Content Menu

● Introduction to Ender 5 Plus and Extruder Upgrades

>> Why Upgrade to an Aluminum Extruder?

● Best Aluminum Extruder Options for Ender 5 Plus

>> 1. Creality Metal Extruder Upgrade Kit

>>> Pros:

>>> Cons:

>> 2. Micro Swiss Direct Drive Extruder

>>> Pros:

>>> Cons:

>> 3. BMG (Bondtech Mini Geared) Extruder

>>> Pros:

>>> Cons:

>> 4. All-Metal Extruder with Capricorn PTFE Tube

>>> Pros:

>>> Cons:

>> 5. Titan Aero Extruder

>>> Pros:

>>> Cons:

● Factors to Consider When Choosing an Aluminum Extruder

>> Filament Compatibility

>> Ease of Installation

>> Durability and Reliability

>> Cost

>> Direct Drive vs. Bowden

● Installation Guide for Aluminum Extruders

>> 1. Preparation:

>> 2. Remove the Stock Extruder:

>> 3. Mount the New Extruder:

>> 4. Connect the Wires:

>> 5. Adjust the Filament Path:

>> 6. Calibrate the Extruder:

>> 7. Test the Extruder:

● Tips for Choosing the Right Aluminum Extruder

● Maintenance of Aluminum Extruders

>> Regular Cleaning

>> Check and Tighten Screws

>> Lubricate Moving Parts

>> Inspect the Filament Path

>> Monitor Extrusion Performance

● Benefits of Upgrading Other Components

>> Hot End Upgrade

>> Bed Leveling System

>> Control Board Upgrade

>> Firmware Upgrade

● Conclusion

● FAQ

>> 1. What are the benefits of using an aluminum extruder over a plastic one?

>> 2. How do I install an aluminum extruder on my Ender 5 Plus?

>> 3. What types of filaments can an aluminum extruder handle?

>> 4. Are there any specific tools required for installing an aluminum extruder?

>> 5. Can I use a direct drive extruder with my Ender 5 Plus?

● Citations:

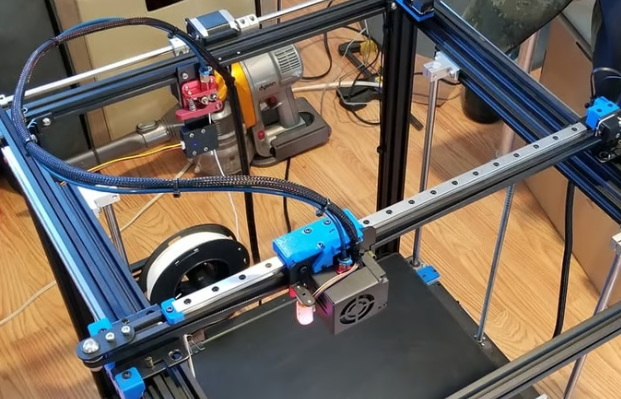

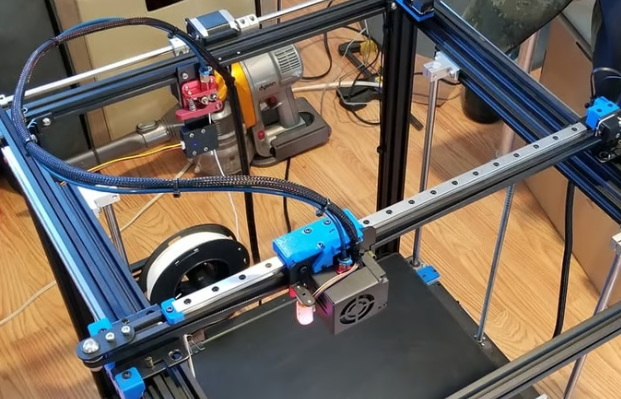

The Ender 5 Plus is a highly popular 3D printer known for its large build volume and versatility. However, like many printers in its class, it often comes with a plastic extruder that may not be ideal for demanding projects. Upgrading to an aluminum extrudercan significantly enhance performance, reliability, and print quality. In this article, we will explore the best options for an Ender 5 Plus aluminum extruder and guide you through the selection and installation process.

Introduction to Ender 5 Plus and Extruder Upgrades

The Ender 5 Plus is renowned for its ease of assembly and large build volume, making it perfect for both beginners and experienced users[1]. However, its stock plastic extruder can be prone to issues such as cracking and inconsistent filament feeding[4]. Upgrading to an aluminum extruder addresses these problems by providing better durability and improved filament handling[5].

Why Upgrade to an Aluminum Extruder?

Upgrading to an aluminum extruder offers several benefits:

- Durability: Aluminum extruders are more resistant to wear and tear compared to plastic ones[3][5].

- Consistent Filament Feeding: They provide better grip and control over the filament, reducing issues like under-extrusion or filament slipping[3][5].

- Enhanced Print Quality: By ensuring consistent and precise filament delivery, aluminum extruders can improve the overall quality of prints[3].

Best Aluminum Extruder Options for Ender 5 Plus

When it comes to upgrading your Ender 5 Plus, there are several aluminum extruder options available, each with its own set of features and benefits. Here, we delve into some of the top contenders:

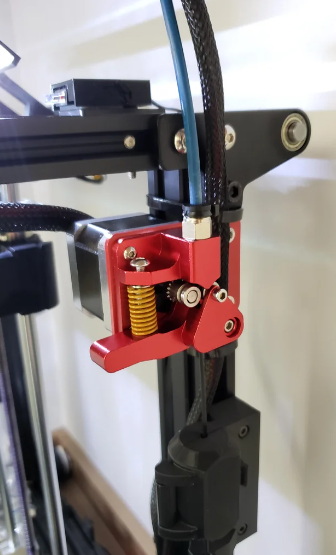

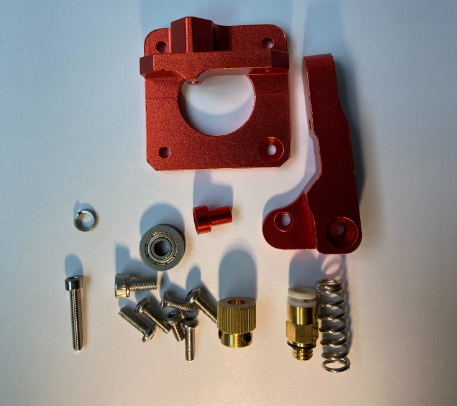

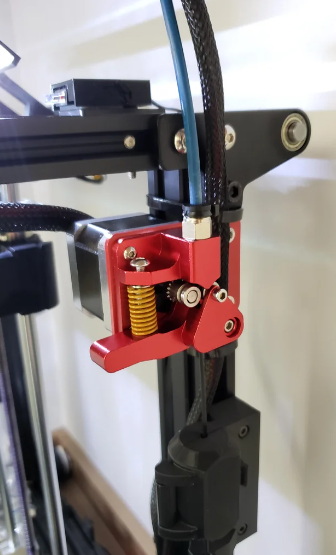

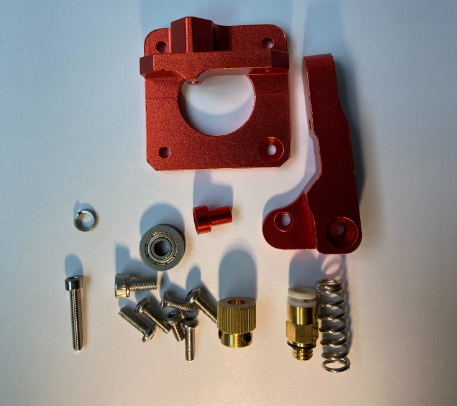

1. Creality Metal Extruder Upgrade Kit

The Creality Metal Extruder Upgrade Kit is a popular choice for upgrading the Ender 5 Plus. It is designed to improve performance and is relatively easy to install[1]. This kit typically includes all the necessary hardware for a straightforward replacement of the stock plastic extruder.

Pros:

- Affordable: Generally one of the more budget-friendly options on the market.

- Easy Installation: Designed for a direct replacement, minimizing the need for complex modifications.

- Improved Durability: Offers better resistance to wear compared to the stock plastic extruder.

Cons:

- Brass Gear Concerns: Some users have reported issues with the brass gear's teeth being shallow, which can lead to slipping.

- Material Limitations: May not be the best choice for highly flexible filaments without additional modifications.

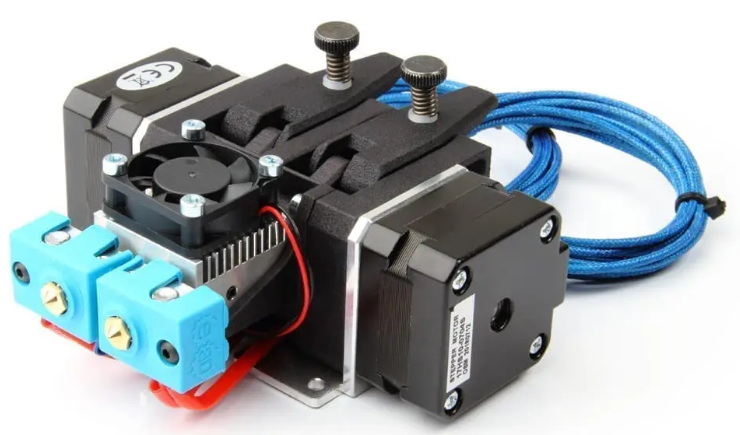

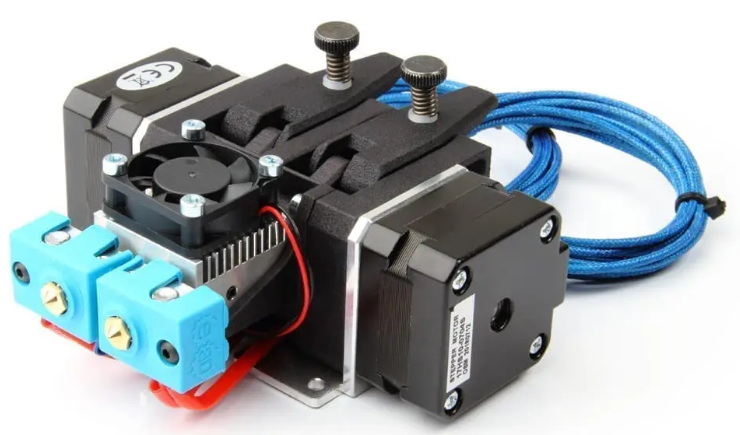

2. Micro Swiss Direct Drive Extruder

The Micro Swiss Direct Drive Extruder is another excellent option, offering a plug-and-play installation with no modifications required. It features a dual-drive train and hardened tool steel gears, making it ideal for printing flexible filaments with high accuracy.

Pros:

- Direct Drive System: Provides better control over filament, especially flexible materials like TPU.

- High Precision: Hardened tool steel gears ensure reliable and accurate filament feeding.

- Easy Installation: Designed for a straightforward installation process.

Cons:

- Higher Cost: Generally more expensive than other upgrade options.

- Increased Weight: The direct drive system can add weight to the print head, which may require adjustments to printer settings.

3. BMG (Bondtech Mini Geared) Extruder

The BMG Extruder is renowned for its exceptional grip and precision. It uses dual-drive gears to ensure the filament is securely held and consistently fed into the hot end. This makes it an excellent choice for a wide range of filaments, including flexible and abrasive materials.

Pros:

- Superior Grip: Dual-drive gears provide unparalleled grip on the filament.

- Versatile: Compatible with a wide range of filaments, including PLA, ABS, PETG, TPU, and nylon[3][5].

- Lightweight Design: Despite its robust performance, the BMG extruder is relatively lightweight.

Cons:

- Cost: One of the more expensive options available.

- Installation: May require some modifications or additional adapters for certain setups.

4. All-Metal Extruder with Capricorn PTFE Tube

Upgrading to an all-metal extruder paired with a Capricorn PTFE tube can significantly enhance print quality and durability. This setup is particularly beneficial for handling high-temperature filaments and reducing wear on the extruder components[2].

Pros:

- High-Temperature Printing: All-metal design allows for printing with filaments that require higher temperatures, such as nylon and polycarbonate.

- Enhanced Durability: All-metal construction ensures longevity and resistance to wear.

- Improved Filament Path: Capricorn PTFE tube provides a smooth and precise filament path, reducing friction and improving extrusion accuracy.

Cons:

- Heat Creep: Requires careful setup to prevent heat creep, which can lead to clogging.

- Cost: Can be more expensive than basic metal extruder upgrades.

5. Titan Aero Extruder

The Titan Aero Extruder is a compact and lightweight direct drive extruder known for its high performance and reliability. It features a short filament path, which improves responsiveness and reduces the risk of filament buckling.

Pros:

- Compact Design: Lightweight and compact, minimizing the impact on print head weight.

- Short Filament Path: Improves responsiveness and reduces the risk of filament issues.

- High Precision: Designed for accurate and consistent filament feeding.

Cons:

- Cost: More expensive than some other options.

- Complexity: May require more advanced knowledge for installation and configuration.

Factors to Consider When Choosing an Aluminum Extruder

Selecting the right aluminum extruder for your Ender 5 Plus involves considering several key factors to ensure it meets your specific printing needs and preferences.

Filament Compatibility

One of the most important considerations is the types of filaments you plan to use. Different extruders are better suited for certain materials. For example, direct drive extruders like the Micro Swiss and Titan Aero are excellent for flexible filaments like TPU, while all-metal extruders are necessary for high-temperature materials like nylon and polycarbonate[3][5]. The Creality aluminum extruders are compatible with a wide range of filaments, including PLA, ABS, PETG, TPU, and nylon[3].

Ease of Installation

The complexity of the installation process can vary significantly between different extruders. Some kits, like the Creality Metal Extruder Upgrade Kit, are designed for a straightforward replacement of the stock extruder, while others may require more advanced modifications[1]. If you are new to 3D printer upgrades, opt for an extruder with a simple and well-documented installation process.

Durability and Reliability

Aluminum extruders are generally more durable than their plastic counterparts, but the quality of the aluminum and the design of the extruder can still impact its longevity[3][5]. Look for extruders made from high-quality materials and with a reputation for reliability.

Cost

The cost of aluminum extruders can range from relatively inexpensive to quite expensive[3][5]. Determine your budget and weigh the cost against the features and benefits offered by each option. Keep in mind that while a cheaper extruder may save you money upfront, it may not offer the same level of performance or durability as a more expensive one.

Direct Drive vs. Bowden

Another important consideration is whether to choose a direct drive or Bowden extruder setup. In a direct drive system, the extruder motor is mounted directly on the print head, which provides better control over filament feeding, especially for flexible materials. Bowden systems, on the other hand, mount the extruder motor on the printer frame and use a PTFE tube to guide the filament to the hot end. Bowden setups reduce the weight on the print head, allowing for faster printing speeds, but may not be as effective with flexible filaments[3].

Installation Guide for Aluminum Extruders

Installing an aluminum extruder on the Ender 5 Plus involves several steps. While the exact process may vary depending on the specific extruder you choose, the general steps are outlined below:

1. Preparation:

- Turn off and unplug your Ender 5 Plus.

- Gather all the necessary tools, including Allen wrenches, screwdrivers, and pliers.

- Refer to the installation manual provided with your new extruder.

2. Remove the Stock Extruder:

- Disconnect the filament from the printer.

- Remove the screws holding the stock extruder in place.

- Gently detach the stock extruder from the printer frame.

- Disconnect the extruder motor wires from the control board.

3. Mount the New Extruder:

- Attach the new aluminum extruder to the printer frame using the provided screws.

- Ensure it is securely fastened and properly aligned.

- If necessary, install any additional brackets or adapters.

4. Connect the Wires:

- Connect the extruder motor wires to the printer's control board.

- Ensure the wires are securely attached and properly oriented.

- Use zip ties or cable sleeves to manage the wires and prevent them from interfering with the printer's movement.

5. Adjust the Filament Path:

- Ensure the filament path is clear and properly aligned with the extruder's intake.

- Install the Capricorn PTFE tube if included with the upgrade.

- Adjust the tension on the extruder arm to ensure proper filament grip.

6. Calibrate the Extruder:

- After installing the new extruder, it's essential to calibrate it to ensure accurate filament extrusion.

- Perform an E-steps calibration by measuring the amount of filament extruded and adjusting the E-steps value in the printer's firmware accordingly.

7. Test the Extruder:

- Perform a test print to ensure the extruder is working correctly and adjust settings as needed.

- Monitor the print for any signs of under-extrusion, over-extrusion, or slipping.

- Make any necessary adjustments to the printer's settings to optimize print quality.

Tips for Choosing the Right Aluminum Extruder

When selecting an aluminum extruder for your Ender 5 Plus, consider the following factors:

- Compatibility: Ensure the extruder is compatible with your printer model[1].

- Material Handling: Choose an extruder that can handle the types of filaments you plan to use[3][5].

- Ease of Installation: Opt for an extruder with a straightforward installation process[1].

- Customer Support: Look for products with good customer reviews and support resources[1].

Maintenance of Aluminum Extruders

Proper maintenance is crucial to ensure the longevity and optimal performance of your aluminum extruder. Here are some essential maintenance tips:

Regular Cleaning

Dust, debris, and filament residue can accumulate in the extruder over time, leading to clogs and reduced performance. Regularly clean the extruder with a soft brush or compressed air to remove any buildup.

Check and Tighten Screws

Vibrations during printing can cause screws to loosen over time. Periodically check all the screws on the extruder and tighten them as needed to ensure the assembly remains secure.

Lubricate Moving Parts

Lubricate the gears and bearings in the extruder with a small amount of high-quality grease to reduce friction and ensure smooth operation.

Inspect the Filament Path

Regularly inspect the filament path for any signs of wear or damage. Replace the Capricorn PTFE tube if it becomes worn or damaged to maintain optimal filament feeding.

Monitor Extrusion Performance

Keep an eye on the extruder's performance during printing. If you notice any signs of inconsistent extrusion, slipping, or other issues, address them promptly to prevent further damage.

Benefits of Upgrading Other Components

While upgrading the extruder is a significant improvement, consider upgrading other components to further enhance your Ender 5 Plus:

Hot End Upgrade

Upgrading to an all-metal hot end allows for printing at higher temperatures and with more exotic materials.

Bed Leveling System

An auto bed leveling system like BLTouch can improve first layer adhesion and overall print quality.

Control Board Upgrade

Upgrading to a more advanced control board can provide features like silent stepper drivers and improved processing power.

Firmware Upgrade

Updating to the latest firmware can unlock new features and improve the printer's overall performance.

Conclusion

Upgrading to an Ender 5 Plus aluminum extruder can significantly enhance your 3D printing experience by improving print quality, durability, and reliability[3][5]. Whether you choose the Creality Metal Extruder Upgrade Kit, the Micro Swiss Direct Drive Extruder, the BMG Extruder, an all-metal extruder with a Capricorn PTFE tube, or another option, ensure it aligns with your printing needs and preferences. By considering factors such as filament compatibility, ease of installation, durability, and cost, you can select the best aluminum extruder to unlock the full potential of your Ender 5 Plus[1]. Remember to follow proper installation procedures and maintenance practices to ensure long-lasting performance and optimal print quality[2]. With the right aluminum extruder, you'll be well-equipped to tackle a wide range of 3D printing projects with confidence[4].

FAQ

1. What are the benefits of using an aluminum extruder over a plastic one?

Aluminum extruders offer better durability, consistent filament feeding, and improved print quality compared to plastic extruders[3][5].

2. How do I install an aluminum extruder on my Ender 5 Plus?

Installation involves removing the stock extruder, mounting the new aluminum extruder, connecting the wires, adjusting the filament path, calibrating the extruder, and testing the extruder[2].

3. What types of filaments can an aluminum extruder handle?

Aluminum extruders can handle a wide range of filaments, including PLA, ABS, PETG, TPU, and nylon[3][5].

4. Are there any specific tools required for installing an aluminum extruder?

Typically, you will need Allen wrenches, screwdrivers, and possibly pliers for handling wires[2].

5. Can I use a direct drive extruder with my Ender 5 Plus?

Yes, direct drive extruders like the Micro Swiss model are compatible with the Ender 5 Plus and offer excellent performance for flexible filaments[2].

Citations:

[1] https://www.aliexpress.com/w/wholesale-ender-5-plus-extruder.html

[2] https://www.youtube.com/watch?v=BrYDH4RWojY

[3] https://www.yjing-extrusion.com/why-should-you-choose-an-aluminum-extruder-for-3d-printing.html

[4] https://3dprintbeginner.com/ender-5-plus-review/

[5] https://www.yjing-extrusion.com/is-it-worth-buying-an-aluminum-extruder-for-my-3d-printer.html

[6] https://www.reddit.com/r/ender5/comments/ut5egw/ender_5_aluminum_extrusion_sizes/

[7] https://automatedhome.party/2019/10/04/my-experience-with-my-first-3d-printer-a-creality-ender-5-with-mini-getting-started-guide/

[8] https://store.micro-swiss.com/products/micro-swiss-direct-drive-extruder-for-creality-ender-5

[9] https://manuals.plus/creality/ender-5-plus-3d-printer-manual

[10] https://www.reddit.com/r/ender3/comments/eqeddp/the_all_aluminum_extruder_upgrade_is_only_ten/

[11] https://www.youtube.com/watch?v=RnByRMVErjU

[12] https://www.reddit.com/r/ender5plus/comments/z30dlz/what_upgrades_would_you_say_are_a_must_have_for/

[13] https://www.youtube.com/watch?v=NmEMwzNrd74

[14] https://3dpros.com/printers/ender-5-plus

[15] https://www.youtube.com/watch?v=hbq5H7R1NLg

[16] https://www.reddit.com/r/ender5plus/comments/wbbgm4/ender_5_plus_drastically_underextruding/

[17] https://www.creality.store/products/all-metal-extruder-aluminum-mk8-extruder-with-capricorn-tubing

[18] https://www.creality.com/blog/the-difference-among-ender-5-ender-5-plus-and-ender-5-pro

[19] https://www.reddit.com/r/ender5plus/comments/152r9wz/is_anybody_really_happy_with_their_ender_5_plus/

[20] https://makersteve.com/2019/07/22/ultimate-build-guide-to-ender-5-step-by-step-a-makersteve-special-report/