air-cooled heat sinks with water-cooled ones, significantly improving thermal management and reducing print failures due to heat-related issues. The design involves machining aluminum or copper blocks to create custom heat sinks, which are then integrated into a water circulation loop.

Dual Extrusion in Various Printers

Dual extrusion capabilities are available in a variety of 3D printers, each with unique features and applications:

- Mendel, Prusa, Makerbot, and Printrboard: These printers can be equipped with dual extruders like the MK8 model, which uses a high hardness aluminum bar for structural support and heat dispersion[1][2].

- Raise3D Pro2: Known for its large build volume and enclosed chamber, this printer benefits from advanced cooling solutions to manage heat effectively[4].

- Zortrax M300 Dual: Offers dual extrusion with a large build volume, ideal for printing complex models with soluble support structures[5].

Advanced Filament Management

Printers like the Zortrax M300 Dual feature advanced filament management systems, which can detect when the filament has run out or jammed, pausing the print and notifying the user. This capability enhances reliability and reduces waste.

Enclosed Printing Chambers

Enclosed printing chambers, such as those found in the Zortrax Inventure, provide tight temperature control, minimizing warping and shrinkage during printing. This feature is particularly beneficial for materials sensitive to temperature fluctuations.

Conclusion

The dual extruder mount bar with an aluminum cooling block is a vital component in dual extrusion 3D printing setups. It provides structural support, enhances thermal management, and supports the creation of complex and aesthetically pleasing prints. By understanding its role and optimizing its design, users can improve print quality and reliability.

FAQs

1. What are the benefits of using a dual extruder setup?

Answer: Dual extrusion allows for printing with multiple colors or materials, enabling more complex and visually appealing prints. It supports various materials like PLA and ABS, enhancing the versatility of 3D printing projects.

2. How does the aluminum cooling block help in thermal management?

Answer: The aluminum cooling block acts as a heat sink, dissipating heat from the extruders and maintaining optimal operating temperatures. This prevents overheating and ensures consistent print quality.

3. What are common issues with dual extrusion setups?

Answer: Common issues include clogging due to heat creep or improper retraction settings. Solutions involve adjusting print settings, ensuring proper cooling, and using all-metal heat breaks.

4. How can cooling efficiency be enhanced in a dual extruder setup?

Answer: Cooling efficiency can be enhanced by using thermal compounds to improve heat transfer, insulating parts of the extruder assembly, and employing additional cooling components like fans or water cooling systems.

5. What materials are suitable for the dual extruder mount bar?

Answer: Aluminum is a preferred material due to its high thermal conductivity and durability, making it ideal for heat dissipation and structural support.

Citations:

[1] https://www.geeetech.com/-p-921.html

[2] https://www.geeetech.com/mk8-dual-extruder-p-921.html

[3] https://groups.google.com/g/makerbot/c/0W9938wsHwU/m/dtFNpVH8_vsJ

[4] https://www.instructables.com/Water-Cooling-System-for-Raise3D-Pro2-Printers-uno/

[5] https://www.farnell.com/datasheets/3980098.pdf

[6] https://www.aliexpress.com/i/4000639946813.html

[7] https://www.aliexpress.com/item/4000505422873.html

[8] https://3dprinting.stackexchange.com/questions/331/levelling-heads-for-dual-extruder

[9] https://robu.in/product/right-side-mk8-extruder-aluminum-3d-printer-block/

[10] https://radianheatsinks.com/custom-heatsink/

[11] https://groups.google.com/g/makerbot/c/BUPYtM7yy64

[12] https://www.dhm-online.com/en/extruder-upright/716-v6-round-aluminum-mount.html

[13] https://lulzbot.com/store/parts

[14] https://forum.seemecnc.com/viewtopic.php?p=75546

[15] https://www.walmart.ca/en/ip/Dual-Gear-Extruder-Easy-To-Install-Extruder-Aluminum-Frame-Block-Compatibility-Large-Extrusion-Force-Right-Hand-For-Ender-5/PRD3OITXIEWIFVQ

[16] https://www.researchgate.net/publication/366627654_Extrusion-Based_Technology_in_Additive_Manufacturing_A_Comprehensive_Review

[17] https://forums.reprap.org/read.php?2%2C781539%2C781539

[18] https://novo3d.in/dual-drive-extruder-gear/

[19] https://forum.makerforums.info/t/are-there-any-dis-advantages-to-extruding-the-aluminum-heatsinks-rather-than-completely-cncing-them/54135