Content Menu

● Introduction to High Moisture Extrusion Cooking

>> Key Components of High Moisture Extrusion Cooking Machinery

● Working Principles of High Moisture Extrusion Cooking Machinery

>> Process Parameters and Their Impact

● Applications of High Moisture Extrusion Cooking Machinery

>> Benefits of High Moisture Extrusion Cooking Machinery

● Advanced Developments in High Moisture Extrusion

>> Use of Alternative Proteins

>> Modeling and Experimental Analysis

● Challenges and Future Directions

>> Sustainability and Environmental Impact

>> Consumer Preferences and Market Trends

● Case Studies: Successful Applications of High Moisture Extrusion

>> Technological Innovations in Extruder Design

● Integration with Other Technologies

>> 3D Printing and High Moisture Extrusion

>> Fermentation and Enzymatic Treatment

● Conclusion

● Frequently Asked Questions

>> 1. What is the primary application of high moisture extrusion cooking machinery?

>> 2. How does high moisture extrusion differ from low moisture extrusion?

>> 3. What are the key components of high moisture extrusion cooking machinery?

>> 4. What process parameters significantly impact the texture of products made using high moisture extrusion cooking machinery?

>> 5. What are the benefits of using high moisture extrusion cooking machinery?

High moisture extrusion cooking machinery is a specialized type of food processing equipment designed to create products with a fibrous texture, similar to meat, by utilizing high moisture levels during the extrusion process. This technology is particularly popular in the production of meat analogs and textured vegetable proteins (TVP). In this article, we will delve into the details of high moisture extrusion cooking machinery, its working principles, applications, and benefits.

Introduction to High Moisture Extrusion Cooking

High moisture extrusion cooking (HMEC) involves processing materials with moisture content typically ranging from 40% to 80%. This process is distinct from low moisture extrusion, which operates with moisture levels below 20% and is often used for producing snacks and cereals. HMEC is favored for creating products that mimic the texture of meat, making it ideal for the production of meat analogs.

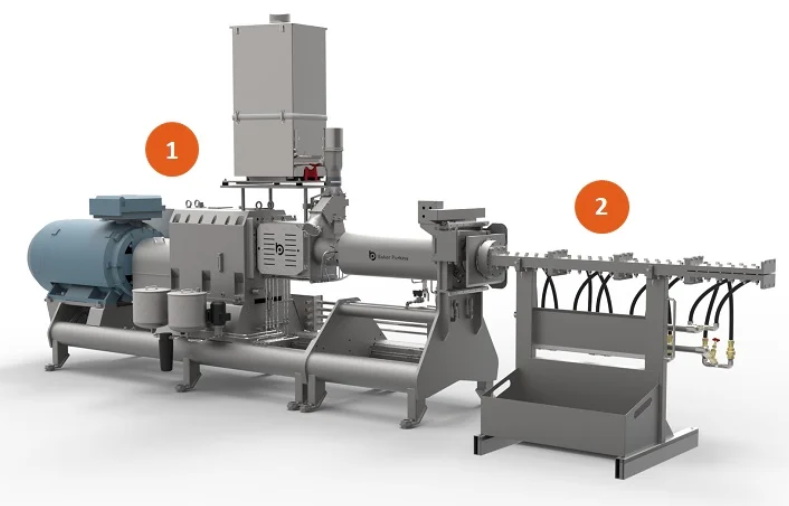

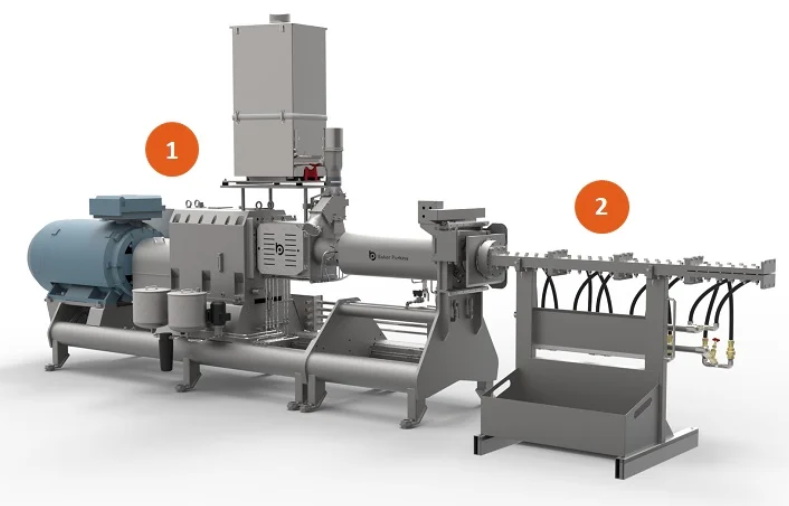

Key Components of High Moisture Extrusion Cooking Machinery

1. Preconditioner: This component is crucial for achieving uniform moisture distribution and temperature control before the material enters the extruder. It ensures that the raw materials are properly mixed with water or steam to achieve the desired moisture level.

2. Extruder Barrel: The extruder barrel is where the actual transformation of raw materials into a fibrous structure occurs. It consists of a screw profile designed to increase pressure and temperature, facilitating protein denaturation and reassembly into a fibrous texture.

3. Die System: The die is responsible for shaping the extruded product into its final form. The shape and size of the die determine the texture and appearance of the final product.

Working Principles of High Moisture Extrusion Cooking Machinery

The process of high moisture extrusion cooking involves several key steps:

1. Preconditioning: Raw materials are mixed with water or steam to achieve a uniform moisture content. This step is critical for ensuring consistent product quality.

2. Extrusion: The preconditioned mixture is fed into the extruder barrel, where it undergoes mechanical and thermal processing. The screw profile and barrel temperature are adjusted to facilitate protein denaturation and reassembly into a fibrous structure.

3. Shaping: The extruded product is then forced through a die, which shapes it into its final form. The die design can vary depending on the desired texture and appearance of the product.

4. Cooling and Packaging: After shaping, the product is cooled and packaged. Cooling is essential to stop the cooking process and preserve the texture of the product.

Process Parameters and Their Impact

- Moisture Content: High moisture levels are essential for creating a fibrous texture. The moisture content affects the formation of hydrogen and disulfide bonds, which contribute to the product's texture.

- Temperature: Moderate temperatures are used in HMEC to prevent excessive nutrient loss. The temperature affects protein denaturation and reassembly.

- Screw Speed: The speed of the extruder screws influences the mechanical energy input, which impacts the texture and structure of the final product.

Applications of High Moisture Extrusion Cooking Machinery

High moisture extrusion cooking machinery is primarily used in the production of:

- Meat Analogs: These are plant-based products designed to mimic the texture and appearance of meat. They are popular among consumers seeking vegetarian or vegan alternatives to traditional meat products.

- Textured Vegetable Proteins (TVP): TVP is used in a variety of food products, including vegetarian burgers and sausages. It provides a meat-like texture without the need for animal products.

Benefits of High Moisture Extrusion Cooking Machinery

1. Nutrient Retention: HMEC operates at moderate temperatures, which helps retain more nutrients compared to low moisture extrusion.

2. Flexibility in Ingredients: A wide range of plant proteins can be used, allowing for diverse product formulations.

3. Customization: The machinery can be customized to produce different textures and shapes, offering flexibility in product design.

Advanced Developments in High Moisture Extrusion

Recent advancements in twin-screw extruder technology have made high moisture extrusion more efficient and versatile. These developments include sophisticated barrel designs and screw profiles that enhance the mixing and conveying capabilities of the extruder. This has enabled the production of complex, fibrous structures that closely mimic whole-muscle meat.

Use of Alternative Proteins

There is growing interest in using alternative proteins such as hemp and rapeseed proteins in high moisture extrusion. These proteins offer unique nutritional profiles and can be used to create a variety of meat analogs with different textures and flavors.

Modeling and Experimental Analysis

Research has focused on modeling and analyzing the solidification process of protein matrices during high moisture extrusion. This involves studying the effects of process conditions such as temperature, moisture content, and cooling rate on the final product texture and structure.

Challenges and Future Directions

Despite the advancements in high moisture extrusion technology, there are challenges related to scaling up production while maintaining product consistency and quality. Future research should focus on optimizing process parameters and exploring new applications for high moisture extrusion products.

Sustainability and Environmental Impact

High moisture extrusion cooking machinery offers a sustainable alternative to traditional meat production by reducing greenhouse gas emissions and conserving water. The use of plant-based proteins can also help mitigate deforestation and biodiversity loss associated with livestock farming.

Consumer Preferences and Market Trends

Consumer demand for plant-based products is increasing globally, driven by health, environmental, and ethical considerations. High moisture extrusion cooking machinery is well-positioned to meet this demand by producing high-quality, meat-like products that appeal to a wide range of consumers.

Case Studies: Successful Applications of High Moisture Extrusion

Several companies have successfully utilized high moisture extrusion to develop innovative plant-based products. For example, companies like Beyond Meat and Impossible Foods have used HMEC to create meat analogs that closely mimic the taste and texture of traditional meat products.

Technological Innovations in Extruder Design

Advancements in extruder design, such as the use of co-rotating twin-screw extruders, have improved the efficiency and versatility of high moisture extrusion. These designs allow for better mixing and heat transfer, enabling the production of complex textures and structures.

Integration with Other Technologies

High moisture extrusion can be integrated with other food processing technologies, such as 3D printing and fermentation, to create even more sophisticated products. This integration can enhance product customization and nutritional value.

3D Printing and High Moisture Extrusion

Combining high moisture extrusion with 3D printing allows for the creation of complex structures that mimic the texture and appearance of whole-muscle meat. This technology has the potential to revolutionize the plant-based meat market by offering products with unprecedented realism.

Fermentation and Enzymatic Treatment

Fermentation and enzymatic treatment can be used to enhance the nutritional and sensory properties of high moisture extruded products. These processes can improve protein digestibility and add unique flavors to the products.

Conclusion

High moisture extrusion cooking machinery is a versatile tool in the food industry, particularly for producing meat analogs and TVP. Its ability to create products with a fibrous texture similar to meat has made it a cornerstone in the development of plant-based alternatives. Understanding the working principles and applications of this machinery is crucial for optimizing its use in food production.

Frequently Asked Questions

1. What is the primary application of high moisture extrusion cooking machinery?

High moisture extrusion cooking machinery is primarily used for producing meat analogs and textured vegetable proteins (TVP), which are designed to mimic the texture and appearance of meat.

2. How does high moisture extrusion differ from low moisture extrusion?

High moisture extrusion operates with moisture levels between 40% and 80%, resulting in products with a fibrous texture, while low moisture extrusion uses moisture levels below 20%, producing crispy or crunchy textures.

3. What are the key components of high moisture extrusion cooking machinery?

The key components include a preconditioner for uniform moisture distribution, an extruder barrel for protein denaturation and reassembly, and a die system for shaping the final product.

4. What process parameters significantly impact the texture of products made using high moisture extrusion cooking machinery?

Moisture content, temperature, and screw speed are critical parameters that affect the texture and structure of the final product.

5. What are the benefits of using high moisture extrusion cooking machinery?

Benefits include better nutrient retention, flexibility in ingredient selection, and customization options for product texture and shape.