Content Menu

● Introduction to Aluminum Extrusion

>> Indonesian Aluminum Extruders

● The Aluminum Extrusion Process

>> Detailed Steps of the Aluminum Extrusion Process

>>> Step 1: Prepare Extrusion Die

>>> Step 2: Pre-Heat Aluminum Billet

>>> Step 3: Move the Billet to the Extrusion Press

>>> Step 4: Press-up Extruded Material Against the Die

>>> Step 5: Quench the Extrusion

>>> Step 6: Shear the Extrusion to Length

>>> Step 7: Cool Extrusion to Room Temperature

>>> Step 8: Transfer Extrusions to Stretcher for Alignment

>>> Step 9: Cut Extrusions to Desired Lengths

>>> Step 10: Perform Secondary Operations (Heat Treatment, Fabrication & Surface Finishing)

● Applications of Aluminum Extrusions in Indonesia

>> Detailed Applications Across Industries

>>> Construction Sector

>>> Automotive Industry

>>> Electronics Sector

● Challenges and Opportunities for Indonesian Aluminum Extruders

>> Challenges Faced by Manufacturers

>> Opportunities in Emerging Markets

>> Diversification of Products

● Recent Innovations in Aluminum Extrusion Technology

● Conclusion

● FAQs

>> 1. What is the role of Indonesian aluminum extruders in the global market?

>> 2. How does the aluminum extrusion process enhance product quality?

>> 3. What are common applications of aluminum extrusions in Indonesia?

>> 4. What challenges do Indonesian manufacturers face?

>> 5. How can manufacturers expand their market reach?

● Citations:

Indonesia has emerged as a significant player in the aluminum extrusion industry, with companies like PT ALCOMEX INDO and PT Alexindo leading the way. The aluminum extrusion process involves transforming raw aluminum into various shapes and profiles, which are used in diverse sectors such as construction, automotive, and electronics. This article will delve into the intricacies of the aluminum extrusion process in Indonesia, highlighting key steps, technologies, and applications.

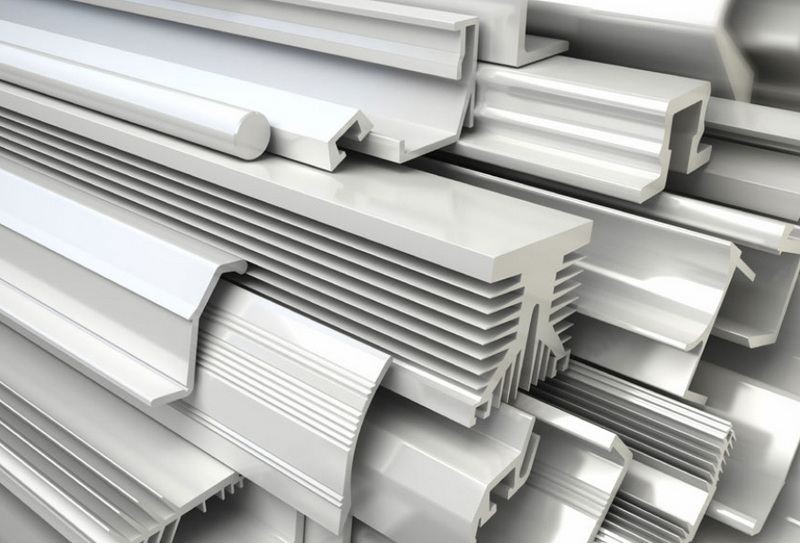

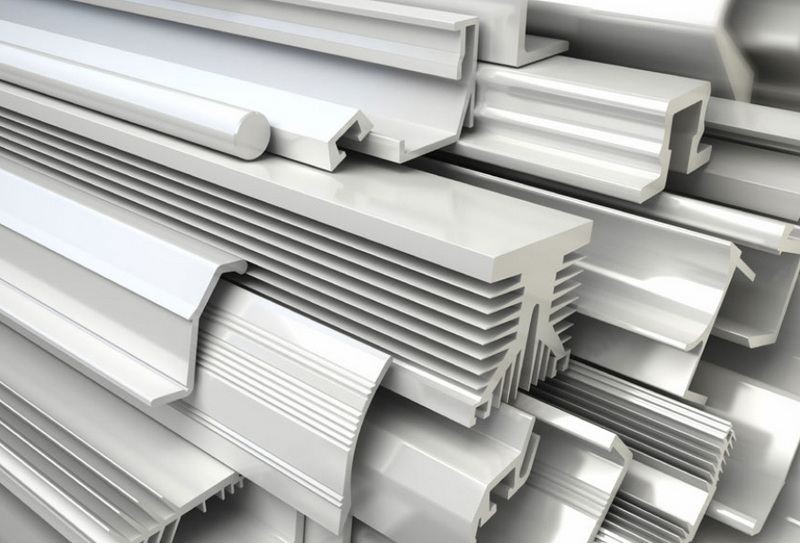

Introduction to Aluminum Extrusion

Aluminum extrusion is a manufacturing process where aluminum is heated and forced through a die to create a desired shape. This process is widely used due to aluminum's lightweight, corrosion-resistant, and versatile properties. Indonesian aluminum extruders have capitalized on these advantages, offering high-quality products both domestically and internationally.

Indonesian Aluminum Extruders

Companies like PT ALCOMEX INDO and PT Alexindo are prominent in the Indonesian aluminum extrusion market. PT ALCOMEX INDO, located in Cibitung, West Java, operates with a production capacity of 18,000 tons per year, utilizing advanced machinery including UBE Press Machines from Japan. PT Alexindo, another major player, boasts a production capacity of 27,000 tons annually and is known for its quality products used in prestigious high-rise buildings across Asia and beyond.

The Aluminum Extrusion Process

The extrusion process involves several key steps:

1. Die Preparation: The extrusion die is preheated to between 450-500°C to ensure uniform metal flow and extend its lifespan.

2. Billet Preheating: An aluminum billet is heated to 400-500°C to make it malleable but not molten.

3. Extrusion: The billet is loaded into the extrusion press, where it is pushed through the die under high pressure.

4. Quenching and Shearing: The extruded profile is cooled and then sheared to the desired length.

5. Stretching and Heat Treatment: The extrusion is stretched to correct any twists and then undergoes heat treatment to enhance its strength.

Detailed Steps of the Aluminum Extrusion Process

Step 1: Prepare Extrusion Die

The first step is to make a round-shaped die or use an existing one if available. Preheat the die to precisely 450-500°C before initiating the extrusion process. This helps ensure that the metal passes through evenly and maximizes the die's longevity.

Step 2: Pre-Heat Aluminum Billet

Next, a cylindrical billet cut from a stretched log of material is preheated in an oven to 400-500°C. This technique prepares the billet, making it malleable for operation without becoming molten.

Step 3: Move the Billet to the Extrusion Press

Transfer the billet mechanically into the press after preheating it. Lubrication is applied before filling the billet into the press, along with a release agent on the extrusion ram to prevent adhesion.

Step 4: Press-up Extruded Material Against the Die

The malleable billet fills the container's walls as it gets pressed against the extrusion die under high pressure. This pressure must be applied continuously until the extruded material emerges through the die opening fully formed.

Step 5: Quench the Extrusion

A puller grasps the extrusion after it exits the press. This puller safeguards it while undergoing a “quenching” process as it moves along a cooling table. The profile cools evenly through either a full water bath or fan cooling.

Step 6: Shear the Extrusion to Length

Once cooled to table length, use a hot saw to shear it. Temperature control remains crucial throughout each step of this process.

Step 7: Cool Extrusion to Room Temperature

After shearing, extrusions are moved from the runout table to a cooling area until they reach room temperature.

Step 8: Transfer Extrusions to Stretcher for Alignment

At this stage, any twists in shape need correcting using a stretcher. Each profile is held at different ends while being pulled until straightened according to specifications.

Step 9: Cut Extrusions to Desired Lengths

Once straightened and work-hardened, extrusions are cut into lengths typically ranging from 8-21 feet before being transferred for aging treatment (T6 or T5 temper).

Step 10: Perform Secondary Operations (Heat Treatment, Fabrication & Surface Finishing)

Upon completion of extrusion, profiles can undergo heat treatment for enhanced properties. Additional fabrication processes may correct dimensions or surface finishes improve aesthetics and corrosion resistance.

Applications of Aluminum Extrusions in Indonesia

Aluminum extrusions are widely used across various sectors:

- Construction: Used in building frames, windows, doors due to their strength and corrosion resistance.

- Automotive: Employed in vehicle parts for lightweighting and improving fuel efficiency.

- Electronics: Used in heat sinks and other components due to aluminum's excellent thermal conductivity.

- Consumer Goods: Found in everyday items such as furniture frames, kitchen utensils, and sporting equipment.

- Industrial Machinery: Essential for conveyor systems and assembly line structures due to their lightweight yet sturdy qualities.

- Renewable Energy Infrastructure: Crucial for solar panel frames and wind turbine structures that require lightweight yet robust materials.

Detailed Applications Across Industries

Construction Sector

In modern architecture, extruded aluminum profiles are essential due to their lightness and durability. They are commonly used for:

- Window Frames

- Curtain Walls

- Door Frames

- Roofing Systems

These applications highlight how aluminum contributes not only structural integrity but also aesthetic appeal in architectural designs.

Automotive Industry

The automotive sector relies heavily on aluminum extrusions for components such as:

- Vehicle Frames

- Engine Blocks

- Bumpers

- Structural Reinforcements

Aluminum's properties enhance fuel efficiency while also providing necessary strength without adding excessive weight.

Electronics Sector

Aluminum's thermal conductivity makes it ideal for managing heat generated by electronic devices. Common applications include:

- Heat sinks for CPUs/GPUs

- Enclosures for electronic devices

- Racks for server equipment

- Housings for power supplies

These applications demonstrate how aluminum supports innovation within electronics by enabling efficient designs that fit compact spaces.

Challenges and Opportunities for Indonesian Aluminum Extruders

Despite growth in demand, Indonesian aluminum extruders face challenges such as competition from global markets and fluctuating raw material prices. However, opportunities abound in expanding into new markets and diversifying product offerings.

Challenges Faced by Manufacturers

One primary challenge faced by manufacturers is rising raw material costs due to global economic fluctuations that affect production costs significantly. Additionally:

- Maintaining consistent product quality amidst fierce competition.

- Adapting production methods for energy efficiency aligns with sustainability goals.

These challenges necessitate innovative solutions within manufacturing processes while also exploring alternative materials or sourcing strategies.

Opportunities in Emerging Markets

Indonesian companies can leverage their strategic location to tap into emerging markets throughout Southeast Asia. For instance:

- PT Alexindo has successfully expanded its reach into regions like Central Europe and the Middle East.

Diversification of Products

Investing in research allows manufacturers like PT ALCOMEX INDO to create specialized profiles catering specifically towards niche industries such as aerospace or renewable energy sectors where both strength and malleability are critical requirements.

Recent Innovations in Aluminum Extrusion Technology

The landscape of aluminum extrusion continues evolving with advancements that enhance production efficiency while addressing sustainability concerns:

1. Nano-Coating Technologies improve durability against corrosion.

2. AI Integration allows real-time adjustments during production processes ensuring quality control.

3. Hybrid Techniques combine traditional methods with advanced processes optimizing material properties.

4. Smart Production Lines equipped with IoT technology enhance monitoring capabilities leading to increased efficiency.

5. Customization through 3D Printing enables intricate designs tailored specifically towards client requirements fostering creativity within engineering fields.

These innovations not only redefine industry standards but also inspire future developments where aluminum remains versatile yet eco-friendly across diverse applications globally.

Conclusion

The aluminum extrusion process in Indonesia represents a sophisticated manufacturing technique that transforms raw aluminum into versatile profiles utilized across various industries. With companies like PT ALCOMEX INDO and PT Alexindo leading this charge towards innovation coupled with sustainable practices; Indonesia stands poised for continued growth within this global market segment while contributing significantly towards advancements seen throughout numerous sectors reliant upon these essential materials.

FAQs

1. What is the role of Indonesian aluminum extruders in the global market?

Indonesian aluminum extruders play a significant role by providing high-quality aluminum profiles across diverse sectors worldwide leveraging their strategic location alongside advanced manufacturing capabilities.

2. How does the aluminum extrusion process enhance product quality?

The extrusion process enhances product quality through precise control over shape/properties allowing techniques like heat treatment/surface finishing further improving durability/aesthetic appeal of final products produced via this method.

3. What are common applications of aluminum extrusions in Indonesia?

Common applications include construction (window frames), automotive (vehicle parts), electronics (heat sinks), consumer goods (furniture), industrial machinery (conveyor systems), renewable energy (solar panel frames).

4. What challenges do Indonesian manufacturers face?

Challenges include rising raw material costs due to global economic conditions along with maintaining consistent product quality amidst fierce competition while adapting production methods towards energy efficiency/sustainability goals.

5. How can manufacturers expand their market reach?

Manufacturers can expand market reach through diversification efforts investing R&D creating specialized profiles catering towards niche industries while leveraging strategic locations tapping emerging markets throughout Southeast Asia/global regions alike.

Citations:

[1] https://waykenrm.com/blogs/aluminum-extrusion/

[2] https://proleantech.com/aluminum-extrusion-applications-across-industries/

[3] https://jmaluminium.com/the-evolution-of-aluminium-extrusion-industry-challenges-and-future-outlook/

[4] https://yamunaind.com/innovation-spotlight-recent-advancements-in-aluminium-extrusion-technology/

[5] https://taberextrusions.com/not-just-a-new-years-resolution-aluminum-extrusion-sustainability/

[6] https://aec.org/aluminum-extrusion-process

[7] https://mpg.co.id/aluminium-extrusion-products-around-us/

[8] https://www.atieuno.com/2023/10/09/aluminium-extrusion-manufacturers/

[9] https://www.alcircle.com/news/tech-trends-driving-the-aluminium-extrusion-industry-111131

[10] https://aluminumextrusions.net/sustainability-practices/

[11] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[12] https://www.linkedin.com/pulse/7-common-applications-industrial-aluminum

[13] https://www.harboraluminum.com/en/news/automotive-aluminum-extrusions-challenges-and-opportunities

[14] https://profileprecisionextrusions.com/the-evolution-of-aluminum-extrusions-emerging-trends-and-technologies/

[15] https://aec.org/sustainability

[16] https://www.impol.com/everything-you-need-to-know-about-aluminum-extrusion/

[17] https://www.wileymetal.com/five-common-applications-of-aluminum-extrusion/

[18] https://www.alcircle.com/news/aluminium-industry-key-global-challenges-and-opportunities-93614

[19] https://nationalindustries.world/2025/01/02/the-future-of-aluminum-how-extrusion-technology-is-transforming-industries/

[20] https://kimsen.vn/the-benefits-of-aluminum-extrusion-for-sustainable-manufacturing-ne142.html