Content Menu

● Overview of Aluminum Extrusion

>> Direct Extrusion Process

>> Indirect Extrusion Process

● The Largest Aluminum Extrusion Press in the United States

>> Facility Details

>> Key Features of Hydro's Press

● Importance of Large Extrusion Presses

>> Benefits of Large Presses

● Comparison with Other Facilities

>> Universal Alloy Corporation

>> Alexandria Industries

>> Tower Extrusions

● Innovations in Aluminum Extrusion Technology

>> Automation and Robotics

>> 3D Printing Integration

● Challenges Facing the Aluminum Extrusion Industry

● Conclusion

● FAQ

>> 1. What is an aluminum extrusion press?

>> 2. How does indirect extrusion differ from direct extrusion?

>> 3. What are some applications of aluminum extrusions?

>> 4. Why are large presses important?

>> 5. How has technology impacted aluminum extrusion?

Aluminum extrusion is a vital manufacturing process used to create a wide variety of products, from structural components to intricate designs. Understanding the scale and capabilities of aluminum extrusion presses is crucial for industries that rely on these materials. This article delves into the largest aluminum extrusion press in the United States, its features, and its significance in the industry.

Overview of Aluminum Extrusion

Aluminum extrusion involves forcing heated aluminum alloy through a die to create a specific cross-sectional shape. This process is widely used due to aluminum's lightweight, strength, and resistance to corrosion. The extrusion process can be categorized into two main types: direct and indirect extrusion.

Direct Extrusion Process

In direct extrusion, the aluminum billet is heated and then pushed through a die using a hydraulic ram. This method is commonly used for producing solid shapes and profiles. The direct extrusion process is efficient for creating simple shapes and is often utilized in applications requiring high-volume production.

Indirect Extrusion Process

Indirect extrusion, on the other hand, involves pushing the die against the billet, which allows for more complex shapes and better material properties. This method is less common but offers advantages in terms of dimensional accuracy and mechanical properties. Indirect extrusion can produce intricate designs that are not feasible with direct extrusion.

The Largest Aluminum Extrusion Press in the United States

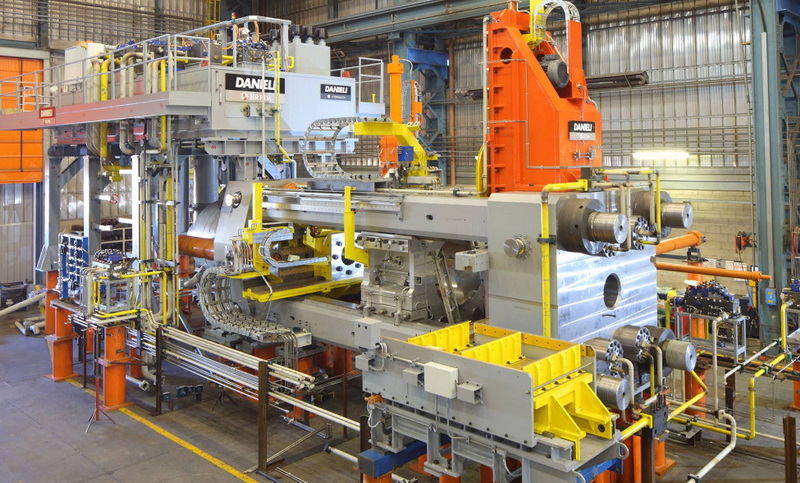

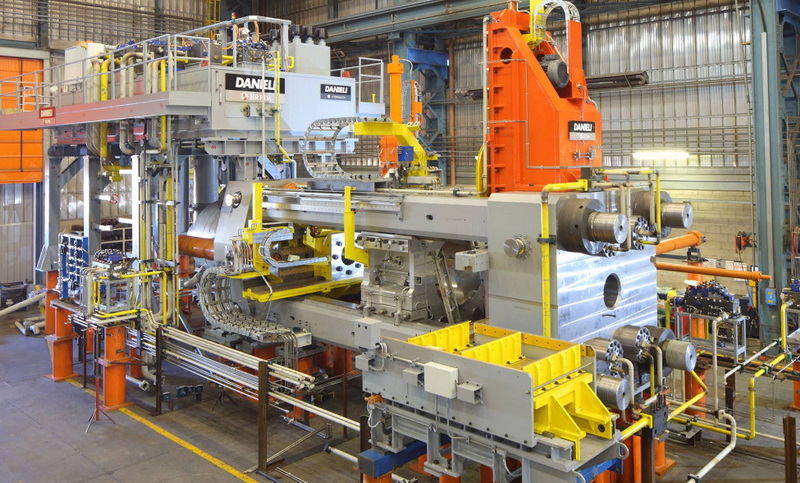

The title of the largest aluminum extrusion press in the United States is held by Hydro's facility in Cressona, Pennsylvania. This facility is not only significant for its size but also for its advanced technology and production capabilities.

Facility Details

- Location: Cressona, Pennsylvania

- Established: Originally built in 1942 by the U.S. government

- Size: Covers 15 hectares (149,000 square meters)

- Employees: Approximately 1,100

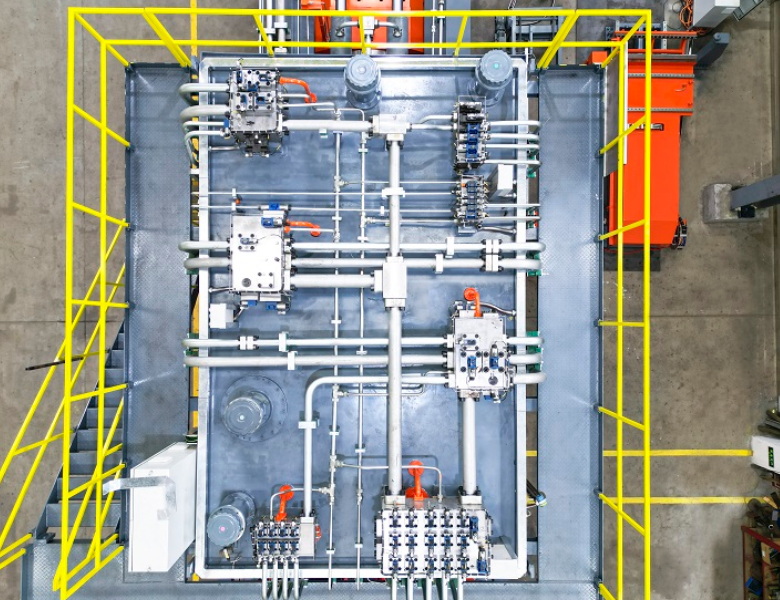

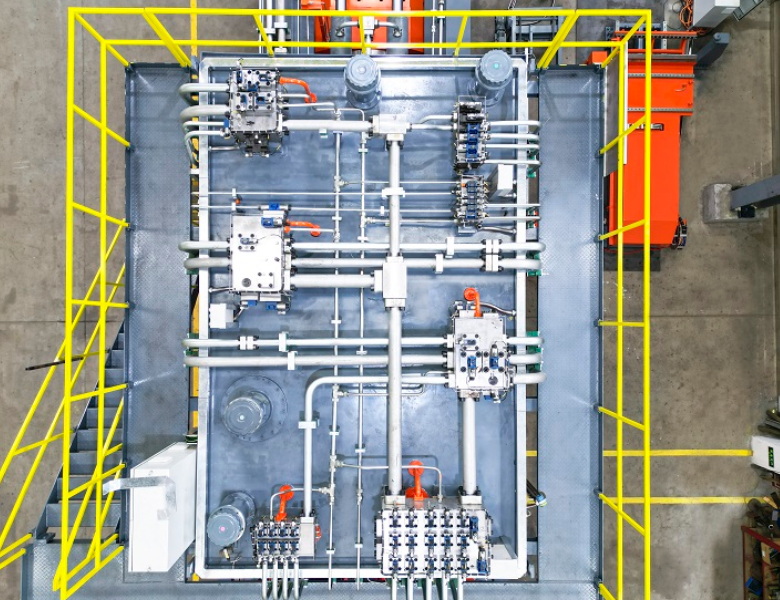

- Extrusion Presses: 11 total presses, including a notable 3,000-ton indirect extrusion press

Key Features of Hydro's Press

The 3,000-ton indirect extrusion press at Hydro's Cressona facility features state-of-the-art technology that enhances production efficiency and product quality. Some of its notable features include:

- Advanced Automation: The press is equipped with sophisticated automation systems that improve monitoring and control during the extrusion process. These systems allow for real-time adjustments to optimize performance.

- Versatile Applications: It serves various markets including transportation, distribution, and industrial sectors. Products manufactured here include everything from structural components for buildings to specialized parts for aerospace applications.

- Recycling Capacity: The facility has increased its recycling capabilities, aligning with sustainability goals in manufacturing. Hydro emphasizes closed-loop recycling processes that significantly reduce waste and energy consumption.

Importance of Large Extrusion Presses

Large aluminum extrusion presses like Hydro's play a critical role in meeting the growing demand for aluminum products across various industries. The ability to produce large quantities of extrusions with consistent quality is essential for applications in construction, automotive, aerospace, and more.

Benefits of Large Presses

1. Increased Production Capacity: Larger presses can handle bigger billets and produce longer extrusions in a single cycle. This capability allows manufacturers to fulfill large orders more efficiently.

2. Enhanced Material Properties: Indirect extrusion processes often result in better mechanical properties due to reduced internal stresses. This leads to stronger and more durable products.

3. Cost Efficiency: High-capacity presses reduce production time and costs per unit. By maximizing output while minimizing waste, manufacturers can achieve higher profit margins.

4. Flexibility in Design: Large presses are capable of producing complex shapes that meet specific engineering requirements. This flexibility allows designers to innovate without being constrained by manufacturing limitations.

5. Sustainability Practices: As environmental concerns grow, large presses enable manufacturers to implement sustainable practices more effectively. For example, they can utilize recycled materials without compromising quality.

Comparison with Other Facilities

While Hydro's Cressona facility stands out as the largest, several other notable facilities across the U.S. also contribute significantly to aluminum extrusion:

| Facility Name | Location | Press Capacity (tons) | Type of Extrusion |

| Universal Alloy Corporation | Canton, Georgia | 16,200 | Indirect |

| Alexandria Industries | Alexandria, Minnesota | Varies | Direct |

| Tower Extrusions | Olney, Texas | Varies | Direct |

These facilities collectively enhance the U.S.'s capacity to produce high-quality aluminum extrusions.

Universal Alloy Corporation

Located in Canton, Georgia, Universal Alloy Corporation operates one of the largest indirect extrusion presses globally with a capacity of 16,200 tons. This facility specializes in producing complex aerospace components that require precision engineering and high-quality standards.

Alexandria Industries

Alexandria Industries in Minnesota focuses on direct extrusion processes but has made significant investments in technology to improve efficiency and product quality. They serve various markets including medical devices and consumer products.

Tower Extrusions

Tower Extrusions based in Olney, Texas primarily utilizes direct extrusion methods but has developed a reputation for producing high-quality custom extrusions tailored to client specifications.

Innovations in Aluminum Extrusion Technology

The aluminum extrusion industry continues to evolve with advancements in technology that improve efficiency and product quality. Key innovations include:

- Smart Manufacturing: Integration of IoT devices allows for real-time monitoring of production processes. This technology enables manufacturers to predict maintenance needs before equipment failures occur.

- Advanced Materials: Development of new aluminum alloys that offer improved performance characteristics has expanded the range of applications for extruded products. These new alloys can provide enhanced strength-to-weight ratios or increased resistance to corrosion.

- Sustainability Practices: Increased focus on recycling processes and energy-efficient operations helps reduce environmental impact while maintaining high production standards. Many companies are adopting life cycle assessments to evaluate their sustainability efforts comprehensively.

Automation and Robotics

The use of robotics in aluminum extrusion facilities has streamlined operations significantly. Automated systems can handle tasks such as material handling, quality inspection, and even packaging without human intervention. This not only increases efficiency but also minimizes human error.

3D Printing Integration

Some companies are exploring how 3D printing technology can complement traditional aluminum extrusion methods. By using 3D printing for prototyping or creating complex dies, manufacturers can reduce lead times and costs associated with product development.

Challenges Facing the Aluminum Extrusion Industry

Despite its advancements, the aluminum extrusion industry faces several challenges:

1. Supply Chain Disruptions: Global supply chain issues have affected raw material availability and pricing stability.

2. Labor Shortages: Finding skilled labor remains a challenge as many experienced workers retire without enough new talent entering the field.

3. Environmental Regulations: Increasingly stringent environmental regulations require manufacturers to invest in cleaner technologies while maintaining profitability.

4. Competition from Alternative Materials: As industries seek lighter yet strong materials, competition from composites and advanced plastics continues to grow.

Conclusion

The largest aluminum extrusion press in the United States is located at Hydro's facility in Cressona, Pennsylvania. This facility exemplifies advancements in aluminum extrusion technology and highlights the importance of large-scale production capabilities in meeting industry demands. As technology continues to evolve alongside increasing sustainability efforts within manufacturing practices, we can expect further innovations that will enhance both efficiency and sustainability within the industry.

FAQ

1. What is an aluminum extrusion press?

An aluminum extrusion press is a machine used to shape aluminum alloy by forcing it through a die under high pressure.

2. How does indirect extrusion differ from direct extrusion?

Indirect extrusion pushes the die against the billet while direct extrusion pushes the billet through the die directly; this can lead to different material properties.

3. What are some applications of aluminum extrusions?

Aluminum extrusions are used in various applications including construction materials, automotive parts, aerospace components, and consumer products.

4. Why are large presses important?

Large presses increase production capacity and efficiency while allowing manufacturers to produce longer extrusions with better mechanical properties.

5. How has technology impacted aluminum extrusion?

Innovations such as smart manufacturing and advanced materials have improved efficiency, product quality, and sustainability practices within the industry.